|

|

August 21st, 2015

Need a boatload of bullets for varmint safaris, or high-volume AR-platform training sessions? Then check out this deal from Midsouth Shooters Supply. Right now you can get six THOUSAND .22-Cal 55gr softpoint bullets for $463.66 delivered. That works out to just $7.73 per 100 bullets. And yes, for a limited time, that price includes FREE Shipping (through August 28, 2015). If you have high-volume applications for .224-diameter projectiles, this deal is hard to beat. You could easily pay two to three tiems as much (per hundred) for similar bullets elsewhere. Buying in bulk saves big bucks.

These 55g Soft Point bullets are made by Hornady. The G1 Ballistic Coefficient (BC) is 0.243. Hornady says these bullets have a “match-grade jacket design” and offer “explosive expansion, even at low velocities”. NOTE: Midsouth also offers Hornady FMJ 55gr 22-cal bullets at low bulk prices.

January 11th, 2015

Georgia-based PolyCase Ammunition has developed innovative polymer-based composite cartridge cases and injection-molded bullets. With a patent-pending design, the polymer cartridge cases are lighter than brass or steel cases, yet are heat-tolerant, and relatively easy to manufacture. These cases will be initially produced for .223 Remington, plus a variety of pistol cartridge types (.380 ACP, .38 SPL, 9mm Luger). PolyCase cartridge cases blend patented heat-resistent polymers with metal elements in the case base. According to the manufacturer, “the net effects are greatly reduced weight (compared to comparable loaded ammunition), durability… and competitive pricing.” Other companies have experimented with polymer cartridge cases in the past — none have successfully perfected the technology in a commercially successful product. Could PolyCase be the first?

PolyCase Ammunition — Material Characteristics

– PolyCase Pistol Cartridge Cases are 11.5 to 20% lighter than brass-cased ammunition.

– PolyCase Rifle Cartridge Cases are 23 to 60% lighter than brass-cased ammunition.

– PolyCase Cartridge Cases are self-lubricating — a positive factor compared to brass or steel cases.

PolyCase Bullets — Injection-Molded Blend of Copper and Plastic

PolyCase has developed its own unique bullets for use in pistol ammunition. PolyCase Cu/P™ bullets are precision injection-molded from a cutting-edge copper-polymer compound. These molded bullets will be offered in both polymer cases and conventional brass cases. (Early in the design process, PolyCase determined that molded bullets work well in both brass and plastic cases). PolyCase co-owner Paul Lemke (Lt. Col. U.S. Army, Ret.) says: “We are able to use essentially the same molds to produce bullets for brass casings and bullets for our polymer casings”.

PolyCase Pioneers Injection-Molded Bullet Technology

Powdered metal has been around for decades, but blending powdered metal with polymers and injection molding precise parts is a fairly modern process. While processes like sintered metal bullets and pressure-formed shotgun pellets have become commonplace, PolyCase is the first American company to produce and sell a completely injection-molded bullet.

For over a century most bullets have been mass-produced with a process called cold-forming. Lead and copper were shaped with brute force in punches and dies to create projectiles. While this is still a viable and effective way to produce bullets, other manufacturing methods are now available. By applying injection-molding technology, Polycase has developed a new type of bullet that has many advantages, as least for handgun applications. Bullets weigh approximately 70% as much as lead bullets with similar profiles. Lighter weight means higher velocities and less recoil. In addition, PolyCase bullets are lead-free, and low ricochet — two qualities important for indoor and close-range training. The injection-molding process also reduces weight variations (compared to cast lead bullets), and ensures excellent concentricity. Molding also allows unique shapes that are impossible to produce with conventional bullet-making methods (see photo).

September 19th, 2014

Here is a simple technique that can potentially help you load straighter ammo, with less run-out. It costs nothing and adds only a few seconds to the time needed to load a cartridge. Next time you’re loading ammo with a threaded (screw-in) seating die, try seating the bullet in two stages. Run the cartridge up in the seating die just enough to seat the bullet half way. Then lower the cartridge and rotate it 180° in the shell-holder. Now raise the cartridge up into the die again and finish seating the bullet. Here is a simple technique that can potentially help you load straighter ammo, with less run-out. It costs nothing and adds only a few seconds to the time needed to load a cartridge. Next time you’re loading ammo with a threaded (screw-in) seating die, try seating the bullet in two stages. Run the cartridge up in the seating die just enough to seat the bullet half way. Then lower the cartridge and rotate it 180° in the shell-holder. Now raise the cartridge up into the die again and finish seating the bullet.

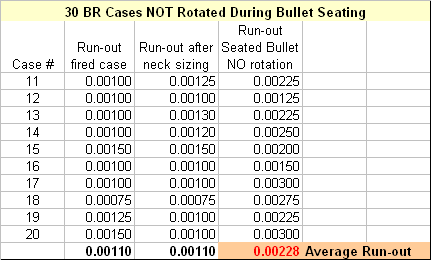

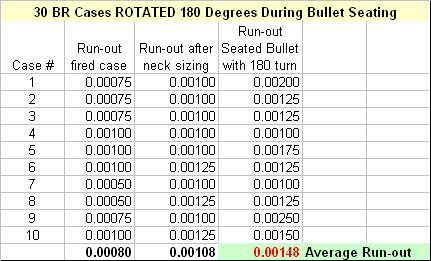

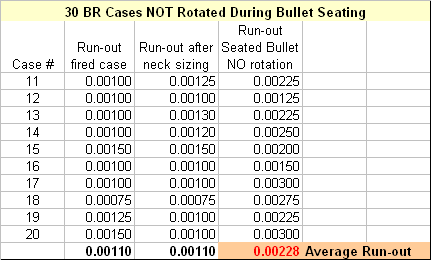

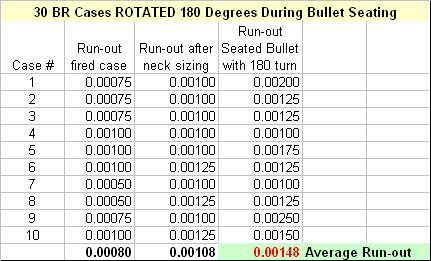

Steve, aka “Short Range”, one of our Forum members, recently inquired about run-out apparently caused by his bullet-seating process. Steve’s 30BR cases were coming out of his neck-sizer with good concentricity, but the run-out nearly doubled after he seated the bullets. At the suggestion of other Forum members, Steve tried the process of rotating his cartridge while seating his bullet. Steve then measured run-out on his loaded rounds. To his surprise there was a noticeable reduction in run-out on the cases which had been rotated during seating. Steve explains: “For the rounds that I loaded yesterday, I seated the bullet half-way, and turned the round 180 degrees, and finished seating the bullet. That reduced the bullet runout by almost half on most rounds compared to the measurements from the first test.”

Steve recorded run-out measurements on his 30BR brass using both the conventional (one-pass) seating procedure, as well as the two-stage (with 180° rotation) method. Steve’s measurements are collected in the two charts above. As you can see, the run-out was less for the rounds which were rotated during seating. Note, the change is pretty small (less than .001″ on average), but every little bit helps in the accuracy game. If you use a threaded (screw-in) seating die, you might try this two-stage bullet-seating method. Rotating your case in the middle of the seating process won’t cost you a penny, and it just might produce straighter ammo (nothing is guaranteed). If you do NOT see any improvement on the target, you can always go back to seating your bullets in one pass. READ Forum Thread….

August 6th, 2014

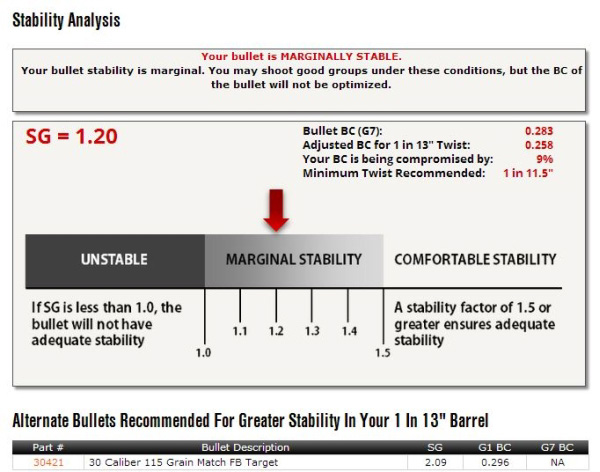

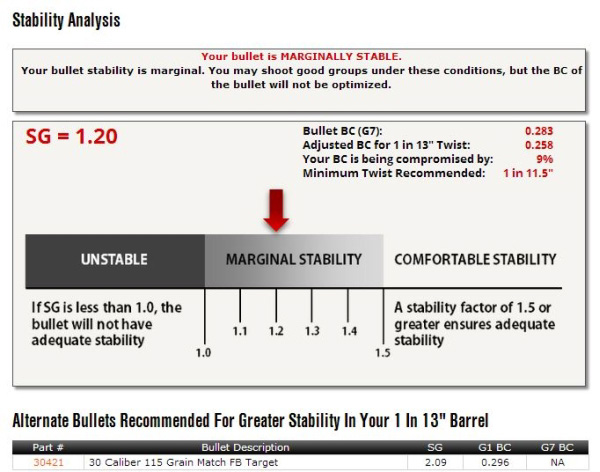

Berger Bullets has improved its online stability calculator. Tests have shown that bullets can suffer from reduced BC if the bullet rpm (spin rate) is less than optimal, even if barrel twist rate is otherwise fast enough to stabilize bullets in flight. Now, the improved, free Stability Calculator can determine if you need a faster-twist barrel to enjoy the best BC from your bullets.

CLICK HERE for FREE Berger Twist Rate Stability Calculator

By Bryan Litz, Chief Ballistician for Berger Bullets

We’re happy to announce a major upgrade to our Twist Rate Stability Calculator which is free to use on the Berger Bullets webpage. The old stability calculator was pretty basic, and would simply return a gyroscopic stability number based on your bullet, twist rate, and atmospheric conditions. This was used to determine if your barrels twist rate was fast enough to stabilize a particular bullet or not, based on the Gyroscopic Stability Factor (SG) being greater than 1.4.

Stability and BC — How Bullet RPM Affects Ballistic Coefficients

The new calculator still calculates SG, but also goes much further. In addition to calculating stability, the upgraded calculator can also tell you if your stability level is harming the effective BC of your bullets or not. Extensive testing has proven that bullets fired with stability levels between 1.2 and 1.5 can fly with excellent precision (good groups), but suffer from a depressed BC, sometimes as much as 10%. Shooting the bullets from faster twist rate barrels allows for the bullets to fly better and realize their full BC potential.

August 3rd, 2014

Need something for the walls of your “man cave” or reloading room? Check out these jumbo-size cartridge posters. The creators of the Cartridge Comparison Guide now offer three very large full-color printed posters. These can be tacked to a wall or matted/framed to hang like paintings. Three different posters are available.

Rifleman’s Classic Poster (38″ x 27″)

The Rifleman’s Classic Poster, a full 38 inches wide and 27 inches tall, is the most comprehensive. This $19.95 poster displays 272 rifle cartridge types at true size (within 4/1000 of an inch). Cartridges shown range from .17 caliber all the way up to the big boomers (including some cannon shells). The Rifleman’s Classic poster includes all American Standardized Rifle Cartridges (as of 2013) and many European rifle cartridges. The poster is a good representation of military cartridges dating back to WWI and includes cartridges such as the 13X92mm MSR and the .55 Boys.

CLICK Image to Enlarge:

American Standard Cartridge Poster (Rifle, Handgun, Shotgun) — $15.95

The 36″ x 24″ American Standard Poster displays 165 rifle cartridges, 55 handgun cartridges, and 9 different shotgun gauges. This includes all American Standardized Cartridges (rifle, handgun, and shotgun) available as of January 2012. All cartridge types are displayed in full color, actual size. The rifle selection includes all standard hunting cartridges from the 17 Mach 2 through the .505 Gibbs and .577 Nitro. Bonus cartridges include the .375 and .408 Chey-Tac, .416 Barrett, .50 BMG, 50-20 and 20mm. The Handgun section covers cartridges from the 17 HMR to the 500 S&W. Shotgun cartridges include the .410 and 32 gauge up to the 8 gauge. NOTE: Wildcat, proprietary, and obsolete-historic cartridges are NOT included in this poster.

CLICK Image to Enlarge:

BIG BORE Cartridge Poster (215 Cartridges) — $15.95

The 36″ x 24″ Big Bore Poster illustrates over 215 large=caliber rifle cartridges, all shown actual size in full color. These include Standard, Historic, Military, Proprietary and Wildcat rifle cartridges side by side. Cartridges illustrated range from the subsonic .338 Spectre up to the monstrous .729 Jongmans. The poster also includes historically significant cartridges such as the 12 Gauge Paradox, 4 Bore, 1″ Nordfelt, 50 BAT Spotter, .50 BMG, .5 Vickers, 12.7×108 Russian, 20mm, 25mm, 30mm and more.

CLICK Image to Enlarge:

June 21st, 2014

Waterloo Labs is a group of engineers from National Instruments and other self-declared “nerds” from Austin, Texas. These folks conducted an interesting demonstration using electronic accelerometers to plot bullet impacts from a suppressed Ruger MKIII .22LR pistol. The accelerometers respond to vibrations caused when the bullets hit a drywall target backer. By triangulating data from multiple accelerometers, each shot’s exact point of impact can be plotted with great precision. These point-of-impact coordinates are then fed into a computer and super-imposed into a Flash version of the Half-Life video game (which is projected on the drywall board). The end result is being able to “play” a video game with a real firearm.

Do-It-Yourself Electronic Target System? Do-It-Yourself Electronic Target System?

Now, we are NOT particularly interested in shooting Zombies in a video game. However, the technology has interesting potential applications for real shooters. Waterloo Labs has published the computer code, used to triangulate bullet impacts from multiple accelerometers. Potentially, a system like this could be built to provide display and scoring of long-range targets. Sophisticated electronic target systems already exist, but they use proprietary hardware and software, and they are very expensive. The Waterloo Labs experiment shows that shooters with some computer and electronic skills could build their own electronic scoring system, one that can be adapted to a variety of target sizes and materials.

In addition, we imagine this system could be utilized for military and law enforcement training. The walls of structures used for “live-fire” room-clearing exercises could be fitted with accelerometers so the bullet impacts could be plotted and studied. Then, later, the impact plots could be combined with a computer simulation so that trainees could “replay” their live-fire sessions, viewing the actual location of their hits (and misses).

Credit The Firearm Blog for finding this Waterloo Labs project.

December 14th, 2013

Lapua just dropped a bombshell — multiple bombshells, in fact. Lapua just announced that it will be producing .221 Fireball brass and .50 BMG brass starting early 2014. This will be the first truly match-grade brass ever offered for the .221 Fireball. That’s great news for varminters, who can use Lapua’s new .221 Fireball brass “as is” or neck it down to .20 Vartarg or 17 Fireball. Tactical shooters can also use the .221 Fireball brass to make the .300 Whisper and 300 Blackout sub-sonic cartridges. At the other end of the spectrum, ultra-long-range shooters now have a new ultra-premium brass source for the mighty .50 BMG. This is potentially a “game-changer” for fifty-cal shooters who have had to “make do” with military surplus brass for the most part. Lapua says the new brass, both .50 BMG and .221 Fireball, should be in the USA by early April, 2014. Sorry, no pricing info is yet available.

Here is the Lapua Product Announcement for .221 Fireball and .50 BMG Brass:

New 180-Grain and 150-Grain 7mm Scenar-L Bullets

The other big news from Lapua is the release of two new 7mm (.284 caliber) Scenar-L target bullets. Recognizing the popularity of 7mm cartridges among F-Class Open Division shooters, Lapua will offer a high-BC, 180-grain bullet. As part of the “L” series, this new 180-grainer bullet should exhibit extreme consistency in base-to-ogive measurements and bullet weight. We expect this new 180gr projectile to be extremely accurate in the .284 Winchester, .284 Shehane, 7mm WSM, and 7mm RSAUM — popular chamberings for F-Class and long-range benchrest shooters. No BC information has been released yet, but we expect the BC number to be quite high, giving this bullet great wind-bucking capability. In addition to the new 180gr 7mm Scenar-L, Lapua will offer a new 150gr 7mm bullet. This is optimized for medium range competition in Silhouette and Across-the-Course competition. It should offer great accuracy, but with less felt recoil than its 180-grain bigger brother.

November 2nd, 2013

The last primary lead smelter facility in the United States will be closing soon. The Doe Run Company smelter in Herculaneum, Missouri has been operating since 1892. The facility will be closed permanently under pressure from the EPA. According to MSNBC.com: “Doe Run Co. was ordered by the EPA to install new pollution control technologies needed to reduce sulfur dioxide and lead emissions as required by the Clean Air Act. The company will instead close its lead smelter.”

Doe Run started life in 1864 as the St. Joseph Lead Company, better known as St. Joe, which started lead mining on a small scale in southeastern Missouri. In 1892 it started up its smelter in Herculaneum, where all smelting was consolidated in 1920.

Cause for Concern? Our readers have been concerned that the closure of the Doe Run smelter will lead to serious shortages in raw materials for bullet-making. Readers fear that bullet-makers won’t be able to source lead, and so the output of bullets and ammo would be reduced. Curtailed bullet production would lead to higher prices, it is feared.

As it turns out, the situation is not as dire as it seems. At least one bullet-maker says the Doe Run smelter closure will have no immediate effect on its raw material supply chain.

Sierra Bullets Responds: Lead Smelter Closure Should Not Cause Supply Shortage

Addressing the issue of supply shortages, Sierra Bullets posted a notice in the Sierra Blog on November 1, 2013. Sierra Bullets Plant Engineer Darren Leskiw stated that the Doe Run smelter closure should create no problems for his company because it uses only recycled lead:

We have had many customers contact us about the closing of the last primary lead smelting facility in the USA. This facility is operated by Doe Run and is located in Herculaneum, Missouri and is just about a 3-hour drive from our facility in Sedalia, Missouri.

The main question asked is “Will this shut down your supply of lead?” The answer to that is no. First, Sierra buys lead from several different vendors to maintain constant supply. Second, this facility only smelts primary lead or lead ore. This is lead ore that has just been brought out of the earth. Sierra uses no primary lead at all and never has, so we use nothing directly from this facility. The lead we buy from Doe Run comes from their recycling facility in Boss, MO that is about 90 miles away from the smelter that is closing.

The facility we buy from is still going strong and delivering to us as scheduled. The lead from this facility is from recycled lead, mostly coming from car batteries. This is a continuing “in and out” cycle for them and the smelter closing will not affect this facility.

Our supply should not be in jeopardy and we do not anticipate any changes in our supply chain at this time. Could the lack of primary lead create a little more demand for recycled lead? Sure, but how much is unknown. Could this increase in demand also create an increase in price? Sure, but again, by how much is unknown at this time.

There are many other primary lead smelters in the world and so the flow of primary lead will not be shut off. Where there is a need for primary lead, I am sure there will be a salesman more than happy to pick up the business. In short, we do not see any reason for alarm. We expect our supply to continue and keep feeding our production lines which are still running 24 hours per day to return our inventory levels to where they should be.

Lead Smelting Operations Have Moved to Mexico

Posting on SnipersHide.com, one industry insider says shooters should not be overly concerned about the Doe Run shut-down, because smelting is still being done in nearby Mexico:

“The lead industry has been transitioning out of the United States for over a decade now. 85% of the lead smelting industry capacity migrated over the Mexican border where there are [fewer environmental regulations]. The remainder of production capacity will be online and running by the third quarter of 2014. There has been no production disruption to speak of in obtaining lead or lead products. The auto battery industry among others has prepared for this eventuality for some time….

The last lead smelter closing in December did not have enough capacity to supply even 10% of the battery industry much less the ammunition industry. The lead being used in ammunition today hasn’t been coming from the United States for years already. The closing of that plant will not have any appreciable effect on lead availability at all. There is a great deal of lead processed here being extruded, made into shot, converted to wire, etc., but the smelting operation is only one part of the production process.”

July 23rd, 2013

On the Applied Ballistics Facebook page, Ballistician Bryan Litz regularly offers a “Tuesday Trivia” question about ballistics. Today’s brain-teaser is a true/false question about bullet stabilization. On shooting forums you often find heated arguments about “over-stabilization”. Bryan wants readers to consider the issue of over-stabilization and answer a challenge question… On the Applied Ballistics Facebook page, Ballistician Bryan Litz regularly offers a “Tuesday Trivia” question about ballistics. Today’s brain-teaser is a true/false question about bullet stabilization. On shooting forums you often find heated arguments about “over-stabilization”. Bryan wants readers to consider the issue of over-stabilization and answer a challenge question…

Is This Statement TRUE or FALSE?

“The problem with ‘over-stabilizing’ a bullet (by shooting it from an excessively fast twist rate) is that the bullet will fly ‘nose high’ on a long range shot. The nose-high orientation induces extra drag and reduces the effective BC of the bullet.”

True or False, and WHY?

Click the “Post Comment” link below to post your reply (and explain your reasoning).

Bullet Movement in Flight — More Complicated Than You May Think

Bullets do not follow a laser beam-like, perfectly straight line to the target, nor does the nose of the bullet always point exactly at the point of aim. Multiple forces are in effect that may cause the bullet to yaw (rotate side to side around its axis), tilt nose-up (pitch), or precess (like a spinning top) in flight. These effects (in exaggerated form) are shown below:

Yaw refers to movement of the nose of the bullet away from the line of flight. Precession is a change in the orientation of the rotational axis of a rotating body. It can be defined as a change in direction of the rotation axis in which the second Euler angle (nutation) is constant. In physics, there are two types of precession: torque-free and torque-induced. Nutation refers to small circular movement at the bullet tip.

Diagram from the University of Utah Health Sciences Library Firearm Ballistics Tutorial

July 8th, 2013

In order to increase deliveries of its most popular types of ammunition and bullets, Hornady announced that it will temporarily suspend production of 150 bullet types and 150 ammo types. IMPORTANT: These bullet and ammo products are NOT being discontinued. Rather, these less-popular, suspended items will simply not be produced for the remainder of 2013. By doing this, Hornady can reduce tool/machinery changes and thereby increase production of products in highest demand. On July 2nd, Hornady issued this statement: In order to increase deliveries of its most popular types of ammunition and bullets, Hornady announced that it will temporarily suspend production of 150 bullet types and 150 ammo types. IMPORTANT: These bullet and ammo products are NOT being discontinued. Rather, these less-popular, suspended items will simply not be produced for the remainder of 2013. By doing this, Hornady can reduce tool/machinery changes and thereby increase production of products in highest demand. On July 2nd, Hornady issued this statement:

Dear Hornady Customer:

As you are aware, 2013 has been one of the most challenging years ever in the sporting arms industry. We are proud of the increases in production we have achieved this year, but we are still faced witha demand that exceeds our ability to produce.

In efforts to increase production, we have reviewed everything, refining procedures, adding people, and equipment when possible. One area that will help us produce more: cutting the number of changeovers in our production machinery.

In order to reduce changeovers, we are announceing the temporary suspension of over 150 ammunition items and 150 bullet items, for the balance of 2013.

Attached you will find the list of items that will be suspended. Our plan is to remove the orders for these items from our system, beginning July 10th, and notify you of the cancellations. We will continue to monitor and update this list as the market conditions change.

Our goal is to try to deliver more to every customer, and while this may impact certain categories, our overall delivery should improve.

Hornady has listed the suspended bullet/ammo items in ten pages of attachments sent out to Hornady wholesalers and retailers. One representative page (covering 6mm, 6.5mm, and 7mm bullets) is shown below. This is NOT the complete list — there are TEN (10) pages! Click on each link below to see suspended items listed by caliber, small to large.

Suspension List Contents by Page Suspension List Contents by Page

1. Suspended Bullets .17 -.25 Caliber

2. Suspended Bullets .270 – .32 Caliber

3. Suspended Bullets .338 – .475 Caliber

4. Suspended Bullets 6mm – 7mm (See at right)

5. Suspended Bullets 8mm – 9mm and Suspended .17 – .223 Ammo

6. Suspended Ammo, .223, .243, 25-06, 270 Win, 280 Rem, 30 Carbine

7. Suspended Ammo 300 Wby Mag, 300 Win Mag, 30-06 Spr, 303 Brit

8. Suspended ammo 6.5 Creed, 6.5×55, 6.8 SPC, 7mm Rem Mag, 7×57 and larger metric

9. Suspended ammo 30-30, .308 Win, .338 Lap, .338 Win Mag, 35 Whelen, .357 Mag

10. Suspended ammo .357 Sig, 38 SPL, 380 ACP, 40 SW, 41 Mag, 44 Mag, 45 ACP, 45 Colt, and rifle 375 H&H, 404 Jef, 45-70 Govt

Notable Bullets on the Suspended List:

22832 – 22 Cal .224 80gr A-Max

22420 – 6mm .243 75gr V-Max

24562 – 6mm .243 105gr A-Max

26101 – 6.5mm .243 100gr A-Max

29402 – 7mm .284 162gr A-Max

29405 – 7mm .285 162gr BTHP Match

30314 – 30 Cal .308 155gr A-Max Moly

30715 – 30 Cal .308 178gr BTHP Match

30733 – 30 Cal .308 208gr BTHP Match

33102 – 338 Cal .338 200gr SST

Note, the above selection of “notable bullets” is just a “short list” of items that caught our attention. Remember 150 bullet types are being suspended for the balance of the year. With some items on the list, partial orders will be filled, or current orders will be filled, but no new orders taken.

|

Here is a simple technique that can potentially help you load straighter ammo, with less run-out. It costs nothing and adds only a few seconds to the time needed to load a cartridge. Next time you’re loading ammo with a threaded (screw-in) seating die, try seating the bullet in two stages. Run the cartridge up in the seating die just enough to seat the bullet half way. Then lower the cartridge and rotate it 180° in the shell-holder. Now raise the cartridge up into the die again and finish seating the bullet.

Here is a simple technique that can potentially help you load straighter ammo, with less run-out. It costs nothing and adds only a few seconds to the time needed to load a cartridge. Next time you’re loading ammo with a threaded (screw-in) seating die, try seating the bullet in two stages. Run the cartridge up in the seating die just enough to seat the bullet half way. Then lower the cartridge and rotate it 180° in the shell-holder. Now raise the cartridge up into the die again and finish seating the bullet.

Do-It-Yourself Electronic Target System?

Do-It-Yourself Electronic Target System?

On the

On the

In order to increase deliveries of its most popular types of ammunition and bullets, Hornady announced that it will temporarily suspend production of 150 bullet types and 150 ammo types. IMPORTANT: These bullet and ammo products are NOT being discontinued. Rather, these less-popular, suspended items will simply not be produced for the remainder of 2013. By doing this, Hornady can reduce tool/machinery changes and thereby increase production of products in highest demand. On July 2nd, Hornady issued this statement:

In order to increase deliveries of its most popular types of ammunition and bullets, Hornady announced that it will temporarily suspend production of 150 bullet types and 150 ammo types. IMPORTANT: These bullet and ammo products are NOT being discontinued. Rather, these less-popular, suspended items will simply not be produced for the remainder of 2013. By doing this, Hornady can reduce tool/machinery changes and thereby increase production of products in highest demand. On July 2nd, Hornady issued this statement: Suspension List Contents by Page

Suspension List Contents by Page