|

|

January 11th, 2018

Written by Sierra Bullets Ballistic Technician Duane Siercks

One of the first things new reloaders notice is that load data varies between reloading manuals. The Sierra Bullets Technicians frequently get inquiries asking us to explain why the load data appears to be inconsistent. This article explains five key factors that can influence published load data.

Example of load data variances for two 168 grain bullets:

Here are five reasons why the load data varies:

The Bullet

Basically, the similarities in the .30 caliber 168 grain Match bullets (for example) end with weight and diameter. The bullets likely have dimensional differences such as bearing surface length. Bearing surface has a large effect on pressure and velocity. There are also differences in boat tail, flat base, ogive and over-all lengths, which each help determine the cartridge over-all-length (COAL). With different COAL’s, we can expect changes in pressure and velocity also. In some calibers there are differences in bullet diameter with different bullet manufacturers.

It is also worth noting that bullet manufacturers do not all use the same copper alloy for their jackets. This produces more or less friction that results in load pressures and velocities. The solid copper bullets also vary quite a bit in comparison to a lead core and copper jacketed bullet.

The Gun

Each gun is unique, even if you are using the same make, model, and caliber. Special consideration should be used to consider that not all firearm chambers are the same either, creating more variables that need consideration. There can be drastic differences in the throat length. This controls the amount of “jump” that a bullet experiences when the cartridge is fired.

The Powder

Within normal manufacturing tolerances, you can see some variation in a given powders burn rate between different lots of the same powder. So naturally when two different Manuals are produced, it would be doubtful that the same lots would be tested.

The Cartridge Cases

New cases are almost always near minimum specs in dimension. A load fired in a new case would likely have slightly more pressure that when fired in a re-sized case. This would certainly be true if we were loading into fire-formed cases that have had minimal re-sizing done. Fired cases that are full length resized most of the time be slightly larger than the new unfired cases. This gives you differences in case capacity. The same powder charge placed within a new case and a full length resized case will produce different pressure levels and probably different velocities.

Conditions

Temperature can cause pressure increases or decreases. Hot temperatures tend to cause pressures to increase, while cold temperatures will usually do the opposite. Humidity and altitude can impact pressures and velocities likewise.

Conclusion

As you can see, an amazing number of variables effect any load combination. With the differences in the manuals, you’re just seeing firsthand examples of what took place when the data was collected with that particular set of components and firearm. Think of a reloading manual as a report. In essence, a reloading manual says, “We tried this particular component combination, and these are the results we obtained.”

Remember that you may or may not reach the same maximum load safely. There is no “one load fits all bullets.” The minimum load data offers a safe place to start. The maximum load data listed should always be regarded as a safety guideline and not necessarily a goal! Your gun should shoot accurately without breaching the maximum load data. The best advice is: always start low and work your load up!

If you have questions about variances in load data or other reloading questions, please call our ballistic technicians at 1-800-223-8799 or send us an email at sierra [at] sierrabullets.com.

December 24th, 2017

Here’a useful article by Sierra Bullets Media Relations Manager Carroll Pilant. This story, which originally appeared in the Sierra Blog, covers some of the more common ammo problems that afflict hand-loaders. Some of those issues are: excessive OAL, high primers, and improperly sized cases. Here Mr. Pilant explains how to avoid these common problems that lead to “headaches at the range.

I had some gentlemen at my house last fall getting rifle zeros for an upcoming elk hunt. One was using one of the .300 short mags and every 3rd or 4th round would not chamber. Examination of the case showed a bulge right at the body/shoulder junction. These were new cases he had loaded for this trip. The seating die had been screwed down until it just touched the shoulder and then backed up just slightly. Some of the cases were apparently slightly longer from the base to the datum line and the shoulder was hitting inside the seating die and putting the bulge on the shoulder. I got to thinking about all the gun malfunctions that I see each week at matches and the biggest percentage stem from improper handloading techniques.

One: Utilize a Chamber Gage

Since I shoot a lot of 3-gun matches, I see a lot of AR problems which result in the shooter banging the butt stock on the ground or nearest solid object while pulling on the charging handle at the same time. I like my rifles too well to treat them that way (I cringe every time I see someone doing that). When I ask them if they ran the ammo through a chamber gage, I usually get the answer, “No, but I need to get one” or “I didn’t have time to do it” or other excuses. The few minutes it takes to check your ammo can mean the difference between a nightmare and a smooth running firearm.

A Chamber Gauge Quickly Reveals Long or Short Cases

Size Your Cases Properly

Another problem is caused sizing the case itself. If you will lube the inside of the neck, the expander ball will come out a lot easier. If you hear a squeak as the expander ball comes out of a case neck, that expander ball is trying to pull the case neck/shoulder up (sometimes several thousandths). That is enough that if you don’t put a bulge on the shoulder when seating the bullet, like we talked about above, it can still jam into the chamber like a big cork. If the rifle is set up correctly, the gun will not go into battery and won’t fire but the round is jammed into the chamber where it won’t extract and they are back to banging it on the ground again (with a loaded round stuck in the chamber). A chamber gage would have caught this also.

Oversizing cases also causes problems because the firing pin doesn’t have the length to reach the primer solid enough to ignite it 100% of the time. When you have one that is oversized, you usually have a bunch, since you usually do several cases at a time on that die setting. If the die isn’t readjusted, the problem will continue on the next batch of cases also. They will either not fire at all or you will have a lot of misfires. In a bolt action, a lot of time the extractor will hold the case against the face of the breech enough that it will fire. The case gets driven forward and the thinner part of the brass expands, holding to the chamber wall and the thicker part of the case doesn’t expand as much and stretches back to the bolt face. If it doesn’t separate that time, it will the next time. When it does separate, it leaves the front portion of the case in the chamber and pulls the case head off. Then when it tries to chamber the next round, you have a nasty jam. Quite often range brass is the culprit of this because you never know how many times it has been fired/sized and in what firearm.’Back to beating it on the ground again till you figure out that you have to get the forward part of the case out. Oversizing cases also causes problems because the firing pin doesn’t have the length to reach the primer solid enough to ignite it 100% of the time. When you have one that is oversized, you usually have a bunch, since you usually do several cases at a time on that die setting. If the die isn’t readjusted, the problem will continue on the next batch of cases also. They will either not fire at all or you will have a lot of misfires. In a bolt action, a lot of time the extractor will hold the case against the face of the breech enough that it will fire. The case gets driven forward and the thinner part of the brass expands, holding to the chamber wall and the thicker part of the case doesn’t expand as much and stretches back to the bolt face. If it doesn’t separate that time, it will the next time. When it does separate, it leaves the front portion of the case in the chamber and pulls the case head off. Then when it tries to chamber the next round, you have a nasty jam. Quite often range brass is the culprit of this because you never know how many times it has been fired/sized and in what firearm.’Back to beating it on the ground again till you figure out that you have to get the forward part of the case out.

Just a quick tip — To extract the partial case, an oversized brush on a cleaning rod [inserted] and then pulled backward will often remove the case. The bristles when pushed forward and then pulled back act like barbs inside the case. If you have a bunch of oversized case that have been fired, I would dispose of them to keep from having future problems. There are a few tricks you can use to salvage them if they haven’t been fired though. Once again, a case gage would have helped.

Two: Double Check Your Primers

Another thing I see fairly often is a high primer, backwards primer, or no primer at all. The high primers are bad because you can have either a slam fire or a misfire from the firing pin seating the primer but using up its energy doing so. So, as a precaution to make sure my rifle ammo will work 100% of the time, I check it in a case gage, then put it in an ammo box with the primer up and when the box is full, I run my finger across all the primers to make sure they are all seated to the correct depth and you can visually check to make sure none are in backwards or missing.

Three: Check Your Overall Cartridge Length

Trying to load the ammo as long as possible can cause problems also. Be sure to leave yourself enough clearance between the tip of the bullet and the front of the magazine where the rounds will feed up 100%. Several times over the years, I have heard of hunters getting their rifle ready for a hunt. When they would go to the range to sight in, they loaded each round single shot without putting any ammo in the magazine. On getting to elk or deer camp, they find out the ammo is to long to fit in the magazine. At least they have a single shot, it could be worse. I have had hunters that their buddies loaded the ammo for them and then met them in hunting camp only to find out the ammo wouldn’t chamber from either the bullet seated to long or the case sized improperly, then they just have a club.

Four: Confirm All Cases Contain Powder

No powder in the case doesn’t seem to happen as much in rifle cartridges as in handgun cartridges. This is probably due to more handgun ammo being loaded on progressive presses and usually in larger quantities. There are probably more rifle cartridges that don’t have powder in them than you realize though. Since the pistol case is so much smaller internal capacity, when you try to fire it without powder, it usually dislodges the bullet just enough to stick in the barrel. On a rifle, you have more internal capacity and usually a better grip on the bullet, since it is smaller diameter and longer bearing surface. Like on a .223, often a case without powder won’t dislodge the bullet out of the case and just gets ejected from the rifle, thinking it was a bad primer or some little quirk. For rifle cases loaded on a single stage press, I put them in a reloading block and always dump my powder in a certain order. Then I do a visual inspection and any case that the powder doesn’t look the same level as the rest, I pull it and the one I charged before and the one I charged after it. I inspect the one case to see if there is anything visual inside. Then I recharge all 3 cases. That way if a case had powder hang up and dump in the next case, you have corrected the problem.

On progressive presses, I try to use a powder that fills the case up to about the base of the bullet. That way you can usually see the powder as the shell rotates and if you might have dumped a partial or double charge, you will notice as you start to seat the bullet if not before. On a progressive, if I don’t load a cartridge in one smooth stroke (say a bullet tipped over sideways and I raised the ram slightly to reset it) Some presses actually back the charge back adding more powder if it has already dumped some so you have a full charge plus a partial charge. When I don’t complete the procedure with one stroke, I pull the case that just had powder dumped into it and check the powder charge or just dump the powder back into the measure and run the case thru later.

I could go on and on but hopefully this will help some of you that are having these problems cure them. A case gage really can do wonders. Stay tuned for Easy Easy Ways to Save Yourself Headaches at the Range Part 2!

December 15th, 2017

CLICK HERE for printable PDF version of this target.

NOTE: The contest is OVER, so ignore information on the PDF about submitting targets — that’s from back in 2013.

Here’s a target for the holidays that can provide some fun at the range. This Christmas Tree Target was created by Sierra Bullets for a 2013 contest. This contest is now over, but you can still have fun with the target. This tree target is designed to be shot at 15 yards with pistol, or at 100 yards with rifle.

Santa’s Extra Accuracy Challenge Santa’s Extra Accuracy Challenge

Start with the big circles, and then work your way down to the small circles (7,8,9,10) as you build your confidence. Shoot the gifts for bonus points.

For an extra challenge (with a real accurate rifle), try working your way back up to the top, aiming for the X-Marks in the circles and finishing with the small, inset star at the top. Try to hit each X-Mark and then put your final shot in the inner star. Have fun!

November 14th, 2017

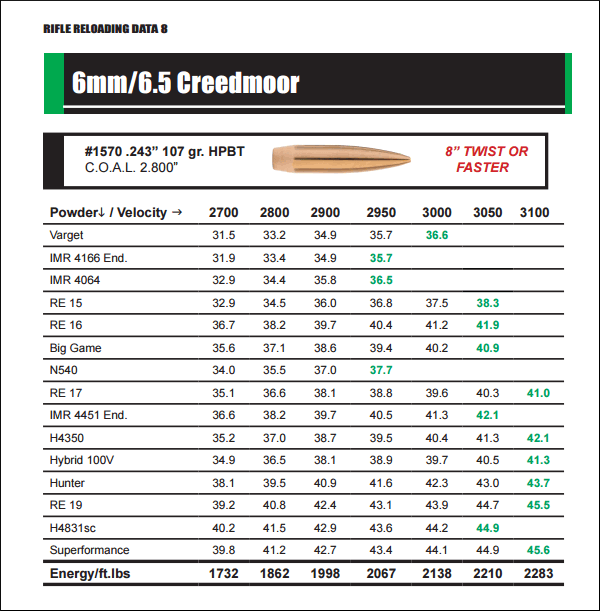

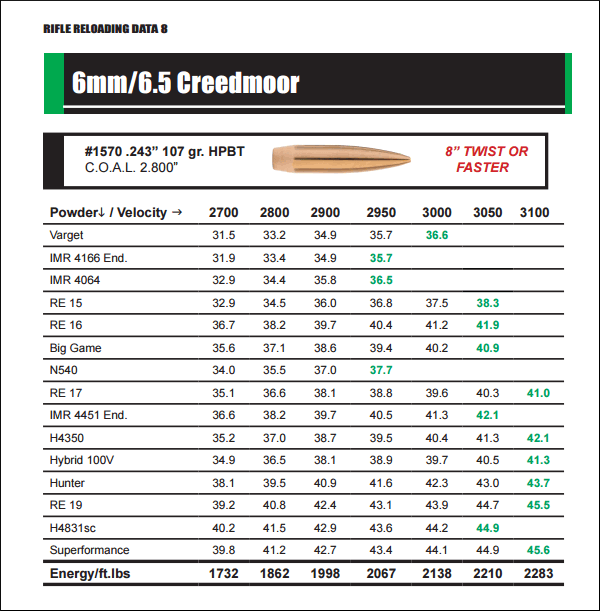

Sierra Bullets has recently released load data for the 6mm Creedmoor cartridge, a necked-down version of the 6.5 Creedmoor, a popular PRS, tactical, and hunting cartridge. Sierra has released very comprehensive 6mm Creedmoor load data, covering fifteen (15) different bullets from 55 to 110 grains. NOTE: Hornady-brand brass was used for Sierra’s 6mm Creedmoor load tests, not the newer, stronger Lapua 6.5 CM brass with small primer pockets. Hand-loaders using Lapua 6.5 Creedmoor brass necked to 6mm may have to adjust their loads.

Sierra writes: “As soon as the 6.5 Creedmoor was released in 2007, a 6mm version was being envisioned. After the 6mm Creedmoor demonstrated its worth at 1000 yards it began to catch the attention of Precision Rifle Series (PRS) competitors. The 6mm/6.5 Creedmoor is a great fit for those looking for an AR platform-friendly cartridge. It delivers velocities very similar to the .243 Win and yet fits the AR10 magazine length[.] The 30-degree shoulder makes this a very efficient case and helps prolong case life as well. The 6mm/6.5 Creedmoor works well with powders such as H4350, RE-17, and Ramshot Hunter for heavier long-range bullet weights. Slightly faster powders such as RE-15, Win 760, and Vihtavuori N540 work well with lighter weight bullets.”

| Sierra Bullets Tested for 6mm Creedmoor Load Data |

55gr BlitzKing (#1502)

60gr HP (#1500)

70gr HPBT (#1505)

70gr BlitzKing (#1507)

75gr HP (#1510) |

80gr SBT (#1515)

85gr Spitzer (#1520)

85gr HPBT (#1530)

90gr FMJBT (#1535)

95gr HPBT (#1537) |

95gr TMK (#7295)

100gr Spitzer (#1540)

100gr SBT (#1560)

107gr HPBT (#1570)

110gr HPBT (#1575) |

In developing its 6mm Creedmoor load data, Sierra tested a very wide selection of propellants, two dozen overall. For the smaller bullets, fast-burning powders such as Benchmark, H4895, and CFE223 were tested. For the heavier 100+ grain bullets, Sierra tested a selection of medium-burn-rate powders including H4350, Reloder 16, Reloder 17, Varget, and Superformance. Sierra did a very thorough job. We know this information will be welcomed by 6mm Creedmoor shooters.

Don’t know what powder to try first? For the 107-110 grain bullets, if you want best accuracy and low ES/SD, our Forum members recommend Alliant Reloder 16 and Hodgdon H4350. If you are seeking max velocity with the 110-grainer, look at Hodgdon Superformance and Reloder 19.

Here are Sierra’s 6mm Creedmoor Load Data Charts for the 107gr MK and 110gr MK. There are a half-dozen other tables for lighter-weight bullets.

October 7th, 2017

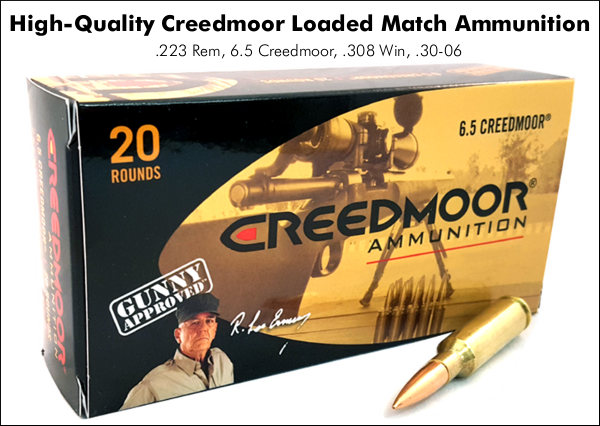

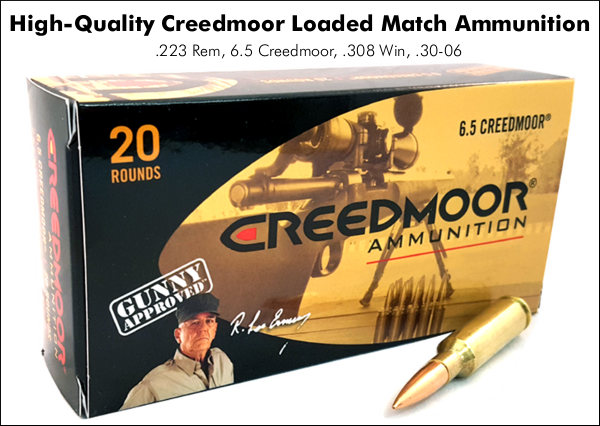

You may not know this, but Creedmoor Sports sells very high-quality loaded ammunition crafted with top-quality bullets and premium-grade Lapua brass for .308 Win and .30-06. We have friends who have shot some of this ammo in .223 Rem and .308 Win, and it is very impressive. The 6.5 Creedmoor ammo is capable of winning PRS matches outright. Creedmoor’s rifle cartridge match ammunition includes:

.223 Rem: (55gr FMJ, 68gr HPBT, 69gr TMK, 75gr HPBT, 77gr TMK)

6.5 Creedmoor: (140gr HPBT Hornady, 140gr HPBT Nosler, 142gr Sierra — all Hornady brass)

.308 Win: (155gr, 167gr, 168gr Sierra, 175gr all in Lapua Brass; also precision hunting in other brass)

.30-06 Springfield: (167gr Lapua Scenar HPBT in Lapua Brass)

Use Coupon Code CS929 to receive Free Ground Shipping on orders over $99!

Oh, the beauty of it — all that Lapua brass. From Finland with love….

What does 13,005 pounds (6.5 tons) of powder look like? That would last most reloaders a few seasons. Hoarders, eat your hearts out….

June 20th, 2017

MidwayUSA is running a big sale on Factory Second and Blemished Bullets. These bullets normally perform just as well as regular bullets, but they may have water spots or other cosmetic defects. MidwayUSA has a very large selection of seconds/blem bullets on sale for both rifles and pistols. Here are some of the best deals we found among the quality varmint and match rifle bullets. All these selections are discounted 30%:

.224 Caliber (5.56mm) 50gr Polymer Tip Spitzer, $13.49/100 (30% Off)

.224 Caliber (5.56mm) 52gr HPBT Match, $13.29/100 (30% Off)

.224 Caliber (5.56mm) 53gr Polymer Tip BT Varmint, $13.29/100 (30% Off)

.224 Caliber (5.56mm) 77gr Nosler HPBT Match, $18.89/100 (30% Off)

.243 Caliber (6mm) 65gr Polymer Tip Spitzer Varmint, $16.09/100 (30% Off)

.264 Caliber (6.5mm) 123gr Polymer Tip BT Match, $20.29/100 (30% Off)

.264 Caliber (6.5mm) 140gr HPBT Match, $21.69/100 (30% Off)

.308 Caliber 155gr Polymer Tip Spitzer BR Match, $20.99/100 (30% Off)

.308 Caliber 168gr Polymer Tip Spitzer BT Match, $21.69/100 (30% Off)

.308 Caliber 195gr BTHP Match, $24.49/100 (30% Off)

.308 Caliber 208gr Polymer Tip Spitzer BT Match, $25.89/100 (30% Off)

December 27th, 2016

Here is the original Sierra manufacturing facility in Whittier, CA.

Sierra Bullets — How It Got Started

Report Based on Story by Carroll Pilant, Sierra Bullets Media Relations Manager

What became Sierra Bullets started in the late 1940s in a Quonset hut in California. In 1947, three aircraft machinists, Frank Snow, Jim Spivey, and Loren Harbor, rented machine space to produce rivets for the aircraft industry along with fishing rod guides and rifle front sight ramps. In the post-WWII years, sport shooting was becoming hugely popular, but quality ammunition was in short supply. For shooting enthusiasts, reloading was the solution to the ammo supply shortage. Snow, Spivey, and Harbor recognized this, creating Sierra Bullets to help fill the void. Before long, they were selling a 53-grain match bullet to the Hollywood Gun Shop. These bullets are still in production today as the Sierra #1400 53-grain MatchKing.

A few years later, an accomplished competitive shooter named Martin Hull joined Sierra. Hull helped develop new bullet types and served as manager of Sierra’s ballistics laboratory for nearly 20 years. With Hull’s help, Sierra’s output grew rapidly. The California company outgrew several locations before it moved to a large facility in Santa Fe Springs, CA, in 1963.

New Owners and New President in the Late Sixties

In 1968, the Leisure Group bought Sierra Bullets. Other Leisure Group companies included Lyman Reloading, High Standard Manufacturing Company, Yard Man, Thompson Sprinkler Systems, Flexible Flyer Sleds, and Dodge Trophies (Which made the Oscar and Rose Bowl Game trophies).

Soon after purchasing Sierra, the Leisure Group hired Robert Hayden as President and General Manager. Hayden was a mechanical engineer who had worked for Remington Arms. Hayden remained the president of Sierra for 42 years, retiring in 2012 when Pat Daly became president.

Sierra Moves to Missouri

In 1990, Sierra relocated to Sedalia, Missouri, where the company remains today. Sierra Bullets now employs over 100 people including five full-time ballistic technicians who answer daily reloading and firearms questions by both phone and e-mail.

The Making of MatchKings — How Sierra Produces SMKs

All Sierra bullets begin life as a strip of gilding metal, an alloy consisting of 95% copper and 5% zinc. To meet Sierra’s strict quality requirements, the gilding metal requires three times more dimensional and quality control standards than is considered standard in the copper manufacturing industry.

A blanking press stamps out a uniform disc and forms the cup that will be drawn into the MatchKing jacket. The cup is then polished and sent to a draw press to be drawn into a jacket that is longer than needed for the future MatchKing, thus allowing for the trim process. Press operators constantly check concentricity to make sure we have only quality jackets. The jackets then go to a trimmer where they are visually inspected again.

After being polished a second time, the jacket travels to the bullet press. In the meantime, 80-pound lead billets are being extruded into lead wire for the cores where great care is taken so that the core wire is not stretched. The core wire is lightly oiled before continuing to the bullet press to be swaged.

The lead core wire and trimmed jacket meet at the bullet press where the first stage forms a boattail on the jacket. The lead core is then formed on top of the bullet press and fed down into the jacket. In one stroke of the press, the MatchKing is formed.

Quality control technicians pull samples from each lot of MatchKings to make sure they meet Sierra’s stringent standards. Samples are then sent to Sierra’s 300-meter underground test range (shown below) to be shot for accuracy on mechanical mounts referred to as “unrestricted return to battery rests” that Sierra designed and built in-house.

After inspection, the bullets are placed in the familiar green box along with reloading labels. They are then shrink-wrapped and shipped all over the world.

December 12th, 2016

Are you feelin’ lucky? Well here’s your chance to win. Over the next twelve days (through December 23, 2016), Powder Valley is giving away a total of $20,000 worth of products from big name suppliers. That’s an average of $1,667 worth of product prizes every day. This is top-of-the-line stuff, including Powder from Accurate, IMR, Ramshot, and Vihtavuori, Bullets from Berger, Berry’s, Hornady, Lapua, and Sierra, Brass from Lapua, Hornady and Nosler, Ammo from Hornady, Nosler, Lapua, and Silver State Armory. Each day there will be a new set of prizes. Today’s prize is a Hornady reloading press.

It’s easy to qualify to win one of the Daily Giveaway prize packages. Simply visit Powder Valley’s Facebook Page, and make a comment on the featured Daily Giveaway Post. You don’t have to fill out any forms, but you must have a Facebook account so you can comment. Each day the folks at Powder Valley will select winners from among the visitors who commented. Today (Dec. 12th) there will be one winner of the Hornady Press. In days ahead there can be multiple daily winners — as many as 20 to 30 per day. NOTE: You can enter multiple times by commenting on multiple days, but sorry, if you win, you are no longer eligible.

Powder Valley Daily Giveaway

The Powder Valley 12 Days of Christmas promotion starts today, December 12th, 2016. To enter, you must visit the Powder Valley Facebook Page. Once there, scroll down to find the Giveaway of the Day. Today’s Giveaway is a Hornady Press. Look for the post shown below. You need to comment on that post to be entered. Winners will be selected by lottery from those who comment. Each successive day through December 23rd, there will be another product giveaway post.

To be entered in this Powder Valley Contest, you need to go to the Powder Valley Facebook Page and post a Facebook Comment for the Daily Prize story. The give-away for today, December 12th, is a Hornady Lock-N-Load AP Press. NOTE: You need to post your comment on Powder Valley’s Facebook Site, NOT HERE. And you need to comment each day to be entered in that particular day’s contest. To have repeat chances to win you need to comment on multiple days. Got it?

November 15th, 2016

Our friend Bill at Rifleshooter.com got his hands on some of Sierra’s brand new .30-Cal match bullets, the 195-grain Tipped Match Kings (TMKs). These feature an impressive 0.610 G1 BC above 2000 fps. We predict these new bullets will be popular with F-TR shooters shooting the .308 Winchester cartridge.

To see how the new 195gr TMKs perform, Bill loaded up some .308 Win ammo with IMR 4064, ranging from 40.5 grains up to 42.5 grains. That gave him a velocity range of 2438 FPS at the lowest charge weight, up to 2552 FPS at 42.5 grains. This was with a relatively short, 22-inch barrel. Best five-shot accuracy (and second lowest SD) was at 41.0 grains even, producing a 0.498 MOA five-shot group at 2480 fps (6.1 SD). CLICK HERE for full accuracy results.

I headed to the range on a brisk November day. Targets were 2″ orange dots at 100 yards. All shooting was done prone from a bipod with a rear bag. The Nightforce 3.5-15X scope was set at 15X. All ballistic information was recorded with a MagnetoSpeed barrel-mounted chronograph. Temperature was 54° F. Standard deviation for the loads ranged from 5.3 to 20.5 FPS. Average standard deviation was 12.5 FPS. Five-shot group sizes ranged from .521″ (.498 MOA, ) to 1.057″ (1.010 MOA). Average group size for all ten loads was .692″ (.661 MOA).

New 195gr TMK offers Impressive Long-Range Ballistics

Bill was also interested in how the ballistics of the new 195gr TMKs compared to other .30-cal projectiles. Even with a moderate, 2539 fps velocity, the new 195gr TMK showed less wind drift than other Sierras, thanks to its high 0.610 G1 BC. It also had a flatter trajectory beyond 600 yards than the 175gr and 190gr Sierra MatchKings. (The faster-flying 175gr TMK had slightly less drop at all yardages.)

Bill explains: “For comparison purposes, I selected the 42.0 grain load, with a muzzle velocity of 2,539 feet/second and an SD of 6.9. This load is compared to loads for the 190 SMK, 175 SMK, 175 TMK, and 168 Federal Gold Medal ammunition in the test rifle. In other words, these aren’t maximum loads, but loads that I have developed and would feel comfortable shooting a match with in the rifle shown (you may note the 190 SMK is fairly slow, but this is what the rifle liked). Also note that this rifle has a relatively short 22″ barrel compared to those you might find on a purpose built f-class rifle.”

Bill provides a full write-up on the Rifleshooter.com website complete with target photos and load details. If you are interested in these new 195-grainers, you should read the full report.

November 7th, 2016

Sierra has just announced a new, high-BC .30-caliber projectile. This provides a very interesting new option for F-TR competitors and long-range benchrest shooters. The new 195-grain Tipped MatchKing (TMK) boasts an impressive 0.610 G1 Ballistic Coefficient. That compares well with any conventional bullet in this caliber and weight range. The key to the high BC is the green acetal resin tip that lowers drag while making the BC more consistent for every bullet in the box. NOTE: This .30-caliber 195 grain TMK requires a twist rate of 1:10” or faster to stabilize.

The new 30 cal. 195 grain Tipped MatchKing® bullets will be available in 500-ct boxes (product #7795C) with a $243.84 MSRP as well as 100-ct boxes (product #7795) with MSRP of $51.19 per box. Note, this new 195gr TMK is designed for competition use — primarily as a paper-puncher. Sierra says: “Tipped MatchKing® bullets are not recommended for most hunting applications.”

New Product Tip from EdLongrange. We welcome reader submissions.

|

Oversizing cases also causes problems because the firing pin doesn’t have the length to reach the primer solid enough to ignite it 100% of the time. When you have one that is oversized, you usually have a bunch, since you usually do several cases at a time on that die setting. If the die isn’t readjusted, the problem will continue on the next batch of cases also. They will either not fire at all or you will have a lot of misfires. In a bolt action, a lot of time the extractor will hold the case against the face of the breech enough that it will fire. The case gets driven forward and the thinner part of the brass expands, holding to the chamber wall and the thicker part of the case doesn’t expand as much and stretches back to the bolt face. If it doesn’t separate that time, it will the next time. When it does separate, it leaves the front portion of the case in the chamber and pulls the case head off. Then when it tries to chamber the next round, you have a nasty jam. Quite often range brass is the culprit of this because you never know how many times it has been fired/sized and in what firearm.’Back to beating it on the ground again till you figure out that you have to get the forward part of the case out.

Oversizing cases also causes problems because the firing pin doesn’t have the length to reach the primer solid enough to ignite it 100% of the time. When you have one that is oversized, you usually have a bunch, since you usually do several cases at a time on that die setting. If the die isn’t readjusted, the problem will continue on the next batch of cases also. They will either not fire at all or you will have a lot of misfires. In a bolt action, a lot of time the extractor will hold the case against the face of the breech enough that it will fire. The case gets driven forward and the thinner part of the brass expands, holding to the chamber wall and the thicker part of the case doesn’t expand as much and stretches back to the bolt face. If it doesn’t separate that time, it will the next time. When it does separate, it leaves the front portion of the case in the chamber and pulls the case head off. Then when it tries to chamber the next round, you have a nasty jam. Quite often range brass is the culprit of this because you never know how many times it has been fired/sized and in what firearm.’Back to beating it on the ground again till you figure out that you have to get the forward part of the case out.

Santa’s Extra Accuracy Challenge

Santa’s Extra Accuracy Challenge