|

|

December 5th, 2017

With all the noise lately about the 6.5 Creedmoor, it’s easy to forget that before we had the Creedmoor, we had another accurate, efficient mid-sized cartridge, the 6.5×47 Lapua. Just as the 6.5 Creedmoor inspired the 6mm Creedmoor, the 6.5×47 Lapua has been successfully necked-down to 6mm (.243) for a 6-6.5×47 variant. This has worked great in a number of roles — benchrest, varminting, and tactical/PRS. This article, from a few seasons back, shows how the 6-6.5×47 Lapua can be successfully packaged as an accurate, potent 6mm varminter.

The 6-6.5×47 Lapua for Precision Long-Range Varminting

Report by Stan Stewart

6mm AI ‘Sellers Remorse’ Spurs New 6mm Project 6mm AI ‘Sellers Remorse’ Spurs New 6mm Project

After selling my 6mm Remington Ackley Improved a couple of years ago and wishing I had not, I thought about a new customer rifle for work on Prairie Dog towns and New York wood chucks at 600+ yards. I have a .223 AR and 22-250 for medium ranges but I missed my 6mm AI for long-range work. The 22-250 is a fine chambering, but it is hard on barrels, and I think the 6mms may have an accuracy edge out past 400 yards. Also, shooters today enjoy a vast collection of really great 6mm bullets. Barrel life and bullet ooptions were two main reasons I decided to build a 6mm rather that another .224-caliber gun. But the question remained — what 6mm chambering to choose? Although I missed my 6mm AI, I did not miss fire-forming the brass, so when I learned about the 6-6.5×47 Lapua, a wildcat case easily formed by necking down the parent 6.5×47 case, I thought this might be the answer.

I started doing serious research on the 6-6.5×47 Lapua. I received a lot of good advice from AccurateShooter.com and other websites on the pros and cons of the new cartridge. Most reports were positive. I also talked to gunsmiths — quite a few recommended the new cartridge as well. Some of the cartridge attributes I liked were the small rifle primer, enough case capacity to efficiently reach 3700 fps with a 70gr bullet and 3400 fps with an 85-grain, without being terribly over-bore.

Most important was the 6-6.5×47’s reputation for inherent accuracy without being finicky like my 6mm AI (my experience). So, having chosen my cartridge, I started asking for gunsmith recommendations. Again the folks on the AccurateShooter Forum were very helpful. After many conversations I settled on Dave Bruno in Dayton, Pennsylvania. He was a good choice. After working with Dave on this project, I could not be happier. He was very helpful considering this was my first complete custom gun.

Putting Together the New Rig with Premium Components

From the get-go, I knew I wanted a BAT action and Krieger barrel. BAT Machine and Krieger Barrels enjoy a great reputation in the shooting industry. BATs are beautifully machined, smooth, and strong. Krieger cut-rifled barrels are known for dependable accuracy and long barrel life. While many 6-6.5×47 shooters choose a 8-twist barrel to shoot the 100-108gr bullets, I would be using smaller, varmint-weight bullets, so I selected a 1:10″-twist Krieger. This would allow me to shoot bullets from 60 grains up to 90 grains. Dave chambered the barrel with an 0.269″ neck and fluted the barrel to save weight. I also had Dave install a Vais muzzle brake. The Vais brake is more expensive than some others, but it is a proven product. Dave fitted the BAT with a 2 oz. Jewell trigger, mounted with a +20 MOA scope rail, then pillar-bedded the BAT into a McMillan Hunter-Class-style fiberglass stock. The scope is a 12-42x56mm Nightforce NSX, mounted in a set of Nightforce rings I hand-lapped for better contact.

Load Development for Varminting Load Development for Varminting

I had selected a few powders and bullets recommended by other 6-6.5×47 shooters and started by seating all the bullets .005″ off the lands. The powders I selected were Varget, Vihtavuori N550, and Reloder 15.

I was very pleased with the 88gr Bergers. In initial testing, they grouped well and I was able to drive them to 3400 fps easily. As I wanted a gun for long-range varmint work, I was hoping the 10-twist barrel would provide enough stability for the heavier weight bullets. It did — the 10-twist worked great! I was able to shoot the lighter weight bullets very well and the 88s were superb. With a BC of 0.391, leaving the barrel at 3400 fps, these bullets were still traveling at 2600 fps at 600 yards!

I did wonder how well the 88s would work on varmints given their small meplats (and limited expansion). A call to Berger reassured me the 88s should work fine on small varmints. The test came last summer when I made a trip to NY and got to visit my old Chuck hunting farms with my new rifle and old hunting buddy. The longest shot we had was only 300 yards, but the Berger 88s did great. None of the eight critters we nailed so much as wiggled after they were hit.

I did a lot of testing, recording group sizes for a variety of different bullets and powders. With all the data collected in a spreadsheet, I was able to “crunch the numbers”, and that helped me choose my preferred loads. By looking at the average group size for the individual bullets and powders, the data drew a clear picture of what the rifle shot best. Below is a chart showing comparative group sizes, arranged by both bullet type and powder brand.

December 17th, 2016

Brux Barrels, based in Lodi, Wisconsin, has earned a reputation for producing great-shooting tubes. Brux-made barrels have won their fair share of matches, and set some notable records in the process. A few years back, Rodney Wagner shot the smallest five-shot, 600-yard group (0.336″) in the history of rifle competition, using a Brux barrel chambered for the 6mm Dasher. Brux Barrels, based in Lodi, Wisconsin, has earned a reputation for producing great-shooting tubes. Brux-made barrels have won their fair share of matches, and set some notable records in the process. A few years back, Rodney Wagner shot the smallest five-shot, 600-yard group (0.336″) in the history of rifle competition, using a Brux barrel chambered for the 6mm Dasher.

Folks often ask us why Brux barrels shoot so well. “What’s the secret?” they ask. We can only answer with what Brux explains on its own website: “To make a cut-rifled barrel you have to start off with the proper ingredients: the best steel available, skill, and experience. Since there are really only two main suppliers of barrel-quality steel, the skill and experience is what really makes a barrel maker stand out.” Here is how Brux’s co-owners, Norman Brux and Ken Liebetrau, explain all the procedures involved in making a Brux cut-rifled barrel:

| Brux Barrel-Making Process, Start to Finish

We start out with either 4150 chrome-moly or 416R stainless steel double stress-relieved bar stock. The bar stock starts out at 1-9/32″ in diameter and 20-24 feet long so we cut it to length.

Step two is to rough-contour the outside of the barrel blank in a lathe.

Thirdly, the blank gets mounted into a Barnes gun drill. The cutter bit has holes through which oil or coolant is injected under pressure to allow the evacuation of chips formed during the cutting process. This is called “oil-through” or “coolant-through”. Without this, you wouldn’t want to even attempt drilling a hole 30” long and under ¼” in diameter. The combination of a 3600rpm and good flushing allows us to drill a beautifully straight and centered hole .005” under “land” diameter at a rate of 1” per minute.

Clean the barrel.

Next the blank is sent back to the lathe to machine the finished contour of the outside.

Clean the barrel again.

Now, the blank is sent on to the Pratt & Whitney reamer in which an “oil through” reaming tool is used to cut away the extra .005” left in the drilling process. The reamer makes an extremely accurate bore size and after it is finished the bore will have a better surface finish and will be at the proper “land” diameter.

Clean the barrel again.

In the sixth step we hand lap each barrel to remove any slight tool marks that may have been left by the reamer and inspect every one with a bore scope. If the barrel doesn’t meet our standards for surface finish and tolerance it doesn’t get any further.

Clean the barrel again.

The barrels then go onto the rifling machine which is responsible for cutting the all so familiar grooves in the bore. A caliber/land configuration-specific rifling head is used to progressively shave away small amounts of steel to form the rifling grooves. This is accomplished by simultaneously pulling the rifling head through the reamed blank as the blank is spun at a controlled rate. After each cut, the blank is rotated 90 degrees (for a four-land configuration) and after one full rotation (360 degrees) the rifling head is slightly raised to shave off the next bit of material. This process is repeated until we reach groove diameter.

Clean the barrel again.

Lastly, the barrel is hand-lapped again (to ensure a smooth bore), and a final inspection is performed with the bore scope.

The barrel is cleaned one last time, wrapped, packed, and shipped to [the customer]. |

Anyone reading this detailed description of the Brux barrel-making process will doubtless come away with a new appreciation for the time, effort, and dedication required to produce a premium match-grade cut-rifled barrel. Obviously, there are no easy shortcuts and great attention to detail is required each step of the way. As shooters we’re lucky that we have barrel-makers so dedicated to their craft.

Credit James Mock for steering us to this Barrel Making 101 feature on the Brux website.

November 11th, 2016

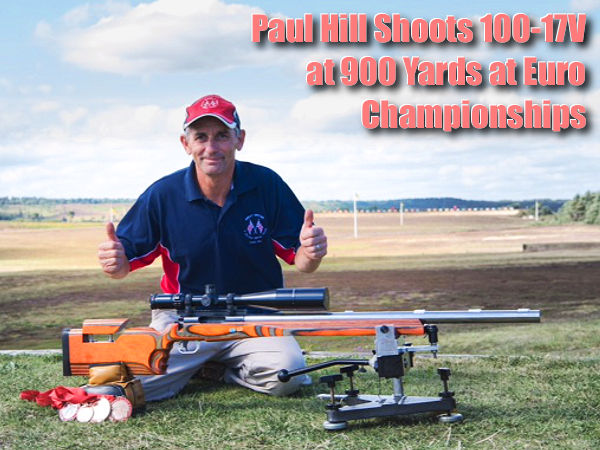

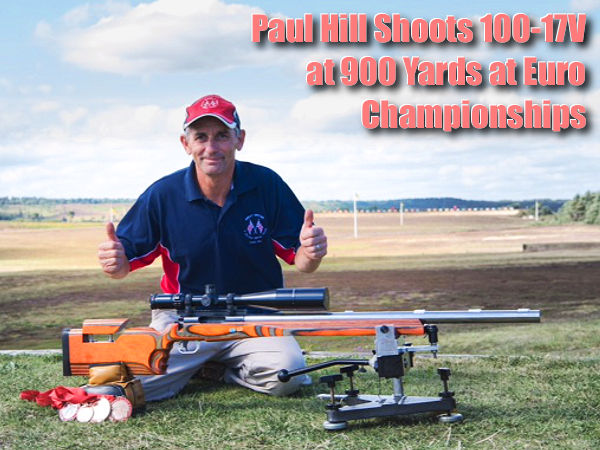

Report by Des Parr

With every new season, standards in the F-Class game are climbing ever higher. Shooter are improving their skills set while equipment and loading techniques are improving (thanks in part to websites such as this). Evidence of the level of improvement in F-Class shooting comes from the UK, where a talented shooter drilled a new GBFCA record score. One of our rising stars on this side of the pond is F-Open shooter Paul Hill. He hails from England’s wide-open flat lands where the wind blows strongly in from the North Sea and where a shooter must soon learn to read the wind.

At the European Championships held in September at the Bisley ranges, Paul set a new record score at 900 yards — a 100-17V! That’s 17 shots placed in a five-inch circle the size of a CD (compact disc) at over half a mile. [NOTE: At Bisley, the maximum score is FIVE points, not ten points. So the maximum score for 20 shots is 100. Also what Americans call an “X” is called a “V” at Bisley.]

Record Set with Slower Pair Firing Method

Bear in mind the style of shooting here in Great Britain is pair-firing. Under this procedure, each of two competitors shoots alternately, taking turns from shot to shot. Each shooter has 45 seconds to get his shot off. Allowing for the target pullers to do their jobs, this means that each shot can take up to one minute. As Paul was pair firing, he had to concentrate for up to 40 minutes to get all 20 shots off! You can imagine how many times the wind changed course in those 40 minutes — pick-ups, let-offs, changes of angle and direction. Paul had to counter each change and still managed to keep 17 shots in that 5-inch circle!

Paul Hill Sets Record with His First-Ever DIY-Chambered Barrel

What makes this new GBFCA record all the more significant is that Paul did it by barreling his own rifle — and for the first time! By simply taking great care and attention he has chambered and fitted a barrel himself to the very highest standards. Paul chambered the Krieger 1:9″-twist barrel for the .284 Winchester cartridge. His action was a Barnard. The stock is by Joe West.

Record Shot with Lapua 180gr Scenars and Russian Primers

We should note that Paul Hill is a very keen fan of Lapua’s 180gr Scenar-L bullet. It has to be said that this bullet doesn’t have the highest BC, yet whatever it lacks in that department it more than makes up for by being remarkably consistent — and consistency counts for a lot. Paul is also a fan of the Russian KVB-7 primers. His achievement is proof that Lapua Scenars and KVB-7 primers are every bit as good as the premium-priced alternatives. The powder was Vihtavuori N160. [Editor: For its 180gr Scenar-L, Lapua lists a 0.661 G1 BC, and a 0.332 G7 BC. Those numbers may not top the charts, but they are still very impressive.]

Records are made to be broken, but we think it will be quite a while before Paul’s 200-17X is surpassed in European competition. If you feel up to that challenge, consider competing in next year’s European Championships in late September 2017.

November 23rd, 2015

At the request of our readers, we have launched a “Deals of the Week” feature. If this proves popular, we’ll try to run this every Monday. Here are some of the best deals on hardware, reloading components, and shooting accessories. Be aware that sale prices are subject to change, and once clearance inventory is sold, it’s gone for good. You snooze you lose.

1. Remington — $100.00 Cash Back on Rem 700 BDL and CDL

Remington is running a Black Friday factory mail-in rebate program. This can save you $100.00 on Remington 700 CDL and BDL rifles. Remington is also offering $50-$75 Rebates on Rem 700 SPS, Rem 700 ADL, and Rem 783 rifles. CLICK HERE to download PDF Rebate Form.

2. Bruno’s — Krieger Barrels $25.00 Off Plus FREE Shipping

Krieger makes some of the very best barrels you can buy. With demand for Krieger cut-rifled barrels being so high, you can expect to wait 3 months or so for a new barrel. Or, you can order from a vendor that maintains Kriegers in inventory. Right now Bruno’s is offering $25 off all Krieger barrels in stock, plus FREE shipping. A variety of lengths/contours are available in .22, 6mm, 6.5mm, 7mm, .308, and .338 calibers. CLICK HERE for Barrel Inventory list.

3. Brownells — Magnetospeed Sporter Chronograph $159.99

You won’t find a better deal on a Magnetospeed Chronograph anywhere. This chrono fits to your barrel so you don’t have to walk downrange to fiddle with a tripod-mounted unit. As part of the Brownells 3-Week “Back to Black” promotion, this Sporter Chrono is marked down to $159.99 for the next few days. Don’t hesitate — this is a killer deal on a very good product.

4. Southern Shooters — Savage A17 in 17 HMR

The Savage A17 is an impressive new semi-auto rifle. With its delayed blow-back mechanism, the A17 can safely handle the added pressure of the 17 HMR cartridge (unlike some previous designs). Though some owners have complained about a stiff trigger (and hard-to-seat magazines), overall the A17 is a very good design — a great choice for small varmints.Now you can purchase one for under $355.00. Southern Shooters is currently offering the A17 for just $352.62. The A17 was named Guns & Ammo Rifle of the Year.

5. Botach Tactical — Double Rifle Padded 36″ Case with Straps

Here’s a nice case for short carbines or hunting rifles. This double Gun Case will transport TWO (2) 35″ rifles inside the main double compartments. This is a nice set-up for hauling a couple of varmint rifles or an AR with a collapsible stock. Three large external pockets will carry magazines, range-finders and other gear. This rugged case includes nice padded shoulder straps so you can carry your rifles backpack-style. Right now this double gun case is just $49.00 from Botach Tactical. That’s $99 off the original price. The case is offered in tan, OD green, or black.

6. Amazon (EuroOptic) — Zeiss Victory Laser Rangefinder

A few years back, we comparison tested four laser rangefinders — a Nikon, Leica, Swarovski, and Zeiss. To make a long story short, three out of four testers preferred the Zeiss PRF Victory. While larger and heavier than the Leica CRF 1600, the Zeiss Victory PRF was easier to hold steady, and it ranged as well as the Leica (and better than the Swaro and Nikon). Now the Zeiss Victory is on sale for $649.00, making it $150.00 cheaper than Leica’s CRF 1600. With this price advantage, we think the Zeiss is the smart choice (unless you need an ultra-compact unit). A recent LRF comparison test in the UK reached the same conclusion.

7. Brownells — Stripped AR Lower Just $39.99

This is the lowest price we’ve seen on a lower with a solid warranty. This Anderson Mfg. Lower sells elsewhere for up to $79.99. If you’re planning a budget AR build, you can start with this inexpensive lower and put the money you save into a top-quality barrel.

8. Bullets.com — Thanksgiving Ultrasonic Cleaner Sale

For Thanksgiving Week, Bullets.com has slashed prices on all its Ultrasonic Cleaning Machines. These start at just $31.95 (for 1 pint capacity), and run up to 9 liter capacity for the biggest jobs. We like the 2.5 liter unit which has been marked down to $89.95 from $199.95. That’s a good price for a 2.5 liter machine.

9. Bushmaster — $200 Cash Back on Select AR & ACR Models

Looking for a Black Rifle on Black Friday? Here’s a sweet deal from Bushmaster. Now through November 30, 2015 you can save $200.00 on a variety of semi-auto “modern sporting rifles” from Bushmaster. This includes AR-clone rifles as well as Bushmaster’s gas piston operated ACR series rifles. You save $200.00 through a $50 Rebate combined with a $150.00 Black Friday Bonus.

10. Gander Mountain — $20 and $50 Discount Coupon “EARLY20″

As a lead-in to Black Friday, Gander Mountain is offering online shoppers $20.00 off a $100.00+ purchase and $50.00 off a $250.00+ purchase. Simply use Code EARLY20 during checkout. This coupon works through midnight on 11/24/2015. Also, during Black Friday (11/27/2015), Gander Mountain will offer big discounts on Liberty Gun Safes.

Credit EdLongrange for finding the Bushmaster Rebate Offer.

November 6th, 2015

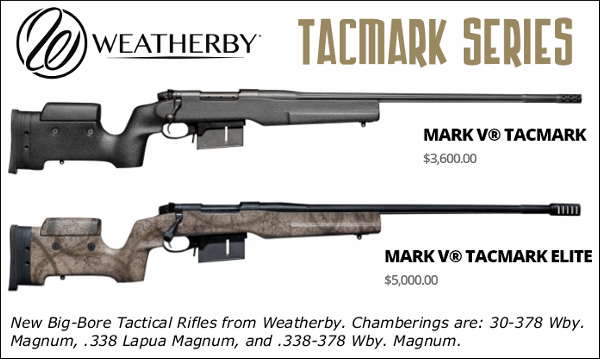

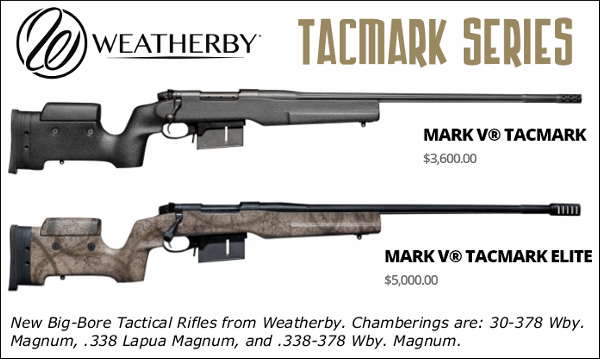

Weatherby’s new TacMark Rifles should be popular with long-range shooters (at least those with plenty of coin). We hope you like recoil — all three chamberings are powerful: .30-378 Wby. Magnum, .338 Lapua Magnum, and .338-378 Wby. Magnum. To handle these powerful cartridge types, TacMark series rifles have a beefy receiver with integral recoil lug, set in a CNC-machined aluminum bedding system. The bolt is interesting — it has nine (9) lugs and a 54-degree bolt throw.

The composite stocks are adjustable for length of pull (13¼ inches to 14¾ inches), drop at comb, and drop at heel. The stock also has a near-vertical pistol grip with a trigger finger depression and a wide, flat-bottom fore-end with a stud for bipod and/or sling. The TacMark (11.25 lbs w/o scope) comes in black while the TacMark Elite (11.75 lbs w/o scope) is finished in High Desert Camo with black accents.

The $5000.00 TacMark Elite features a hand-lapped 28″ Krieger cut-rifled barrel*, fitted with a large muzzle brake. The Range Certified (RC) TacMark Elite is accompanied by an Oehler Ballistic Imaging System printout signed and certified by Ed or Adam Weatherby, verifying the accuracy. The Elite is guaranteed to shoot sub-MOA for three shots (and we suspect it can do a lot better than that).

The less expensive ($3600.00) TacMark also boasts a 28″ barrel — one of the longest barrels currently available on a factory rifle. This should be good for a little extra velocity. Both the TacMark and the TacMark Elite feature Weatherby’s Mark V action and Weatherby’s new LXX trigger, which is user-adjustable for pull weight down to 2.5 pounds. The Mark V TacMark and TacMark Elite rifles will be available through the Weatherby Custom Shop.

* A features list on the Weatherby website shows 26″ barrel length for the Elite. However the actual specifications show the barrel to be 28″ for both TacMark and TacMark Elite. You should verify barrel length before ordering.

August 2nd, 2014

Brux Barrels, based in Lodi, Wisconsin, has earned a reputation for producing great-shooting tubes. Brux-made barrels have won their fair share of matches, and set some notable records in the process. Last year, Rodney Wagner shot the smallest five-shot, 600-yard group (.0349″) in the history of rifle competition, using a Brux barrel chambered for the 6mm Dasher. Brux Barrels, based in Lodi, Wisconsin, has earned a reputation for producing great-shooting tubes. Brux-made barrels have won their fair share of matches, and set some notable records in the process. Last year, Rodney Wagner shot the smallest five-shot, 600-yard group (.0349″) in the history of rifle competition, using a Brux barrel chambered for the 6mm Dasher.

Folks often ask us why Brux barrels shoot so well. “What’s the secret?” they ask. We can only answer with what Brux explains on its own website: “To make a cut-rifled barrel you have to start off with the proper ingredients: the best steel available, skill, and experience. Since there are really only two main suppliers of barrel-quality steel, the skill and experience is what really makes a barrel maker stand out.” Here is how Brux’s co-owners, Norman Brux and Ken Liebetrau, explain all the procedures involved in making a Brux cut-rifled barrel:

| Brux Barrel-Making Process, Start to Finish

We start out with either 4150 chrome-moly or 416R stainless steel double stress-relieved bar stock. The bar stock starts out at 1-9/32″ in diameter and 20-24 feet long so we cut it to length.

Step two is to rough-contour the outside of the barrel blank in a lathe.

Thirdly, the blank gets mounted into a Barnes gun drill. The cutter bit has holes through which oil or coolant is injected under pressure to allow the evacuation of chips formed during the cutting process. This is called “oil-through” or “coolant-through”. Without this, you wouldn’t want to even attempt drilling a hole 30” long and under ¼” in diameter. The combination of a 3600rpm and good flushing allows us to drill a beautifully straight and centered hole .005” under “land” diameter at a rate of 1” per minute.

Clean the barrel.

Next the blank is sent back to the lathe to machine the finished contour of the outside.

Clean the barrel again.

Now, the blank is sent on to the Pratt & Whitney reamer in which an “oil through” reaming tool is used to cut away the extra .005” left in the drilling process. The reamer makes an extremely accurate bore size and after it is finished the bore will have a better surface finish and will be at the proper “land” diameter.

Clean the barrel again.

In the sixth step we hand lap each barrel to remove any slight tool marks that may have been left by the reamer and inspect every one with a bore scope. If the barrel doesn’t meet our standards for surface finish and tolerance it doesn’t get any further.

Clean the barrel again.

The barrels then go onto the rifling machine which is responsible for cutting the all so familiar grooves in the bore. A caliber/land configuration-specific rifling head is used to progressively shave away small amounts of steel to form the rifling grooves. This is accomplished by simultaneously pulling the rifling head through the reamed blank as the blank is spun at a controlled rate. After each cut, the blank is rotated 90 degrees (for a four-land configuration) and after one full rotation (360 degrees) the rifling head is slightly raised to shave off the next bit of material. This process is repeated until we reach groove diameter.

Clean the barrel again.

Lastly, the barrel is hand-lapped again (to ensure a smooth bore), and a final inspection is performed with the bore scope.

The barrel is cleaned one last time, wrapped, packed, and shipped to [the customer]. |

Anyone reading this detailed description of the Brux barrel-making process will doubtless come away with a new appreciation for the time, effort, and dedication required to produce a premium match-grade cut-rifled barrel. Obviously, there are no easy shortcuts and great attention to detail is required each step of the way. As shooters we’re lucky that we have barrel-makers so dedicated to their craft.

Credit James Mock for steering us to this Barrel Making 101 feature on the Brux website.

May 3rd, 2014

On German Salazar’s Rifleman’s Journal website, you’ll find an excellent 5-Part Series on barrel chambering. The Series, entitled The Voyeur’s Guide to Barrel Chambering, is not intended to be a “how-to” instructional treatise for gunsmiths. Instead, German’s 5-Part Guide is aimed at the end user — the shooter. German explains: “This Series isn’t intended for anyone who owns a lathe; instead it is for those of us who send an action off to get a new barrel installed. Those who have the equipment know what to do and how to do it and I have nothing to teach them. On the other hand, if you’ve ever wondered just what goes into barrel fitting, this is it.” On German Salazar’s Rifleman’s Journal website, you’ll find an excellent 5-Part Series on barrel chambering. The Series, entitled The Voyeur’s Guide to Barrel Chambering, is not intended to be a “how-to” instructional treatise for gunsmiths. Instead, German’s 5-Part Guide is aimed at the end user — the shooter. German explains: “This Series isn’t intended for anyone who owns a lathe; instead it is for those of us who send an action off to get a new barrel installed. Those who have the equipment know what to do and how to do it and I have nothing to teach them. On the other hand, if you’ve ever wondered just what goes into barrel fitting, this is it.”

PART I | PART II | PART III | PART IV | PART V

With well-written text and dozens of very high-quality images, German takes you through the chambering, threading, shoulder-fitting, and crowning processes from start to finish. The idea is to give the “barrel consumer” a clear idea of the processes involved when a barrel blank is converted into functional form, complete with chamber, threaded tenon, fitted breech, and crown.

We highly recommend German’s 5-Part Voyeur’s Guide to Barrel Chambering. German, with the aid of John Lowther (who ran the machines), did a great job. The series has already drawn much attention from our Forum members, along with praise. After reading the articles, John C. from Australia wrote: “Your Chambering articles… really are excellent [and] informative for those of us too scared to watch our gunsmith chamber one of our barrels lest we distract him at a crucial moment!”

We know you’ll learn something from reading through German’s 5-Part Series. And if you see a photo on German’s website that intrigues you, simply click on it to see a larger, higher-resolution version. All the images in the Voyeur Series on RiflemansJournal.com can be zoomed to larger formats.

March 18th, 2012

Dansig’s Hot-Rod Howa – Forum member Dansig has been busy during the long, cold winter in his native Iceland. He transformed a homely-looking Howa m1500 Axiom into a beautiful candy-red thumbhole Varminter that shoots in the threes. This was truly a “labor of love” that required many dollars invested and dozens of hours of home-workshop labor. But the results speak for themselves. Dansig now owns what may be the best-looking Howa on the planet. And this rig isn’t just a beauty queen — it’s very accurate as well. With a new Krieger barrel chambered in 6mmBR Norma, the Howa shoots repeatable, five-shot groups in the threes, and Dansig has managed a few “wallet groups” in the low twos. Dansig’s Hot-Rod Howa – Forum member Dansig has been busy during the long, cold winter in his native Iceland. He transformed a homely-looking Howa m1500 Axiom into a beautiful candy-red thumbhole Varminter that shoots in the threes. This was truly a “labor of love” that required many dollars invested and dozens of hours of home-workshop labor. But the results speak for themselves. Dansig now owns what may be the best-looking Howa on the planet. And this rig isn’t just a beauty queen — it’s very accurate as well. With a new Krieger barrel chambered in 6mmBR Norma, the Howa shoots repeatable, five-shot groups in the threes, and Dansig has managed a few “wallet groups” in the low twos.

From this beast….

To this beauty … All it takes is imagination, hard work, and the right components….

Read Dansig’s account of the project from start to finish…

For this project I acquired a new Howa m1500 axiom. The transformation began with a $99.00 (USA retail) Boyds’ thumbhole stock.

When I got the stock, I found that even the standard barrel was too big for it, so I had to modify it quite a bit. To help ride the front bags, I added a wood block to make the fore-end wider, and to provide a flat section in the front. This required cutting the sides of the fore-end to mate with the wider block, which was glued in place. I also added an inch to the stock length.

Then I spent a few weeks sanding and filling…

Then it was time for the paintjob ($270). The multi-coat finish was applied by a professional, using car paint and clear coat so it’s very strong and scratch resistant. The color was a customized red with gold metal-flakes, and it looks awesome on a gun.

Bolt Sleeved, Trigger Tuned, and Krieger Barrel Fitted

While I was working on the stock I took the action to the local gunsmith. He fitted a new 1:13.5″-twist Krieger HV barrel and he put a sleeve in the action to make it tighter. He also tuned the trigger, taking it down from 56 ounces (ouch!) to just 14 ounces. Finally, my smith bedded the stock before I took it in for the paintwork.

Project Completed — Looks Great and Shoots Great

And this is the finished product of very hard labor. The project was a lot of work, mostly because it was all done by hand and not with machines. I may do a similar project again, but I would make the stock from oak or other strong wood. The wood I used is a bit soft for this kid of project.

Hot-Rod Howa Shoots as Good as She Looks Hot-Rod Howa Shoots as Good as She Looks

Dansig reports: “How does my Hot-Rod Howa shoot? Repeatable 5-shot accuracy with me as a shooter is in the threes, but with a more experienced shooter, the gun could probably shoot even better. I say this because I just started shooting Benchrest for the first time when this project gun was completed. Here’s an exceptional (much better than average) ‘wallet group’ that shows what the gun can do ‘when the stars align’. This group, shot with VV N135 and Nosler Ballistic Tips, made my buddies really roll their eyes! I wish I had more groups like this one!”

Editor’s Note: Groups shown were shot on Caldwell “Tip-Top” laminated weatherproof targets, which display a distinctive punch — similar to a wad-cutter hole — as opposed to the standard gray donut smudge on a normal paper target. The holes appear black because the targets were placed over a black background sheet before being photographed.

|

6mm AI ‘Sellers Remorse’ Spurs New 6mm Project

6mm AI ‘Sellers Remorse’ Spurs New 6mm Project

Load Development for Varminting

Load Development for Varminting

On German Salazar’s

On German Salazar’s

Dansig’s Hot-Rod Howa – Forum member Dansig has been busy during the long, cold winter in his native

Dansig’s Hot-Rod Howa – Forum member Dansig has been busy during the long, cold winter in his native

Hot-Rod Howa Shoots as Good as She Looks

Hot-Rod Howa Shoots as Good as She Looks