|

|

November 11th, 2021

Do you enjoy plinking with rimfire rifles and shooting reactive targets with handguns? Champion has developed a series of fun targets that tilt, spin, hop, or roll when hit. Made from a “self-healing” rubber-like polymer, Champion’s DuraSeal Targets can be hit dozens of times before they need to be replaced. (If you shoot only rimfire, they might last 200 rounds or more.) Along with the varmint spinners, we like Champion’s weighted wobble targets. These are offered in both a bowling pin shape and a sphere on a post (photo right). When you hit these targets they rock back and forth and side to side. Weights in the round bottom then bring the target back to an upright position. Do you enjoy plinking with rimfire rifles and shooting reactive targets with handguns? Champion has developed a series of fun targets that tilt, spin, hop, or roll when hit. Made from a “self-healing” rubber-like polymer, Champion’s DuraSeal Targets can be hit dozens of times before they need to be replaced. (If you shoot only rimfire, they might last 200 rounds or more.) Along with the varmint spinners, we like Champion’s weighted wobble targets. These are offered in both a bowling pin shape and a sphere on a post (photo right). When you hit these targets they rock back and forth and side to side. Weights in the round bottom then bring the target back to an upright position.

Weighing 80% less than metal targets. DuraSeal spinning targets are extremely reactive so you can see every time your shot impacts the target. DuraSeal self-sealing, hole-closing material lets bullets pass through with little damage to the target prolonging the life of the target. DuraSeal is constructed to absorb hundreds of rounds from rifles and handguns.

Champion also offers “bouncing balls” and a 3D Star targets that hop and roll when shot. These make good long-range tactical rifle targets. The lifespan is not that great with large heavy bullets, but one of the ball or star targets should survive many dozens of hits with a .223 Rem or 6mmBR. We do recommend sticking to .22 LR rimfire rounds for best target longevity.

April 5th, 2016

Federal Ammunition is releasing a new line of range ammunition with polymer-encased projectiles. American Eagle Syntech is the first range-specific factory-loaded ammunition designed to reduce fouling and extend barrel life with a high-tech polymer bullet coating plus specially-formulated clean-burning powders. The potential for reduced wear and fouling is real — when tested against conventional FMJ ammunition, Federal claims Syntech produced an average of 12% less barrel friction and 14% less heat. Also, since Syntech bullets lack a metal jacket, there is less chance of ricochets on steel targets. Initially, three (3) types of Syntech ammo will be offered: 9mm Luger (115 grain); 40 S&W (165 grain); and .45 ACP (230 grain).

For years this Editor has loaded his .45 ACP and .44 Mag handguns with polymer/moly matrix-coated bullets from Precision Bullets in Texas. Those poly/moly-encased lead bullets shot VERY accurately and I found that my barrels fouled much less than with conventional lead bullets. Likewise, there was much less cylinder fouling on my revolvers. If the American Syntech bullets work as well as those Precision bullets, I think the Syntech line will be a winner. Syntech bullets should benefit any shooter who frequents a range where lead ammo is not allowed.

Features & Benefits

• Polymer-encapsulated Syntech bullet prevents metal-on-metal contact in the bore, eliminating copper and lead fouling, while extending barrel life.

• Exclusive primer formulation provides reliable, consistent ignition.

• Clean-burning propellants minimize residue and fouling.

• Significantly reduces the required frequency of cleaning.

• Absence of a copper jacket minimizes splash-back on steel targets.

December 15th, 2015

For years we have touted the advantages of Burris Signature rings, with polymer Pos-Align Inserts. Now this system is available in a beefier, heavy-duty ring system for tactical rifles. The new Burris XTR Signature Rings offer six (6) clamping bolts per ring plus strong, dual steel base-clamps that self-center on Weaver or Picatinny rails. These aluminum XTR Signature Rings provide strength and holding power, plus the key benefits of Pos-Align inserts. As impressive as XTR rings are — they aren’t that expensive, with 1″-diameter XTRs starting at about $90.00 per pair (30mm and 34mm XTRs cost a bit more).

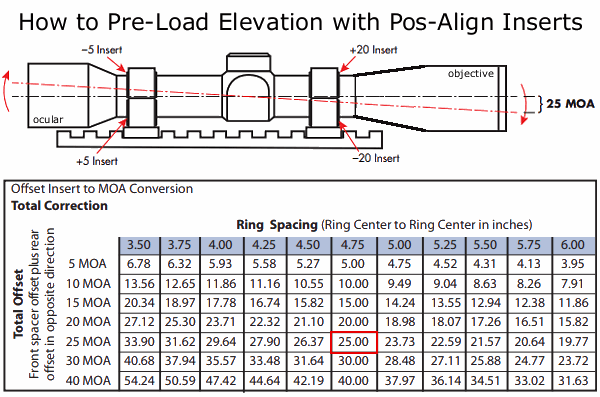

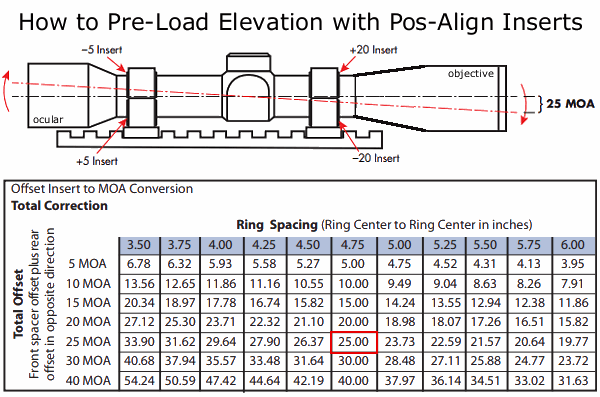

The polymer inserts in Signature rings perform three key functions. First, the inserts provide full, uniform scope-to-ring contact, with no need for lapping. You get a very secure “grip” on your scope without ring marks. Second, the Pos-Align inserts can provide elevation “pre-load”. With eccentric (offset) inserts, you can raise the back of the scope relative to the front, gaining up to 54 MOA of built-in elevation, without the need for expensive tapered bases. Third, the offset inserts can be rotated clockwise or counter-clockwise to shift point of impact. This lets you zero your rifle easily while keeping the turrets in the center of their travel.

Burris XTR Signature Rings are offered in 1″, 30mm, and 34mm diameters, and three (3) different heights: 1″, 1.25″, and 1.5″. Each ring set includes two sets of concentric inserts and one set each of the following offset inserts: +/-5 MOA, +/-10 MOA, +/-20 MOA. These allow you to “pre-load” elevation and/or center up your cross-hairs.

– Pre-load Elevation. No need for expensive tapered bases for long-range shooting.

– Correct misalignment caused by off-center receiver holes.

– Correct for bases or rings being slightly off-center.

How to Pre-load Elevation

To add elevation, set the Pos-Align Offset Inserts to raise the rear of the scope and lower the front. As long as there remains sufficient clearance between the front objective bell and the barrel, Burris recommends lowering the front of the scope the most and raising the rear of the scope the least. The amount of actual elevation “pre-load” will depend on the ring spacing (see chart). In the illustration, with 4.75 inches between ring centers, a +/- 20 MOA pair in the front combined with a -/+ 5 MOA pair in the rear will yield +25 MOA of total elevation. (If the rings are positioned further apart, you’ll get less elevation pre-load.)

Using Inserts to Adjust Point of Impact in Any Direction

Although it is convenient and most understandable to refer to the ring inserts as a “bottom” or “top” insert, the inserts may be rotated to any angle within the scope rings. This allows the shooter to correct the point-of-impact in any direction. The drawings below show how the inserts can be rotated to induce both elevation and windage changes at the same time.

Product tip from Boyd Allen. We welcome reader submissions.

October 2nd, 2015

BIG news in the shooting sports industry — Ruger has entered the ammo business. Ruger now offers high-tech handgun ammunition, using licensed polymer-composite, lead-free bullet technology. According to the Shooting Wire: “Ruger’s new lead-free ammunition will be produced under a licensing agreement with Savannah, Georgia-based PolyCase Ammunition.”

|

Ruger’s new ARX line of lead-free ammo features injection-molded bullets that are much lighter than conventional projectiles, caliber by caliber: 56 grains for .380 ACP, 74 grains for 9x19mm, 107 grains for .40 SW, and 114 grains for .45 ACP. The lighter bullets fly faster, but ARX ammo still offers reduced perceived recoil.

|

ARX Ammo for SALE

.380 ACP

9mm Luger

.40 SW

.45 ACP |

Ruger ARX Ammo with Injection-Molded Matrix Bullets

The fluted projectiles are injection-molded from a copper/polymer matrix. This offers many advantages. First, being completing lead-free, these bullets can be used at indoor facilities that prohibit lead-based ammo. Second, because the composite bullets weigh 30% less than comparable lead-based projectiles, shooters experience noticeably less recoil (even though velocities are higher). Third, the composite matrix bullet has low-ricochet properties. When these bullets strike metal, they are designed to disintegrate (into a powder), rather than ricochet. This makes them well-suited for indoor use, or use with metal plates.

Shooting Wire Editor Jim Shepherd reports that ARX ammo delivers on its low-recoil promise: “Having spent time testing the PolyCase ammunition (largely in Ruger firearms), I know the reduction in felt recoil isn’t just hype. While firing PolyCase ARX ammunition in calibers ranging from .380 in small concealed carry pistols (including a Ruger’s LCP) up to .458 SOCOM in modern sporting rifles, the lessened felt recoil was noticeable.”

PolyCase Molded Bullet Design Technology

For over a century most bullets have been mass-produced with a process called cold-forming. Lead and copper were shaped with brute force in punches and dies to create projectiles. While this is still a viable and effective way to produce bullets, other manufacturing methods are now available. By applying injection-molding technology, Polycase has developed a new type of bullet that has many advantages, as least for handgun applications. Bullets weigh approximately 70% as much as lead bullets with similar profiles. Lighter weight means higher velocities and less recoil. In addition, PolyCase bullets are lead-free, and low-ricochet — two qualities important for indoor and close-range training. The injection-molding process also reduces weight variations (compared to cast lead bullets), and ensures excellent concentricity. Molding also allows unique shapes that are impossible to produce with conventional bullet-making methods (see photo).

April 26th, 2015

Magpul caused a stir with its surprise introduction of an advanced stock for Rem 700 actions. Now Magpul has followed that with a product that could be even more successful — a tactical-style reinforced polymer stock for the popular Ruger 10/22 rimfire rifle.

Priced at just $139.95, Magpul’s new Hunter X-22 stock features tactical styling and adjustable ergonomics. Like Magpul’s Hunter 700 stock for the Rem 700, the new X-22 stock offers adjustable length-of-pull (LOP) via spacers, plus adjustable comb height via optional Cheek Riser Kits. To ensure compatibility with all Ruger 10/22s, the Magpul X-22 stock features an innovative reversible barrel tray that fits heavy bull barrels as with as thinner, factory-contour barrels. Fitted with M-LOK accessory slots and a rubber buttpad, Magpul’s new Hunter X-22 will be offered in four colors: Black, Gray, Dark Earth (Tan), Olive Drab (Green). See all four colors below:

January 11th, 2015

Georgia-based PolyCase Ammunition has developed innovative polymer-based composite cartridge cases and injection-molded bullets. With a patent-pending design, the polymer cartridge cases are lighter than brass or steel cases, yet are heat-tolerant, and relatively easy to manufacture. These cases will be initially produced for .223 Remington, plus a variety of pistol cartridge types (.380 ACP, .38 SPL, 9mm Luger). PolyCase cartridge cases blend patented heat-resistent polymers with metal elements in the case base. According to the manufacturer, “the net effects are greatly reduced weight (compared to comparable loaded ammunition), durability… and competitive pricing.” Other companies have experimented with polymer cartridge cases in the past — none have successfully perfected the technology in a commercially successful product. Could PolyCase be the first?

PolyCase Ammunition — Material Characteristics

– PolyCase Pistol Cartridge Cases are 11.5 to 20% lighter than brass-cased ammunition.

– PolyCase Rifle Cartridge Cases are 23 to 60% lighter than brass-cased ammunition.

– PolyCase Cartridge Cases are self-lubricating — a positive factor compared to brass or steel cases.

PolyCase Bullets — Injection-Molded Blend of Copper and Plastic

PolyCase has developed its own unique bullets for use in pistol ammunition. PolyCase Cu/P™ bullets are precision injection-molded from a cutting-edge copper-polymer compound. These molded bullets will be offered in both polymer cases and conventional brass cases. (Early in the design process, PolyCase determined that molded bullets work well in both brass and plastic cases). PolyCase co-owner Paul Lemke (Lt. Col. U.S. Army, Ret.) says: “We are able to use essentially the same molds to produce bullets for brass casings and bullets for our polymer casings”.

PolyCase Pioneers Injection-Molded Bullet Technology

Powdered metal has been around for decades, but blending powdered metal with polymers and injection molding precise parts is a fairly modern process. While processes like sintered metal bullets and pressure-formed shotgun pellets have become commonplace, PolyCase is the first American company to produce and sell a completely injection-molded bullet.

For over a century most bullets have been mass-produced with a process called cold-forming. Lead and copper were shaped with brute force in punches and dies to create projectiles. While this is still a viable and effective way to produce bullets, other manufacturing methods are now available. By applying injection-molding technology, Polycase has developed a new type of bullet that has many advantages, as least for handgun applications. Bullets weigh approximately 70% as much as lead bullets with similar profiles. Lighter weight means higher velocities and less recoil. In addition, PolyCase bullets are lead-free, and low ricochet — two qualities important for indoor and close-range training. The injection-molding process also reduces weight variations (compared to cast lead bullets), and ensures excellent concentricity. Molding also allows unique shapes that are impossible to produce with conventional bullet-making methods (see photo).

September 23rd, 2013

Do you enjoy plinking with rimfire rifles and shooting reactive targets with handguns? Champion has developed a series of fun targets that tilt, spin, hop, or roll when hit. Made from a “self-healing” rubber-like polymer, Champion’s DuraSeal Targets can be hit dozens of times before they need to be replaced. (If you shoot only rimfire, they might last 200 rounds or more.) Along with the varmint spinners, we like Champion’s weighted wobble targets. These are offered in both a bowling pin shape and a sphere on a post (photo right). When you hit these targets they rock back and forth and side to side. Weights in the round bottom then bring the target back to an upright position. Do you enjoy plinking with rimfire rifles and shooting reactive targets with handguns? Champion has developed a series of fun targets that tilt, spin, hop, or roll when hit. Made from a “self-healing” rubber-like polymer, Champion’s DuraSeal Targets can be hit dozens of times before they need to be replaced. (If you shoot only rimfire, they might last 200 rounds or more.) Along with the varmint spinners, we like Champion’s weighted wobble targets. These are offered in both a bowling pin shape and a sphere on a post (photo right). When you hit these targets they rock back and forth and side to side. Weights in the round bottom then bring the target back to an upright position.

Champion also offers “bouncing balls” and a 3D Star targets that hop and roll when shot. These make good long-range tactical rifle targets. The lifespan is not that great with large heavy bullets, but one of the ball or star targets should survive many dozens of hits with a .223 Rem or 6mmBR.

January 3rd, 2011

Ruger has just introduced a new 9mm carry pistol. Very light (17 oz.), very thin (0.9″), Ruger’s LC9 is the bigger brother to the company’s successful LCP pocket 380acp. According to Ruger CEO Michael Fifer, consumer demand inspired this new pistol: “Customers repeatedly requested a lightweight, compact 9mm pistol. Frankly, they wanted an LCP chambered in 9mm.”

Ruger LC9 Press Release

The LC9™ [is] a lightweight, compact 9mm pistol for discreet carry by law abiding citizens, or a full-power, no-compromise backup for off-duty law enforcement officers. This highly requested pistol was developed through Ruger’s Voice of the Customer program…. The LC9™ [is] a lightweight, compact 9mm pistol for discreet carry by law abiding citizens, or a full-power, no-compromise backup for off-duty law enforcement officers. This highly requested pistol was developed through Ruger’s Voice of the Customer program….

The LC9 has a 3.12″ barrel, is 6.0″ long and 4.5″ tall, making for a very compact 9mm pistol. The LC9 is impressively narrow at a mere .90″ wide, and weighs only 17.1 ounces with an empty magazine. Featuring a black polymer (glass-filled nylon) frame and blued alloy steel slide and barrel, the lightweight, full-featured Ruger LC9 offers the versatility and capability of the popular 9mm cartridge in a highly compact, reliable, and user-friendly pistol.

LC9 Design Features

The LC9 is a double-action-only, hammer-fired, locked-breech pistol with external extractor, and single-sided manual safety. The Ruger LC9’s polymer frame and steel slide feature smooth “melted” edges. One seven-round, single-column magazine is provided with each LC9 pistol, with an optional finger grip extension. Yes there is a nanny-state mag disconnect, and a California-approved loaded chamber indicator. Sights are low-profile with one dot in front, two in the rear.

December 4th, 2010

ARES Puškárska Dielňa, a Slovakian bullet-maker, has come up with a new colorized bullet coating for cast lead bullets. This coating provides a surface barrier so that the lead does not contact the rifling in the barrel. In addition, no bullet lube is required and the colored coating reduces friction. As explained on the Wieder-Lader.de website, “Please take into consideration that ARES Colored Bullets are more quick than copper plated/FMJ bullets. If you used to [shoot] copper plated/FMJ bullets, please start reloading Colored Bullets (CB) with approx. 5% less powder and adjust the final quantity of powder on basis of your own speed measurements. CBs keep the barrel clean. CBs are ready for reloading, i.e. it is not necessary to grease CBs.” ARES Puškárska Dielňa, a Slovakian bullet-maker, has come up with a new colorized bullet coating for cast lead bullets. This coating provides a surface barrier so that the lead does not contact the rifling in the barrel. In addition, no bullet lube is required and the colored coating reduces friction. As explained on the Wieder-Lader.de website, “Please take into consideration that ARES Colored Bullets are more quick than copper plated/FMJ bullets. If you used to [shoot] copper plated/FMJ bullets, please start reloading Colored Bullets (CB) with approx. 5% less powder and adjust the final quantity of powder on basis of your own speed measurements. CBs keep the barrel clean. CBs are ready for reloading, i.e. it is not necessary to grease CBs.”

In the photo below, a .40-caliber bullet is shown before and after firing (the bullet was recovered from the target). You can see that the fired bullet (labeled “after”) has been engraved by the rifling, but very little, if any, lead was exposed.

No this is not a hoax — no Photoshop tricks here. ARES offers a a full line of colored pistol and rifle bullets from .25 caliber up to .58 caliber. Ares even offers colored shotgun slugs. We haven’t seen ARES bullets in the USA yet, but they are sold throughout Europe by ARES Distributors.

Don’t Snack on ARES Bullets

Though ARES colored bullets do look like Jelly Beans, they are most definitely NOT to be eaten. We will still have to wait a while for snack bullets, such as BIO-Bullets, the vitamin-enriched “Incredible Edibles” unveiled in our 2010 April Fool’s Edition.

Moly-Polymer Coated Bullets in USA

Precision Bullets in Texas sells cast lead bullets coated with a proprietary moly-polymer matrix. With this special coating, the moly does not rub off like most moly-coated pistol bullets. The coating is tough enough to survive heat that will melt the lead core (See Photo). This Editor has shot thousands of Precision Bullets’ coated bullets in my .45 ACP and .40SW pistols. These “Black Bullets” are extremely accurate and the leading in the barrel is dramatically reduced compared to normal cast lead bullets.

May 23rd, 2009

Champion’s line of DuraSeal™ targets won the NRA’s 2009 Golden Bullseye Award as American Rifleman’s “Accessory of the Year”. According to the NRA, “these auto-resetting targets handle varmint rifles and handguns, as well as many large-caliber rifles. This is the kind of product that makes shooting more fun.”

Champion’s DuraSeal Spinner Targets feature a non-metal, self-healing DuraSeal material. Weighing 80 percent less than metal equivalents, this space-age polymer material allows bullets to pass through the target, so the targets are “self-healing” and will survive hundreds of centerfire hits. We wish the wire support frame supports were a bit stronger — an errant shot CAN bend or break the wire supports, but the targets are still fun and inexpensive. DuraSeal targets range in price from $17.95 to $24.95 (MSRP).

These lightweight DuraSeal targets are much easier to haul to the range than armored steel gongs or poppers. They are useful for varmint silhouette practice and the single 5.5″ diamond is a good, challenging size for 600-yard precision rifle practice (provided you have a larger paper target to get zeroed at 600).

|

Do you enjoy plinking with rimfire rifles and shooting reactive targets with handguns? Champion has developed a series of fun targets that tilt, spin, hop, or roll when hit. Made from a “self-healing” rubber-like polymer, Champion’s DuraSeal Targets can be hit dozens of times before they need to be replaced. (If you shoot only rimfire, they might last 200 rounds or more.) Along with the varmint spinners, we like Champion’s weighted wobble targets. These are offered in both a bowling pin shape and a sphere on a post (photo right). When you hit these targets they rock back and forth and side to side. Weights in the round bottom then bring the target back to an upright position.

Do you enjoy plinking with rimfire rifles and shooting reactive targets with handguns? Champion has developed a series of fun targets that tilt, spin, hop, or roll when hit. Made from a “self-healing” rubber-like polymer, Champion’s DuraSeal Targets can be hit dozens of times before they need to be replaced. (If you shoot only rimfire, they might last 200 rounds or more.) Along with the varmint spinners, we like Champion’s weighted wobble targets. These are offered in both a bowling pin shape and a sphere on a post (photo right). When you hit these targets they rock back and forth and side to side. Weights in the round bottom then bring the target back to an upright position.

The LC9™ [is] a lightweight, compact 9mm pistol for discreet carry by law abiding citizens, or a full-power, no-compromise backup for off-duty law enforcement officers. This highly requested pistol was developed through Ruger’s Voice of the Customer program….

The LC9™ [is] a lightweight, compact 9mm pistol for discreet carry by law abiding citizens, or a full-power, no-compromise backup for off-duty law enforcement officers. This highly requested pistol was developed through Ruger’s Voice of the Customer program….