|

|

April 20th, 2025

Editor’s NOTE: Shelley Davidson passed away in 2008 after a courageous battle with cancer. He was one of the great innovators in benchrest rifle design. This article, written before Shelley died, showcases Shelley’s creative talents at their best. His “Tinker Toy” design will always be a tribute to Shelley’s fabricating skills and imagination.

Shelley Davidson — a brilliant innovator. R.I.P. Shelley — you will not be forgotten.

Shelley Davidson’s peers called his radical rifle the “Tinker Toy” gun. We call it revolutionary. Even now, 14 years after its creation, there’s nothing quite like it. This innovative, skeleton design threw conventional wisdom to the winds. Shelley readily concedes he “broke the rules” of benchrest rifle building. But this was inspired rule-breaking, because Davidson’s rifle shot like a house on fire. The Tinker Toy gun won its first matches, both for Score AND for Group. And this rifle also delivered many “zero groups” in Gene Begg’s Texas Tunnel. Hats off to Shelley for conceiving and building a truly radical rifle that was also wicked accurate and successful in competition.

Tinker Toy 30 BR — Radical As It Gets

Report by Shelley Davidson

Although I’m not big on naming rifles, my shooting buddies have christened the gun “Tinker Toy.” I can live with that as it does kind of look as if it was made with a Tinker Toy set.

Origins of the Project

This project began with some wild ideas I had in the fall of 2006 about using magnets to tune a barrel. My idea was to use one magnet on the barrel and another on the stock so they pushed against each other to counter gravity-induced barrel sag (and possibly) tame barrel vibration in a beneficial manner. The only way to test these ideas was to build the device and mount it on a gun. That meant I had to build a new rifle because there was no place to mount a magnet on the stock of a conventional benchrest rig. I had a Kelbly-stocked heavy varmint stock with a Michael Kavanaugh paint job on it. I didn’t think Kav would ever forgive me if I started drilling holes in one of his works of art. My light varmint was in a carbon fiber Scoville stock that costs about a grand. Drilling into the Scoville for an experiment just smacked of bad judgment. So, the magnet thing was my first motivation for designing a new stock. As long as I was building from scratch I decided to offset the barrel and action 0.75″ to the right to counteract the spin/torque from the bullet.

Although there’s nothing new here, my second motivation was to build a 30BR that could shoot in the 10.5 lb light varmint class in NBRSA. The magnetic tuner will automatically make this gun illegal in the IBS. The IBS has declared all barrel attachments un-safe and have outlawed them. I personally feel that the IBS really outlawed all barrel attachments to prevent experimentation and innovation. But at least we have NBRSA matches.

Designing the New Gun — Thinking “Outside the Box”

Once I’d decided to build a lightweight stock that could support experimental devices out near the muzzle, I started drawing up some rough plans. I also took a trip to Jerry Stiller’s shop in Wylie, Texas for a brainstorming session with Jerry, the maker of Viper and other Benchrest actions. Jerry is a school-trained mechanical engineer and thinks differently than I do. I came away from Stiller’s shop with my design roughed out and sketched on paper. The design violated several covenants of conventional wisdom for building competition BR rifles. For instance, two-piece stocks stress the action. Stress reduction is why most BR rifles are glued into the stock. Another myth is that metal stocks vibrate too much so wood or foam-filled fiberglass or carbon fiber are used.

Tinker Toy Rifle DESIGN FEATURES

Shelly Davidson’s Rifle was so innovative, that almost every feature, except the bare action, is very different than you’ll find on most Benchrest rigs. Accordingly we felt it would be useful to isolate and describe the key design features, from stem to stern. Click thumbnails to view FULL-SIZE PHOTOS.

Front Bracket with Magnetic Tuner Front Bracket with Magnetic Tuner

The tuner consists of one rare earth magnet attached to the stock and another attached to a barrel sleeve with the magnets oriented so as to make the magnetic force repel each other. The purpose is to counter “barrel droop” and, hopefully, dampen barrel vibration. The lower magnet is carried on a threaded shaft (with lock ring), allowing the magnet to be raised up and down to adjust the “up push” on the barrel.

Tubular Fore-Arm Supported by Brackets Tubular Fore-Arm Supported by Brackets

Three brackets support two tubes, one on either side of the barrel. The rear-most bracket is sandwiched between the barrel and the action. Four inches forward (max distance allowed for barrel blocks) a second bracket grips the barrel. Near the muzzle a third bracket secures the ends of the tubes and holds the magnetic tuner. To allow barrel offset, the left tube is 1″ diameter tube while the right tube is 5/8″ diameter.

Offset Barrel Offset Barrel

The rifle rests on a 3″ wide plate attached to the underside of the two fore-end tubes. With the plate centered in the front sandbag, the barreled action is actually offset 0.75″ to the right (looking forward from the breech). The purpose of this offset is to keep more weight on the right side to counter the tendency of the rifle to torque counter-clockwise. Two different diameter tubes allow for the built-in offset.

Floating Action without Sub-Support or Bedding Floating Action without Sub-Support or Bedding

On the Tinker Toy gun, the action serves as a load-bearing assembly, holding the barrel in the front, and the skeleton buttstock (or “keel”) in the rear. Shelley was told that accuracy would suffer if you stressed a benchrest action in this manner but that proved untrue. It is a very simple solution to building a rifle, and it eliminates the need to bed the action. The forearm attaches to the action via a bracket installed like a recoil lug.

Skeleton Rear “Keel” Affixed Directly to Action Skeleton Rear “Keel” Affixed Directly to Action

Davidson’s Tinker Toy does not have a conventional rear buttstock. Instead there is low-profile, v-shaped metal “keel”, as Davidson calls it, that rides the rear bag. The keel is supported by a tubular backbone that attaches at the rear of the Diamondback action. At the butt end is an aluminum plate covered with bubble wrap that serves as a butt pad. The skeletonized rear section helps the rifle maintain a very low center of gravity.

Locked Scope with External Windage and Elevation Adjustment Locked Scope with External Windage and Elevation Adjustment

Shelley ran an older Leupold 36X Benchrest Scope with front-adjusting objective. To eliminate slop or loose tolerances in the erector mechanism that could cause changes in point of impact, the internals have been locked up by Jackie Schmidt. To move the cross-hairs relative to the bore axis, Shelley has a special Jewell/Foster rear ring that allows a limited amount of lateral and vertical movement of the entire scope body.

|

TINKER TOY SPECIFICATIONS

Action: Stiller SS Diamondback Drop-Port (1/2″ short), with .308 Bolt Face.

Barrel: Shilen .308 caliber, 17-twist, HV.

Chambering: 30BR, .330″ neck, Pacific Tool & Gauge Robinett Reamer.

Stock: Davidson Custom Tubular Stock with 0.75″ Offset Barreled Action.

Tube Construction: 6061 Aluminum, 1″ diameter (left), 5/8″ diameter (right).

Load: H4198 powder and 118gr Ronnie Cheek bullets. Loaded to 2980 fps.

Trigger: Jewell, 2 ounce BR.

Tuner: Custom, Adjustable with Opposing Magnets.

Optics: Leupold 36X (locked by J. Schmidt).

Rings: Jewell Foster External Adjusting Rings. |

Stiller Diamondback Action and Shilen 17-Twist Barrel

I had wanted to use an aluminum Stiller Cobra drop port with a 6mmBR bolt face but Jerry had none in stock and he estimated it would be a year before one was available. Although I’ve waited for up to a year for an action in the past, I wanted to build this rifle during the fall of 2006 while the weather was pleasant enough to work in my unheated and un-air-conditioned garage shop. Jerry did have a 1/2″ short stainless steel Diamondback in stock so I purchased it even though it would add 3 ounces to the gun compared to the aluminum Cobra. Three ounces is a lot of weight when you’re working with a 10.5-lb limit. I had a heavy varmint contour Shilen 17-twist barrel that would work nicely and I had a Jewell trigger on a rifle that I wasn’t using at the time. I also decided to use my Leupold 36X (locked-up by Jackie Schmidt) with the Jewell/Foster adjustable rings.

Building the Tube Fore-Arm and Brackets

I took a wild guess as to tubing thickness and settled on .035″ for the 1″ left fore-arm tube and .058″ for the 5/8″ right fore-arm tube. All of the flat stock and tubes are 6061 Aluminum. I did the lathe work and the mill work and every evening I’d put the parts together and think about the proper way to proceed.

When the parts were mostly made, I started thinking that this was a truly ugly rifle. I thought about painting it but that wasn’t a good option as many of the parts are designed to slide over others and glue together. Anodizing was the best answer so while looking on the Internet for local anodizing shops I Googled “Home Anodizing”. Sure enough there were a few sites that told about how to anodize at home. I picked up some battery acid from NAPA Auto Supply, some Rit Clothes Dye from Wal-Mart, and a bunch of distilled water from the grocery store. Using an old battery charger as my dc power supply I started anodizing and dying the eighteen parts that went into the stock. Although I had to strip and re-anodize some of the parts, the work turned out acceptable.

Putting it All Together–Lug-Mounting the Fore-Arm and Lots of Epoxy

The barrel contour had to be modified to work with the stock which attaches by way of a rear plate which mounts like a recoil lug and a plate that ties the barrel and the stock tubes together 4″ forward of the bolt face. The four-inch maximum distance is a NBRSA rule concerning barrel blocks.

The recoil lug-style stock mount is probably the only truly innovative thing I did other than the opposing-magnet tuner. Basically, the rear bracket is sandwiched between the receiver face and the barrel shoulder–positioned where a conventional recoil lug would go. I also added a brass ring (visible in photo) between the anodized bracket and the barrel. This was done to distribute loads over a wider surface area. (I was concerned that the bracket material was fairly soft and I didn’t want to crush it as I torqued the barrel in place.) After fitting the barrel and plates I glued the entire gun together using epoxy and various LocTite adhesives. The rest of the parts were assembled but I did not Loctite the scope bases since I thought I’d be disassembling the rifle for re-work after the first trials. That came back to bite me during later testing when the gun started shooting erratically and I went down a couple of blind alleys before finding the loose bases. The recoil lug-style stock mount is probably the only truly innovative thing I did other than the opposing-magnet tuner. Basically, the rear bracket is sandwiched between the receiver face and the barrel shoulder–positioned where a conventional recoil lug would go. I also added a brass ring (visible in photo) between the anodized bracket and the barrel. This was done to distribute loads over a wider surface area. (I was concerned that the bracket material was fairly soft and I didn’t want to crush it as I torqued the barrel in place.) After fitting the barrel and plates I glued the entire gun together using epoxy and various LocTite adhesives. The rest of the parts were assembled but I did not Loctite the scope bases since I thought I’d be disassembling the rifle for re-work after the first trials. That came back to bite me during later testing when the gun started shooting erratically and I went down a couple of blind alleys before finding the loose bases.

Range Testing–Results Are Very Positive

The first range session was a real shocker. Even though the wind was up to 10mph and twitchy, the rifle showed promise from the very first shot. I really didn’t expect that kind of performance without, at least, some rework. After sighting in, I shot five, 5-shot groups that, when averaged together, measured .223″. That’s good enough to win some benchrest group matches. But I wasn’t finished with the gun yet–I still wanted to try out my magnetic tuner concept.

The Magnetic Tuner

Next, I built the magnetic tuner. The tuner consists of one rare earth magnet attached to the stock and another attached to a barrel sleeve with the magnets oriented so the magnetic forces repel each other. In order to test the magnets and to determine if the rifle really shot as well as it seemed to, I took it to Gene Beggs’s shooting tunnel in Odessa, Texas. I spent two days at the tunnel testing loads and then installed the magnetic tuner. The gun shoots well with the magnets and shoots well without them. I suppose I can’t make any claims as to how much, if any, improvement the magnets make. Gene said that my gun was the most accurate rifle to be tested at his one-year-old shooting facility: “Shelley Davidson brought one of the most unusual rifles I had ever seen; he called it his ‘Tube Gun.’ And boy, did it ever shoot! It still holds the record in the tunnel as the rifle that shot more zeros than any other to date.” I definitely recommend Gene’s facility for testing and refining shooting techniques and loads.

| Competition — Tinker Toy Won Both Score and Group Matches |

Finally the big day arrived when I’d shoot the first match with my new gun. The North Texas Shooters Association was holding its first club match of the 2007 season. At the Denton, Texas matches we shoot a Score Match in the morning and a Group Match in the afternoon. The March event was at 100 yards and the April match will be at 200 yards and so on alternating throughout the benchrest season.

Match One–Tinker Toy Wins Score with a 250 – 17X Match One–Tinker Toy Wins Score with a 250 – 17X

Since the gun is chambered in 30BR and that chambering is almost immune to tuning woes, I preloaded 130 rounds with H4198 powder and 118gr Cheek bullets. I used my SEB front rest and rear bag which are made by Sebastian Lambang in Indonesia. Everything came together, and Tinker Toy demonstrated that the accuracy it showed in the tunnel was no fluke. The gun shot great and I won the morning match with a 250, 17X. The day was quite windy and the next best shooter scored a 250, 15X. So I’d chalked up my first win.

Match Two–Tinker Toy Wins Group with a .2282″ Agg

Tinker Toy won the afternoon group match I entered with a five-group Aggregate of .2282″. (The second place score was .2568″.) My groups were .149″, .197″, .243″, .302″ (oops), and .250″. You know how some folks say a 30BR can’t be competitive with a PPC? Well that .2282″ Agg won’t break any records, but it is good enough to win some regional registered BR matches. So this rifle has demonstrated an ability to win in both Score and Group matches. Obviously I have a very good Shilen barrel, great Cheek bullets and the rest of the components are doing their jobs as well. But, the stock is also working well.

Score Shooting vs. Group Shooting–The Rules

In a score match, the shooter shoots one bullet at each of five record targets, which are clustered on one target sheet. The Aggregate score of five of these targets determines the winner. If the shooter touches the 10 ring on all of his 25 targets he can score a “clean” 250 score. Usually there will be more than one shooter who scores a 250 so the winner is determined by the X-count. The 1/2″ 10-point ring has a 1/16″ dot in its center. Touching the X dot adds to the shooters X count. In short-range group matches, the shooter must try to put five bullets through the same hole. At each distance (100 or 200), five, 5-shot matches are scored, the group sizes are added together (MOA equivalent at 200) and the total is divided by five to arrive at an Aggregate score.

September 27th, 2020

Editor’s NOTE: Shelley Davidson passed away in 2008 after a courageous battle with cancer. He was one of the great innovators in benchrest rifle design. This article, written before Shelley died, showcases Shelley’s creative talents at their best. His “Tinker Toy” design will always be a tribute to Shelley’s fabricating skills and imagination.

Shelley Davidson — a brilliant innovator. R.I.P. Shelley — you will not be forgotten.

Shelley Davidson’s peers called his radical rifle the “Tinker Toy” gun. We call it revolutionary. Even now, 14 years after its creation, there’s nothing quite like it. This innovative, skeleton design threw conventional wisdom to the winds. Shelley readily concedes he “broke the rules” of benchrest rifle building. But this was inspired rule-breaking, because Davidson’s rifle shot like a house on fire. The Tinker Toy gun won its first matches, both for Score AND for Group. And this rifle also delivered many “zero groups” in Gene Begg’s Texas Tunnel. Hats off to Shelley for conceiving and building a truly radical rifle that was also wicked accurate and successful in competition.

Tinker Toy 30 BR — Radical As It Gets

Report by Shelley Davidson

Although I’m not big on naming rifles, my shooting buddies have christened the gun “Tinker Toy.” I can live with that as it does kind of look as if it was made with a Tinker Toy set.

Origins of the Project

This project began with some wild ideas I had in the fall of 2006 about using magnets to tune a barrel. My idea was to use one magnet on the barrel and another on the stock so they pushed against each other to counter gravity-induced barrel sag (and possibly) tame barrel vibration in a beneficial manner. The only way to test these ideas was to build the device and mount it on a gun. That meant I had to build a new rifle because there was no place to mount a magnet on the stock of a conventional benchrest rig. I had a Kelbly-stocked heavy varmint stock with a Michael Kavanaugh paint job on it. I didn’t think Kav would ever forgive me if I started drilling holes in one of his works of art. My light varmint was in a carbon fiber Scoville stock that costs about a grand. Drilling into the Scoville for an experiment just smacked of bad judgment. So, the magnet thing was my first motivation for designing a new stock. As long as I was building from scratch I decided to offset the barrel and action 0.75″ to the right to counteract the spin/torque from the bullet.

Although there’s nothing new here, my second motivation was to build a 30BR that could shoot in the 10.5 lb light varmint class in NBRSA. The magnetic tuner will automatically make this gun illegal in the IBS. The IBS has declared all barrel attachments un-safe and have outlawed them. I personally feel that the IBS really outlawed all barrel attachments to prevent experimentation and innovation. But at least we have NBRSA matches.

Designing the New Gun — Thinking “Outside the Box”

Once I’d decided to build a lightweight stock that could support experimental devices out near the muzzle, I started drawing up some rough plans. I also took a trip to Jerry Stiller’s shop in Wylie, Texas for a brainstorming session with Jerry, the maker of Viper and other Benchrest actions. Jerry is a school-trained mechanical engineer and thinks differently than I do. I came away from Stiller’s shop with my design roughed out and sketched on paper. The design violated several covenants of conventional wisdom for building competition BR rifles. For instance, two-piece stocks stress the action. Stress reduction is why most BR rifles are glued into the stock. Another myth is that metal stocks vibrate too much so wood or foam-filled fiberglass or carbon fiber are used.

Tinker Toy Rifle DESIGN FEATURES

Shelly Davidson’s Rifle was so innovative, that almost every feature, except the bare action, is very different than you’ll find on most Benchrest rigs. Accordingly we felt it would be useful to isolate and describe the key design features, from stem to stern. Click thumbnails to view FULL-SIZE PHOTOS.

Front Bracket with Magnetic Tuner Front Bracket with Magnetic Tuner

The tuner consists of one rare earth magnet attached to the stock and another attached to a barrel sleeve with the magnets oriented so as to make the magnetic force repel each other. The purpose is to counter “barrel droop” and, hopefully, dampen barrel vibration. The lower magnet is carried on a threaded shaft (with lock ring), allowing the magnet to be raised up and down to adjust the “up push” on the barrel.

Tubular Fore-Arm Supported by Brackets Tubular Fore-Arm Supported by Brackets

Three brackets support two tubes, one on either side of the barrel. The rear-most bracket is sandwiched between the barrel and the action. Four inches forward (max distance allowed for barrel blocks) a second bracket grips the barrel. Near the muzzle a third bracket secures the ends of the tubes and holds the magnetic tuner. To allow barrel offset, the left tube is 1″ diameter tube while the right tube is 5/8″ diameter.

Offset Barrel Offset Barrel

The rifle rests on a 3″ wide plate attached to the underside of the two fore-end tubes. With the plate centered in the front sandbag, the barreled action is actually offset 0.75″ to the right (looking forward from the breech). The purpose of this offset is to keep more weight on the right side to counter the tendency of the rifle to torque counter-clockwise. Two different diameter tubes allow for the built-in offset.

Floating Action without Sub-Support or Bedding Floating Action without Sub-Support or Bedding

On the Tinker Toy gun, the action serves as a load-bearing assembly, holding the barrel in the front, and the skeleton buttstock (or “keel”) in the rear. Shelley was told that accuracy would suffer if you stressed a benchrest action in this manner but that proved untrue. It is a very simple solution to building a rifle, and it eliminates the need to bed the action. The forearm attaches to the action via a bracket installed like a recoil lug.

Skeleton Rear “Keel” Affixed Directly to Action Skeleton Rear “Keel” Affixed Directly to Action

Davidson’s Tinker Toy does not have a conventional rear buttstock. Instead there is low-profile, v-shaped metal “keel”, as Davidson calls it, that rides the rear bag. The keel is supported by a tubular backbone that attaches at the rear of the Diamondback action. At the butt end is an aluminum plate covered with bubble wrap that serves as a butt pad. The skeletonized rear section helps the rifle maintain a very low center of gravity.

Locked Scope with External Windage and Elevation Adjustment Locked Scope with External Windage and Elevation Adjustment

Shelley ran an older Leupold 36X Benchrest Scope with front-adjusting objective. To eliminate slop or loose tolerances in the erector mechanism that could cause changes in point of impact, the internals have been locked up by Jackie Schmidt. To move the cross-hairs relative to the bore axis, Shelley has a special Jewell/Foster rear ring that allows a limited amount of lateral and vertical movement of the entire scope body.

|

TINKER TOY SPECIFICATIONS

Action: Stiller SS Diamondback Drop-Port (1/2″ short), with .308 Bolt Face.

Barrel: Shilen .308 caliber, 17-twist, HV.

Chambering: 30BR, .330″ neck, Pacific Tool & Gauge Robinett Reamer.

Stock: Davidson Custom Tubular Stock with 0.75″ Offset Barreled Action.

Tube Construction: 6061 Aluminum, 1″ diameter (left), 5/8″ diameter (right).

Load: H4198 powder and 118gr Ronnie Cheek bullets. Loaded to 2980 fps.

Trigger: Jewell, 2 ounce BR.

Tuner: Custom, Adjustable with Opposing Magnets.

Optics: Leupold 36X (locked by J. Schmidt).

Rings: Jewell Foster External Adjusting Rings. |

Stiller Diamondback Action and Shilen 17-Twist Barrel

I had wanted to use an aluminum Stiller Cobra drop port with a 6mmBR bolt face but Jerry had none in stock and he estimated it would be a year before one was available. Although I’ve waited for up to a year for an action in the past, I wanted to build this rifle during the fall of 2006 while the weather was pleasant enough to work in my unheated and un-air-conditioned garage shop. Jerry did have a 1/2″ short stainless steel Diamondback in stock so I purchased it even though it would add 3 ounces to the gun compared to the aluminum Cobra. Three ounces is a lot of weight when you’re working with a 10.5-lb limit. I had a heavy varmint contour Shilen 17-twist barrel that would work nicely and I had a Jewell trigger on a rifle that I wasn’t using at the time. I also decided to use my Leupold 36X (locked-up by Jackie Schmidt) with the Jewell/Foster adjustable rings.

Building the Tube Fore-Arm and Brackets

I took a wild guess as to tubing thickness and settled on .035″ for the 1″ left fore-arm tube and .058″ for the 5/8″ right fore-arm tube. All of the flat stock and tubes are 6061 Aluminum. I did the lathe work and the mill work and every evening I’d put the parts together and think about the proper way to proceed.

When the parts were mostly made, I started thinking that this was a truly ugly rifle. I thought about painting it but that wasn’t a good option as many of the parts are designed to slide over others and glue together. Anodizing was the best answer so while looking on the Internet for local anodizing shops I Googled “Home Anodizing”. Sure enough there were a few sites that told about how to anodize at home. I picked up some battery acid from NAPA Auto Supply, some Rit Clothes Dye from Wal-Mart, and a bunch of distilled water from the grocery store. Using an old battery charger as my dc power supply I started anodizing and dying the eighteen parts that went into the stock. Although I had to strip and re-anodize some of the parts, the work turned out acceptable.

Putting it All Together–Lug-Mounting the Fore-Arm and Lots of Epoxy

The barrel contour had to be modified to work with the stock which attaches by way of a rear plate which mounts like a recoil lug and a plate that ties the barrel and the stock tubes together 4″ forward of the bolt face. The four-inch maximum distance is a NBRSA rule concerning barrel blocks.

The recoil lug-style stock mount is probably the only truly innovative thing I did other than the opposing-magnet tuner. Basically, the rear bracket is sandwiched between the receiver face and the barrel shoulder–positioned where a conventional recoil lug would go. I also added a brass ring (visible in photo) between the anodized bracket and the barrel. This was done to distribute loads over a wider surface area. (I was concerned that the bracket material was fairly soft and I didn’t want to crush it as I torqued the barrel in place.) After fitting the barrel and plates I glued the entire gun together using epoxy and various LocTite adhesives. The rest of the parts were assembled but I did not Loctite the scope bases since I thought I’d be disassembling the rifle for re-work after the first trials. That came back to bite me during later testing when the gun started shooting erratically and I went down a couple of blind alleys before finding the loose bases. The recoil lug-style stock mount is probably the only truly innovative thing I did other than the opposing-magnet tuner. Basically, the rear bracket is sandwiched between the receiver face and the barrel shoulder–positioned where a conventional recoil lug would go. I also added a brass ring (visible in photo) between the anodized bracket and the barrel. This was done to distribute loads over a wider surface area. (I was concerned that the bracket material was fairly soft and I didn’t want to crush it as I torqued the barrel in place.) After fitting the barrel and plates I glued the entire gun together using epoxy and various LocTite adhesives. The rest of the parts were assembled but I did not Loctite the scope bases since I thought I’d be disassembling the rifle for re-work after the first trials. That came back to bite me during later testing when the gun started shooting erratically and I went down a couple of blind alleys before finding the loose bases.

Range Testing–Results Are Very Positive

The first range session was a real shocker. Even though the wind was up to 10mph and twitchy, the rifle showed promise from the very first shot. I really didn’t expect that kind of performance without, at least, some rework. After sighting in, I shot five, 5-shot groups that, when averaged together, measured .223″. That’s good enough to win some benchrest group matches. But I wasn’t finished with the gun yet–I still wanted to try out my magnetic tuner concept.

The Magnetic Tuner

Next, I built the magnetic tuner. The tuner consists of one rare earth magnet attached to the stock and another attached to a barrel sleeve with the magnets oriented so the magnetic forces repel each other. In order to test the magnets and to determine if the rifle really shot as well as it seemed to, I took it to Gene Beggs’s shooting tunnel in Odessa, Texas. I spent two days at the tunnel testing loads and then installed the magnetic tuner. The gun shoots well with the magnets and shoots well without them. I suppose I can’t make any claims as to how much, if any, improvement the magnets make. Gene said that my gun was the most accurate rifle to be tested at his one-year-old shooting facility: “Shelley Davidson brought one of the most unusual rifles I had ever seen; he called it his ‘Tube Gun.’ And boy, did it ever shoot! It still holds the record in the tunnel as the rifle that shot more zeros than any other to date.” I definitely recommend Gene’s facility for testing and refining shooting techniques and loads.

| Competition — Tinker Toy Won Both Score and Group Matches |

Finally the big day arrived when I’d shoot the first match with my new gun. The North Texas Shooters Association was holding its first club match of the 2007 season. At the Denton, Texas matches we shoot a Score Match in the morning and a Group Match in the afternoon. The March event was at 100 yards and the April match will be at 200 yards and so on alternating throughout the benchrest season.

Match One–Tinker Toy Wins Score with a 250 – 17X Match One–Tinker Toy Wins Score with a 250 – 17X

Since the gun is chambered in 30BR and that chambering is almost immune to tuning woes, I preloaded 130 rounds with H4198 powder and 118gr Cheek bullets. I used my SEB front rest and rear bag which are made by Sebastian Lambang in Indonesia. Everything came together, and Tinker Toy demonstrated that the accuracy it showed in the tunnel was no fluke. The gun shot great and I won the morning match with a 250, 17X. The day was quite windy and the next best shooter scored a 250, 15X. So I’d chalked up my first win.

Match Two–Tinker Toy Wins Group with a .2282″ Agg

Tinker Toy won the afternoon group match I entered with a five-group Aggregate of .2282″. (The second place score was .2568″.) My groups were .149″, .197″, .243″, .302″ (oops), and .250″. You know how some folks say a 30BR can’t be competitive with a PPC? Well that .2282″ Agg won’t break any records, but it is good enough to win some regional registered BR matches. So this rifle has demonstrated an ability to win in both Score and Group matches. Obviously I have a very good Shilen barrel, great Cheek bullets and the rest of the components are doing their jobs as well. But, the stock is also working well.

Score Shooting vs. Group Shooting–The Rules

In a score match, the shooter shoots one bullet at each of five record targets, which are clustered on one target sheet. The Aggregate score of five of these targets determines the winner. If the shooter touches the 10 ring on all of his 25 targets he can score a “clean” 250 score. Usually there will be more than one shooter who scores a 250 so the winner is determined by the X-count. The 1/2″ 10-point ring has a 1/16″ dot in its center. Touching the X dot adds to the shooters X count. In short-range group matches, the shooter must try to put five bullets through the same hole. At each distance (100 or 200), five, 5-shot matches are scored, the group sizes are added together (MOA equivalent at 200) and the total is divided by five to arrive at an Aggregate score.

March 3rd, 2018

This story, from our Gun of the Week Archives, offers a good intro to the 30 BR cartridge, which is still the leading chambering for short-range Score Benchrest.

What’s better than one custom-built 30 BR with gorgeous wood and top-shelf components? A matching pair of course. Just ask Australian shooter Greg Roche (“Caduceus” in our Forum). A decade ago, Greg spent two years living and working in the USA. While in America, he commissioned two matched custom rifles to bring back to Australia for Hunter Class BR matches. Though the look-alike rigs are both chambered in 30 BR, one is designed for the Australian “Traditional” centerfire Hunter Class (10-lb limit), while the other is purpose-built for the “Custom” centerfire Hunter Class (14-lb limit). The 10-lb Traditional rifle features a fully-functioning two-round magazine and a 6-power scope. In contrast the Custom Class rifle is a single-shot action, with a 45X Leupold scope. The Custom weighs 13.5 pounds so it can also be used in traditional Heavy Varmint Benchrest matches if desired.

Tale of Two Rifles

Story and Photos by Greg Roche (“Caduceus”)

The USA boasts some of the finest precision rifle-builders and Benchrest parts suppliers in the world. Before returning to Australia after two years in the States, I decided to have two special BR rifles built using American components and skilled labor. I wanted a matched pair–twin guns that would be as handsome as they were accurate. The heavier gun of the pair, the 13.5-lb Custom Class rifle, features top-of-the-line (but well-proven) technologies and components. With the 10.5-lb Traditional Class rifle, we had to develop new solutions to allow the 30 BR cartridge to feed from a functional two-round magazine. Here is my saga of how my twin 30 BRs were conceived and built, and how they have performed in competition.

| BACKGROUND — The 30 BR for Score Competition

The 30 BR is a wildcat cartridge based on a necked-up version of the 6mmBR Norma case. It originated in U.S. Benchrest circles where it found its niche in Varmint For Score (VFS) matches. Unlike traditional Benchrest, where group size determines the winner, VFS matches are shot on a target with multiple, concentric-ringed bullseyes. Point total is based on “best edge” shot location (one shot per bull). In score competition, the 30 BR’s “supersized” .308-diameter hole offers an advantage over the 6mm hole created by a 6 PPC, the dominant group BR chambering.

The starting point for loading the 30 BR wildcat is Lapua 6mmBR brass. These are necked up as a single-step operation using a .30 caliber tapered expander ball (or dedicated expander mandrel). This will leave a bulge in the neck, so the expanded case neck is normally turned to bring the thickness down to the correct dimension for the chamber. I turned these necks down to .010″ wall thickness using a Stiller neck-turning tool. It features an eccentric mandrel similar to the Nielson “Pumpkin”. Loaded rounds measure .328″ neck diameter. This gives minimum clearance in my .330″ neck chamber, so very little neck resizing is needed after firing. Cases are trimmed to 1.500″ prior to turning to ensure consistency since the Stiller tool indexes the length of cut off the case mouth. Other than that, cases are just chamfered, loaded and made ready to shoot. No special fire-forming is required.

17-Twist Barrels for Both Rifles

Texan gunsmith Mike Bryant chambered both barrels. Mike also polished both barrels to a high-gloss to match the receivers. In this game, barrels are consumables, much like powder and primers, so most owners wouldn’t bother to polish their barrels. However a 30 BR barrel can provide up to 5000 rounds of accurate life (unlike a 6PPC barrel which might be tossed after 800-1000 rounds.) So, these barrels are likely to be on the rifles for many seasons. Given the high-gloss finish of the Grizzly actions and the beauty of the Red Cedar stocks, it would have been an injustice to leave a dull finish on the barrels.

The chambers were both cut with the same reamer supplied by Dave Kiff of Pacific Tool and Gauge. Randy Robinett, one of the originators of the 30 BR wildcat, specified the reamer dimensions. Randy’s 118gr, 10-ogive custom BIB bullets and the 30 BR cartridge enjoy a winning track record in the USA. The 30 BR Robinette reamer has zero free-bore and a .330″ neck, and is optimized for the BIB 118s. The bullets perform best when seated far enough out to jam firmly into the rifling as the bolt is closed. The long ogive means the bullet’s bearing surface is very short.

Slow Twists for Maximum Accuracy

You may note the unusually slow twist rate of both barrels. In most .30-caliber chamberings, the barrel twist rate is 1:11 or 1:12 to stabilize 150gr to 200gr bullets. The 30 BR is optimized for 115gr to 118gr flat-base bullets and 1:17 provides sufficient stability at muzzle velocities around 2900-3000 fps. In competitive Benchrest, where every thousandth of an inch counts, over-stabilization of projectiles can hurt accuracy, so “just stable enough” is the goal; hence the 1:17 twist.

|

Case Forming, Case Prep, and Reloading Methods

A Sinclair case neck micrometer indicates neck thickness of 0.010″ after neck turning.

30 BR dies are readily available from a number of manufacturers. I personally use Wilson neck and seating dies with a Sinclair Arbor press, but Redding and Forster both supply high-quality threaded dies for use in a conventional press. For under $100.00 US, custom full-length dies can be obtained from Hornady and CH Tool & Die by sending them reamer prints or a couple of fired cases. Harrell’s Precision offers “semi-custom” dies. Just send them some fired cases and they select a pre-made CNC-cut die that ideally fits your chamber. You can ask the Harrell brothers for a die that’s tighter at the shoulder or base, or otherwise customized to your preferences. 30 BR dies are readily available from a number of manufacturers. I personally use Wilson neck and seating dies with a Sinclair Arbor press, but Redding and Forster both supply high-quality threaded dies for use in a conventional press. For under $100.00 US, custom full-length dies can be obtained from Hornady and CH Tool & Die by sending them reamer prints or a couple of fired cases. Harrell’s Precision offers “semi-custom” dies. Just send them some fired cases and they select a pre-made CNC-cut die that ideally fits your chamber. You can ask the Harrell brothers for a die that’s tighter at the shoulder or base, or otherwise customized to your preferences.

Load Development and Accuracy Testing

With cases formed and bullets selected, load development is simply a matter of choosing the right primer, powder and charge weight, and loading the most consistent ammunition possible. The Lapua BR cases use a small rifle primer. The choice here was Federal 205 Match primers vs. CCI BR4 Benchrest primers. Some shooters have also had success using CCI 450 Magnum primers but it is very unlikely the small case needs this much spark to light off regular extruded powders. In my case, I selected Federal primers because availability tends to be better in Australia.

The relatively large bore-to-capacity ratio of the 30 BR case means that fast burning powders are the order of the day. Once again, US experience suggests H4198 (the Hodgdon equivalent of ADI AR2207) is the choice of match winners. The fact that H4198/AR2207 is an Australian-made product is an added bonus. So, I loaded up test rounds with AR2207 from 32.5 grains to 35.0 grains in approximately 0.3 grain increments. All bullets were seated to jam +0.010″ into the lands. This places the bullet base about two-thirds of the way down the neck and well short of the neck-shoulder junction.

April 19th, 2015

Forum member Scott S. (Sunbuilder) has built a sweet long-range varminter based on the 6.5×47 Lapua cartridge necked down to 6mm and then improved to 40 degrees, with slightly less body taper. Scott tells us that “improving the case adds about 2.0 grains to the case capacity”. This allows Scott to run the 103-108gr bullets at well over 3100 fps, with no pressure issues. Scott calls his Improved case a “Long Dasher”, a name suggested by Dave Kiff of Pacific Tool & Gauge.

6-6.5×47 Improved Works Well with Many Powders

Scott’s 6-6.5×47 Lapua Improved varmint rifle features a Stiller Diamondback action, Lilja 30″ 8-twist barrel, Richard Franklin stock, and a NightForce 8-32×56 NXS. Scott has had excellent success — his two longest groundhog hits were at 778 and 810 yards. Scott has tested many powders with his 6-6.5×47 wildcat: “I tried several powders (H4350, N160, N560, H4831sc), and primers (CCI 450, BR4, Rem 7 1/2, Fed 205Ms). I got better velocity with H4350, but my barrel likes the N160. I did find a [high-speed] node with H4350. The increased velocity potential of this cartridge is partially due to the slightly increased case capacity. The load I am shooting now is 40.5gr N160, Berger 105gr Match BT, .010″ jam, CCI BR4, .002″ neck tension at 3115 fps. This has an ES under 15 fps, and it will group under 2″ at 500 yards if conditions hold. This ‘Long Dasher’ (6-6.5×47) seems to have a lot of potential (and that’s an understatement).”

A Better Mount for the Spotter and Rangefinder

Scott designed and fabricated a very slick set-up to hold his Zeiss spotting scope and Leica CRF RangeFinder. He’s built a combo bracket that holds both units rock steady, with a parallel line of sight (same axis and elevation). Smart. Very smart. Scott explains: “I built a mount to connect my rangefinder to my spotting scope. The mount can be adjusted, so the spotting scope and rangefinder are both centered on the same object. The only way I have found to get repeatable long-range readings is to make them from a stable base.” Scott, we think you’ve got a winner here with your innovative and clever design.

June 24th, 2014

Texan Mike Bryant is a superb gunsmith and a very successful benchrest competitor. And though he is getting up in years, he hasn’t lost any of his talent as a trigger-puller. In fact, if recent results are any indication, Mike Bryant isn’t getting older, he’s getting better. Texan Mike Bryant is a superb gunsmith and a very successful benchrest competitor. And though he is getting up in years, he hasn’t lost any of his talent as a trigger-puller. In fact, if recent results are any indication, Mike Bryant isn’t getting older, he’s getting better.

Check out this set of targets Mike recently shot, which represent the best 100-Yard Aggregate of Mike’s shooting career. Maybe being a grandfather has improved his skill set.

Mike reports: “Here’s the set of targets I shot at the East-West HV100. Needless to say, I was tickled to death. This is the best 100-yard Agg I’ve ever shot [in benchrest competition]: 0.1744″ average.”

Click Photo for Full-Size Version

Mike is a great gunsmith, but he’s retired for the most part now: “I’ve closed up my shop and won’t be gunsmithing for the general public. I want to help my son on the ranch and shoot more benchrest.”

As far as the “shoot more benchrest” part, it looks like Grandfather Bryant is doing well indeed. Mike credits his recent success to other shooters:

“I owe a lot of what I was able to accomplish with this Agg to Gene Bukys. Gene is currently one of the hottest-shooting benchrest competitors in the United States, and a member of the Benchrest Hall of Fame. After the Cactus Classic this year, Gene shared with us the make, twist rate, and contour of the barrels that he had been using to win everything in sight. He also told me which of his reamers that Dave Kiff had made him that he had been using and which one to order from Kiff to shoot the same chamber.” “I owe a lot of what I was able to accomplish with this Agg to Gene Bukys. Gene is currently one of the hottest-shooting benchrest competitors in the United States, and a member of the Benchrest Hall of Fame. After the Cactus Classic this year, Gene shared with us the make, twist rate, and contour of the barrels that he had been using to win everything in sight. He also told me which of his reamers that Dave Kiff had made him that he had been using and which one to order from Kiff to shoot the same chamber.”

“Gene had already matched a die to my previous chamber that [eliminated] the click at the top of the bolt stroke to insure smooth bolt operation. After the Cactus I ordered some of the same barrels that Gene was using and ordered a reamer from Kiff. I chambered two of the barrels with the reamer that Gene was using on Monday and fire-formed brass for them on Tuesday and spent a little time at home trying to get the rifles tuned up for the East-West.”

“On Saturday morning I started with one of the rifles and shot it through the LV 100. Not doing particularly well. So, switched rifles to the other one for the HV 100. It seemed to be working better and seemed to get better as the day went along. After the match, I was out pulling up my flags and Wade Hull walks up to me and holds out his hand and says ‘Congratulations, you won the Heavy 100′.”

Hall of Famers Helping Other Benchresters

Mike concludes: “If there is a story in my experience, it is really about benchresters helping other benchresters. People like Gene Bukys, Jack Neary, and Bart Sauter, all Hall of Fame members, are giving back to other benchrest shooters to help them become better. Jack Neary has been giving Vihtavuori tuning classes for many years, passing on the info that helped him get into the Hall of Fame. Bart Sauter posts on Benchrest.com, passing on key secrets of his success. And let’s not forget Tony Boyer who has helped others in many ways, including one-on-one private benchrest lessons. So, if there is a story here, it’s about these guys, not about me.”

Between benchrest matches, Mike Bryant likes to spend “quality time” with his children and grandchildren. Here is Mike on a playground slide with his grandson. Mike’s philosophy is to enjoy life and stay young at heart. We think that’s a good approach to life.

January 17th, 2014

Here are some more quick highlights from SHOT Show in Las Vegas. There are some brilliantly designed new products, as well as some items that are interesting simply because they depart from the norm. Enjoy these images of interesting products (and people) we saw this week in Vegas.

Era-Tac Adjustable-Angle Scope Mount (0 to +70 MOA)

This is a unique, variable-angle scope mount (with integral rings) that adjusts from 0 MOA to +70 MOA pre-load, in precise, ten-MOA increments. Once adjusted and tensioned, there is no play in the system so your elevation is repeatable. This Era-Tac Mount, made by Recknagel (Germany) is a very advanced design that really works. CLICK HERE for details.

Mossberg Gets Patriotic

Mossberg was “showing the flag” (literally) at its SHOT Show booth. Here a row of camo-dipped Mossberg shotguns and rifles are decorated with Old Glory.

New Precise Micrometer-Top Bullet Seaters from Sinclair Int’l

Sinclair showed off its new dial-adjustable seating dies for use with arbor presses. Though produced by L.E. Wilson, these are a step up from the regular Wilson micro-adjusting hand dies. These new Sinclair dies eliminate the guesswork. Each hashmark actually gives you a .001″ (one-thousandth) change in bullet seating depth. There’s a tactile click as you rotate the micrometer top past each hash mark.

World Champions Gather At Sands Expo

Four members of the World Championship-winning USA F-TR Team were on hand when we paid a visit to the Nightforce booth at SHOT Show. Left to right, here are four of the team that triumphed at Raton: Ray Gross, Dan Pohlabel (with rifle), Phillip Kelley, and Brad Sauve.

Wow, Is There Anything PT&G Isn’t Making These Days?

Pacific Tool & Gauge had dozens of new products on hand. There were gunsmithing tools, replacement bolts (for many different action types), barrel vises, action truing tools, you name it. Heck, Dave Kiff even showed us a new aluminum rifle chassis PT&G will be manufacturing. This company is now producing a vast selection of precision metal parts and tools.

300 AAC Blackout, Actually Blacked-Out

Australian Outback, backed by the folks who acquired ADI, is making a big push to sell loaded ammunition in the USA. To jazz up their new 300 Blackout ammo, the bodies of the brass cases have a distinctive black finish. So the Blackout Ammo is black… get it?

Kimber SOC (Not Your Ordinary Kimber Bolt-Gun)

No, this is not an Accuracy International, or a Surgeon, or even a Colt tactical rifle. Believe it or not, this is the new Kimber “Advanced Tactical” metal-chassis rifle, dubbed the “SOC” for “Special Operations Capable”. The chassis felt stiff and strong. The bolt cycled smoothly, but the trigger pull was pretty heavy (we’re told it can be adjusted.)

January 10th, 2013

Pacific Tool and Gauge is running a SHOT Show Special with big savings on bolts, bottom metal, chamber reamers, gauges and more. SHOT Show Special prices are offered for FOUR DAYS ONLY: January 15 through January 18, 2013. If you see something you want in the Specials list below, don’t hesitate. You can save $20-$30 (or more) on these SHOT Show Special items. Pacific Tool and Gauge is running a SHOT Show Special with big savings on bolts, bottom metal, chamber reamers, gauges and more. SHOT Show Special prices are offered for FOUR DAYS ONLY: January 15 through January 18, 2013. If you see something you want in the Specials list below, don’t hesitate. You can save $20-$30 (or more) on these SHOT Show Special items.

Call (541) 826-5808 to order and mention the SHOT Show Special. Remember deals expire at the end of the day on January 18, 2013!!

PT&G 2013 SHOT Show Specials

CHAMBER REAMERS

Custom and Wildcat Chamber Reamers

(Sm to Med) with removable pilot — $135 each

Standard SAAMI or CIP Chamber Reamers

HSS with removable pilot — $110 each

Carbide with removable pilot — $175 each

BOTTOM METAL

Remington “Stealth” Detachable Mag Bottom Metal — $99 each

L/A: BDL bolt in black | L/A: M5 black | S/A: M5 black

(Not including mag box and no engraving)

Remington & Winchester Trigger Guard — $79 each

Long Action and Short Action Aluminum in the white

(Not including follower or spring)

ONE-PIECE BOLTS

RH custom size on the OD. L/A or S/A, with or without flutes

Your choice of extractor type — $175 each

RH standard size .699 OD, with or without flutes.

Your choice of extractor type — $149 each

HEADSPACE GAUGES

Small to medium — $25 each

Large (50BMG) gauges — $42.50 each

PT&G Expands Plant, Adds New Products, Launches Custom Shop

Dave Kiff, founder of PT&G, tells us there are many positive new developments at his company: “We will have new products coming out for 2013. There will be 14 new reamers, fixtures and rifle parts coming out after SHOT Show [plus] we are adding more bolts and bottom metal. Plus, we are now able to sell overseas with our ITAR in place.”

With ever-increasing demand for its products, PT&G has grown dramatically in recent years. The company has invested $2.5 million dollars, expanded its production facilities, and added many more highly-trained staffers. Dave notes: “We have gone from 49 people to 126 toolmakers and office staff. Two years ago I decided to grow to meet the demands and needs of our customers and added machinery, buildings, and new employees. It has been a long, hard road but… we are just about over our growing pains.” With ever-increasing demand for its products, PT&G has grown dramatically in recent years. The company has invested $2.5 million dollars, expanded its production facilities, and added many more highly-trained staffers. Dave notes: “We have gone from 49 people to 126 toolmakers and office staff. Two years ago I decided to grow to meet the demands and needs of our customers and added machinery, buildings, and new employees. It has been a long, hard road but… we are just about over our growing pains.”

New PT&G Custom Shop

Dave has started a custom shop with fast turn-around. Dave says: “We are offering a 48-hour delivery on emergency tools and a 1-6 week delivery on tools that a gunsmith can wait on[.] We are able to stock SAAMI and Match grade chamber reamers on the shelf.”

Enhanced Certification System

Dave has created a new certification system: “[We have] put together a certification-auditable form that is stapled to the invoice and is filed so that if a customer has a question on a reamer size we can look up the tool and read the inspection data. This is working great.”

November 9th, 2012

Want to invest in a gun-making milestone, with authentic “PPC Provenance”? Here is a rare opportunity to acquire a set of guns that forged new frontiers for rifle accuracy. Dave Kiff, founder of Pacific Tool & Gauge, is selling a consecutive built and numbered set of four (4) benchrest rifles which belonged to Ferris Pindell, one of the fathers of the PPC cartridge. These four game-changing guns were custom-crafted by Pindell with help from his friend and fellow PPC inventor Lou ‘Doc’ Palmisano. Want to invest in a gun-making milestone, with authentic “PPC Provenance”? Here is a rare opportunity to acquire a set of guns that forged new frontiers for rifle accuracy. Dave Kiff, founder of Pacific Tool & Gauge, is selling a consecutive built and numbered set of four (4) benchrest rifles which belonged to Ferris Pindell, one of the fathers of the PPC cartridge. These four game-changing guns were custom-crafted by Pindell with help from his friend and fellow PPC inventor Lou ‘Doc’ Palmisano.

Dave Kiff tells us: “These are the four rifles that June Pindell had sold me a while back. I have #1, #2, #3 and #4 of Ferris Pindell’s original custom-made Benchrest rifles. These are consecutive builds. I am selling all four at cost! Several collectors (and one museum) have offered a generous amount of money for only one or two of them, but I would hate to split them up. I would much rather sell all four of them complete for $6,900.00 and keep them all together. There are two PPCs and two BRs from what his wife told me. June told me these are the rifles that Ferris and ‘Doc’ Palmisano built when they created the PPC cartridge. This would be a great addition to any collection or a great start for anyone interested in shooting competition, as the rifles look very usable.”

For more information, call Yvette of PT&G at (541) 826-5808, or send email to yvette [at] pacifictoolandgauge.com .

Sale tip by Boyd Allen. We welcome reader submissions.

June 6th, 2012

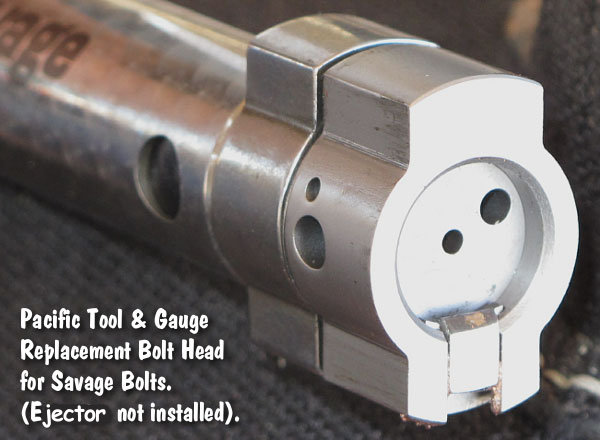

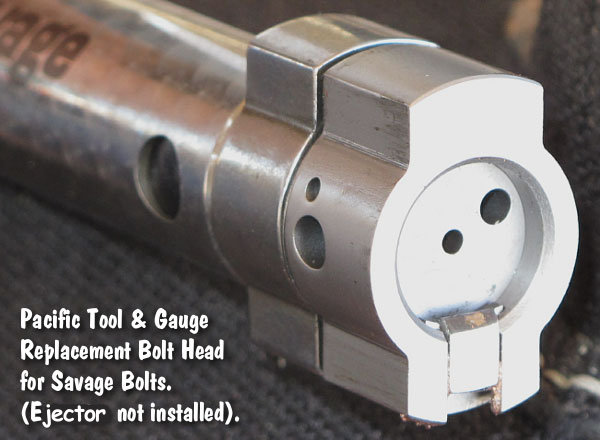

Pacific Tool & Gauge, has an outstanding new product, a precision-machined replacement bolt head for Savages. This product, available in a variety of bolt face sizes for $49.99 per unit, can benefit nearly everyone who shoots Savage bolt guns.

CLICK HERE for Full Product Review of PT&G Savage Bolt Head

When visiting German Salazar’s excellent Rifleman’s Journal website, we were pleased to see a recent, in-depth review of the PT&G Replacement Bolt Head for Savage Bolts. Written by Norm Darnell, this detailed review explains the benefits of the PT&G replacements, compared to the standard Savage bolt heads. After polishing, the factory bolt head can become slightly dished. According to Darnell: “The area around the firing pin hole sometimes has an indentation deep enough to allow the primer to flow into this void. This makes an unsightly blemish on a fired primer and can lead to hard extraction or worse. One [Savage] rifle I inspected had a continuing problem with pierced primers despite reasonably mild loads[.]” Even after machining the factory bolt face to make it flat, Darnell encountered problems: “The firing pin hole seemed to wear excessively which was of some concern. Material strength of the investment-cast bolt head* appears to be the source of these recurring problems.”

After testing out PT&G replacement bolt heads, Darnell found that his problems were solved. With the PT&G replacement bolt head, “the cartridge case heads and primers indicated no case-head rounding or primer damage”. Darnell was convinced, so he proceeded to fit PT&B bolt heads “on all three of my 308 bolts and one 223 with one spare bolt of each.” It appears that PT&G has a winner here — a smart, affordable new product that remedies a commonly-observed problem with factory Savage bolt heads.

* In the article, author Darnell writes that Savage factory bolt heads are investment cast. Fred Moreo of Sharp Shooter Supply says this is not correct: “Savage bolt heads were NEVER investment cast. From the get-go they were machined from solid stock. In 1988 they went to special profiled 41L40 bar stock to save machining operations and heat treated to 35-42 RC.”

April 13th, 2012

Pacific Tool & Gauge is now offering a Full-Length Re-Size Reamer and Die Blank Kit for $107.50. Yep, you read that right — you get a solid pilot (HSS) reamer AND the die body blank for $107.50, total. The reamer can be a standard-spec chambering or you can send in a file or print to have the FL re-size reamer match your current chambering. Some folks have wondered: “Can’t I just make a sizing die using my chambering reamer?” The answer is no. A resize die needs to be smaller than your actual chamber so that it can down-size the brass to ensure proper feeding and extraction. This kit from PT&G is a great way to get a custom sizing die for an affordable price. NOTE: You must still get a competent gunsmith to run the FL re-size reamer into the die body blank to create the finished die. Pacific Tool & Gauge is now offering a Full-Length Re-Size Reamer and Die Blank Kit for $107.50. Yep, you read that right — you get a solid pilot (HSS) reamer AND the die body blank for $107.50, total. The reamer can be a standard-spec chambering or you can send in a file or print to have the FL re-size reamer match your current chambering. Some folks have wondered: “Can’t I just make a sizing die using my chambering reamer?” The answer is no. A resize die needs to be smaller than your actual chamber so that it can down-size the brass to ensure proper feeding and extraction. This kit from PT&G is a great way to get a custom sizing die for an affordable price. NOTE: You must still get a competent gunsmith to run the FL re-size reamer into the die body blank to create the finished die.

The resizing die kit (item N3861330) contains: One (1) Solid Pilot (HSS) Re-Size Reamer (excludes 50 BMG & Canon Type Reamers); and One (1) Caliber-Specific Die Blank. NOTE: This offer excludes 50 BMG and canon-type reamers.

|

PT&G 10% Discount for Owners of Stiller Actions

Here’s a great deal if you own a Predator, Tac30/300 or other Rem-clone type action from Stiller’s Precision Firearms. Last week, PT&G announced that it will give a 10% Discount on Remington-type PT&G parts used with compatible Stiller Actions. To qualify for the 10% discount, customers must provide proof that they own, or have purchased a Stiller Action for which there are compatible parts from Pacific Tool & Gauge. Please contact the PT&G sales staff for more information. Send email to pacpes [at] medford.net or call (541) 826-5808.

Story Tip from EdLongrange. We welcome reader submissions.

|

|

Front Bracket with Magnetic Tuner

Front Bracket with Magnetic Tuner Tubular Fore-Arm Supported by Brackets

Tubular Fore-Arm Supported by Brackets Offset Barrel

Offset Barrel Floating Action without Sub-Support or Bedding

Floating Action without Sub-Support or Bedding Skeleton Rear “Keel” Affixed Directly to Action

Skeleton Rear “Keel” Affixed Directly to Action Locked Scope with External Windage and Elevation Adjustment

Locked Scope with External Windage and Elevation Adjustment

The recoil lug-style stock mount is probably the only truly innovative thing I did other than the opposing-magnet tuner. Basically, the rear bracket is sandwiched between the receiver face and the barrel shoulder–positioned where a conventional recoil lug would go. I also added a brass ring (visible in photo) between the anodized bracket and the barrel. This was done to distribute loads over a wider surface area. (I was concerned that the bracket material was fairly soft and I didn’t want to crush it as I torqued the barrel in place.) After fitting the barrel and plates I glued the entire gun together using epoxy and various LocTite adhesives. The rest of the parts were assembled but I did not Loctite the scope bases since I thought I’d be disassembling the rifle for re-work after the first trials. That came back to bite me during later testing when the gun started shooting erratically and I went down a couple of blind alleys before finding the loose bases.

The recoil lug-style stock mount is probably the only truly innovative thing I did other than the opposing-magnet tuner. Basically, the rear bracket is sandwiched between the receiver face and the barrel shoulder–positioned where a conventional recoil lug would go. I also added a brass ring (visible in photo) between the anodized bracket and the barrel. This was done to distribute loads over a wider surface area. (I was concerned that the bracket material was fairly soft and I didn’t want to crush it as I torqued the barrel in place.) After fitting the barrel and plates I glued the entire gun together using epoxy and various LocTite adhesives. The rest of the parts were assembled but I did not Loctite the scope bases since I thought I’d be disassembling the rifle for re-work after the first trials. That came back to bite me during later testing when the gun started shooting erratically and I went down a couple of blind alleys before finding the loose bases.

Match One–Tinker Toy Wins Score with a 250 – 17X

Match One–Tinker Toy Wins Score with a 250 – 17X

30 BR dies are readily available from a number of manufacturers. I personally use Wilson neck and seating dies with a Sinclair Arbor press, but Redding and Forster both supply high-quality threaded dies for use in a conventional press. For under $100.00 US, custom full-length dies can be obtained from

30 BR dies are readily available from a number of manufacturers. I personally use Wilson neck and seating dies with a Sinclair Arbor press, but Redding and Forster both supply high-quality threaded dies for use in a conventional press. For under $100.00 US, custom full-length dies can be obtained from

Texan Mike Bryant is a superb gunsmith and a very successful benchrest competitor. And though he is getting up in years, he hasn’t lost any of his talent as a trigger-puller. In fact, if recent results are any indication, Mike Bryant isn’t getting older, he’s getting better.

Texan Mike Bryant is a superb gunsmith and a very successful benchrest competitor. And though he is getting up in years, he hasn’t lost any of his talent as a trigger-puller. In fact, if recent results are any indication, Mike Bryant isn’t getting older, he’s getting better.

“I owe a lot of what I was able to accomplish with this Agg to Gene Bukys. Gene is currently one of the hottest-shooting benchrest competitors in the United States, and a member of the Benchrest Hall of Fame. After the Cactus Classic this year, Gene shared with us the make, twist rate, and contour of the barrels that he had been using to win everything in sight. He also told me which of his reamers that Dave Kiff had made him that he had been using and which one to order from Kiff to shoot the same chamber.”

“I owe a lot of what I was able to accomplish with this Agg to Gene Bukys. Gene is currently one of the hottest-shooting benchrest competitors in the United States, and a member of the Benchrest Hall of Fame. After the Cactus Classic this year, Gene shared with us the make, twist rate, and contour of the barrels that he had been using to win everything in sight. He also told me which of his reamers that Dave Kiff had made him that he had been using and which one to order from Kiff to shoot the same chamber.”

With ever-increasing demand for its products, PT&G has grown dramatically in recent years. The company has invested $2.5 million dollars, expanded its production facilities, and added many more highly-trained staffers. Dave notes: “We have gone from 49 people to 126 toolmakers and office staff. Two years ago I decided to grow to meet the demands and needs of our customers and added machinery, buildings, and new employees. It has been a long, hard road but… we are just about over our growing pains.”

With ever-increasing demand for its products, PT&G has grown dramatically in recent years. The company has invested $2.5 million dollars, expanded its production facilities, and added many more highly-trained staffers. Dave notes: “We have gone from 49 people to 126 toolmakers and office staff. Two years ago I decided to grow to meet the demands and needs of our customers and added machinery, buildings, and new employees. It has been a long, hard road but… we are just about over our growing pains.”

Want to invest in a gun-making milestone, with authentic “PPC Provenance”? Here is a rare opportunity to acquire a set of guns that forged new frontiers for rifle accuracy. Dave Kiff, founder of

Want to invest in a gun-making milestone, with authentic “PPC Provenance”? Here is a rare opportunity to acquire a set of guns that forged new frontiers for rifle accuracy. Dave Kiff, founder of