Southwest Nationals 2026 — 600-yard Results and Day 3 Report

Today marks the third day of competition at the 2026 Berger Southwest Nationals (SWN). And yes, it’s Friday the 13th — causing some concerns among competitors. The superstitious types among the competitors viewed the day with some trepidation. But most shooters didn’t worry too much about the date — they were more concerned about calling the wind correctly. As Bryan Litz said at the SWN a decade ago: “I don’t believe in superstition. We make our own luck”.

On Wednesday, February 11th, the 600-yard competition was held for all three competition classes: Sling (Palma), F-Open, and F-TR. 600-Yard match results for all three classes are shown below for the Top 10 in each class. For F-Open, F-TR, and Sling Divisions there were three relays, each with 20 rounds for score. Thus, the maximum possible score was 600-60X. There were some very impressive performances with the top 9 F-Open Shooters, top 5 F-TR Shooters, and Sling Winner Fazal Mohideen not dropping a single point. Congrats to the winners — Fazal Mohideen, Sling P 600-34X; Cal Waldner, F-Open 600-49X; and Brad Sauve, F-TR 600-44X. CLICK HERE for full 600-yard results for all competitors.

600-Yard SWN Top 10 Results

Here are the Top TEN 600-Yard Competitors for each Division:

Sling (Two Divisions, “P” and “A”) 600-yard Top 10

1. Fazal Mohideen — 600-34X (Match Winner, P-HM)

2. Avtar Nanrey — 599-40X (P-MA)

3. Bobby Gill — 599-39X (High Senior, A-HM)

4. Zevin Linse — 599-34X (P-HM)

5. Justin Skaret — 599-33X (P-HM)

6. Brandon Green — 598-39X (A-HM)

7. Rob Nabower — 598-35X (A-HM)

8. Jess Mellen — 597-39X (A-HM)

9. Kimberly Rowe — 597-33X (A-HM)

10. Phil Hayes — 597-29X (A-HM)

The Southwest Nationals is one of the few American events where sling shooters compete on the same firing line as F-Class competitors (though in separate groups). At the SWN this sling division has two sub-classes: “A” for “Any Rifle, Any Sight” and “P” for Palma rifles.

F-Open 600-yard Top 10

1. Cal Waldner 600-49X (Match Winner, MA)

2. Antun Kovacevic — 600-48X (MA)

3. Joe Traylor — 600-44X (HM)

4. Jason Simes — 600-42X (HM)

5. Dan DiLeva — 600-40X (HM)

6. Brian Bowling — 600-39X (HM)

7. Ryan Pierce — 600-37X (HM)

8. Eric Houser — 600-36X (HM)

9. Martin Tardif — 600-31X (HiGS)

10HM. Peter Johns — 599-47X (HM)

10MA. Noah Burleson — 599-47X (MA)

Modern F-Open Rifle with SEB Mini front rest with Blake Machine accessories.

F-TR 600-yard Top 10

1. Brad Sauve — 600-44X (Match Winner, HM)

2. Keith Trapp — 600-43X (HM)

3. Alan Barnhart — 600-39X (HiGS)

4. Alton Johnson — 600-35X (HiSr)

5. Anthony Jordan — 600-34X (HM)

6. Tracy Hogg — 599-42X (HM)

7. Adam Husted — 599-38X (MA)

8. Ryan Crozier — 599-36X (MA)

9. Benoit Vautour — 598-42X (MA)

10. Jeremy Newell — 598-39X (HM)

F-TR Rifle looking downrange at the targets.

Palma Format Multi-Distance Matches on Friday the 13th

Today, Friday is the Palma format match. This is not limited to “hard-hold” sling Palma rifles, but the match utilizes a multi-distance target sequence similar to Palma rifle matches. All three rifle classes will be shooting: Sling, F-Open, and F-TR. There will be three target distances with 15 shots for record at 800, 900, and 1000 yards.

In the video below, you’ll see highlights from last year’s SW Nationals from the break of dawn throughout the day. This also features new products on display. This video was created by our friend F-Class John, who is competing right now at the 2026 SWN event.

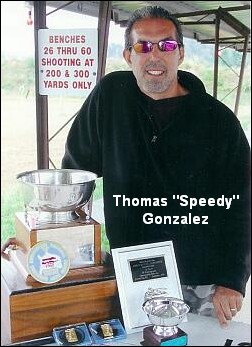

Two respected shooters have observed an increase in velocity with new barrels, typically after 100 rounds. Gunsmith and Hall-of-Fame benchrest shooter Thomas “Speedy” Gonzalez has documented barrel speed-up with testing. Moreover, Speedy’s bore-scope barrel inspections revealed a smoothing of the barrel lands. Jim See, a top PRS competitor, has encountered barrel speed-up many times. Accordingly, he re-tunes his load at 150 rounds.

Two respected shooters have observed an increase in velocity with new barrels, typically after 100 rounds. Gunsmith and Hall-of-Fame benchrest shooter Thomas “Speedy” Gonzalez has documented barrel speed-up with testing. Moreover, Speedy’s bore-scope barrel inspections revealed a smoothing of the barrel lands. Jim See, a top PRS competitor, has encountered barrel speed-up many times. Accordingly, he re-tunes his load at 150 rounds.