Saturday Movies: Ammo Production Factories in USA and Europe

While many AccurateShooter.com readers load their own competition centerfire rifle ammunition, we all still need factory ammo for our rimfire rifles in .17 and .22 calibers. And most of the 65+ million American handgun owners rely on factory-made ammunition for their pistols and revolvers.

Today’s video collection showcases state-of-the-art ammunition factories in Europe and the United States. You can see the extremely accurate Lapua .22 LR ammo being produced, as well as excellent centerfire ammunition being made by Norma, Remington, Sellier & Bellot and other makers.

From the creation of lead bullet cores to the final packing of ammunition, you can see it all in these videos. Watch primers being made, brass being annealed, bullets being jacketed, tips being inserted, and every phase of production. Weighing and testing procedures are also revealed.

Modern Ammo Production in Multiple Facilities

This 11.5-minute video shows highly automated bullet and ammunition production in multiple facilities in Europe and the USA. You can see bullets produced from start to finish beginning with lead smelting. Then watch pistol and rifle cartridges being made on modern, computer-controlled assembly lines. Watch from start to finish. Here are some notable highlights:

00:10 — Lead Melting Pots and Billet Caster

01:20 — Lead made into strings and then formed into bullets

01:50 — Brass alloy sheets fed into machine and then punched (2:10-2:35).

03:35 — Lead pistol cores being produced

04:15 — Pistol ammo being packaged

06:15 — Ammo loaded into belts

07:15 — Completed primers being shuttled then loaded into brass (Second factory)

07:20 — Bullets being seating into rifle ammunition

07:32 — Cartridge case-neck treatment

07:42 — Robot arm loads finishes cartridges into boxes

08:04 — Cups being pressed (Third Factory S&B)

08:45 — Cartridge case draw

09:06 — Priming pistol cases

09:20 — Bullet production and weight control (10:02)

10:08 — Cartridge assembly and cartridge sealing (10:38)

11:00 — Pistol ammo packaging

Lapua Rimfire Ammunition Production in Germany

This video shows Lapua rimfire ammo production in Schönebeck, Germany. The video shows quantities of the excellent X-ACT .22 LR ammunition being produced and packaged. Starting at the one-minute mark, you can see the ammo being inspected with advanced scanning machines. Then at 1:16 time-mark you can see the ammo accuracy-tested in a tunnel, with results displayed on a computer screen (1:27).

Norma Ammunition Production in Sweden

In this video, the RecoilTV team lead by EIC Iain Harrison ventures to Sweden to visit the Norma ammunition production plant in Huvudentré, Sweden. Demand for Norma ammo has risen dramatically. A Norma marketing manager notes that production has doubled in the last three years.

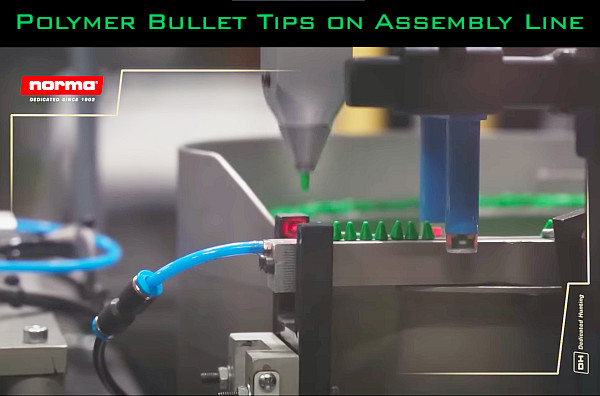

This second Norma ammunition video shows close-ups of the production process and the machinery used for centerfire ammo. This was filmed at the Norma factory in Åmotfors, Sweden, which has operated continuously for over 120 years. Among the many interesting highlight is a sequence showing how polymer bullet tips are inserted. See 6:50 time-mark.

Sellier & Bellot Ammunition Factory in Czech Republic

In this video, Larry Vickers of Vickers Tactical tours a Sellier & Bellot ammunition plant in the Czech Republic. This video shows details of primer production as well as bullet-making, brass-making, and production-line cartridge manufacturing.

Remington Ammunition Plant Re-Opened by Vista Outdoors

This video shows ammo production at the re-opened Remington ammunition plant in Lonoke, Arkansas. “This is one of the largest ammunition manufacturing plants in the world” said Mark Keefe, NRA Publications editorial director. “It was set up in 1969 by DuPont, who owned Remington at the time. They do it all here. Cases, bullets, centerfire rifle, centerfire pistol, rimfire and shotshell.” It’s great to see this plant back in production after Remington Ammunition filed for bankruptcy in 2020 and the assets of the Remington conglomerate were auctioned off. Ultimately, Vista Outdoor, owner of Federal, CCI and Speer, purchased the assets of Remington Ammunition and got the Lonoke plant running again, better than ever.

This article is Copyright 2024 AccurateShooter.com. Republication on any other site gives rise to statutory penalties and compensatory damages.