|

|

January 18th, 2024

Custom hunting rifle photo courtesy Kilimanjaro Rifles.

The folks at Sierra Bullets asked a few staff bulletsmiths a classic question about guns: “If you could own only one firearm which one would you choose?” There were many interesting answers including a “cheater” response — the drilling — which is really two guns in one. The most-often mentioned chambering was the venerable .30-06. Respondents cited its versatility, hunting prowess, and ready availability of ammo. The popular .308 Winchester, as expected, got mentions as did its cousins the .243 Win and 7mm-08. There were quite a few votes for classic lever guns, as well as 12-gauge shotguns. Two bulletsmiths cited the .22 LR, and we can certainly see the logic in that answer. The little rimfire cartridge is versatile, quiet, and inexpensive. SEE All Answers.

We ask our readers the same question — if you could only have one long gun, what type of firearm would it be? List the gun type and chambering in the comments section.

If You Could Have Just One Long-Gun — ANSWERS:

Media Relations Manager Carroll Pilant answered: “I would NEVER own only one gun. If I HAD to pick one, it would be a drilling in 12 gauge over .30-06.”

Ballistic Technician Rich Machholz answered: “The early tang safety Ruger M77s pretty much have all you could want in a bolt gun, but I do like the Winchester lever guns and the combination guns, particularly the drillings. Since I have the first two, I’m going for a Doug Turnbull 1886 or a side by side 20 gauge over .223 drilling.”

Ballistic Technician Philip Mahin answered: “More than likely it would have to be a bolt action .30-06. The reliability is legendary on a wide range of game animals and factory ammunition has still been available at my local stores even in these tough times.”

Ballistic Technician Duane Siercks answered: “If I had to boil it all down to one gun, it would probably be a .30-06. I have a Remington 700C (custom shop gun) that has worked very well for anything and everything I have ever wanted to do with it.”

Ballistic Technician Paul Box answered: “A .22 Rimfire.”

Chief Ballistician Tommy Todd answered: “Remington 700 in .308 Winchester.”

VP – Sales & Marketing Matt Reams answered: “A light weight Kimber in 25-06.”

Production Toolsetter Brad Vansell answered: “Savage weather warrior 7mm-08 is my rifle of choice.”

Production Toolsetter Dan Mahnken answered: “The .308 Winchester rifle — [based on the] wide range of bullets made and the wide range of things that one can hunt with it.”

Process Engineer David Palm answered: “Savage action 243 Winchester.”

Ballistic Technician Gary Prisendorf answered: “Probably a .22 LR. It may not be the best choice, but you could use it for about anything if you really had to.”

Production Manager Chris Hatfield answered: “Beretta A300 Outlander 12 gauge.”

Machine Shop Manager Craig Westermier answered: “12 gauge shotgun.”

This article originally appeared in the Sierra Bullets Blog.

December 27th, 2023

NOTE: There are ten (10) shots in the group, but for simplicity we are only displaying five (5) shot circles. Adding more circles won’t change the measurement because the two most distant shots, which determine group size, ARE included.

What kind of 200-yard accuracy can you get in an enclosed, underground test range? Would you believe 0.162 MOA at 200 yards with a .338? Have a look at these test targets from Sierra Bullets. Like most bullet manufacturers, Sierra does live-fire bullet testing to ensure that Sierra projectiles perform as promised, with repeatable accuracy. Sierra tests bullets in its own underground test complex. Sierra’s 300-meter test range is the longest, privately-owned underground bullet test facility in the Western Hemisphere.*

Day in and day out, various bullet types are tested using a big collection of barreled actions. These barreled actions are clamped in stout, return-to-battery test fixtures. These big, heavy test fixtures provide near-perfect repeatability (with no human-induced holding or aiming errors).

Sierra Bullets 10-Shot Groups at 200 yards

Check out these 10-shot test groups shot at the Sierra Test Range at 200 yards. Note that the numbers listed on each sample are actual measurements in inches. To convert to MOA, cut those numbers in half (to be more precise, divide by 2.094, which is 1 MOA at 200 yards). For example, the 0.340″ middle group works out to 0.162 MOA at 200 yards.

Scan-Verified 0.162 MOA Accuracy at 200 Yards Scan-Verified 0.162 MOA Accuracy at 200 Yards

To verify the accuracy of Sierra’s measurements, we measured the middle (.338 caliber) 10-shot group with our On-Target Group Measurement software. We registered a group size reading of 0.339″ — within one-thousandth of the Sierra measurement. The calculated group size in MOA (Minute of Angle) is 0.162.

That’s amazingly good for ten rounds of big .338 caliber bullets. A FIVE-shot 0.162 MOA group at 200 would be considered excellent at any benchrest match. But remember this target has TEN shots. The current, one-target IBS world record for ten shots at 200 yards is 0.245″, set by Ed Watson in 1999.

Bevy of Barreled Actions for Bullet Testing

Sierra Bullets uses dozens of barreled actions for testing bullets in its enclosed, 200-yard test range. Each barrel has its own logbook to track the barrel’s usage.

Click Photo to Zoom

*Even Longer Test Tunnels Exist in Europe: At Stadeln in Germany, RWS (now part of RUAG) owns a 500 meter tunnel (above ground level) which has existed for decades. In Thun, Switzerland, RUAG has a fully-instrumented 500 meter underground tunnel. Near Ulm, Germany, there is a 5-lane 300 meter underground shooting range that is open to the public.

December 16th, 2023

Sierra Bullets Ballistic Technician Gary Prisendorf has written a nice essay about how reloading can become a life-time hobby, a rewarding pastime that can bring together a father and son…

Memories of My Father — Reloading As a Life-Time Hobby

by Gary Prisendorf

For as long as I can remember I have been around reloading. I have tons of childhood memories of my father reloading and shooting. I remember how he would let me help him load his ammunition, by letting me clean primer pockets or wipe the sizing lube off of his cases. I really thought I was doing something. Well, I guess I was, I was spending quality time with my father doing something that would become a great hobby and eventually land me a great job working for Sierra Bullets.

If you are a reloader, teach someone. You may just give them a hobby for the rest of their life and who knows, you could help them find an enjoyable career, doing something that they love. — Gary Prisendorf

I remember watching my father sizing cases on his Herters press, dropping his powder charges with a Belding & Mull powder measure and weighing powder charges with his Texan scales. Heck, I can even remember when he would buy powder at a local pawn shop, and they would weigh it out and put it in a paper sack. He would save his empty powder cans, wrap them with masking tape and write what the powder was on them with a black magic marker.

When I was in Junior High, I got my first shotgun, a 20 gauge Mossberg 500 and within a couple of weeks my father came home with a 20 gauge Lee Load-All and a pound of Blue Dot. He gave me a crash course on how to use it, and got me up and running with a couple of safe loads. I put a lot of shells through that old 20 gauge.

From that day forward I was hooked. If I got a new gun, I was loading ammunition for it. I don’t buy factory ammunition unless I just want to shoot it up so I can get some once fired brass. I reload everything that I shoot, except for rimfire stuff, and if I could figure out how to do that safely, I would probably load that too.

Through the years I have learned to appreciate things — such as once-fired military .30-06 cases that can be converted to obscure cartridge types. And I know the value of a five-gallon bucket of lead wheel weights that will be melted down and cast into bullets.

I remember finding 19 once-fired Norma 7.7×58 Arisaka cases laying on the ground at a public shooting range, and it was like Christmas came early. I must have looked for that 20th case for about thirty minutes, but I never did find it.

I can’t thank my father enough for getting me started in reloading, he gave me a great hobby, many wonderful memories and taught me the skills that gave me a career doing something that I love.

November 22nd, 2023

Sierra Bullets has released load data for the 6.5 Grendel, a popular cartridge that works equally well in bolt guns and AR15-platform gas guns. Sierra published comprehensive 6.5 Grendel load data, covering 19 powders and eight (8) different bullets from 85 to 130 grains. NOTE: Hornady-brand brass (see below) was used for Sierra’s 6.5 Grendel tests, not the stronger Lapua 6.5 Grendel brass. Hand-loaders using Lapua 6.5 Grendel brass may need to adjust their loads. Also Winchester WSR primers were used. We imagine most precision hand-loaders will prefer CCI or Federal primers.

| Sierra Bullets Tested for 6.5 Grendel Load Data |

85gr HP (#1700)

100gr HP (#1710)

107gr HPBT (#1715) |

120gr Spitzer (#1720)

120gr HPBT (#1725)

123gr HPBT (#1727) |

130gr HPBT (#1728)

130gr TMK (# 7430) |

In developing its 6.5 Grendel load data, Sierra tested a very wide selection of propellants, 19 in all. For the 85gr to 100gr varmint bullets, modern powders such as XMR 2230, Power Pro Varmint, and Ramshot TAC offered the best velocity in the 24″ test barrel. For the heavier 120gr to 130gr match bullets, Sierra tested a selection of powders. Highest velocities came with Power Pro Varmint and TAC. If you’re looking for best accuracy, consider the slower burn-rate powders such as IMR 8208 XBR and Varget — but you’ll sacrifice some speed. Overall, Sierra’s latest 6.5 Grendel load data is an excellent addition to the 6.5 Grendel knowledge base. Thanks Sierra!

Here are Sierra’s 6.5 Grendel Load Data Charts for Sierra’s 123gr HPBT, 130gr HPBT, and 130gr TMK. There are a five other tables for lighter-weight Sierra bullets.

History of the 6.5 Grendel Cartridge

The 6.5 Grendel originated as a 6mm PPC necked up to 6.5 mm. After Alexander Arms relinquished the “6.5 Grendel” Trademark, the 6.5 Grendel was standardized as an official SAAMI cartridge. It has become popular with target shooters and hunters alike because it is accurate, efficient, and offers modest recoil. Good for small to medium game, the 6.5 Grendel is available in lightweight hunting rifles, such as the Howa Mini Action Rifle. And the 6.5 Grendel is one of the most accurate cartridges suitable for modern AR-15 platform rifles.

CLICK HERE for 6.5 Grendel Cartridge History (Wikipedia entry).

CLICK HERE for 6.5 Grendel Cartridge History (Wikipedia entry).

October 28th, 2023

Here’s a helpful hint for hand-loaders from Sierra Bullets. While this article focuses on Sierra’s new Tipped Match-King bullets, the recommended solutions apply to other bullet types as well. The article explains how sharp edges on a seating stem can cause a ring to be pressed into the bullet jacket — especially with compressed loads that resist downward bullet movement. Here Sierra technician Rich Machholz diagnoses the problem and provides a solution.

Solutions for Ring Marks Caused by Seating Stems

by Sierra Bullets Ballistic Technician Rich Machholz

Now that the new Tipped MatchKing® (TMK) bullets are being shipped and shooters are putting them to use I have received several calls regarding marking on the bullet ogive from the seating stem.

The cause can be traced to one of several things. In the .223 and especially with the long, 77 grain TMK seated at 2.250” or even 2.260” most loads of Varget® and Reloder® 15 are compressed loads, sometimes heavily compressed. This puts a great deal of pressure on the bullet through the seating stem. The result of all this pressure is a mark of varying depth and appearance on the ogive of the bullet. [Editor: We have seen this issue with a variety of other bullet types/shapes as well, including non-tipped VLDs. The solution is profiling the internal cone of the seating stem to match your bullet shape.]

Some older seating stems might even bear against the tip of the bullet which can make a slight bulge in the jacket just below the junction of the resin tip and the copper jacket in a compressed load. If this is the case there is not a ready fix other than calling the die manufacturer and requesting a new deeper seating stem.

Polish Your Seating Stem to Remove Sharp Internal Edges

If the seating stem is of proper depth the culprit most generally is a thin sharp edge on the inside taper of the seating stem. This is an easy fix that can be accomplished by chucking a spare 77 grain bullet in your drill, coating it with valve grinding compound or even rubbing compound or in a pinch even tooth paste.* Remove the seating stem assembly from the seating die. Turn the drill on and put the seating stem recess over the spinning bullet with the polishing compound to break or smooth the sharp edge that is making the offending mark. This might take more than one application to get the proper polish depending upon what you use, but the more you polish the better the blend of angles which will [ensure the stem matches the bullet contours, not leaving a sharp ring].

If the above is a little more than you care to tackle you might try very fine emery cloth twisted to a point that can be inserted into the mouth to the seating stem and rotated to polish the inside to eliminate any sharp edges that might be present.

Load Advice for 77gr TMKs in the .223 Rem

And last but certainly not least. Actually, even though we don’t say you need additional data for the TMKs, remember you are dealing with heavily-compressed loads in some cases because of the additional bullet length. Due to the additional length of these new bullets and in the interest of gaining some room in the case you might consider trying a slightly faster extruded powder like BenchMark or the 4895s or an even more dense powder like the spherical H335®, CFE223 or TAC. The extra room will allow for trouble free bullet seating also.

August 26th, 2023

Here’a useful article by Sierra Bullets Media Relations Manager Carroll Pilant. This story, which originally appeared in the Sierra Bullets Blog, covers some of the more common ammo problems that afflict hand-loaders. Some of those issues are: excessive OAL, high primers, and improperly-sized cases. Here Mr. Pilant explains how to avoid these common problems that lead to “headaches at the range.

I had some gentlemen at my house last fall getting rifle zeros for an upcoming elk hunt. One was using one of the .300 short mags and every 3rd or 4th round would not chamber. Examination of the case showed a bulge right at the body/shoulder junction. These were new cases he had loaded for this trip. The seating die had been screwed down until it just touched the shoulder and then backed up just slightly. Some of the cases were apparently slightly longer from the base to the datum line and the shoulder was hitting inside the seating die and putting the bulge on the shoulder. I got to thinking about all the gun malfunctions that I see each week at matches and the biggest percentage stem from improper handloading techniques.

One: Check Your Cases with a Chamber Gage

Since I shoot a lot of 3-gun matches, I see a lot of AR problems which result in the shooter banging the butt stock on the ground or nearest solid object while pulling on the charging handle at the same time. I like my rifles too well to treat them that way (I cringe every time I see someone doing that). When I ask them if they ran the ammo through a chamber gage, I usually get the answer, “No, but I need to get one” or “I didn’t have time to do it” or other excuses. The few minutes it takes to check your ammo can mean the difference between a nightmare and a smooth running firearm.

A Chamber Gauge Quickly Reveals Long or Short Cases

Size Your Cases Properly

Another problem is caused sizing the case itself. If you will lube the inside of the neck, the expander ball will come out a lot easier. If you hear a squeak as the expander ball comes out of a case neck, that expander ball is trying to pull the case neck/shoulder up (sometimes several thousandths). That is enough that if you don’t put a bulge on the shoulder when seating the bullet … it can still jam into the chamber like a big cork. If the rifle is set up correctly, the gun will not go into battery and won’t fire but the round is jammed into the chamber where it won’t extract and they are back to banging it on the ground again (with a loaded round stuck in the chamber). A chamber gage would have caught this also.

Oversizing cases also causes problems because the firing pin doesn’t have the length to reach the primer solid enough to ignite it 100% of the time. When you have one that is oversized, you usually have a bunch, since you usually do several cases at a time on that die setting. If the die isn’t readjusted, the problem will continue on the next batch of cases also. They will either not fire at all or you will have a lot of misfires. In a bolt action, a lot of time the extractor will hold the case against the face of the breech enough that it will fire. The case gets driven forward and the thinner part of the brass expands, holding to the chamber wall and the thicker part of the case doesn’t expand as much and stretches back to the bolt face. If it doesn’t separate that time, it will the next time. When it does separate, it leaves the front portion of the case in the chamber and pulls the case head off. Then when it tries to chamber the next round, you have a nasty jam. Quite often range brass is the culprit of this because you never know how many times it has been fired/sized and in what firearm. Back to beating it on the ground again till you figure out that you have to get the forward part of the case out. Oversizing cases also causes problems because the firing pin doesn’t have the length to reach the primer solid enough to ignite it 100% of the time. When you have one that is oversized, you usually have a bunch, since you usually do several cases at a time on that die setting. If the die isn’t readjusted, the problem will continue on the next batch of cases also. They will either not fire at all or you will have a lot of misfires. In a bolt action, a lot of time the extractor will hold the case against the face of the breech enough that it will fire. The case gets driven forward and the thinner part of the brass expands, holding to the chamber wall and the thicker part of the case doesn’t expand as much and stretches back to the bolt face. If it doesn’t separate that time, it will the next time. When it does separate, it leaves the front portion of the case in the chamber and pulls the case head off. Then when it tries to chamber the next round, you have a nasty jam. Quite often range brass is the culprit of this because you never know how many times it has been fired/sized and in what firearm. Back to beating it on the ground again till you figure out that you have to get the forward part of the case out.

Just a quick tip — To extract the partial case, an oversized brush on a cleaning rod [inserted] and then pulled backward will often remove the case. The bristles when pushed forward and then pulled back act like barbs inside the case. If you have a bunch of oversized case that have been fired, I would dispose of them to keep from having future problems. There are a few tricks you can use to salvage them if they haven’t been fired though. Once again, a case gage would have helped.

Two: Double Check Your Primers

Another thing I see fairly often is a high primer, backwards primer, or no primer at all. The high primers are bad because you can have either a slam fire or a misfire from the firing pin seating the primer but using up its energy doing so. So, as a precaution to make sure my rifle ammo will work 100% of the time, I check it in a case gage, then put it in an ammo box with the primer up and when the box is full, I run my finger across all the primers to make sure they are all seated to the correct depth and you can visually check to make sure none are in backwards or missing.

Three: Check Your Overall Cartridge Length

Trying to load the ammo as long as possible can cause problems also. Be sure to leave yourself enough clearance between the tip of the bullet and the front of the magazine where the rounds will feed up 100%. Several times over the years, I have heard of hunters getting their rifle ready for a hunt. When they would go to the range to sight in, they loaded each round single shot without putting any ammo in the magazine. On getting to elk or deer camp, they find out the ammo is to long to fit in the magazine. At least they have a single shot, it could be worse. I have had hunters that their buddies loaded the ammo for them and then met them in hunting camp only to find out the ammo wouldn’t chamber from either the bullet seated to long or the case sized improperly, then they just have a club.

Four: Confirm All Cases Contain Powder

No powder in the case doesn’t seem to happen as much in rifle cartridges as in handgun cartridges. This is probably due to more handgun ammo being loaded on progressive presses and usually in larger quantities. There are probably more rifle cartridges that don’t have powder in them than you realize though. Since the pistol case is so much smaller internal capacity, when you try to fire it without powder, it usually dislodges the bullet just enough to stick in the barrel. On a rifle, you have more internal capacity and usually a better grip on the bullet, since it is smaller diameter and longer bearing surface. Like on a .223, often a case without powder won’t dislodge the bullet out of the case and just gets ejected from the rifle, thinking it was a bad primer or some little quirk.

For rifle cases loaded on a single stage press, I put them in a reloading block and always dump my powder in a certain order. Then I do a visual inspection and any case that the powder doesn’t look the same level as the rest, I pull it and the one I charged before and the one I charged after it. I inspect the one case to see if there is anything visual inside. Then I recharge all 3 cases. That way if a case had powder hang up and dump in the next case, you have corrected the problem.

On progressive presses, I try to use a powder that fills the case up to about the base of the bullet. That way you can usually see the powder as the shell rotates and if you might have dumped a partial or double charge, you will notice as you start to seat the bullet if not before. On a progressive, if I don’t load a cartridge in one smooth stroke (say a bullet tipped over sideways and I raised the ram slightly to reset it) Some presses actually back the charge back adding more powder if it has already dumped some so you have a full charge plus a partial charge. When I don’t complete the procedure with one stroke, I pull the case that just had powder dumped into it and check the powder charge or just dump the powder back into the measure and run the case through later.

August 19th, 2023

NOTE: The 6mm Creedmoor now does have an official SAAMI specification. It is no longer just a wildcat.

Sierra Bullets has published load data for the 6mm Creedmoor cartridge, a necked-down version of the popular 6.5 Creedmoor. Sierra has released very comprehensive 6mm Creedmoor load data, covering fifteen (15) different bullets from 55 to 110 grains. NOTE: Hornady-brand brass was used for Sierra’s 6mm Creedmoor load tests, not the newer, stronger Lapua 6.5 CM brass with small primer pockets. Hand-loaders using Lapua 6.5 Creedmoor brass necked to 6mm may have to adjust their loads.

Sierra writes: “As soon as the 6.5 Creedmoor was released in 2007, a 6mm version was being envisioned. After the 6mm Creedmoor demonstrated its worth at 1000 yards it began to catch the attention of Precision Rifle Series (PRS) competitors. The 6mm Creedmoor is a great fit for those looking for an AR platform-friendly cartridge. It delivers velocities very similar to the .243 Win and yet fits the AR10 magazine length[.] The 30-degree shoulder makes this a very efficient case and helps prolong case life as well. The 6mm Creedmoor works well with powders such as H4350, [RE-16], RE-17, and Ramshot Hunter for heavier long-range bullet weights. Slightly faster powders such as RE-15, Win 760, and Vihtavuori N540 work well with lighter weight bullets.”

| Sierra Bullets Tested for 6mm Creedmoor Load Data |

55gr BlitzKing (#1502)

60gr HP (#1500)

70gr HPBT (#1505)

70gr BlitzKing (#1507)

75gr HP (#1510) |

80gr SBT (#1515)

85gr Spitzer (#1520)

85gr HPBT (#1530)

90gr FMJBT (#1535)

95gr HPBT (#1537) |

95gr TMK (#7295)

100gr Spitzer (#1540)

100gr SBT (#1560)

107gr HPBT (#1570)

110gr HPBT (#1575) |

In developing its 6mm Creedmoor load data, Sierra tested a very wide selection of propellants, two dozen overall. For the smaller bullets, fast-burning powders such as Benchmark, H4895, and CFE223 were tested. For the heavier 100+ grain bullets, Sierra tested a selection of medium-burn-rate powders including H4350, Reloder 16, Reloder 17, Varget, and Superformance. Sierra did a very thorough job. We know this information will be welcomed by 6mm Creedmoor shooters.

Don’t know what powder to try first? For the 107-110 grain bullets, if you want best accuracy and low ES/SD, our Forum members recommend Alliant Reloder 16 and Hodgdon H4350. If you are seeking max velocity with the 110-grainer, look at Hodgdon Superformance and Reloder 19.

Here are Sierra’s 6mm Creedmoor Load Data Charts for 90-95 grain bullets plus the 107gr MK and 110gr MK. There are five other tables for other bullet types.

BONUS: PRB 6mm Creedmoor and 6.5 Creedmoor Load Survey

The Precision Rifle Blog compiled Load Data from PRS Competitors, for both 6mm Creedmoor and 6.5 Creedmoor. This is a good place to start. PRB surveyed the match loads for “173 of the top-ranked precision rifle shooters in the country”. One cautionary note: These PRS guys may be loading fairly hot, so work up gradually, 0.3 grains at a time. CLICK HERE.

August 7th, 2023

Understanding Twist: Bullet Stabilization

by Sierra Bullets Ballistic Technician Paul Box for Sierra Bullets Blog.

Based on the questions we get on a daily basis on our 800 (Customer Support) line, twist is one of the most misunderstood subjects in the gun field. So let’s look deeper into this mystery and get a better understanding of what twist really means.

When you see the term 1:14″ (1-14) or 1:9″ twist, just exactly what does this mean? A rifle having a 1:14″ twist means the bullet will rotate one complete revolution every fourteen inches of the barrel. Naturally a 1:9″ turns one time every nine inches that it travels down the barrel. Now, here’s something that some people have trouble with. I’ve had calls from shooters thinking that a 1:14″ twist was faster than a 1:9″ because the number was higher with the 1:14″. The easiest way to remember this is the higher the number, the slower the twist rate is.

Now, the biggest misconception is that if a shooter has a .223 with a 1:8″ twist, his rifle won’t stabilize a 55gr bullet or anything lighter. So let’s look at what is required. The longer a bullet is for its diameter, the faster the twist has to be to stabilize it. In the case of the .223 with a 1:8″ twist, this was designed to stabilize 80gr bullets in this diameter. In truth the opposite is true. A 1:8″ will spin a 55gr faster than what is required in order to stabilize that length of bullet. If you have a bullet with good concentricity in its jacket, over-spinning it will not [normally] hurt its accuracy potential. [Editor’s Note: In addition, the faster twist rate will not, normally, decrease velocity significantly. That’s been confirmed by testing done by Bryan Litz’s Applied Ballistics Labs. There may be some minor speed loss.]

Many barrel-makers mark the twist rate and bore dimensions on their barrel blanks.

Think of it like tires on your truck. If you have a new set of tires put on your truck, and they balance them proper at the tire shop, you can drive down a street in town at 35 MPH and they spin perfect. You can get out on the highway and drive 65 MPH and they still spin perfect. A bullet acts the same way.

Once I loaded some 35gr HP bullets in a 22-250 Ackley with a 1:8″ twist. After putting three shots down range, the average velocity was 4584 FPS with an RPM level of 412,560. The group measured .750″ at 100 yards. This is a clear example that it is hard to over-stabilize a good bullet.

Twist-rate illustration by Erik Dahlberg courtesy FireArmsID.com. Krieger barrel photo courtesy GS Arizona.

August 4th, 2023

Ever wondered what caused a particular bulge or marking on a case? And more importantly, does the issue make the case unsafe for further use? Sierra Bullets Ballistic Technician Duane Siercks offers some insight into various issues and their causes in two Case Diagnostic articles from the Sierra Blog.

Incipient Case-Head Separation

This is a Winchester .308 Win case that has a real issue. This case has a very obvious incipient case head separation in the process of becoming a complete failure.

This is most commonly caused by over-sizing the case causing there to be excess headspace on the case. After a few firings and subsequent re-sizing, this case is just about ready to come completely apart. Proper die adjustment is certainly a requirement here. Of course this case is not safe to reuse.

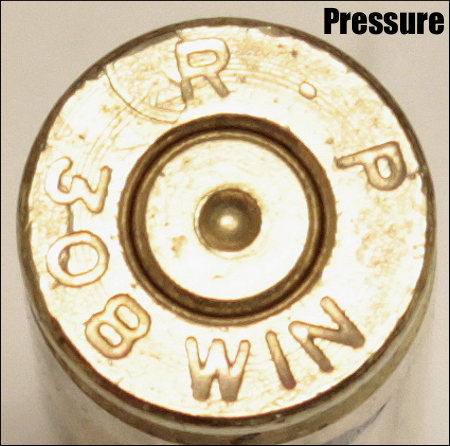

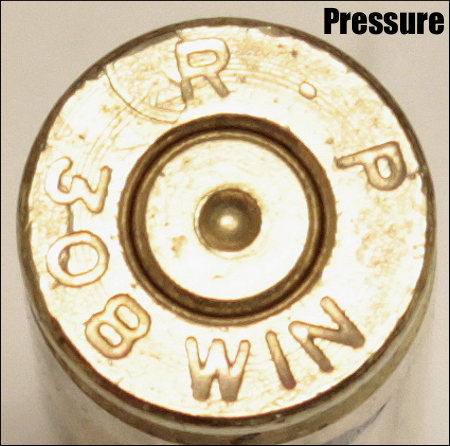

Excessive Pressure (Load Too Hot)

If you will notice in the picture of the case rim, there are two pressure signs to notice. First, look at the primer. It is basically flattened to about the max of what could be considered safe. If this was the only pressure sign noted, I would probably be fine with this load, but would constantly keep an eye on it especially if I was going to use this load in warmer temperatures. This load could easily cross into the “excess pressure” realm very quickly.

There is another sign of pressure that we cannot ignore. If you’ll notice, there is an ejector mark apparent that is located over the “R” of the R-P headstamp. This absolutely tells us that this load would not have been in the safe pressure range. If there were any of these rounds loaded, they should not be fired and should be dis-assembled. This case should not be reloaded.

Split Case-Neck

Here we have an R-P .22-250 case that has died the death. Everything looks fine with this case except the neck is split. This case must be tossed.

A split neck is a normal occurrence that you must watch for. It is caused by work-hardening of the brass. Brass cases get harder with age and use. Brand new cases that are stored for a period of time can become hard enough that they will split like this case within one to two firings. I have had new factory loads do the same thing. Then as we resize and fire these cases repeatedly, they tend to get harder and harder. Eventually they will split. The life of the case can be extended by careful annealing practices. This is an issue that would need to be addressed in an article by itself. Of course this case is no longer usable.

In the classes that I teach, I try to use examples like this to let the students see what they should be looking for. As always, if we can assist you, whether you are new to reloading or very experienced, contact us here at Sierra Bullets by phone at 1-800-223-8799 or by email at sierra@sierrabullets.com.

Dented Case Body

Here we have a Lake City 7.62×51 (.308 Win.) case with two heavy marks/dents in the case body.

This one may be a bit of a mystery. It appears as if this case may have been caught in the action of a semi-auto rifle when the firearm jammed or the case failed to clear during the cycling process. I probably would not reload this case just to prevent any feeding problems. This also appeared to be a factory loaded round and I don’t really see any pressure issues or damage to the case.

Multiple Problems — Lake City 5.56×45 unknown year.

This case has suffered multiple failures and cannot be re-used. First its has have a very rounded shoulder that is split. Upon first look it was obvious that this round had been a victim of excess pressure. The firearm (perhaps an AR?) was apparently not in full battery, or there was possibly a headspace issue also. While taking a closer look, the primer was very flat and the outside radius of the primer cup had been lost. High pressure! Then I also noticed that there was an ejector mark on the case rim. This is most certainly an incident of excessive pressure. This case is ruined and should be discarded.

To see more examples, view both Part I and Part II of the Case Diagnostics from Sierra Bullets:

It is very important to observe and inspect your cases before each reloading. After awhile it becomes second nature to notice the little things. Never get complacent as you become more familiar with the reloading process. If ever in doubt, call Sierra’s Techs at 1-800-223-8799.

July 31st, 2023

At the request of our readers, we provide select “Deals of the Week”. Every Sunday afternoon or Monday morning we offer our Best Bargain selections. Here are some of the best deals on firearms, hardware, reloading components, optics, and shooting accessories. Be aware that sale prices are subject to change, and once clearance inventory is sold, it’s gone for good. You snooze you lose.

NOTE: All listed products are for sale to persons 18 years of age or older. No products are intended for use by minors.

1. Natchez — Leupold Scope Sale and VH6-HD Rebate

⏺ Large selection of Leupold optics at significant savings

Leupold scopes rank among the best for hunting or target shooting. Leupold’s VX series of scopes offer a wide variety of magnification ranges and reticles. Right now Natchez is running a major Leopold sale. You can save hundreds on Leupold scopes, ranging from the 1-6x24mm VX-6HD to the powerful 4-24x52mm VX-6HD, now $1899.99, which is $500.00 off the original price. Leupold spotting scopes, binoculars, and laser rangefinders are also on sale.

The Natchez sale prices reflect a manufacturer’s price reduction of $300 on VX-6HD scopes. This Leupold promo applies to select VX-6HD riflescopes purchased from July 24 through September 3, 2023.

2. Creedmoor Sports — Sierra Bullet Sale

⏺ Big savings on popular Sierra match bullets

If you hand-load for hunting or competition you need quality bullets. Sierra makes great bullets in popular calibers with both hunting and match versions such as the Sierra MatchKing. Creedmoor Sports has significant discounts right now on .224, 6.5mm, .308, and .338 caliber Sierra bullets, including the latest generation MatchKings which come with uniformed tips from the factory.

3. Midsouth — New LEE Deluxe APP Processing Press, $109.99

⏺ Unique processing unit does many bulk tasks efficiently

The very affordable LEE Deluxe APP (Automatic Processing Press) performs a number of key reloading functions efficiently. This new Deluxe APP can prime a large number of cases rapidly, employing a clever case-feeding system. The Deluxe APP also has a very good depriming operation. Key features in this upgraded system include: Universal Case Feeder, APP Deprime Kit, Priming System, Deluxe Roller Handle, and Bottle Adapter. This complete set-up is on sale this week for $109.99, a 15% ($20) savings.

4. MidwayUSA — Sierra .223 Rem Hunting Ammo, $9.99/20 rds

⏺ Super deal on quality .223 Rem ammunition for hunting/varminting

Need quality .223 Rem hunting ammo? Right now Sierra .223 Rem Outdoor Master 55gr JHP ammunition is just $9.99 for a 20-rd box. That’s $0.50 per round, a 56% savings off the regular price. This ammo fits AR15 mags for reliable feeding in AR-platform rifles. This ammo features GameKing Hollow Point BT bullets. The cartridges have quality brass cases, so you can reload the brass many times.

5. Amazon — Lyman Universal Press Stand, $79.70

⏺ Strong, versatile stand works with many press types/brands

Do you wish your reloading press was a little higher so it was more ergonomic to use? A great fix for this is the Lyman Universal Press Stand. This is the only press stand on the market that will accept most current single station, turret, and progressive presses of all brands! This heavy-duty steel stand comes with two mounting plates pre-drilled for your favorite press. If by chance you have a press that does not match up with any of the numerous patterns, there is also a blank area where you can drill your own mounting holes. The stand will raise your press 9¼” above your bench surface, which will lessen fatigue from having to bend over to cycle your press. The raised height also provides a clear view of reloading operations. All hardware needed to mount your press is included.

6. CDNN Sports — Ruger EC9s 9mm Carry Pistol, $249.99

⏺ Save 36% on great little 9mm carry pistol

Many CCW holders prefer 9mm handguns that are small and compact, with smooth edges on the slide and frame. The Ruger EC9s Safety model fits the bill. Slim, lightweight, and compact, this pistol features smooth edges and comes with a Hogue grip sleeve. The striker-fired EC9S features both a manual safety and a Glock-style trigger safety. With 7+1 magazine, but not ammo, this pistol weighs just 18 ounces. It is now on sale for just $249.99 — $139 off (36%) the regular price — a real bargain.

7. Amazon — Caldwell E-Max Shadows PRO Plugs, $123.99

⏺ State of the art electronic plugs with NRR 25 protection

All shooters need quality ear protection. Electronic plugs protect your hearing while allowing you to hear conversations and range commands. The Caldwell E-MAX Shadows Pro plugs are quality electronic plugs with a 25 dB Noise Reduction Rating — very good for plugs alone. These E-MAX plugs come with multiple size tips to help ensure a good fit. Controls on each of the ear pieces allow for volume and mode adjustments while an optional lanyard keeps the earbuds secure. NOTE: These plugs will connect with your mobile device via Bluetooth. In addition, the included storage case serves as a charger for the plugs!

8. Amazon — G4Free Sling Pack with Pistol Holster, $27.99

⏺ Sling pack offers ready access plus handgun storage

The advantage of a sling pack is that you can swing it around to the front to easily access the contents. This rugged G4Free Tactical EDC Sling Pack offers multiple pockets plus a Velcro-attached pistol holster. Starting at $27.99, this 10.6″ x 5.9″ x 8.6″ sling pack is offered in four styles: Tan, Green, Black, and Dark Grey Camo. For $5.00 more ($32.99) you can get Sling Pack Combo with an additional 6.3″ x 4.3″ multifunction pouch that can securely hold a pistol plus a mobile device.

9. Amazon — Biometric Pistol Safe, $179.99

⏺ High-tech pistol safe allows instant access with fingerprint or PIN code

If you keep a handgun for defense use at a home or business, you need a secure, but rapid access storage solution. The Biometric Slider Handgun Safe is a good product that allows instant gun access via your fingerprint. This product has a 508 dpi Biometric sensor capable of storing 20 unique fingerprints for ultra-fast entry. You can also use manual keys or a 4-8 digit PIN code. This system easily mounts to the inside of a desk or the side of a nightstand.

10. Amazon — Vortex Bubble Level, From $31.20

⏺ High quality scope level for 1″, 30mm, 34mm, and 35mm optics

All serious competitive shooters should have a bubble level because rifle cant (angle rotated off bore axis) will alter shot Point of Impact. The Vortex bubble level is a high-quality level that is available for 1″, 30mm, 34mm, and 35mm scope diameters. This level features a quick and easy mounting system.

|

Scan-Verified 0.162 MOA Accuracy at 200 Yards

Scan-Verified 0.162 MOA Accuracy at 200 Yards

Oversizing cases also causes problems because the firing pin doesn’t have the length to reach the primer solid enough to ignite it 100% of the time. When you have one that is oversized, you usually have a bunch, since you usually do several cases at a time on that die setting. If the die isn’t readjusted, the problem will continue on the next batch of cases also. They will either not fire at all or you will have a lot of misfires. In a bolt action, a lot of time the extractor will hold the case against the face of the breech enough that it will fire. The case gets driven forward and the thinner part of the brass expands, holding to the chamber wall and the thicker part of the case doesn’t expand as much and stretches back to the bolt face. If it doesn’t separate that time, it will the next time. When it does separate, it leaves the front portion of the case in the chamber and pulls the case head off. Then when it tries to chamber the next round, you have a nasty jam. Quite often range brass is the culprit of this because you never know how many times it has been fired/sized and in what firearm. Back to beating it on the ground again till you figure out that you have to get the forward part of the case out.

Oversizing cases also causes problems because the firing pin doesn’t have the length to reach the primer solid enough to ignite it 100% of the time. When you have one that is oversized, you usually have a bunch, since you usually do several cases at a time on that die setting. If the die isn’t readjusted, the problem will continue on the next batch of cases also. They will either not fire at all or you will have a lot of misfires. In a bolt action, a lot of time the extractor will hold the case against the face of the breech enough that it will fire. The case gets driven forward and the thinner part of the brass expands, holding to the chamber wall and the thicker part of the case doesn’t expand as much and stretches back to the bolt face. If it doesn’t separate that time, it will the next time. When it does separate, it leaves the front portion of the case in the chamber and pulls the case head off. Then when it tries to chamber the next round, you have a nasty jam. Quite often range brass is the culprit of this because you never know how many times it has been fired/sized and in what firearm. Back to beating it on the ground again till you figure out that you have to get the forward part of the case out.