|

|

December 13th, 2014

Here’s one of the latest F-Class projects from Enda Walsh of Custom & Precision Rifles in Ireland. This rifle features a free-floated BAT Machines ‘M’ action with a Benchmark barrel chambered in .300 Blaser Magnum (300 BM). The barreled action is secured with a large barrel block. This handsome, long-wheelbase F-Class rig is “new-born”, but it has already demonstrated some stunning accuracy at 1000 yards. Enda tells us: “I couldn’t wait until the rifle was fully polished before testing. I went to MNSCI (Midlands National Shooting Centre of Ireland) to shoot my new barrel block rifle. I came home with a huge smile on my face after shooting a five-shot group with 1.5″ vertical and 3″ horizontal at 1000 yards in an 8 mph wind.” Here’s one of the latest F-Class projects from Enda Walsh of Custom & Precision Rifles in Ireland. This rifle features a free-floated BAT Machines ‘M’ action with a Benchmark barrel chambered in .300 Blaser Magnum (300 BM). The barreled action is secured with a large barrel block. This handsome, long-wheelbase F-Class rig is “new-born”, but it has already demonstrated some stunning accuracy at 1000 yards. Enda tells us: “I couldn’t wait until the rifle was fully polished before testing. I went to MNSCI (Midlands National Shooting Centre of Ireland) to shoot my new barrel block rifle. I came home with a huge smile on my face after shooting a five-shot group with 1.5″ vertical and 3″ horizontal at 1000 yards in an 8 mph wind.”

Click Photo for full-screen version

|

AUDIO FILE: Enda Walsh Talks about his New .300 BM Barrel Block F-Open Rifle. |

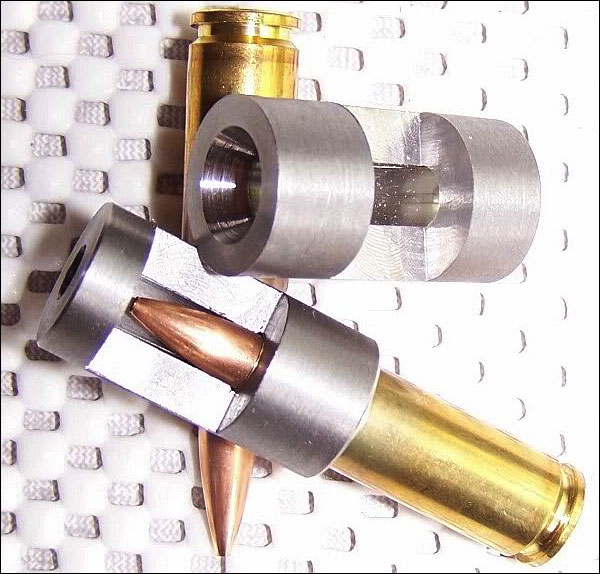

Below you can see the barrel block in the handsome Padouk wood and carbon fiber stock. Enda uses high-spec epoxy layered between the barrel and the aluminum barrel block. Yes, those three “super-sized” cartridges are .300 Blaser Magnums loaded with with 230gr Berger Hybrids. The smaller cartridge is a .308 Win (with 150gr bullet), provided for comparison. This .300 BM drives the 230s at 3140 FPS.

CLICK HERE for Horizontal Version of above photo.

.300 BM Runs 230-grainers at 3140 FPS! .300 BM Runs 230-grainers at 3140 FPS!

Enda tells us: “I wanted something to beat the 300 WSM. After studying the .300 Blaser Magnum, I decided this was the [chambering] that could deliver high accuracy consistently and be able to shoot the 230gr Bergers at 3140 FPS. Using H1000 powder, they do very well but the case life is short at these speeds. We have backed them off a little and retained the accuracy and extended case life considerably.”

Enda says the 230gr Hybrids at 3140 fps drift much less in the wind than do 7mm 180gr Hybrids launched from a 7mm WSM. A quick run through JBM Ballistics for a 10 mph, full-value crosswind at 1000 yards (sea-level) tells the tale. JBM predicts 4.2 MOA horizontal deflection for the .30-caliber 230s at 3140 fps vs. 5.0 MOA for the 7mm 180s at 3050 fps. That 0.8 MOA difference represents more than 8 inches at 1000 yards. When you consider the small size of the F-Open X-Ring, you can see how the enhanced ballistics could be a game-changer in the wind.

Barrel Block Acts as Heat Sink

Enda needed a way to beat the heat, with this big case. He explains: “Because of the large case volume (roughly 82 grains of usable capacity) there are two issues. Firstly, throat wear, and secondly heat. To combat this I have a new reamer on order with slight alterations which will help the throat wear. To combat the heat affecting a 34″ barrel I decided to build a barrel block rifle. It was previously mounted in a standard stock, and when the barrel got too hot accuracy was an issue. The barrel block acts as a heat sink and also shortens the overhanging barrel considerably, which has greatly improved accuracy over a complete string. The block is made from aircraft grade aluminium.” As a final note, Enda wanted to thank Pacific Tool & Gauge for the special-order reamers.

Note the metal bag-rider “keel” on the underside of the buttstock.

December 8th, 2014

Need a new barrel for your Remington-actioned hunting or tactical rifle? McRee’s Precision has you covered. McRee’s is now offering complete, no-gunsmithing re-barreling kits for Remington and Rem-clone actions. These feature a high-quality, pre-chambered “PRE-FIT” stainless barrel from Criterion, a Savage-style barrel nut, a recoil lug, and a special barrel-nut wrench. With this system you can easily re-barrel your favorite Remington rifle yourself in less than an hour. You don’t need to pay gunsmithing fees, or wait weeks (or months) for a busy smith to do the job.

McRee’s Precision Remington DIY Barrel Kit includes Criterion Pre-Fit Stainless Barrel, Barrel Nut, Recoil Lug, and Barrel Nut Wrench:

CLICK HERE for Barrel Specifications PDF Sheet

Right now McRee’s Precision is offering Rem-action Pre-Fit barrel packages (complete with barrel nut, recoil lug, and wrench) starting at just $412.50 (On Sale). Choose from four chamberings: .243 Win, .260 Rem, .308 Win, and .300 Win Mag. These Pre-Fit barrel kits are “100% complete and ready-to-install”. All you need to do is remove your current barrel, place the recoil lug, spin on the new tube, follow the instructions for setting head-space, then torque the barrel nut against the lug. NOTE: You may require a barrel vise and action wrench to remove the original barrel. Minor inletting changes may be needed forward of the action.

The folks at McRee’s Precision say their Pre-Fit system offers many advantages: “Remington Pre-Fitted Barrel Kits have become popular over the years. If Savage can do it, why not for our Remingtons? Our [Criterion-supplied] barrels are spec’d to the McRee standard of performance. We require a minimum of 0.5 MOA with good factory ammo and 0.2 MOA with quality handloads. There are several places to get the tools required to remove your factory barrel correctly. Once you have your barrel removed all you have to do is follow the normal Savage procedure to install your new barrel. We recommend that you contact your local gunsmith for the install. Feel free to call us with any questions.”

Product Tip from Ed LongRange. We welcome readers’ submissions.

December 6th, 2014

According to a CNBC report, Remington has agreed to replace (or upgrade) the triggers on 7.85 million Remington rifles including ALL Remington 700s, and a dozen other models including the Model Seven, Sportsman 78, 673, 710, 715, 770, 600, 660, XP-100, 721, 722, and 725. CNBC reported that, as part of the settlement of a class action lawsuit, Remington has agreed to provide trigger replacements (or other solutions) to all owners of the affected rifle models. While Remington is not specifically recalling all the affected firearms, Big Green has committed to offering trigger upgrades (or other compensation) on millions of firearms produced over many decades. In a released statement, Remington insisted it was not “recalling” the affected rifles, but Remington did offer to replace the triggers on request. This corrective program could, potentially, involve millions of rifles (though we doubt that most Rem 700 and Model Seven owners will actually request trigger modifications.) According to a CNBC report, Remington has agreed to replace (or upgrade) the triggers on 7.85 million Remington rifles including ALL Remington 700s, and a dozen other models including the Model Seven, Sportsman 78, 673, 710, 715, 770, 600, 660, XP-100, 721, 722, and 725. CNBC reported that, as part of the settlement of a class action lawsuit, Remington has agreed to provide trigger replacements (or other solutions) to all owners of the affected rifle models. While Remington is not specifically recalling all the affected firearms, Big Green has committed to offering trigger upgrades (or other compensation) on millions of firearms produced over many decades. In a released statement, Remington insisted it was not “recalling” the affected rifles, but Remington did offer to replace the triggers on request. This corrective program could, potentially, involve millions of rifles (though we doubt that most Rem 700 and Model Seven owners will actually request trigger modifications.)

Affected Remington Products: Model 700, Seven, Sportsman 78, 673, 710, 715, 770, 600, 660, XP-100, 721, 722 and 725.

According to CNBC: “America’s oldest gun manufacturer, Remington, has agreed to replace millions of triggers in its most popular product — the Model 700 rifle. While insisting its action is not a recall of the iconic gun, Remington says in a statement that it is agreeing to make the changes ‘to avoid the uncertainties and expense of protracted litigation.’ The settlement involves a class action suit brought in 2013 by Ian Pollard of Concordia, Missouri, who claimed his Remington 700 rifle fired on multiple occasions without the trigger being pulled.”

According to the Montana Standard, the proposed Remington class action settlement will include model-by-model solutions:

— For Models 700, Seven, Sportsman 78 and 673 rifles, Remington will remove the original Walker trigger mechanism and replace it with a new X-Mark Pro mechanism.

— For Models 710, 715 and 770, Remington will remove the original trigger mechanism and replace it with a Model 770 connector-less mechanism.

— For Models 600, 660, XP-100, 721, 722 and 725, Remington will provide vouchers of $12.50 or $10, depending on the model, redeemable for Remington products.

— For Models 700 and Seven rifles made between May 2006 and April 9, 2014 with an X-Mark Pro trigger mechanism, Remington will retro-fit a new, improved assembly.

Under the terms of the settlement (which must ultimately receive Court approval), Remington will pay for the parts and labor involved to replace or fix trigger mechanisms, at no cost to the owner. The scope of the settlement may include rifles which previously had trigger upgrades done by owners. According to CNBC, “For guns that cannot be retrofitted, the company plans to offer vouchers for Remington products”. LINK: Related Story with Mis-Fire Demo Video.

CLICK HERE to view Remington Proposed Settlement Document (PDF file)

Will This be a Thirty Million-Dollar Fix?

How much will the trigger fix program cost Remington? That is hard to predict. However, Remington Outdoors (previously known as “The Freedom Group”) told its investors last month that it had allocated $29.7 million for a “Model 700 settlement reserve”.

December 6th, 2014

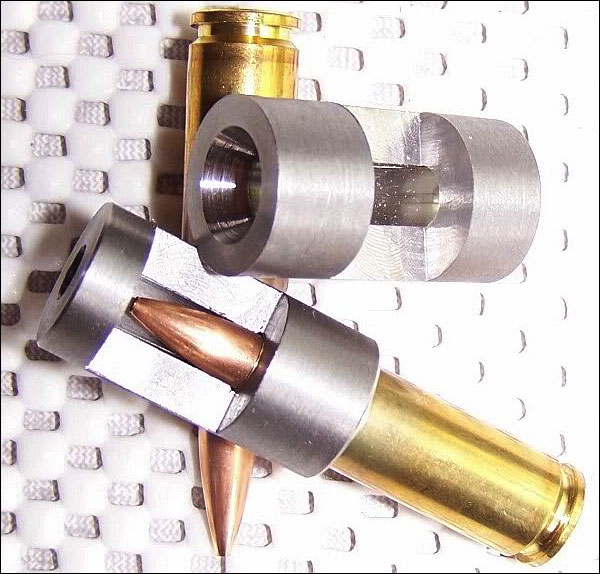

Next time you have a barrel fitted, consider having your gunsmith create a “stub gauge” from a left-over piece of barrel steel (ideally taken from your new barrel blank). The outside diameter isn’t important — the key thing is that the stub gauge is created with the same reamer used to chamber your current barrel, and the stub must have the same bore diameter, with the same land/groove configuration, as the barrel on your rifle. When properly made, a stub gauge gives you an accurate three-dimensional model of the upper section of your chamber and throat. This comes in handy when you need to bump your case shoulders. Just slide a fired case (with spent primer removed) in the stub gauge and measure from base of case to the end of the gauge. Then, after bumping, re-measure to confirm how much you’ve moved the shoulder.

In addition, the stub gauge lets you measure the original length to lands and freebore when your barrel was new. This gives you a baseline to accurately assess how far your throat erodes with use. Of course, as the throat wears, to get true length-to-lands dimension, you need take your measurement using your actual barrel. The barrel stub gauge helps you set the initial bullet seating depth. Seating depth is then adjusted accordingly, based on observed throat erosion, or your preferred seating depth.

Forum member RussT explains: “My gunsmith [makes a stub gauge] for me on every barrel now. I order a barrel an inch longer and that gives him enough material when he cuts off the end to give me a nice case gauge. Though I don’t have him cut that nice-looking window in the side (as shown in photos). That’s a neat option. You can tell how much throat erosion you are getting from when it was new as well. For measuring initial seating depths, this is the most useful item on my loading bench next to calipers. Everyone should have a case gauge made by there smith if you have a new barrel put on.”

Forum member Lawrence H. has stub gauges made with his chamber reamers for each new barrel. He has his smith cut a port in the stub steel so Lawrence can actually see how the bullet engages the rifling in a newly-cut chamber. With this “view port”, one can also see how the case-neck fits in the chamber. Lawrence tells us: “My stub gauges are made from my barrels and cut with my chamber reamers. With them I can measure where my bullets are ‘touching the lands’ and shoulder bump dimensions. This is a very simple tool that provides accurate information.” To learn more about stub gauges, read this Forum Thread. The photos above and below show Lawrence’s stub gauges:

November 18th, 2014

Tubegun Guru Gary Eliseo of Competition Machine will be offering a new finish option on his Eliseo chassis kits. Remarkably, this will be a true “custom camo” option, with hand-applied graphics. No two rifles will be exactly alike. Gary tells us: “My Daughter Tamira has joined us at the new shop in Arizona. She’s a gifted artist and has been doing great work on our custom paint jobs. I challenged her to come up with something original. She thought we could do something a little more unique than the cut stencil technique normally used with our Cerakote camo finishes. Needless to say, I was impressed with the outcome. We call her handiwork ‘Tamifleck’.” This combines a unique look with the rock hard durability of Cerakote. Each chassis finished with this special “Tamifleck” camo finish is truly one-of-a-kind.

“Tamifleck” camo is Competition Machine’s newest Cerakote finishing technique for its rifles and chassis kits. Each “Tamifleck” chassis is hand-painted by Tamira Eliseo.

November 16th, 2014

Forum Member Chuck L. (aka “Ridgeway”) has created a handsome duo of 6mm Dashers for competitive benchrest and varmint matches in Pennsylvania. Both guns are built on Kelbly Panda RBLP actions, with Bartlein 8-twist barrels, and Shehane Laminated Tracker Stocks. However, the two rifles are not exact twins, as you can see. One, which we’ll call the Big Dasher, is built on a Shehane ST1000 Tracker stock. The other gun, the Small Dasher, sports Shehane’s “Baby Tracker” stock — a design used with great success by Richard Schatz. The Big Dasher, optimized for 1000-yard competition, also has a slightly longer freebore — 0.136″ vs. 0.104″ for the Small Dasher.

Chuck tells us: “I don’t get out shooting competition as much as I want due to time and family, but when I do compete, I shoot a Groundhog match at Southfork Rifle Club in Beaverdale, PA. Info on Southfork Club events can be found at Southforkrifleclub.com. The Southfork match is basically a 100-, 300- and 500-yard match with one sighter the entire match and 5 shots at each yardage for score. The Small Dasher, with the shorter ‘Baby Tracker’ stock, was set up for the Southfork Rifle Club’s ‘Light Unlimited’ class which has a 13.5-lb max weight.” (Editor: ‘unlimited’ is a misnomer for a weight-limited category.)

Chuck adds: “The Big Dasher with the heavy ST-1000 stock is set up for 1000-yard benchrest matches in Light Gun class. I hope to shoot a couple 1K matches with it at Reade Range in southwest Pennsylvania. I am still in load development for this rifle since it was just finished in January. One ironic thing is, it shoots the same load I’m shooting out of the lighter gun rather well. The only difference between the two chambers is the freebore is roughly thirty thousandths longer on the 1K gun (Large Dasher). I will also shoot this at Southfork in the ‘Heavy Unlimited’ class.”

| Specifications for the Dasher Duo:

Small Dasher (13.5-pounder): Chambered for 6mm Dasher with approximately .104 freebore and a .264 NK. (No way of knowing exactly since it freebore was done in a separate operation by Kelbly.) Components are: Shehane Baby Tracker stock, Kelbly Panda RPLB action, Bartlein 1:8″ LV barrel at 26 ¾”, Kelbly Rings, Weaver T36, Jewell trigger. The barrel was chambered by Kelblys and the stock was bedded, glued and balanced by a shooting buddy (Forum Member johara1). I clear-coated the stock with auto urethane. Total weight is 13 lbs., 4 ounces.

Big Dasher (1K Light Gun, 17-pounder): Chambered for 6mm Dasher with a .136 freebore and .264 neck (PTG Reamer). Components are: Shehane ST-1000 stock, Kelbly Panda RPLB action, Bartlein 1:8″ HV 5R barrel at 28″, Shehane +20-MOA rings, Nightforce NXS 12-42x56mm, Jewell trigger. The barrel work, pillar installation, and bedding was done by Dave Bruno. The stock was clear-coated by Chuck with auto urethane. Chuck also made the rear butt plate and balanced the rifle. Total weight: 16 lbs., 13 ounces. |

Dasher Case-Forming: Neck-Turn then Fire-form with Bullets Hard in Lands

To fireform, I turn my cases down to fit the chamber and stop where the false shoulder makes snug contact with the chamber. Fire-forming rounds are loaded up with a 29-grain charge of H4895 or Varget and a 108gr Berger bullet seated hard into the lands about 0.020″ past initial contact with the rifling. It takes about three firings to make a nice clean Dasher case with a sharp shoulder. I anneal about every 3-4 firings. I have many cases that have about 10+ firings on them and they are still shooting well. The primer pockets are a little looser, but still hold a primer.

Both Dashers Group in the Ones at 100 Yards

My main bullet for both rifles is the 107gr Sierra MK, loaded with Reloder 15 powder, Lapua cases and CCI 450 primers. My main load for the Small Dasher is 33.0 grains of Reloder 15. This load shoots in the ones at 100 yards. For the Big Dasher, I’m still working on a load, although the same 33.0 grain load shoots in the ones in the heavier gun as well. I’m still looking for more velocity and my ‘max’ node. So far, I’ve gone well above 33.0 grains of RL 15 without pressure signs, but that load produces vertical at 100 yards, so I’m going to tinker with the load until I see pressure or it starts to shoot.

November 13th, 2014

Avid Design sells a unique multi-tool designed expressly for rifles and shotguns. The $24.99 Gun Tool combines 18 of the most commonly used long gun tools in a compact package. The Gun Tool boasts three Torx wrenches (T20; T15; T10), two Allen hex drives (3/32″; 5/32″), and four screwdriver blades (1/8″ flat; 3/16″ flat; Phillips 1 & 2). In addition, there is a magnetic 3/16″ driver, a pin punch, and a stainless claw blade useful for opening shipping boxes or trimming target backers.

The most unique feature of the Gun Tool is a stepped, multi-size choke-tube wrench that fits six shotgun bores from .410 all the way up to 10 gauge (see photo below right). For active shotgunners, that provides great versatility in a small package.

Praise from Respected Reviewers

In 2012, the NRA’s American Hunter magazine awarded The Gun Tool their Golden Bullseye award in the “Gear of the Year” category. The Gun Tool has also been awarded an outstanding 100% approval rating and a full endorsement by the North American Hunting Club.

Noted gun journalist Jim Shepard wrote: “I’ve been playing with ‘The Gun Tool’… and I’ve found it to be a pretty promising device that really should find a place in lots of range bags. If you’re a long gun shooter, it has something you’ll eventually need in the way of a tightening/loosening/adjusting tool.” Jim cautions that the claw blade does not lock into place.

November 13th, 2014

Winter storms are raging in many areas of the country right now, and we know that many of our readers are holed up inside. To help delay the onset of “cabin fever”, we’re offering some nice outdoor photos from Forum member Paul Fakenbridge (aka “Boltfluter”) up in Idaho.

One of Fakenbridge’s favorite rifles is a suppressed 22BR varminter with a 22″ barrel. All-up weight is 12 lbs. including bipod and suppressor. He uses this compact rifle on varmint excursions up in Idaho. Paul’s 22BR features a Rem short action in an H&S Precision PSS stock. The scope is a Leupold 12x40mm FX-3 (fixed power) in Warne Q/R rings. Paul notes: “In my .22BR the 75gr A-Maxes travel right at 3000 fps (with a 22″ barrel). My ‘go-to’ powder is IMR 8208 XBR with CCI 450 primers.” For those considering a build with a similar cartridge, Paul adds: “I think you will be pleasantly surprised.”

When he’s not hunting varmints, Boltfluter operates Pro-Precision Rifles, LLC which offers bolt fluting, bolt finishing, and barrel fluting (including AR15 barrels). Boltfluter also sells and installs bolt knobs and muzzle brakes. Shown below are two helical-fluted bolts with custom-machined bolt knobs. Very nice work by one of our Forum members…

November 12th, 2014

Looking to shoot an AR-platform rifle out past 500 yards? Then you should read two recent articles by AR guru Glen Zediker. Author of The New Competitive AR-15 and The Competitive AR15 Builders Guide, Zediker is an expert when it comes to AR-platform rifles — he knows as much as any guy around. Glen believes ARs have excellent long-range capability, provided they are built to high standards, with good barrels. Glen says: “a properly configured AR-15 is easily capable of good performance at 500+ yards. Good performance means it can hit a 1-foot-square target all the time. Competitive shooters can cut that standard in nearly half (the X-Ring on an MR1 600-yard NRA High Power Rifle target is 6 inches, and high X-counts are commonplace among more skilled shooters).”

Published in the Cheaper than Dirt Shooter’s Log, Zediker’s pair of articles cover the history and upgrading of the AR-15. Part One reviews the AR’s development as an accurate firearm, tracing its evolution from a Vietnam-era combat weapon to what is now a favored target rifle of High Power competitors. READ PART ONE.

Part Two discusses the specifics that make an AR accurate at 500 yards and beyond. Zediker talks about barrel configuration (profile and twist rate), bullet selection, floating handguards, and proper mounting of optics or iron sights. READ PART TWO.

Here are some highlights from Long-Range AR-15 Part TWO:

Barrel Twist Rate

To stabilize anything longer than a 68- or 69-grain bullet, the barrel twist rate must be — at minimum– 1-in-8. Twist rates reflect how far the bullet travels along the lands or rifling to make one complete revolution. So, 1-in-8 (or 1-8, 1:8) means “one turn in eight inches.” I think it’s better to go a little faster in twist. There is nothing wrong with a 1:7 twist. The 90-grain bullets require a 1:6.5, and that is getting on the quick side. If you want to shoot Sierra 77s or equivalent, and certainly anything longer, 1:8 is necessary. By the way, it is bullet length, not weight, which constitutes the necessary twist rate to launch a stable bullet.

Optics Mounting

Correct optical sight positioning can be a challenge. With a flattop upper, I need a good inch additional forward extension at the muzzle side of the upper for the sight mount bases to avoid holding my head “back” to get the optimal view through the scope. A longer rail piece is necessary for my builds as a result.

Buttstock Length and Adjustment

An adjustable buttstock is valuable, and even more valuable if it’s well-designed. Mostly, a standard stock is too short, and the cheek area sits too low. Adding length helps a lot by itself. There are assemblies that replace the standard buttplate to allow for length and, usually, height and rotation adjustments for the buttpad. An elevation-adjustable cheekpiece is a big help to attain a solid position.

November 10th, 2014

A Negligent Shooter Gets Lucky

Here we have a story so filled with negligent acts that I can only marvel that the shooter survived the experience. The photo and narrative were provided by the gunsmith who took in the repair job, my comments are in italics. It’s worth reading, we can’t get enough safety warnings in our hobby. — GS Arizona, Riflemans Journal

Below is a sectioned barrel showing an 80gr Sierra that was fired in a .223 bolt action with a cleaning rod in the bore. Both the bullet and the rod are still in the bore.

This article originally appeared in the Riflemans Journal website.

Description of Incident (with Commentary)

The shooter had a stuck case in his .223 chamber. The stuck case was actually a loaded round that didn’t fire. It wouldn’t extract because it was a .222 case that got mixed in with his .223 brass. [He had loaded the wrong brass.] I saw the loaded round with an 80gr bullet in it and a light primer strike. Negligent Act #1: Wrong brass was mixed in with the brass being reloaded.

The shooter removed the stuck case with a 3-piece aluminum rod. Negligent Act #2: Hammering out a loaded round with a cleaning rod. People have been killed doing this as the round can fire and drive the cleaning rod right into you. I remember one such incident about 5 years ago, the shooter was pounding out a stuck round, the cleaning rod went right through him, he didn’t survive.

The shooter didn’t notice only two segments of the cleaning rod came out when he removed it. Negligent Act #3: If you put anything at all down the barrel of a rifle you’d better make darn sure you got it all out before doing anything else!

He then chambered another round and fired it. Negligent act #4: If you’ve had a barrel obstruction of any kind, and if you’ve put something in the barrel, look through the barrel before proceeding! Within the past two years I know of an incident in which a benchrest shooter was killed in exactly this manner. The pressure built up and the rifle bolt came out of the receiver and into his chest.

The shooter is ‘OK’, but did not escape unscathed. He said there was a huge explosion and after regaining his senses found he was bleeding heavily from his forehead. The blood was thick enough that it ran in his eyes and he couldn’t see. In his words “I thought I was going to die”.

He has what looks like a pretty deep cut about an inch long on the side of his head, right in line with his right eye starting where the eye socket turns out to the side of the skull. And no telling what he’s got in the way of brass particles embedded in his forehead.

He was shooting on private property, and was alone when this happened. Negligent Act #5: Don’t shoot alone! Accidents happen, this is just one more example. If we could predict accidents, we wouldn’t have them. Always shoot with at least one other person.

He managed to get the bleeding stopped, or at least under control, packed his car and drove himself home without seeking immediate medical attention. Negligent Act #6: This one could have cost him his life after being lucky enough to survive the incident. There’s no way to know what’s happened just after an incident like this. He should have been at a hospital getting checked for shrapnel in the head.

The rod and slug could not be driven out. Since the barrel had a high round count there was no point in trying to salvage it. Note that the aluminum rod is expanded to a tight fit in the bore for the first couple inches. The base of the bullet is a little over 2″ from the mouth of the chamber.

What we’ve seen here is negligence and an absolute indifference to the established rules of safe reloading and gun handling, from start to finish, capped off with the shooter’s foolish avoidance of medical treatment. This shooter is lucky to be alive, but he’s surely used up all his luck. Don’t assume you’ll be so fortunate.

|

Here’s one of the latest F-Class projects from Enda Walsh of Custom & Precision Rifles in Ireland. This rifle features a free-floated BAT Machines ‘M’ action with a Benchmark barrel chambered in .300 Blaser Magnum (300 BM). The barreled action is secured with a large barrel block. This handsome, long-wheelbase F-Class rig is “new-born”, but it has already demonstrated some stunning accuracy at 1000 yards. Enda tells us: “I couldn’t wait until the rifle was fully polished before testing. I went to MNSCI (Midlands National Shooting Centre of Ireland) to shoot my new barrel block rifle. I came home with a huge smile on my face after shooting a five-shot group with 1.5″ vertical and 3″ horizontal at 1000 yards in an 8 mph wind.”

Here’s one of the latest F-Class projects from Enda Walsh of Custom & Precision Rifles in Ireland. This rifle features a free-floated BAT Machines ‘M’ action with a Benchmark barrel chambered in .300 Blaser Magnum (300 BM). The barreled action is secured with a large barrel block. This handsome, long-wheelbase F-Class rig is “new-born”, but it has already demonstrated some stunning accuracy at 1000 yards. Enda tells us: “I couldn’t wait until the rifle was fully polished before testing. I went to MNSCI (Midlands National Shooting Centre of Ireland) to shoot my new barrel block rifle. I came home with a huge smile on my face after shooting a five-shot group with 1.5″ vertical and 3″ horizontal at 1000 yards in an 8 mph wind.”

.300 BM Runs 230-grainers at 3140 FPS!

.300 BM Runs 230-grainers at 3140 FPS!

According to a

According to a