October 3rd, 2015

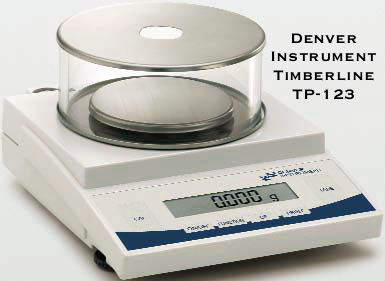

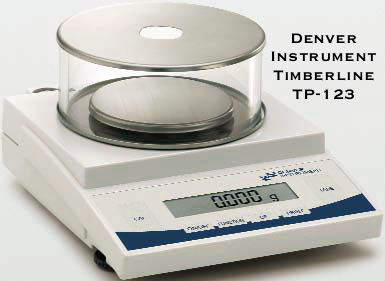

Denver Instrument, maker of the MXX and Timberline Series of precision balances, has created a helpful guide explaining how to get the best performance from a digital scale. Denver Instrument knows that, to achieve and maintain a very high level of accuracy with digital scales, they must be calibrated regularly, leveled properly, and kept away from sources of interference. Unfortunately, some reloaders treat their electronic scales as if the machines were toasters — something to place on a tabletop, plug into an outlet, then “set and forget.” There’s a better way to set up your scale and keep it functioning optimally. Here are ten guidelines provided by Denver Instrument. Follow these “Ten Commandments” and you’ll benefit:

ONE: Thou shalt choose the best resting spot. The performance of your balance depends greatly on the surrounding environment. Choose a location away from the main traffic flow of the room, especially doors. Also be aware of heating and cooling vents as these produce air movement. You can adjust the environmental settings on your balance to provide the best performance in the chosen location. Balances must be placed away from magnets as they affect the weigh cell performance.

ONE: Thou shalt choose the best resting spot. The performance of your balance depends greatly on the surrounding environment. Choose a location away from the main traffic flow of the room, especially doors. Also be aware of heating and cooling vents as these produce air movement. You can adjust the environmental settings on your balance to provide the best performance in the chosen location. Balances must be placed away from magnets as they affect the weigh cell performance.

TWO: Thou shalt avoid vibrations. Vibrations can come from large machinery in production environments and from fume hoods in laboratories. An alternative to fume hoods are Power Safety Workstations which are designed specifically for use with a balance.

THREE: Thou shalt watch temperature changes. On an analytical balance a one degree temperature change can cause a 1 digit (0.0001g) drift. Although Denver balances have temperature correction built-in, it is still important to calibrate your balance when the temperature changes significantly. Choosing to place your balance in a temperature controlled room, away from sunlight, and calibrating often helps minimize the effects of temperature.

FOUR: Thou shalt calibrate often. Upon installation and each time the balance is moved you should calibrate your balance. For example moving an analytical balance to a location that is only 13 feet higher changes the weight reading from 200.0000 g to 199.9997 g; which means the result is 0.0003 g lighter than the actual mass.

FIVE: Remember to check the level. The instrument should be leveled upon installation with all feet (two front feet for round pan units, four feet for square pan units) touching the countertop. If the level changes, the balance should be re-leveled and recalibrated. As an example, a 200g sample would weigh 0.0025 g less when tilted at an angle of 0.3°.

SIX: Honor thy weights. Keep in mind that weights are only as reliable as their quality and certification. Remember, a 1 g does not weigh precisely 1.00000 grams. Weights should be recertified annually. Denver Instrument offers recertification services on all weights 1 mg to 5 kg. Check to make sure you have selected the proper weight class for your balance. The weight tolerance should be better than balance readability. Always use tweezers or gloves when handling weights as smudges and indentations change the value of the weight. Keep weights in cases so they don’t get scratched or dusty.

SEVEN: Thou shalt always use a small container and weigh in the center of the pan. Especially when using an analytical balance, the effects of air buoyancy increase as the sample container size increases. Using a small sample container will minimize the effects. Items placed on the pan provide a downward force. Placing them directly in the center of the pan keeps corner loading errors at a minimum.

SEVEN: Thou shalt always use a small container and weigh in the center of the pan. Especially when using an analytical balance, the effects of air buoyancy increase as the sample container size increases. Using a small sample container will minimize the effects. Items placed on the pan provide a downward force. Placing them directly in the center of the pan keeps corner loading errors at a minimum.

EIGHT: Thou shalt not unplug. To perform within published speci-fications, balances must have power applied for 30 minutes to 48 hours depending on the resolution of the balance. Denver balances have a standby mode which turn the display to standby but keep power cycling through the electronics.

NINE: Thou shalt not ignore static. Static is one of the most common weighing “noises”. It can cause reading to appear too high, too low or just be unstable. Denver balances include grounding methods to reduce the effects of static. However sometimes extra supplies are needed. Consider anti-static weigh dishes, anti-static brushes or low tech ways to increase the humidity of the chamber like placing damp cotton balls or glass wool in a small vial in the corner of the analytical draft shield.

TEN: Thou shalt clean often. Dirty weigh pans and powder in weighing chamber can contribute to static issues and lead to a wide variety of problems. Denver weigh pans are made from stainless steel and can be cleaned using a variety of household and laboratory chemicals. A small paint brush can be used to get power away from the edges of the draft shield for easy clean up.

Share the post "Ten Commandments for Use of Electronic Scales"

Can you guess what your next barrel will weigh? In many competition disciplines, “making weight” is a serious concern when putting together a new match rifle. A Light Varmint short-range Benchrest rifle cannot exceed 10.5 pounds including scope. An F-TR rifle is limited to 18 pounds, 2 oz. (8.25 kg) with bipod.

Can you guess what your next barrel will weigh? In many competition disciplines, “making weight” is a serious concern when putting together a new match rifle. A Light Varmint short-range Benchrest rifle cannot exceed 10.5 pounds including scope. An F-TR rifle is limited to 18 pounds, 2 oz. (8.25 kg) with bipod.

ONE: Thou shalt choose the best resting spot. The performance of your balance depends greatly on the surrounding environment. Choose a location away from the main traffic flow of the room, especially doors. Also be aware of heating and cooling vents as these produce air movement. You can adjust the environmental settings on your balance to provide the best performance in the chosen location. Balances must be placed away from magnets as they affect the weigh cell performance.

ONE: Thou shalt choose the best resting spot. The performance of your balance depends greatly on the surrounding environment. Choose a location away from the main traffic flow of the room, especially doors. Also be aware of heating and cooling vents as these produce air movement. You can adjust the environmental settings on your balance to provide the best performance in the chosen location. Balances must be placed away from magnets as they affect the weigh cell performance. SEVEN: Thou shalt always use a small container and weigh in the center of the pan. Especially when using an analytical balance, the effects of air buoyancy increase as the sample container size increases. Using a small sample container will minimize the effects. Items placed on the pan provide a downward force. Placing them directly in the center of the pan keeps corner loading errors at a minimum.

SEVEN: Thou shalt always use a small container and weigh in the center of the pan. Especially when using an analytical balance, the effects of air buoyancy increase as the sample container size increases. Using a small sample container will minimize the effects. Items placed on the pan provide a downward force. Placing them directly in the center of the pan keeps corner loading errors at a minimum. Are you re-barreling a match rifle and need to know if you will still make weight? Or perhaps you want to select the right contour to hit an optimal carry weight for a new varmint rifle? Dan Lilja offers

Are you re-barreling a match rifle and need to know if you will still make weight? Or perhaps you want to select the right contour to hit an optimal carry weight for a new varmint rifle? Dan Lilja offers

It is well-established that mid-barrel tuners can work on rimfire rifles, and we also know that certain types of materials (such as rubber, cork, and Delrin) can have beneficial damping effects on both rimfire and centerfire barrels. Given these facts, we were quite interested in the new Flexi-Weight System introduced by

It is well-established that mid-barrel tuners can work on rimfire rifles, and we also know that certain types of materials (such as rubber, cork, and Delrin) can have beneficial damping effects on both rimfire and centerfire barrels. Given these facts, we were quite interested in the new Flexi-Weight System introduced by