|

|

August 16th, 2025

POWDER GRAIN SHAPES — What You Need to Know

The shape of powder grains has a profound effect on the performance of the powder charge, as it concerns both pressure and velocity. There are multiple powder shapes including flake, ball, and extruded or “stick” (both solid and perforated).

So how does powder grain shape affect pressure and muzzle velocity?

In general, it can be said that powder that burns progressively achieves a desired muzzle velocity at lower maximum pressure than a powder that burns neutrally, not to mention a degressive powder. As grain size increases, the maximum pressure moves towards the muzzle, also increasing muzzle blast. Muzzle velocity and pressure can be adjusted by means of the amount of powder or loading density, i.e. the relationship between the powder mass and the volume available to it. As the loading density increases, maximum pressure grows.

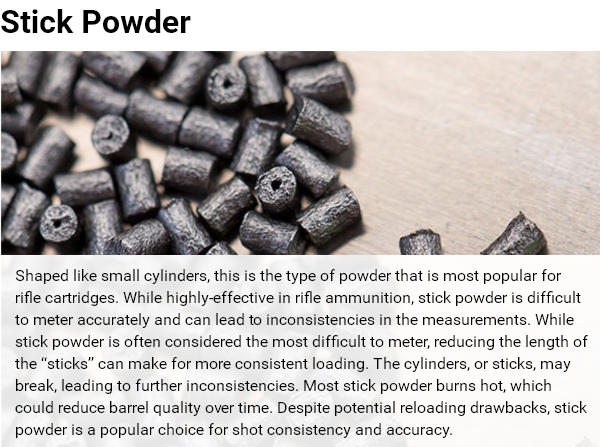

All Vihtavuori reloading powders are of the cylindrical, single-perforated extruded stick type. The differences in burning rate between the powders depend on the size of the grain, the wall thickness of the cylinder, the surface coating and the composition. Cylindrical extruded powders can also have multi-perforated grains. The most common types are the 7- and 19-perforated varieties. A multi-perforated powder grain is naturally of a much larger size than one with a single perforation, and is typically used for large caliber ammunition.

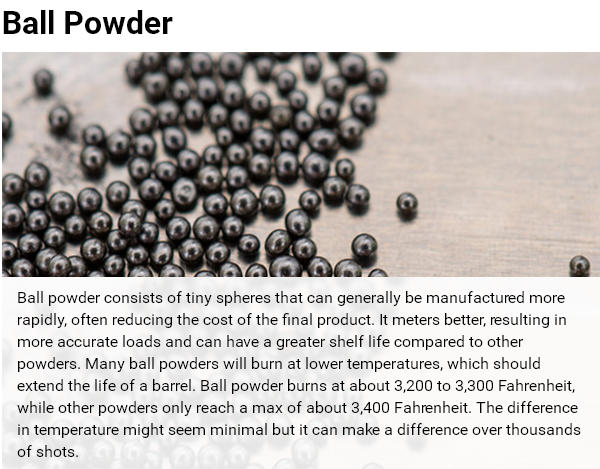

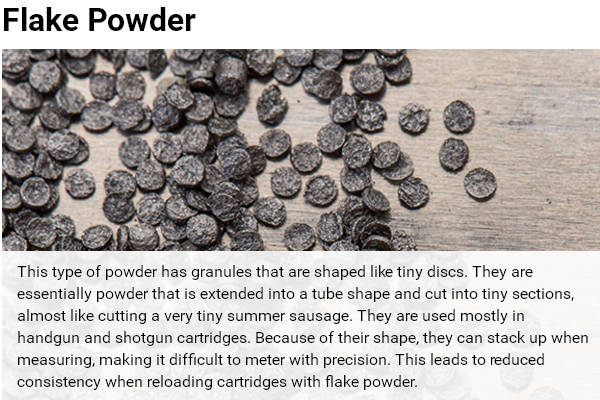

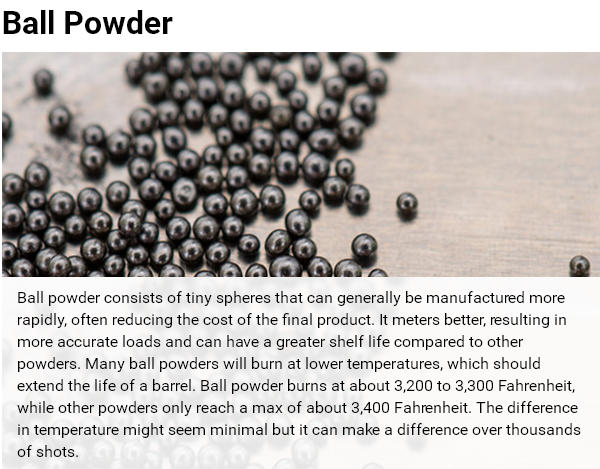

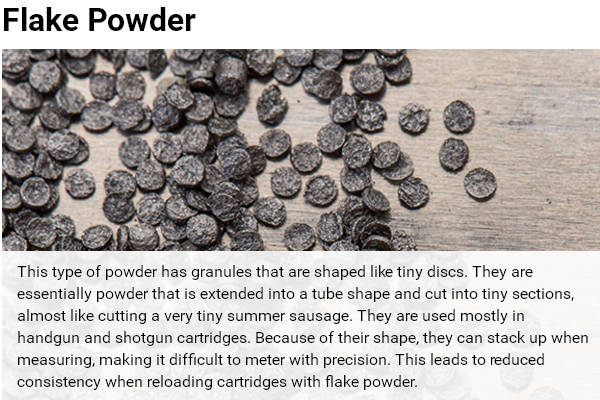

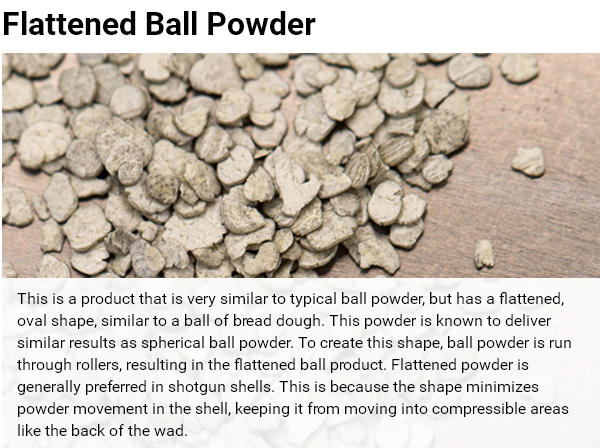

Other types of powder grain shapes include sphere or ball, and flake. The ball grains are typically used in automatic firearms but also in rifles and handguns. The ball grain is less costly to produce, as it is not pressed into shape like cylindrical grains. Flake shaped grains are typically used in shotgun loadings.

Web thickness in gunpowder terminology means the minimum distance that the combustion zones can travel within the powder grain without encountering each other. In spherical powders, this distance is the diameter of the “ball”; in flake powder it is the thickness of the flake; and in multi-perforated extruded powders it is the minimum distance (i.e. wall thickness) between the perforations.

The burning rate of powder composed of grains without any perforations or surface treatment is related to the surface area of the grain available for burning at any given pressure level. The change in the surface area that is burning during combustion is described by a so-called form function. If the surface area increases, the form function does likewise and its behavior is termed progressive. If the form function decreases, its behavior is said to be degressive. If the flame area remains constant throughout the combustion process, we describe it as “neutral” behavior.

The cylindrical, perforated powders are progressive; the burning rate increases as the surface area increases, and the pressure builds up slower, increasing until it reaches its peak and then collapses. Flake and ball grains are degressive; the total powder surface area and pressure are at their peak at ignition, decreasing as the combustion progresses.

This article originally appeared on the Vihtavuori Website.

July 26th, 2025

Widener’s Reloading & Shooting Supply has published a helpful introduction to reloading powders. Widener’s online Guide to Smokeless Powders shows the various types of powders, and explains how the differences in powder kernel/flake size and shape, and burn rate affect performance. We recommend you visit Widener’s website and read the Powder Guide in full.

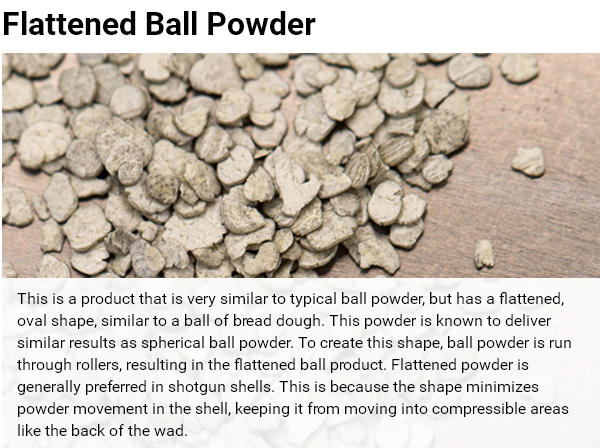

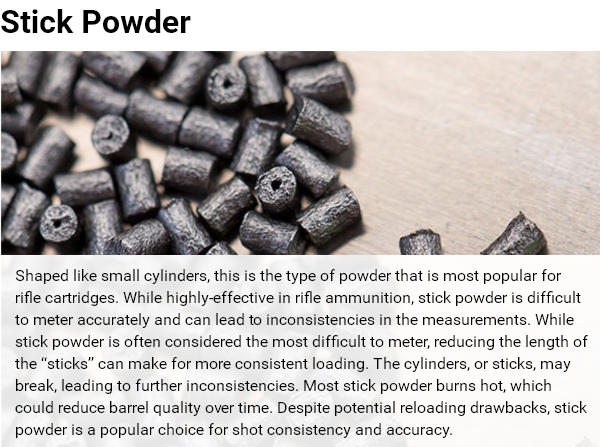

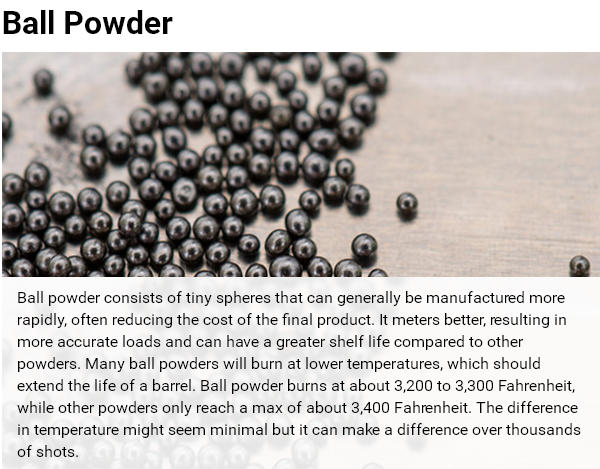

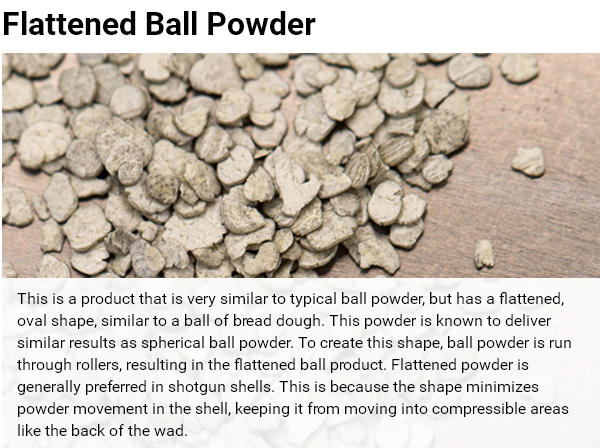

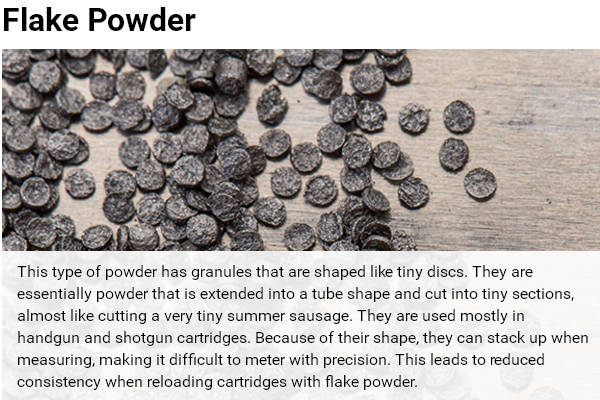

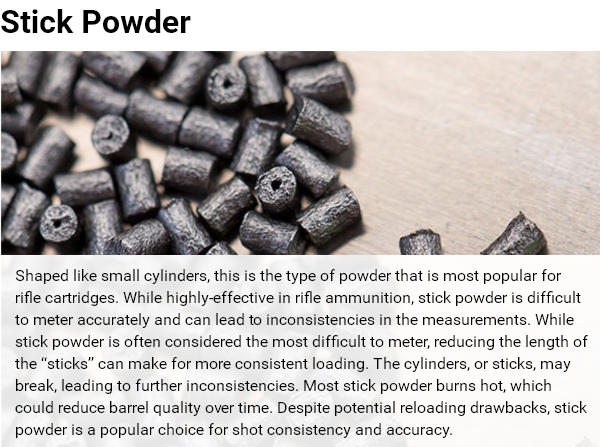

Take a close look at these illustrations which show the key differences between the four main powder types: extruded (stick) powder, ball (spherical) powder, flattened ball powder, and flake powder.

Burn Rate Basics

Widener’s Guide to Smokeless Powders also has a useful discussion of Burn Rate (a confusing topic for many hand-loaders). Wideners explains: “While a gun powder explosion in the cartridge seems instantaneous, if you slow it down you will actually find that each powder has a different ‘burn rate’, or speed at which it ignites.” This video shows powders with two very different burn rates. Watch closely.

Different burn rates suit different cartridge types notes Widener’s: “In general a fast-burning powder is used for light bullets and low-speed pistols and shotguns. Medium-rate powders are used for magnum pistols, while high-velocity, large bore rifle cartridges will need slow powders[.]

It should be noted that burn rate does not have a standardized unit of measurement. In fact, burn rate is really only discussed in comparison to other powders; there is no universal yardstick. Specifics will change by cartridge and bullet types[.]”

February 19th, 2025

POWDER GRAIN SHAPES — What You Need to Know

The shape of powder grains has a profound effect on the performance of the powder charge, as it concerns both pressure and velocity. There are multiple powder shapes including flake, ball, and extruded or “stick” (both solid and perforated).

So how does powder grain shape affect pressure and muzzle velocity?

In general, it can be said that powder that burns progressively achieves a desired muzzle velocity at lower maximum pressure than a powder that burns neutrally, not to mention a degressive powder. As grain size increases, the maximum pressure moves towards the muzzle, also increasing muzzle blast. Muzzle velocity and pressure can be adjusted by means of the amount of powder or loading density, i.e. the relationship between the powder mass and the volume available to it. As the loading density increases, maximum pressure grows.

All Vihtavuori reloading powders are of the cylindrical, single-perforated extruded stick type. The differences in burning rate between the powders depend on the size of the grain, the wall thickness of the cylinder, the surface coating and the composition. Cylindrical extruded powders can also have multi-perforated grains. The most common types are the 7- and 19-perforated varieties. A multi-perforated powder grain is naturally of a much larger size than one with a single perforation, and is typically used for large caliber ammunition.

Other types of powder grain shapes include sphere or ball, and flake. The ball grains are typically used in automatic firearms but also in rifles and handguns. The ball grain is less costly to produce, as it is not pressed into shape like cylindrical grains. Flake shaped grains are typically used in shotgun loadings.

Web thickness in gunpowder terminology means the minimum distance that the combustion zones can travel within the powder grain without encountering each other. In spherical powders, this distance is the diameter of the “ball”; in flake powder it is the thickness of the flake; and in multi-perforated extruded powders it is the minimum distance (i.e. wall thickness) between the perforations.

The burning rate of powder composed of grains without any perforations or surface treatment is related to the surface area of the grain available for burning at any given pressure level. The change in the surface area that is burning during combustion is described by a so-called form function. If the surface area increases, the form function does likewise and its behavior is termed progressive. If the form function decreases, its behavior is said to be degressive. If the flame area remains constant throughout the combustion process, we describe it as “neutral” behavior.

The cylindrical, perforated powders are progressive; the burning rate increases as the surface area increases, and the pressure builds up slower, increasing until it reaches its peak and then collapses. Flake and ball grains are degressive; the total powder surface area and pressure are at their peak at ignition, decreasing as the combustion progresses.

This article originally appeared on the Vihtavuori Website.

March 7th, 2024

POWDER GRAIN SHAPES — What You Need to Know

The shape of powder grains has a profound effect on the performance of the powder charge, as it concerns both pressure and velocity. There are multiple powder shapes including flake, ball, and extruded or “stick” (both solid and perforated).

So how does powder grain shape affect pressure and muzzle velocity?

In general, it can be said that powder that burns progressively achieves a desired muzzle velocity at lower maximum pressure than a powder that burns neutrally, not to mention a degressive powder. As grain size increases, the maximum pressure moves towards the muzzle, also increasing muzzle blast. Muzzle velocity and pressure can be adjusted by means of the amount of powder or loading density, i.e. the relationship between the powder mass and the volume available to it. As the loading density increases, maximum pressure grows.

All Vihtavuori reloading powders are of the cylindrical, single-perforated extruded stick type. The differences in burning rate between the powders depend on the size of the grain, the wall thickness of the cylinder, the surface coating and the composition. Cylindrical extruded powders can also have multi-perforated grains. The most common types are the 7- and 19-perforated varieties. A multi-perforated powder grain is naturally of a much larger size than one with a single perforation, and is typically used for large caliber ammunition.

Other types of powder grain shapes include sphere or ball, and flake. The ball grains are typically used in automatic firearms but also in rifles and handguns. The ball grain is less costly to produce, as it is not pressed into shape like cylindrical grains. Flake shaped grains are typically used in shotgun loadings.

Web thickness in gunpowder terminology means the minimum distance that the combustion zones can travel within the powder grain without encountering each other. In spherical powders, this distance is the diameter of the “ball”; in flake powder it is the thickness of the flake; and in multi-perforated extruded powders it is the minimum distance (i.e. wall thickness) between the perforations.

The burning rate of powder composed of grains without any perforations or surface treatment is related to the surface area of the grain available for burning at any given pressure level. The change in the surface area that is burning during combustion is described by a so-called form function. If the surface area increases, the form function does likewise and its behavior is termed progressive. If the form function decreases, its behavior is said to be degressive. If the flame area remains constant throughout the combustion process, we describe it as “neutral” behavior.

The cylindrical, perforated powders are progressive; the burning rate increases as the surface area increases, and the pressure builds up slower, increasing until it reaches its peak and then collapses. Flake and ball grains are degressive; the total powder surface area and pressure are at their peak at ignition, decreasing as the combustion progresses.

This article originally appeared on the Vihtavuori Website.

July 22nd, 2023

Widener’s Reloading & Shooting Supply recently published a helpful introduction to reloading powders. Widener’s online Guide to Smokeless Powders shows the various types of powders, and explains how the differences in powder kernel/flake size and shape, and burn rate affect performance. We recommend you visit Widener’s website and read the Powder Guide in full.

Take a close look at these illustrations which show the key differences between the four main powder types: extruded (stick) powder, ball (spherical) powder, flattened ball powder, and flake powder.

Burn Rate Basics

Widener’s Guide to Smokeless Powders also has a useful discussion of Burn Rate (a confusing topic for many hand-loaders). Wideners explains: “While a gun powder explosion in the cartridge seems instantaneous, if you slow it down you will actually find that each powder has a different ‘burn rate’, or speed at which it ignites.” This video shows powders with two very different burn rates. Watch closely.

Different burn rates suit different cartridge types notes Widener’s: “In general a fast-burning powder is used for light bullets and low-speed pistols and shotguns. Medium-rate powders are used for magnum pistols, while high-velocity, large bore rifle cartridges will need slow powders[.]

It should be noted that burn rate does not have a standardized unit of measurement. In fact, burn rate is really only discussed in comparison to other powders; there is no universal yardstick. Specifics will change by cartridge and bullet types[.]”

August 24th, 2021

POWDER GRAIN SHAPES — What You Need to Know

The shape of powder grains has a profound effect on the performance of the powder charge, as it concerns both pressure and velocity. There are multiple powder shapes including flake, ball, and extruded or “stick” (both solid and perforated).

So how does powder grain shape affect pressure and muzzle velocity?

In general, it can be said that powder that burns progressively achieves a desired muzzle velocity at lower maximum pressure than a powder that burns neutrally, not to mention a degressive powder. As grain size increases, the maximum pressure moves towards the muzzle, also increasing muzzle blast. Muzzle velocity and pressure can be adjusted by means of the amount of powder or loading density, i.e. the relationship between the powder mass and the volume available to it. As the loading density increases, maximum pressure grows.

All Vihtavuori reloading powders are of the cylindrical, single-perforated extruded stick type. The differences in burning rate between the powders depend on the size of the grain, the wall thickness of the cylinder, the surface coating and the composition. Cylindrical extruded powders can also have multi-perforated grains. The most common types are the 7- and 19-perforated varieties. A multi-perforated powder grain is naturally of a much larger size than one with a single perforation, and is typically used for large caliber ammunition.

Other types of powder grain shapes include sphere or ball, and flake. The ball grains are typically used in automatic firearms but also in rifles and handguns. The ball grain is less costly to produce, as it is not pressed into shape like cylindrical grains. Flake shaped grains are typically used in shotgun loadings.

Web thickness in gunpowder terminology means the minimum distance that the combustion zones can travel within the powder grain without encountering each other. In spherical powders, this distance is the diameter of the “ball”; in flake powder it is the thickness of the flake; and in multi-perforated extruded powders it is the minimum distance (i.e. wall thickness) between the perforations.

The burning rate of powder composed of grains without any perforations or surface treatment is related to the surface area of the grain available for burning at any given pressure level. The change in the surface area that is burning during combustion is described by a so-called form function. If the surface area increases, the form function does likewise and its behavior is termed progressive. If the form function decreases, its behavior is said to be degressive. If the flame area remains constant throughout the combustion process, we describe it as “neutral” behavior.

The cylindrical, perforated powders are progressive; the burning rate increases as the surface area increases, and the pressure builds up slower, increasing until it reaches its peak and then collapses. Flake and ball grains are degressive; the total powder surface area and pressure are at their peak at ignition, decreasing as the combustion progresses.

This article originally appeared on the Vihtavuori Website.

April 5th, 2021

Outstanding New Powder from Alliant — Reloder TS 15.5

New Product Review by DasherDude

Alliant has devloped a new temperature-stable powder for long range applications. According to Alliant, this is a “slower burning version of the popular RL 15 with TZ technology” and brings some significant advantages over RL 15 and powders in the similar burn rate range (like Varget). The powder is named “Reloder TS 15.5″ (RL TS 15.5) and is created using the same TZ technology used in Reloder 16 (RL 16) and Reloder 23 (RL 23) whereby it manipulates the response of the propellant and resists the natural tendency to generate more pressure at higher temperatures and less pressure at lower temperatures. That makes RL TS 15.5 extremely stable across the full temperature range a shooter may encounter.

When Can You Get This New Alliant RL TS 15.5 Powder?

Alliant tells us that new RL TS 15.5 should start arriving on dealer’s shelves by the end of the month. Officially: “We will be putting it into distribution probably in April 2021 sometime”. Remember you heard about this powder here first.

The burn rate of RL TS 15.5 lies between RL 15 and RL 16 making it ideal for loading heavier bullets in .308 Win, 6.5 Creedmoor, 6mm Creedmoor, .223 Rem, and 6mm wildcats such as the 6mm Dasher or 6 BRA (BR Ackley). Being a bit slower than RL 15, new TS 15.5 offers higher velocities for the same charge weight as well as ability to load heavier charges for additional velocity without generating excessive pressure.

Testing Reloder TS 15.5 in 6 Dasher and .308 Winchester

I got a chance to test a pre-production powder sample of RL TS15.5 from Alliant. In my own tests with my 6mm Dasher and .308 Win, I extensively compared it with Varget that I normally use in these cartridges. In both cases, the results were nothing short of spectacular.

Powder Characteristics and Metering

This is an extruded powder and looks and feels similar to RL 16. The kernels are about 0.03 – 0.04 grains each (with the resolution of A&D FX 120i scale). RL TS 15.5 meters very well, although I had to slightly adjust the AutoTrickler to get it to meter perfectly.

As I found, later in the testing, that the powder compresses before it can generate excessive pressure in the Dasher, a drop tube helps to fill the case more efficiently if higher charges and velocities are desired.

6mm Dasher Test Rifle and Load

For testing I used my 6mm Dasher benchrest match rifle. This has a BAT 3L action, 28″ Krieger barrel, and McMillan stock. I use Lapua brass with CCI 450 primers to propel Berger 105gr Hybrids and this combination shoots quite well.

Test Firearm: 6mm Dasher, Bat 3L, 28″ 6mm HV Krieger Barrel, McMillan Stock.

Components: Lapua fire-formed brass, CCI 450 primers, Berger 105 grain Hybrid

Powder: Alliant Reloder TS 15.5

Load Testing and Velocities

Test in 6mm Dasher — Excellent Velocity, Low ES/SD

The testing comprised of shooting groups at 100 yards with increasing powder charges (OCW method) and then selecting a node. That node was found at 33.4 grains. The accuracy was excellent with remarkably low Extreme Spread and Standard Deviation (ES/SD)

My usual load is 32.9 grains of Hodgdon Varget which runs 2925 fps with an ES of around 12 fps and SD around 5 fps. For comparison, 32.9 grains of RL TS 15.5 delivered a velocity of 3022 fps. That is 97 fps greater than Varget for the same load weight (of RL TS15.5).

When used in the 6 Dasher, RL TS 15.5 had ES of 13 for 28 Shots — Remarkable!

More Velocity Plus Consistent ES/SD

With the Dasher since the new node (the sweet spot) was found at 33.4 grains, that resulted in a velocity of 3050 fps (a 125 fps velocity increase) from the same rifle setup. Not only did the velocity increase, but the SD was lowered to 3.6 with an ES of 13 (calculated over 28 shots). You read that right… 13 fps ES over 28 shots! With the Dasher since the new node (the sweet spot) was found at 33.4 grains, that resulted in a velocity of 3050 fps (a 125 fps velocity increase) from the same rifle setup. Not only did the velocity increase, but the SD was lowered to 3.6 with an ES of 13 (calculated over 28 shots). You read that right… 13 fps ES over 28 shots!

At 34 grains without any drop tube, the load was compressed. However, there were no pressure signs. That indicates that the 6 Dasher cartridge can be loaded with a higher charge, if a drop tube was used.

.308 Winchester Velocity Results

Similar results (velocity gains) were obtained from my .308 Win with Berger 200.20X bullets. For the same charge of 44.2 grains, I recorded about 100 fps higher velocity with RL TS 15.5, compared to Varget.

Accuracy Results at 100 and 300 Yards — Very Impressive

How does RL TS 15.5 shoot on paper? Very well indeed.

6mm Dasher Load Testing with Various RL TS 15.5 Charge Weights

The groups on paper told similar stories. For the OCW method, I shot groups of increasing charges at 100 yards and then selected 33.4 grains as the optimum charge (incidentally, it was one ragged hole).

While testing at 300 yards, the conditions were very windy but since I was testing for vertical, the point of aim was kept the same for every shot. No attempt was made to correct for wind, so the groups spread horizontally (15 mph, 3 o’clock wind) but the vertical spread of all the groups was under 0.3 MOA. That gives me great hopes for the long-range capabilities of the powder.

Thoughts and Conclusions

For the past year, Alliant powders have been a welcome surprise for this tester and they have found a home in my reloading room. I struggled to find a load for my .284 Win with H4831sc and H4350 before trying out Reloder 16 and voila, it was perfect.

I have used Hodgdon Varget powder for a long time in both my 6mm Dasher and my .308 Winchester. With the .308 Win I’ve used various bullets from 168 to 200 grains. Varget has served me well. I do always need to keep the powder charge in check and so the velocities are held back a bit. Now RL TS 15.5 looks like a very impressive competitor to Varget.

With Reloder TS 15.5, Alliant seems to have delivered a harmonious mix of great accuracy, higher velocities, and lower SDs without creating excessive pressure. All of this is delivered with a very temperature-stable package. The higher velocities may allow some shooters to hit a new, better-performing node. These qualities are highly sought after by long range shooters. Accordingly, I have no qualms in saying that Alliant has created a winner here.

Alliant Official Load Data for Reloder TS 15.5

Along with the cartridge types shown below, Alliant has also released load data for .30-06 Springfield, 7x57mm Mauser, .270 Win, .260 Rem, 6.5 Grendel, .257 Roberts, 22-250 Rem, and 224 Valkyrie. CLICK for all data (larger format).

April 28th, 2020

POWDER GRAIN SHAPES — What You Need to Know

The shape of powder grains has a profound effect on the performance of the powder charge, as it concerns both pressure and velocity. There are multiple powder shapes including flake, ball, and extruded or “stick” (both solid and perforated).

All Vihtavuori reloading powders are of the cylindrical, single-perforated extruded stick type. The differences in burning rate between the powders depend on the size of the grain, the wall thickness of the cylinder, the surface coating and the composition. Cylindrical extruded powders can also have multi-perforated grains. The most common types are the 7- and 19-perforated varieties. A multi-perforated powder grain is naturally of a much larger size than one with a single perforation, and is typically used for large caliber ammunition.

Other types of powder grain shapes include sphere or ball, and flake. The ball grains are typically used in automatic firearms but also in rifles and handguns. The ball grain is less costly to produce, as it is not pressed into shape like cylindrical grains. Flake shaped grains are typically used in shotgun loadings.

Web thickness in gunpowder terminology means the minimum distance that the combustion zones can travel within the powder grain without encountering each other. In spherical powders, this distance is the diameter of the “ball”; in flake powder it is the thickness of the flake; and in multi-perforated extruded powders it is the minimum distance (i.e. wall thickness) between the perforations.

The burning rate of powder composed of grains without any perforations or surface treatment is related to the surface area of the grain available for burning at any given pressure level. The change in the surface area that is burning during combustion is described by a so-called form function. If the surface area increases, the form function does likewise and its behavior is termed progressive. If the form function decreases, its behavior is said to be degressive. If the flame area remains constant throughout the combustion process, we describe it as “neutral” behavior.

The cylindrical, perforated powders are progressive; the burning rate increases as the surface area increases, and the pressure builds up slower, increasing until it reaches its peak and then collapses. Flake and ball grains are degressive; the total powder surface area and pressure are at their peak at ignition, decreasing as the combustion progresses.

So how does the shape affect pressure and muzzle velocity? In general, it can be said that powder that burns progressively achieves a desired muzzle velocity at lower maximum pressure than a powder that burns neutrally, not to mention a degressive powder. As grain size increases, the maximum pressure moves towards the muzzle, also increasing muzzle blast. Muzzle velocity and pressure can be adjusted by means of the amount of powder or loading density, i.e. the relationship between the powder mass and the volume available to it. As the loading density increases, maximum pressure grows.

This article originally appeared on the Vihtavuori Website.

July 9th, 2019

Big news for the shooting community! Just six years after it acquired Savage Arms, outdoor industry mega-corp Vista Outdoor is selling off Savage Arms. The firearms-maker will be acquired by a private investment group led by Savage’s current management. When the sale is complete, Vista Outdoor, parent company of dozens of outdoor brands such as Bushnell, Bell Helmets, CCI, Camelback, Federal, RCBS, and Weaver, will no longer produce firearms of any kind. The sell-back to the Savage management group will include Stevens Arms*, which primarily produces shotguns.

There were multiple reasons given for the sale, which include:

1. Cutting costs, reducing corporate debt, and consolidating operations at Vista Outdoor.

2. Focusing more on the ammunition brands Alliant, CCI, Speer, and Federal.

3. Giving Vista Outdoor’s “ammunition brands flexibility to work with any industry partner”.

In addition, we suspect that, given the current political climate and media antagonism towards gun-makers, Vista Outdoor’s leadership deemed that owning Savage was bad for the company’s overall image. The potential profits from Savage were simply not worth the negative press as well as the potential liabilities from gun-related lawsuits.

By the Numbers: Vista Outdoor acquired Savage Arms (and Stevens) in July 2013 for $315 million. The July 2019 sell-off of Savage Arms (and Stevens) for $170 million represents a $145 million loss for Vista Outdoor. That’s not a good business model.

Founded in 1894, Massachusetts-based Savage Arms is one of America’s oldest gun-makers. While it has produced a wide variety of firearms over the past 125 years, Savage is now best known for its affordable bolt-action hunting rifles that feature barrels attached by a barrel-nut. In recent years, Savage has also moved aggressively into the “black rifle” market producing its MSR series of AR-platform rifles in a variety of chamberings. Savage also produces a popular semi-auto Rimfire rifle, the Savage A17/A22 series.

Here is the official Press Release covering Vista Outdoor’s sale of Savage Arms to a group of investors headed by Al Kasper, Savage’s President and CEO (emphasis added):

Vista Outdoor Announces Sale of Savage Brand

Vista Outdoor Inc. (“Vista Outdoor”) (NYSE: VSTO) announced today that it has completed the sale of the legal entity operating its Savage Arms and Stevens firearms brands to a financial buyer for a total purchase price of $170 million, comprised of $158 million paid at closing and $12 million to be paid upon maturity of a five-year seller note issued by the buyer to Vista Outdoor in connection with the transaction.

The sale is part of Vista Outdoor’s previously announced transformation plan, which outlined the intent to reshape the company’s portfolio by cutting costs, consolidating leadership, paying down debt, and divesting certain brands, including both its eyewear brands and firearms brands, in order to pursue growth in product categories where the company believes it can be market leaders. As the company now looks forward, the focus is on ammunition, hunting and shooting accessories, hydration bottles and packs, outdoor cooking products, and cycling/ski helmets and accessories.

“Divesting our Savage brand was a key aspect of our transformation plan,” said Chris Metz, CEO of Vista Outdoor. “While it was a difficult decision to sell such an iconic brand, I remain confident that this was the correct choice to help Vista Outdoor grow in those categories where we can have leadership positions. Savage is a fantastic business, and it deserves to continue to evolve into other firearms categories. At this time, however, we simply do not have the resources to transform Savage into the full-service firearms company that it deserves to be and, therefore, we determined the brand would be better off with a different owner. We’re excited to see Savage reach its full potential under new ownership.”

Savage was acquired by Vista Outdoor’s predecessor, ATK, in 2013. ATK’s sporting business – which included Savage, Bushnell, Federal and CCI Ammunition, and dozens of other hunt/shoot accessories brands, spun off in 2015 to become Vista Outdoor.

“The Savage acquisition helped create Vista Outdoor, and we’re grateful for all the success the brand brought to our company over the past six years,” said Metz. “However, this divestiture now gives our ammunition brands flexibility to work with any industry partner to create the best products and meet our consumers’ needs.”

At closing, Vista Outdoor received gross proceeds from the divestiture of $158 million. Vista Outdoor will use the net after-tax proceeds of the sale to repay outstanding indebtedness.

“Reducing our debt is a key part of turning around our business,” said Metz. “Selling Savage and further reducing our overall leverage will improve our financial flexibility and better position the company for long-term growth. We’ve now rebuilt the company’s foundation to provide a more stable base upon which to grow. We have a portfolio of brands that all have the potential to be strong, market leaders in their respective categories and I’m proud of my team’s efforts in reshaping the portfolio over the course of the past year.”

*American firearms manufacturer J. Stevens Arms & Tool Company, now part of Savage Arms, introduced the .22 Long Rifle cartridge in 1887. Savage Arms was founded in 1894 by Arthur Savage in Utica, New York. Within 20 years Savage was producing rifles, handguns, and ammunition. Savage introduced the first hammerless lever-action rifle, the Model 1895, derived from Arthur Savage’s Model 1892 rifle that he had designed for Colt.

Story tip from EdLongrange. We welcome reader submissions.

June 12th, 2019

In response to a Bulletin story about Norma powders at Midsouth Shooters Supply, one of our Forum members asked: “I’m having trouble finding Reloder 15 for my 6.5×47 Lapua — should I consider running Norma 203B instead?” As we’ve explained before, these two powders, both made by Bofors in Europe, are very, very similar. Here are some hard numbers that should demonstrate how virtually identical these powders really are.

Target Shooter Magazine writer Laurie Holland compared Norma 203B and Reloder 15 using data from QuickLOAD. Laurie also checked load manuals to see how listed charge weights varied for the two propellants. Laurie concluded there was very little difference between Norma 203B and Reloder 15.

Norma 203B vs. Alliant Reloder 15 Norma 203B vs. Alliant Reloder 15

Commentary by Laurie Holland

Running [203B and RL15] through QuickLOAD doing a ‘charge table’ run for a 130gn Berger VLD at 2.700 COAL in 6.5X47 Lapua, gives very similar positions in the table [for both powders]. The charge required to achieve 62,000 psi estimated pressure varies by a mere 0.2 grains between the pair, Norma 203B being the heavier of the two. The estimated Muzzle Velocity (MV) also varies by a mere 2 fps, RL15 estimated to produce 2,946 fps MV compared to 2,944 fps for N203B at 62,000 psi (with the parameters I used).

If they aren’t the same thing, they’re so close as to make no difference and as Forum Boss points out, they’re made by the same people (Bofors) in the same plant.

[The Berger Reloading Manual includes data for both powders] for the .308 Winchester and heavier bullets (185 to 230 grains). Maximum charges and claimed MVs are not always identical, but are so close as to be marginally different production lots of the same thing, or maybe the result of minor testing variations.

.308 Win Max Charge Weights in Grains (RL15 / N203B) (Berger Manual)

MVs [for the four bullet types] are close but not identical, the largest difference being for the 210s which shows RL15 producing 2,428 fps MV v 2,383 for Norma 203B.

Norma 203B Chemistry

According to the Norma Reloading Handbook #1, Norma 203B has the following composition:

85% Nitrocellulose

7.5% Nitroglycerin

2.0% surface coating

4.6% Various chemicals

0.9% Water

3,957 J/g specific energy

890 g/l specific density

For comparison, the 7.5% NG component compares to 15% in Viht N500 series powders and 10% in Ramshot TAC / Big Game / Hunter.

|

With the Dasher since the new node (the sweet spot) was found at 33.4 grains, that resulted in a velocity of 3050 fps (a 125 fps velocity increase) from the same rifle setup. Not only did the velocity increase, but the SD was lowered to 3.6 with an ES of 13 (calculated over 28 shots). You read that right… 13 fps ES over 28 shots!

With the Dasher since the new node (the sweet spot) was found at 33.4 grains, that resulted in a velocity of 3050 fps (a 125 fps velocity increase) from the same rifle setup. Not only did the velocity increase, but the SD was lowered to 3.6 with an ES of 13 (calculated over 28 shots). You read that right… 13 fps ES over 28 shots!

Norma 203B vs. Alliant Reloder 15

Norma 203B vs. Alliant Reloder 15