|

|

November 10th, 2016

Widener’s Reloading & Shooting Supply recently published a helpful introduction to reloading powders. Widener’s online Guide to Smokeless Powders shows the various types of powders, and explains how the differences in powder kernel/flake size and shape, and burn rate affect performance. We recommend you visit Widener’s website and read the Powder Guide in full.

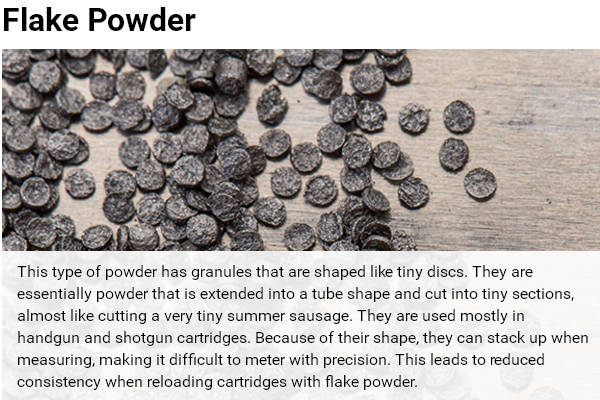

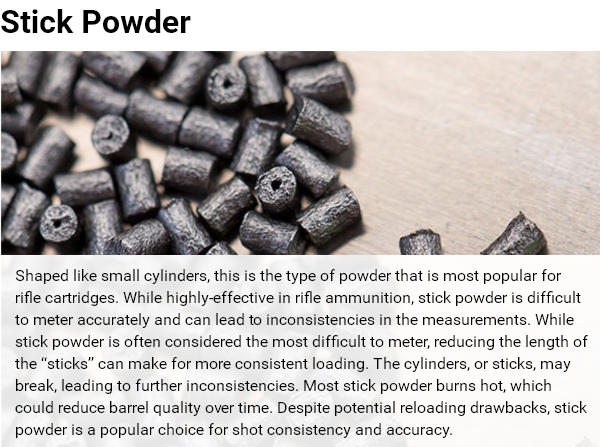

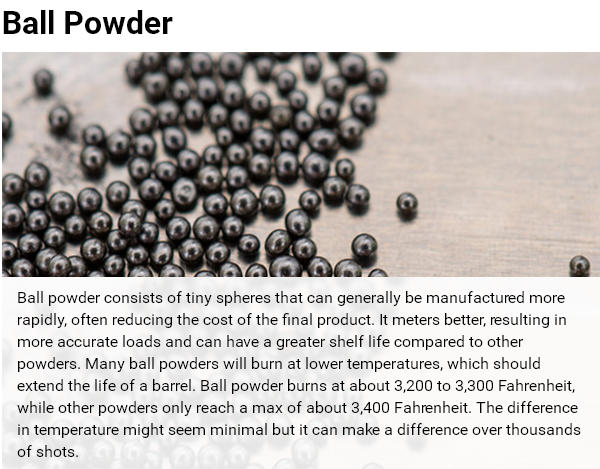

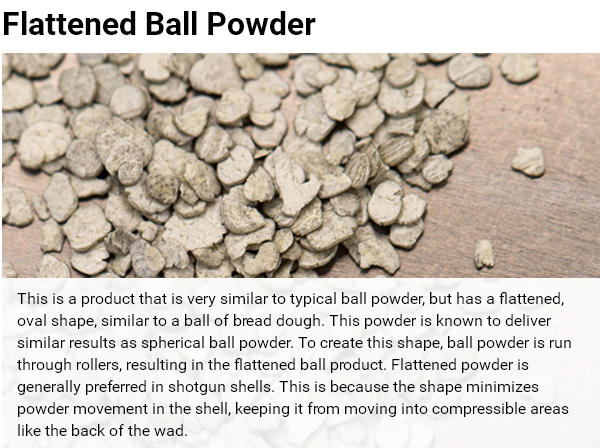

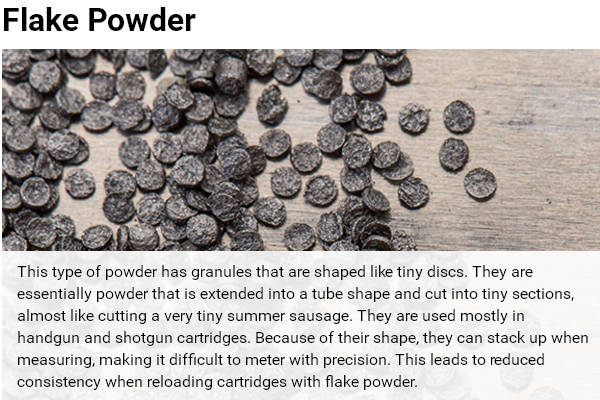

Take a close look at these illustrations which show the key differences between the four main powder types: extruded (stick) powder, ball (spherical) powder, flattened ball powder, and flake powder.

Burn Rate Basics

Widener’s Guide to Smokeless Powders also has a useful discussion of Burn Rate (a confusing topic for many hand-loaders). Wideners explains: “While a gun powder explosion in the cartridge seems instantaneous, if you slow it down you will actually find that each powder has a different ‘burn rate’, or speed at which it ignites.” This video shows powders with two very different burn rates. Watch closely.

Different burn rates suit different cartridge types notes Widener’s: “In general a fast-burning powder is used for light bullets and low-speed pistols and shotguns. Medium-rate powders are used for magnum pistols, while high-velocity, large bore rifle cartridges will need slow powders[.]

It should be noted that burn rate does not have a standardized unit of measurement. In fact, burn rate is really only discussed in comparison to other powders; there is no universal yardstick. Specifics will change by cartridge and bullet types[.]”

January 17th, 2016

Are you a 6 PPC shooter who relies on Vihtavuori N133? Or maybe you’re a .45 ACP Bullseye shooter who uses N310 or N320. Or perhaps you favor N150 in your 6mmBR or .308 Winchester. If you are a Vihtavuori powder user (or are considering trying these fine Finnish powders), then check out Vihtavuori’s new FREE mobile App.

The new Vihtavuori Reload App lets you keep track of your favorite reloading recipes, and manage load development. You can log load recipes for as many firearms and cartridge types as you want. The App holds all relevant data — cartridge class, bullet, loads specs. The Vihtavuori Reload App also provides instant access to the latest Vihtavuori Reloading Data as well as other Vihtavuori information. If you want hard copy of your load recipes, just email the recipe(s) to your personal e-mail account and then you can print out the info with a networked printer.

Download for iOS from Apple App Store | Download for Android from Google Play Store

For over 90 years, Vihtavuori has been known for producing high-quality propellants with reliable ballistic performance, long shelf-Life, and a wide selection of burn rates. Vihtavuori powders are manufactured to very high standards, and many world records have been set with Vihtavuori propellants. For more information, visit www.Vihtavuori.com.

January 4th, 2016

Hey guys, you’ll probably want to download this new Powder Burn Rate Chart issued by Hodgdon/IMR. This new table shows the latest IMR powders including the Enduron series (IMR 4166, 4451, 4955, 7977), shown in green below. This chart provides useful information for all hand-loaders. When doing load development, and testing one powder versus another, it’s generally wise to choose propellants that share the same relative burn rate, as least for starters. NOTE: Hodgdon powders are shown in blue, while IMR standard powders are shown in yellow. DOWNLOAD Chart HERE.

NEW POWDER BURN RATE TABLE from IMRPowder.com

CLICK HERE to Download Chart as PDF File.

Story find by EdLongrange. We welcome reader submissions.

October 26th, 2015

We’ve all heard the old adage: “Keep your powder dry.” Well, tests by Norma have demonstrated that even normal environmental differences in humidity can affect the way powders burn, at least over the long term. In the Norma Reloading Manual, Sven-Eric Johansson, head of ballistics at Nexplo/Bofors, presents a very important discussion of water vapor absorption by powder. Johansson demonstrates that the same powder will burn at different rates depending on water content.

Powders Leave the Factory with 0.5 to 1.0% Water Content

Johansson explains that, as manufactured, most powders contain 0.5 to 1% of water by weight. (The relative humidity is “equilibrated” at 40-50% during the manufacturing process to maintain this 0.5-1% moisture content). Importantly, Johansson notes that powder exposed to moist air for a long time will absorb water, causing it to burn at a slower rate. On the other hand, long-term storage in a very dry environment reduces powder moisture content, so the powder burns at a faster rate. In addition, Johansson found that single-base powders are MORE sensitive to relative humidity than are double-base powders (which contain nitroglycerine).

Tests Show Burn Rates Vary with Water Content Tests Show Burn Rates Vary with Water Content

In his review of the Norma Manual, Fred Barker notes: “Johansson gives twelve (eye-opening) plots of the velocities and pressures obtained on firing several popular cartridges with dehydrated, normal and hydrated Norma powders (from #200 to MRP). He also gives results on loaded .30-06 and .38 Special cartridges stored for 663 to 683 days in relative humidities of 20% and 86%. So Johansson’s advice is to keep powders tightly capped in their factory containers, and to minimize their exposure to dry or humid air.”

Confirming Johansson’s findings that storage conditions can alter burn rates, Barker observes: “I have about 10 pounds of WWII 4831 powder that has been stored in dry (about 20% RH) Colorado air for more than 60 years. It now burns about like IMR 3031.”

What does this teach us? First, all powders start out with a small, but chemically important, amount of water content. Second, a powder’s water content can change over time, depending on where and how the powder is stored. Third, the water content of your powder DOES make a difference in how it burns, particularly for single-base powders. For example, over a period of time, a powder used (and then recapped) in the hot, dry Southwest will probably behave differently than the same powder used in the humid Southeast.

Reloaders are advised to keep these things in mind. If you want to maintain your powders’ “as manufactured” burn rate, it is wise to head Johannson’s recommendation to keep your powders tightly capped when you’re not actually dispensing charges and avoid exposing your powder to very dry or very humid conditions. The Norma Reloading Manual is available from Amazon.com.

| Real-World Example — “Dry” H4831sc Runs Hotter

Robert Whitley agrees that the burn rate of the powder varies with the humidity it absorbs. Robert writes: “I had an 8-lb. jug of H4831SC I kept in my detached garage (it can be humid there). 43.5-44.0 gr of this was superbly accurate with the 115 Bergers out of my 6mm Super X. I got tired of bringing it in and out of the garage to my house for reloading so I brought and kept the jug in my reloading room (a dehumidified room in my house) and after a few weeks I loaded up 43.5 gr, went to a match and it shot awful. I could not figure out what was going on until I put that load back over the chronograph and figured out it was going a good bit faster than before and the load was out of the “sweet spot” (42.5 – 43.0 gr was the max I could load and keep it accurate when it was stored in less humid air). I put the jug back in the garage for a few weeks and I now am back to loading 43.5 – 44.0 gr and it shoots great again. I have seen this with other powders too.”

If you have two jugs of the same powder, one kept in a room in your house and one somewhere else where it is drier or more humid, don’t expect the two jugs of the same lot of powder to chrono the same with the same charge weights unless and until they are both stored long enough in the same place to equalize again. |

June 11th, 2011

Here’s a good deal for magnum shooters on a tight budget. If you need a quality, slow burn-rate powder suitable for large-capacity cartridges, check out Winchester WXR powder. Production of WXR has been discontinued, but quantities are still available. PrecisionReloading.com has 8-lb jugs of Winchester WXR for $104.49, which works out to just $13.06 per pound. Grafs.com has 1-lb containers of Winchester WXR for $13.99, on “close-out” pricing (limited quantities, no back-orders). Winchester WXR is a Swedish-made, double-base, slow-burning extruded propellant used in larger-size cartridges. WXR is an excellent choice for the .25-06, .270 Win, .30-06, 7mm Rem Mag, 300 Win Mag, 7mm WSM and 300 WSM cartridges. Some industry observers have suggested that Winchester WXR is virtually the same as Alliant Reloder 22. We can’t confirm that, but the load recipes are similar. Keep in mind that, at $13.06 per pound, WXR is nearly six bucks per pound cheaper than Reloder 22 (in 5-lb containers).

The Reload Bench’s Burn Rate Comparison Chart shows WXR having a burn rate very close to Vihtavuori N165 and IMR 7828. In tests with a .25-06, WXR delivered velocities 30 to 60 fps higher than Reloder 22, with equal loads grain for grain (see WXR vs. RL22 report). In the .25-06, the WXR was slightly more energetic than Reloder 22, so a max load with WXR proved to be about 1.0 grain lower than a RL22 max load. Another WXR user writes: “I’ve been using it for the last three years in my 7 STW, 7mm Mag, 300 WSM, 300 Win Mag, .30-06 and .270 Win. It chronographs nearly identical to Reloder 22, so keep that in mind when working up loads with it. From what I’ve researched about it, the company in Sweden who makes powder for Norma, also makes Reloder 22 and made Win WXR. Remember powder can vary slightly from lot to lot, so start low and work your way up.”

Winchester Catalog with WXR Load Data (PDF File) Winchester Catalog with WXR Load Data (PDF File)

Burn rates (faster to slower):

152. H4831 (Hodgdon)

153. MRP (Norma)

154. Reloder 22 (Alliant)

155. WW785 (Winchester)

156. H450 (Hodgdon)

157. Mag Pro (Accurate)

158. N165 (Vihtavuori)

159. WXR (Winchester)

160. 7828 (IMR)

|

Tests Show Burn Rates Vary with Water Content

Tests Show Burn Rates Vary with Water Content