|

|

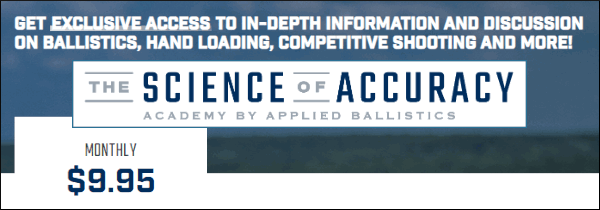

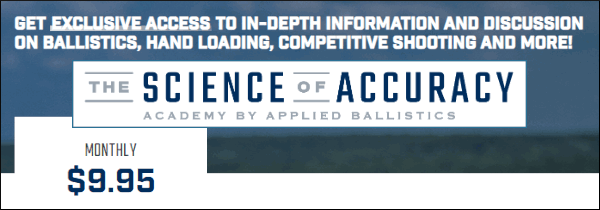

February 11th, 2026

The 2026 Southwest Nationals (SWN) start today, 2/11/2026, at the Ben Avery Range outside Phoenix, AZ. The big event starts with a 600-yard Mid-Range Match. Many of the nation’s most talented F-Class and sling shooters will be there. But no matter what your skill level, it is still possible to make major mistakes that can spoil the day and/or put you out of the running for the entire match. This article aims to help competitors avoid the big errors/oversights/failures, aka “train wrecks”, that can ruin a match.

Photo by Sherri Jo Gallagher.

In any shooting competition, you must try to avoid major screw-ups that can ruin your day (or your match). In this article, past F-TR National Mid-Range and Long Range Champion Bryan Litz talks about “Train Wrecks”, i.e. those big disasters (such as equipment failures) that can ruin a whole match. Bryan illustrates the types of “train wrecks” that commonly befall competitors, and he explains how to avoid these “unmitigated disasters”.

Urban Dictionary “Train Wreck” Definition: “A total @#$&! disaster … the kind that makes you want to shake your head.”

Train Wrecks (and How to Avoid Them) Train Wrecks (and How to Avoid Them)

by Bryan Litz of Applied Ballistics LLC

Success in long range competition depends on many things. Those who aspire to be competitive are usually detail-oriented, and focused on all the small things that might give them an edge. Unfortunately it’s common for shooters lose sight of the big picture — missing the forest for the trees, so to speak.

Consistency is one of the universal principles of successful shooting. The tournament champion is the shooter with the highest average performance over several days, often times not winning a single match. While you can win tournaments without an isolated stellar performance, you cannot win tournaments if you have a single train wreck performance. And this is why it’s important for the detail-oriented shooter to keep an eye out for potential “big picture” problems that can derail the train of success!

Train wrecks can be defined differently by shooters of various skill levels and categories. Anything from problems causing a miss, to problems causing a 3/4-MOA shift in wind zero can manifest as a train wreck, depending on the kind of shooting you’re doing.

Below is a list of common Shooting Match Train Wrecks, and suggestions for avoiding them.

1. Cross-Firing. The fastest and most common way to destroy your score (and any hopes of winning a tournament) is to cross-fire. The cure is obviously basic awareness of your target number on each shot, but you can stack the odds in your favor if you’re smart. For sling shooters, establish your Natural Point of Aim (NPA) and monitor that it doesn’t shift during your course of fire. If you’re doing this right, you’ll always come back on your target naturally, without deliberately checking each time. You should be doing this anyway, but avoiding cross-fires is another incentive for monitoring this important fundamental. In F-Class shooting, pay attention to how the rifle recoils, and where the crosshairs settle. If the crosshairs always settle to the right, either make an adjustment to your bipod, hold, or simply make sure to move back each shot. Also consider your scope. Running super high magnification can leave the number board out of the scope’s field view. That can really increase the risk of cross-firing.

2. Equipment Failure. There are a wide variety of equipment failures you may encounter at a match, from loose sight fasteners, to broken bipods, to high-round-count barrels that that suddenly “go south” (just to mention a few possibilities). Mechanical components can and do fail. The best policy is to put some thought into what the critical failure points are, monitor wear of these parts, and have spares ready. This is where an ounce of prevention can prevent a ton of train wreck. On this note, if you like running hot loads, consider whether that extra 20 fps is worth blowing up a bullet (10 points), sticking a bolt (DNF), or worse yet, causing injury to yourself or someone nearby.

3. Scoring/Pit Malfunction. Although not related to your shooting technique, doing things to insure you get at least fair treatment from your scorer and pit puller is a good idea. Try to meet the others on your target so they can associate a face with the shooter for whom they’re pulling. If you learn your scorer is a Democrat, it’s probably best not to tell Obama jokes before you go for record. If your pit puller is elderly, it may be unwise to shoot very rapidly and risk a shot being missed (by the pit worker), or having to call for a mark. Slowing down a second or two between shots might prevent a 5-minute delay and possibly an undeserved miss.

Photo by Sherri Jo Gallagher.

4. Wind Issues. Tricky winds derail many trains. A lot can be written about wind strategies, but here’s a simple tip about how to take the edge off a worse case scenario. You don’t have to start blazing away on the command of “Commence fire”. If the wind is blowing like a bastard when your time starts, just wait! You’re allotted 30 minutes to fire your string in long range slow fire. With average pit service, it might take you 10 minutes if you hustle, less in F-Class. Point being, you have about three times longer than you need. So let everyone else shoot through the storm and look for a window (or windows) of time which are not so adverse. Of course this is a risk, conditions might get worse if you wait. This is where judgment comes in. Just know you have options for managing time and keep an eye on the clock. Saving rounds in a slow fire match is a costly and embarrassing train wreck. 4. Wind Issues. Tricky winds derail many trains. A lot can be written about wind strategies, but here’s a simple tip about how to take the edge off a worse case scenario. You don’t have to start blazing away on the command of “Commence fire”. If the wind is blowing like a bastard when your time starts, just wait! You’re allotted 30 minutes to fire your string in long range slow fire. With average pit service, it might take you 10 minutes if you hustle, less in F-Class. Point being, you have about three times longer than you need. So let everyone else shoot through the storm and look for a window (or windows) of time which are not so adverse. Of course this is a risk, conditions might get worse if you wait. This is where judgment comes in. Just know you have options for managing time and keep an eye on the clock. Saving rounds in a slow fire match is a costly and embarrassing train wreck.

5. Mind Your Physical Health. While traveling for shooting matches, most shooters break their normal patterns of diet, sleep, alcohol consumption, etc. These disruptions to the norm can have detrimental effects on your body and your ability to shoot and even think clearly. If you’re used to an indoor job and eating salads in air-conditioned break rooms and you travel to a week-long rifle match which keeps you on your feet all day in 90-degree heat and high humidity, while eating greasy restaurant food, drinking beer and getting little sleep, then you might as well plan on daily train wrecks. If the match is four hours away, rather than leaving at 3:00 am and drinking five cups of coffee on the morning drive, arrive the night before and get a good night’s sleep.”

Keep focused on the important stuff. You never want to lose sight of the big picture. Keep the important, common sense things in mind as well as the minutia of meplat trimming, weighing powder to the kernel, and cleaning your barrel ’til it’s squeaky clean. Remember, all the little enhancements can’t make up for one big train wreck!

February 7th, 2026

Here’s a smart tip from Bryan Litz, explaining how damage to a bullet jacket can harm the projectile’s Ballistic Coefficient (BC). This tip is posted on Bryan’s new Bryan Litz Ballistics Facebook page. We recommend you subscribe to that page to access Bryan’s latest informative posts.

Bryan notes: “If the case mouth scratches the bullet when you seat it, the damage can cause the BC to be inconsistent, which shows up as vertical dispersion at long range.”

We see this sometimes when running Doppler Radar for competitors at Applied Ballistics Mobile Lab events. If someone is shooting a bullet that typically has a very consistent BC (1% or less) but they’re seeing a higher BC variation, it can be due to the bullets being damaged in the loading process.”

The lead photo above shows the badly-scratched jacket of a bullet seated in a rough-mouthed case. To prevent such jacket damage, one should chamfer, deburr, and smooth case mouths after trimming.

Below is a recorded Doppler radar result showing excessive BC variation. Such variation can increase vertical dispersion at long range. This can result in larger group sizes and lower scores.

February 2nd, 2026

“Shoot Like a Champion”. Bryan Litz, author of Applied Ballistics for Long-Range Shooting, says he often sees notes like this tucked in shooter’s gear (or taped to an ammo box) at matches. What “marksmanship mantras” do you use? Do you have a favorite quote that you keep in mind during competition? “Shoot Like a Champion”. Bryan Litz, author of Applied Ballistics for Long-Range Shooting, says he often sees notes like this tucked in shooter’s gear (or taped to an ammo box) at matches. What “marksmanship mantras” do you use? Do you have a favorite quote that you keep in mind during competition?

On the Applied Ballistics Facebook Page, Bryan invited other shooters to post the motivating words (and little reminders) they use in competition. Here are some of the best responses:

“Shoot 10s and No One Can Catch You…” — James Crofts

“You Can’t Miss Fast Enough to Win.” — G. Smith

“Forget the last shot. Shoot what you see!” — P. Kelley

“Breathe, relax, you’ve got this, just don’t [mess] up.” — S. Wolf

“It ain’t over ’til the fat lady sings.” — J. McEwen

“Keep calm and shoot V-Bull.” — R. Fortier

“Be still and know that I am God[.]” (PS 46:10) — D.J. Meyer

“Work Hard, Stay Humble.” — J. Snyder

“Shoot with your mind.” — K. Skarphedinsson

“The flags are lying.” — R. Cumbus

“Relax and Breathe.” — T. Fox

“Zero Excuses.” — M. Johnson

“SLOW DOWN!” — T. Shelton

“Aim Small.” — K. Buster

“Don’t Forget the Ammo!” (Taped on Gun Case) — Anonymous

PARTING SHOT: It’s not really a mantra, but Rick Jensen said his favorite quote was by gunsmith Stick Starks: “Them boys drove a long ways to suck”. Rick adds: “I don’t want to be that guy”, i.e. the subject of that remark.

February 1st, 2026

Wind-Reading Lesson from Bryan Litz

Q: What’s more important — wind speed, or direction?

A: Obviously they both matter, but they do trade dominance based on direction. For example, a 10 mph wind between 2:30 and 3:30 is only changing its value from 9.7 to 10 to 9.7 mph (bracket of 0.3 mph). However a 10 mph wind between 11:30 and 12:30 is changing its cross wind component value from 2.6 mph left to zero to 2.6 mph right (bracket of 5.2 mph). There is the same 30° change in direction, but this results in a massively different bracket.

Point being, in this case, a direction change is far more critical if it’s near 6 or 12 o’clock. A small direction change when it’s close to 3 or 9 o’clock is negligible.

On the contrary, a change in wind SPEED when it’s near 3 or 9 affects your crosswind component directly. But for a near head or tail wind, a fluctuation in wind speed only causes a small fraction of a change to the crosswind component.

SUMMARY: If you’re in a near full-value wind, pay more attention to wind SPEED. If you’re closer to a head- or tail-wind, nailing the exact DIRECTION will be more important.

Get More Tips on Bryan Litz Ballistics Facebook Page

This post is from the new Bryan Litz Ballistics Facebook Page. FB users should check that page regularly for more tips from Bryan, American’s leading ballistics expert and founder of Applied Ballistics LLC.

READ MORE TIPS HERE: www.Facebook.com/BryanLitzBallitics

Bryan Litz coaching Team USA in Canada using a WIND PLOT.

December 29th, 2025

When shooting any match that requires moving back and forth between multiple target distances it is very handy to have your ballistics data, i.e. your “come-ups”, placed within easy view. That way you can instantly see your elevation for various target distances in seconds. This can really help a PRS/NRL competitor on timed stages. And having a convenient “Dope” display of elevation at various distances can also benefit varminters who are shooting critters. In our varmint hunters we targeted p-dogs from about 80 yards out to 500+.

PRC DOPE Roller QD Ballistic Data Turret

The PRC DOPE Roller QD Ballistic Data Turret provides a handy, low profile display of windage and elevation data. You can see your “dope” without breaking position from behind the rifle. Then simply rotate the knob to display data from various distances. The ballistic data is placed by wrapping a simple 1″ x 3″ adhesive address label around the outside surface of the DOPE Roller. This handy quick-detach roller retails for $64.95 from Precision Rifle Components.

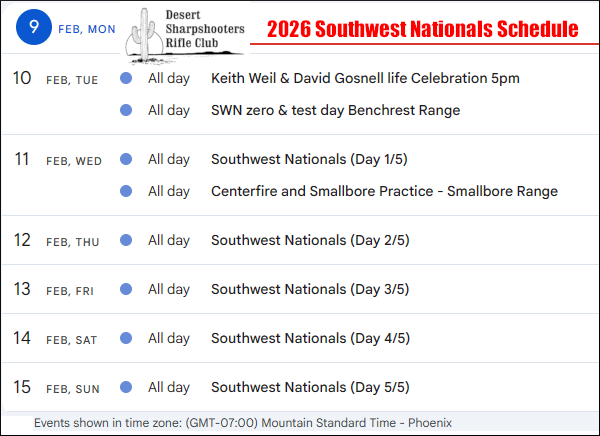

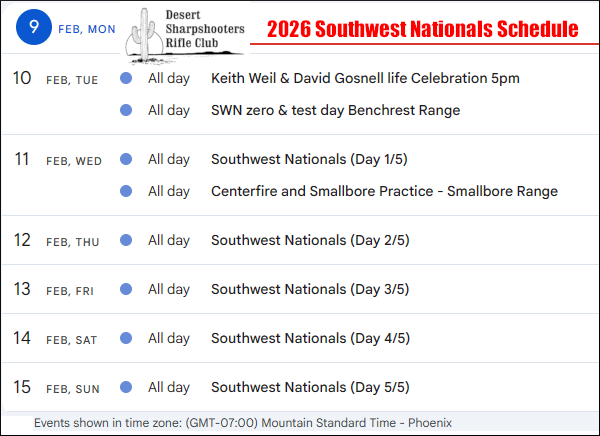

MDT M-LOK Data Card Holder

The MDT M-LOK Data Card Holder has an adjustable neck allowing you to easily position your ballistics data for optimal viewing. Data entries are written on on a reusable card that attaches with Velcro. The Data Card Holder Kit comes with hardware to mount to any M-Lok rail. In addition the card holder fits directly to an MDT ACC chassis attachment point. This MDT kit includes: M-LOK Data Card Holder, Wet Erase Data Card, Wet Erase Marker, and installation hardware. NOTE: The Card Holder sticks out about 6.7″ when fully extended, but arm links can be removed to make the arm shorter. The unit folds flat for storage. This complete kit is $59.95 at Creedmoor Sports.

Warne Universal Data Card Holder

The Warne Universal Data Card Holder easily attaches to the scope tube, in left or right configurations, for a universal fit. Data is displayed in a convenient location to make quick and accurate target transitions, and the articulating arm allows for low profile storage while not in use. The Warne Universal Data Card Holder retails for $88.49 at Warnescopemounts.com. Three ring sizes are offered: 30mm, 34mm, 35mm. A 50-pack of Warne Data Card label refills is currently $16.99 from Warne.

Scope-Cover Mounted Ballistics Table Scope-Cover Mounted Ballistics Table

Another option is to place your ballistics card on the back of the front flip-up scope cover. This set-up is used by Forum member Greg C. (aka “Rem40X”).

With your ‘come-up’ table on the flip-up cover you can check your windage and elevation drops easily without having to move out of shooting position.

Greg tells us: “Placing my trajectory table on the front scope cover has worked well for me for a couple of years and thought I’d share. It’s in plain view and not under my armpit. And the table is far enough away that my aging eyes can read it easily. To apply, just use clear tape on the front objective cover.”

Cheap But Effective — Tape on the Stock with Ballistics Data

At the 2021 Nightforce ELR Steel Challenge, Applied Ballistics guru Bryan Litz wrote his come-ups on blue masking tape applied to his stock. He did this based on a tip from Chase Stroud. With the tape applied behind the action, the numbers are easily visible. This “cheap trick” does work apparently — Bryan won the match with a convincing victory over 220 other shooters. READ Match Report.

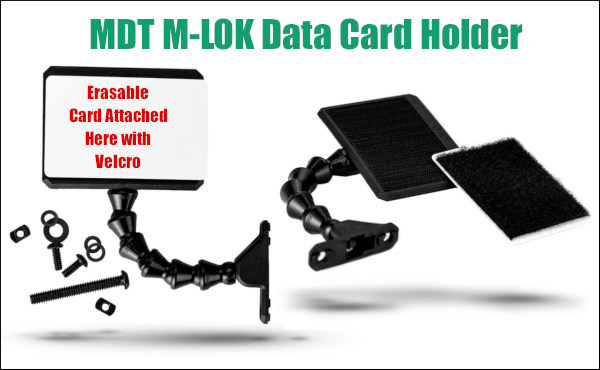

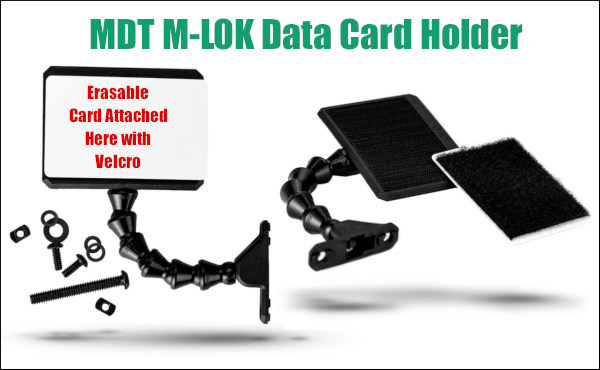

Cheap But NOT So Effective — Numbers on Hand

Many of us have scribbled some come-ups on the back of a hand or on our forearm using a marking pen. That can work if you only have a couple distances to deal with — say 100 and 300 yards. But if you want a more complete Come-up table, get one of the card-holders shown above. Writing numbers on the skin is generally not such a good idea….

December 16th, 2025

Photo shows Bryan Litz (on right) and tester Mitchell Fitzpatrick. Bryan said: “Only 2,445 rounds to go! We’re testing over 50 ammo types in five different twist barrels… science can be exhausting!”

Do you know the actual BC (Ballistic Coefficient) of your rimfire ammunition? Well Applied Ballistics has the data, thanks to a comprehensive, marathon ammo testing session. Some years back, in an effort to determine the “real world” BCs of various rimfire ammo types, Bryan Litz and his team at Applied Ballistics did an extraordinary, in-depth shooting test. Litz and company tested over fifty types of .22 LR ammo, using five different twist-rate barrels. This was one of the most comprehensive and through rimfire ammo tests ever done.

Bryan tolds us: “We tested many types of .22 rimfire ammo for the 2nd Edition of the Ballistic Performance of Rifle Bullets book. We used a pair of Oehler chronographs to measure velocity at the muzzle (MV) and velocity at 100 yards.” With these numbers (average and SD) Bryan can calculate G1 BCs for all the 50+ types of rimfire ammo. What’s more, because every sample is shot through five different barrels (each with a different twist rate) Bryan can also determine how velocity is affected by twist rate. Bryan tolds us: “We tested many types of .22 rimfire ammo for the 2nd Edition of the Ballistic Performance of Rifle Bullets book. We used a pair of Oehler chronographs to measure velocity at the muzzle (MV) and velocity at 100 yards.” With these numbers (average and SD) Bryan can calculate G1 BCs for all the 50+ types of rimfire ammo. What’s more, because every sample is shot through five different barrels (each with a different twist rate) Bryan can also determine how velocity is affected by twist rate.

The tests are primarily to determine velocities for BC calculations — this was not an accuracy test. Bryan explains: “Our tests are not really looking at accuracy, mainly because that’s so subjective to different rifles. Our testing is primarily focused on measuring the BC of rimfire rounds from different twist-rate barrels. The MVs and BCs from the different twist test barrels was then published by Applied Ballistics in print books. Bryan Litz told us: “The .22 LR Rimfire data was originally published in Ballistic Performance of Rifle Bullets, 2nd Edition, which is now out of print. The 3rd Edition of that book doesn’t have rimfire data. The rimfire testing results and data were re-published in Modern Advancements in Long Range Shooting – Volume II (along with many other topics).

Bringing Science to the Rimfire World

Bryan’s goal with this project was to increase the rimfire knowledge base: “We hope to give the world of .22 LR rimfire a good dose of science. How is the BC of .22 rimfire ammo affected by barrel twist? Do subsonic rounds have more consistent BCs than supersonic or transonic rounds? What brands have the highest BCs? What brands have the most consistent MVs?”

Data from two Oehler chronographs is recorded in a computer. Ammo samples were tested in five (5) different barrels (of varying twist rates). Give credit to Dane Hobbs who supplied a test rifle, multiple barrels, and most of the ammo types for the test.

.22 LR at 300 Yards?

Bryan also conducted some longer range rimfire tests. His interesting findings have appeared in the Modern Advancements in Long Range Shooting book series. Bryan notes: “While .22 rimfire isn’t typically considered ‘long range’, we were able to consistently hit a two-MOA steel target at 300 yards with the trajectory predicted by AB software and the measured BC of some standard .22 LR rimfire ammo. The info we’’re generating may make it possible to push the range of target engagement for a round that’s not seen much advancement in many decades.”

December 1st, 2025

Figure 1. When the bullet is seated farther out of the case, there is more volume available for powder. This enables the cartridge to generate higher muzzle velocity with the same pressure.

Effects Of Cartridge Over All Length (COAL) And Cartridge Base To Ogive (CBTO) – Part 1 Effects Of Cartridge Over All Length (COAL) And Cartridge Base To Ogive (CBTO) – Part 1

by Bryan Litz for Berger Bullets.

Many shooters are not aware of the dramatic effects that bullet seating depth can have on the pressure and velocity generated by a rifle cartridge. Cartridge Overall Length (COAL) is also a variable that can be used to fine-tune accuracy. It’s also an important consideration for rifles that need to feed rounds through a magazine. In this article, we’ll explore the various effects of COAL, and what choices a shooter can make to maximize the effectiveness of their hand loads.

Sporting Arms and Ammunition Manufacturers’ Institute (SAAMI)

Most loading manuals (including the Berger Manual), present loading data according to SAAMI (Sporting Arms and Ammunition Manufacturers’ Institute) standards. SAAMI provides max pressure, COAL and many other specifications for commercial cartridges so that rifle makers, ammo makers, and hand loaders can standardize their products so they all work together. As we’ll see later in this article, these SAAMI standards are in many cases outdated and can dramatically restrict the performance potential of a cartridge.

Bullet seating depth is an important variable in the accuracy equation. In many cases, the SAAMI-specified COAL is shorter than what a hand loader wants to load their rounds to for accuracy purposes. In the case where a hand loader seats the bullets longer than SAAMI specified COAL, there are some internal ballistic effects that take place which are important to understand.

Effects of Seating Depth / COAL on Pressure and Velocity

The primary effect of loading a cartridge long is that it leaves more internal volume inside the cartridge. This extra internal volume has a well known effect; for a given powder charge, there will be less pressure and less velocity produced because of the extra empty space. Another way to look at this is you have to use more powder to achieve the same pressure and velocity when the bullet is seated out long. In fact, the extra powder you can add to a cartridge with the bullet seated long will allow you to achieve greater velocity at the same pressure than a cartridge with a bullet seated short.

When you think about it, it makes good sense. After all, when you seat the bullet out longer and leave more internal case volume for powder, you’re effectively making the cartridge into a bigger cartridge by increasing the size of the combustion chamber. Figure 1 illustrates the extra volume that’s available for powder when the bullet is seated out long.

Before concluding that it’s a good idea to start seating your bullets longer than SAAMI spec length, there are a few things to consider.

Geometry of a Chamber Throat

The chamber in a rifle will have a certain throat length which will dictate how long a bullet can be loaded. The throat is the forward portion of the chamber that has no rifling. The portion of the bullet’s bearing surface that projects out of the case occupies the throat (see Figure 2).

The length of the throat determines how much of the bullet can stick out of the case. When a cartridge is chambered and the bullet encounters the beginning of the rifling, known as the lands, it’s met with hard resistance. This COAL marks the maximum length that a bullet can be seated. When a bullet is seated out to contact the lands, its initial forward motion during ignition is immediately resisted by an engraving force.

Seating a bullet against the lands causes pressures to be elevated noticeably higher than if the bullet were seated just a few thousandths of an inch off the lands.

A very common practice in precision reloading is to establish the COAL for a bullet that’s seated to touch the lands. This is a reference length that the hand loader works from when searching for the optimal seating depth for precision. Many times, the best seating depth is with the bullet touching or very near the lands. However, in some rifles, the best seating depth might be 0.100″ or more off the lands. This is simply a variable the hand loader uses to tune the precision of a rifle.

CLICK HERE to Read Full Article with More Info

November 22nd, 2025

Bryan Litz and The Science of Accuracy Academy have released a Podcast with vital information for all handloaders. This Podcast examines the effects of humidity variances on powder. Bryan notes: “If you want to know how much this can matter, we’re talking up to 200 fps difference for the same load of H4350 in 6.5 Creedmoor” at opposite extremes of humidity.

Bryan adds that “Most shooters don’t realize what a big deal this can be — it overshadows many of our efforts to make consistent velocity and hit targets. This can happen in loaded rounds not just for hand loading where you expose powder to ambient humidity. This is especially important for hunters considering the range of environments hunting ammo goes through.”

Subscriptions for Applied Ballistics The Science of Accuracy Academy Podcasts

If you like this podcast, and want to learn more from Brian Litz and his Applied Ballistics team, you can order a subscription to the Academy. Priced at $9.95/mo, this subscription will allow you to access all podcasts, exclusive videos, learning resources, and bullet data sheets.

November 13th, 2025

The USAMU has published a “how-to” article about bullet sorting. While many of us may sort bullets by base-to-ogive length (and/or weight), the USAMU story explores the “how and why” of sorting bullets by Overall Length (OAL). Read the article highlights below, and make your own decision as to whether OAL sorting is worth the time and effort. Bryan Litz of Applied Ballistics says that sorting by OAL is not a bad idea, but base-to-ogive bullet sorting probably represents a better investment of your time.

Bullet Sorting by Overall Length

We’d like to share a specialized handloading technique which we’ve long found beneficial to our long-range (600 yards and beyond) accuracy. Sorting of bullets for extreme long range (LR) accuracy is not difficult to do, but some background in theory is needed.

Here at USAMU’s Handloading Shop, we only sort individual bullets for the most demanding Long-Range applications and important competitions. Only the most accurate rifles and shooters can fully exploit the benefits of this technique. The basic sorting process involves measuring the Overall Length (OAL) of the bullets, and grouping them in 0.001″ increments. It’s not unusual to find lots of match bullets that vary as much as 0.015″-0.020″ in length throughout the lot, although lots with much less variation are seen as well. Even in bullet lots with 0.015″ OAL variation, the bullet base-to-ogive length will show much less variation. Hence, our basic sort is by bullet OAL. One obvious benefit of sorting is easily seen in the attached photo. The few bullets that are VERY different from the average are culled out, reducing probable fliers.

How does one know what OAL increments to use when sorting? The answer is simple. As each lot of bullets is unique in its OAL distribution, it’s best to sample your bullet lot and see how they are distributed. In the attached photo, you will see a set of loading trays with a strip of masking tape running along the bottom. Each vertical row of holes is numbered in 0.001″ increments corresponding to the bullets’ OAL. A digital caliper makes this task much easier. As each bullet is measured, it is placed in the line of holes for its’ OAL, and gradually, a roughly bell-shaped curve begins to form.

Note that near the center, bullets are much more plentiful than near the edges. At the extreme edges, there are a few that differ markedly from the average, and these make great chronograph or sighting-in fodder. We recommend using a sample of 200 bullets from your lot, and 300 is even better. Some bullet lots are very consistent, with a tall, narrow band of highly-uniform bullets clustered together over just a few thousandths spread. Other lots will show a long, relatively flat curve (less uniform), and you may also see curves with 2 or more “spikes” separated by several 0.001″ OAL increments.

Bullet Sorting — OAL vs. Base-to-Ogive vs. Weight

Expert advice from Bryan Litz, Applied Ballistics

I’m often asked what is a the best measure to sort bullets by, and the answer (to this and many other questions in ballistics) is: it depends.

Choosing to sort by overall length (OAL), base to ogive (BTO), bearing surface, weight, etc. can get overwhelming. Shooters typically look for something they can measure, which shows a variation and sort by that. It’s common for dimensional variations to correlate. For example, bullets which are longer in OAL are typically also shorter in BTO, and have longer noses. All these are symptoms of a bullet that was pushed a little further into the pointing die, or possibly had more than average lube while being swaged. So in essence, if you sort by BTO, you’re measuring one symptom which can indicate a pattern in the bullets shape.

So, the question still stands — what should you measure? You’ll always see more variation in OAL than BTO, so it’s easier to sort by OAL. But sometimes the bullet tips can be jagged and have small burrs which can be misleading. Measuring BTO will result in a lower spread, but is a more direct measure of bullet uniformity.

Then there’s the question of; how much variation is too much, or, how many bins should you sort into? Shooters who see 0.025” variation in BTO may choose to sort into 5 bins of 0.005”. But if you have only 0.005” variation in the box, you’ll still sort into 5 bins of 0.001”. What’s correct? You have to shoot to know. Live fire testing will answer more questions, and answer them more decisively than any amount of discussion on the subject. The test I recommend is to identify bullets on the extreme short end of the spectrum, and some on the extreme long end. Load at least 10 rounds of each, and take turns shooting 5-shot groups with them. If there is a difference, it will be evident. The results of the testing will answer your question of: should I sort based on X, Y, or Z?”

You can read more discussions on this and other similar subjects in our Accurateshooter.com Shooters’ Forum. Here’s a link to a thread discussing bullet sorting: Bullet Sorting Thread

October 3rd, 2025

With hunting season in full swing, many folks will be shooting factory hunting ammunition. In setting scope elevation clicks for various distances, it would seem logical to use the velocity listed on the ammo box with your ballistics App or drop chart. But that could be a problem. You SHOULD still chronograph the ammo to determine its true velocity in your rifle. Read on to understand why. With hunting season in full swing, many folks will be shooting factory hunting ammunition. In setting scope elevation clicks for various distances, it would seem logical to use the velocity listed on the ammo box with your ballistics App or drop chart. But that could be a problem. You SHOULD still chronograph the ammo to determine its true velocity in your rifle. Read on to understand why.

Why You CANNOT Rely on the Muzzle Velocity

Printed on the Ammo Box!

When figuring out your come-ups with a ballistics solver or drop chart it’s “mission critical” to have an accurate muzzle velocity (MV). When shooting factory ammo, it’s tempting to use the manufacturer-provided MV which may be printed on the package. That’s not such a great idea says Bryan Litz of Applied Ballistics. Don’t rely on the MV on the box, Bryan advises — you should take out your chrono and run your own velocity tests. There are a number of reasons why the MV values on ammo packaging may be inaccurate. Below is a discussion of factory ammo MV from the Applied Ballistics Facebook Page.

Five Reasons You Cannot Trust the Velocity on a Box of Ammo:

1. You have no idea about the rifle used for the MV test.

2. You have no idea what atmospheric conditions were during testing, and yes it matters a lot.

3. You have no idea of the SD for the factory ammo, and how the manufacturer derived the MV from that SD. (Marketing plays a role here).

4. You have no idea of the precision and quality of chronograph(s) used for velocity testing.

5. You have no idea if the manufacturer used the raw velocity, or back-calculated the MV. The BC used to back track that data is also unknown.

1. The factory test rifle and your rifle are not the same. Aside from having a different chamber, and possibly barrel length some other things are important too like the barrel twist rate, and how much wear was in the barrel. Was it just recently cleaned, has it ever been cleaned? You simply don’t know anything about the rifle used in testing.

2. Temperature and Humidity conditions may be quite different (than during testing). Temperature has a physical effect on powder, which changes how it burns. Couple this with the fact that different powders can vary in temp-stability quite a bit. You just don’t know what the conditions at the time of testing were. Also a lot of factory ammunition is loaded with powder that is meter friendly. Meter friendly can often times be ball powder, which is less temperature stable than stick powder often times.

3. The ammo’s Standard Deviation (SD) is unknown. You will often notice that while MV is often listed on ammo packages, Standard Deviation (normally) is not. It is not uncommon for factory ammunition to have an SD of 18 or higher. Sometimes as high as 40+. As such is the nature of metering powder. With marketing in mind, did they pick the high, low, or average end of the SD? We really don’t know. You won’t either until you test it for yourself. For hand-loaded ammo, to be considered around 10 fps or less. Having a high SD is often the nature of metered powder and factory loads. The image below is from Modern Advancements in Long Range Shooting: Volume II.

4. You don’t know how MV was measured. What chronograph system did the manufacturer use, and how did they back track to a muzzle velocity? A chronograph does not measure true velocity at the muzzle; it simply measures velocity at the location it is sitting. So you need to back-calculate the distance from the chrono to the end of the barrel. This calculation requires a semi-accurate BC. So whose BC was used to back track to the muzzle or did the manufacturer even do that? Did they simply print the numbers displayed by the chronograph? What kind of chronograph setup did they use? We know from our Lab Testing that not all chronographs are created equal. Without knowing what chronograph was used, you have no idea the quality of the measurement.

5. The MV data may not be current. Does the manufacturer update that data for every lot? Or is it the same data from years ago? Some manufacturers rarely if ever re-test and update information. Some update it every lot (ABM Ammo is actually tested every single lot for 1% consistency). Without knowing this information, you could be using data for years ago.

CONCLUSION: Never use the printed MV off a box of ammo as anything more than a starting point, there are too many factors to account for. You must always either test for the MV with a chronograph, or use carefully obtained, live fire data. When you are using a Ballistic Solver such as the AB Apps or Devices integrated with AB, you need to know the MV to an accuracy down to 5 fps. The more reliable the MV number, the better your ballistics solutions.

|

Train Wrecks (and How to Avoid Them)

Train Wrecks (and How to Avoid Them)

4. Wind Issues. Tricky winds derail many trains. A lot can be written about wind strategies, but here’s a simple tip about how to take the edge off a worse case scenario. You don’t have to start blazing away on the command of “Commence fire”. If the wind is blowing like a bastard when your time starts, just wait! You’re allotted 30 minutes to fire your string in long range slow fire. With average pit service, it might take you 10 minutes if you hustle, less in F-Class. Point being, you have about three times longer than you need. So let everyone else shoot through the storm and look for a window (or windows) of time which are not so adverse. Of course this is a risk, conditions might get worse if you wait. This is where judgment comes in. Just know you have options for managing time and keep an eye on the clock. Saving rounds in a slow fire match is a costly and embarrassing train wreck.

4. Wind Issues. Tricky winds derail many trains. A lot can be written about wind strategies, but here’s a simple tip about how to take the edge off a worse case scenario. You don’t have to start blazing away on the command of “Commence fire”. If the wind is blowing like a bastard when your time starts, just wait! You’re allotted 30 minutes to fire your string in long range slow fire. With average pit service, it might take you 10 minutes if you hustle, less in F-Class. Point being, you have about three times longer than you need. So let everyone else shoot through the storm and look for a window (or windows) of time which are not so adverse. Of course this is a risk, conditions might get worse if you wait. This is where judgment comes in. Just know you have options for managing time and keep an eye on the clock. Saving rounds in a slow fire match is a costly and embarrassing train wreck.

“Shoot Like a Champion”. Bryan Litz, author of

“Shoot Like a Champion”. Bryan Litz, author of

Scope-Cover Mounted Ballistics Table

Scope-Cover Mounted Ballistics Table

Bryan tolds us: “We tested many types of .22 rimfire ammo for the 2nd Edition of the

Bryan tolds us: “We tested many types of .22 rimfire ammo for the 2nd Edition of the

Effects Of Cartridge Over All Length (COAL) And Cartridge Base To Ogive (CBTO) – Part 1

Effects Of Cartridge Over All Length (COAL) And Cartridge Base To Ogive (CBTO) – Part 1