|

|

April 11th, 2015

Gear Review by Germán A. Salazar, Contributing Editor

Reloading at the range with an arbor press and Wilson dies is my preferred method of load development. I’ve had a chance to test and evaluate the Arbor Press from 21st Century Shooting. I have to say I’m very favorably impressed by it.

An arbor press’ basic function is simple enough: exert sufficient downward pressure on the die to either size the case neck or seat the bullet depending on which die is in use. It isn’t a mechanically challenging function. So why do we use an arbor press and what should be look for in one? Consistent operation, sensitive feel, quality of design and machining are the hallmarks of a good arbor press and this one from 21st Century comes away with good marks in all areas. An arbor press’ basic function is simple enough: exert sufficient downward pressure on the die to either size the case neck or seat the bullet depending on which die is in use. It isn’t a mechanically challenging function. So why do we use an arbor press and what should be look for in one? Consistent operation, sensitive feel, quality of design and machining are the hallmarks of a good arbor press and this one from 21st Century comes away with good marks in all areas.

For my initial session with the press, I seated 72 bullets in .30-06 cases, another 70 in .308 cases and neck sized a handful of cases (just for evaluation since I prefer to full-length size). The design of the actuating arm, which angles slightly away from the press was very convenient, allowing me to operate it with less jostling of the press because my fingers weren’t bumping into the press head as they sometimes do with my previous press that has the handle parallel to the press head. That’s a nice touch and shows the press was designed by someone who has used these things.

|

|

The press uses a relatively light return spring which materially aids the feel of seating pressure. I prefer this to a heavier return spring which would reduce the feel that I really look for in an arbor press. For someone who uses very heavy neck tension this might not be a big concern, but because I usually use 0.001″ to 0.002″ neck tension, the ability to detect small levels of variance in seating pressure is important to me.

High Quality Machining and Parts Finishing High Quality Machining and Parts Finishing

Every part of the 21st Century press reflects careful thought and skilled machining. The knurled wheel for adjusting the height of the press head is a distinct improvement over the plastic hardware store knobs seen on many presses.

The aluminum press head itself is nicely anodized, the steel base well blued and the shaft nicely polished. Even the decapping base (photo at left) reflects careful design as well as precise machining. Overall, the press gives a look and feel of quality and is a welcome addition to my range reloading setup.

Editors’ Note: The designer of the 21st Century Arbor Press has decades of tool-making experience, and he has designed tools for many “big-name” companies. 21st Century stands behind the product with a lifetime warranty for the original purchaser. The Arbor Press is currently offered in four different versions, with two post heights (8.5″ or 10.5″), and two baseplate sizes (small 3″ x 4″ or large 4″ x 5″). Prices start at $94.99 for the 8.5″ post and small baseplate. CLICK HERE for more info. Editors’ Note: The designer of the 21st Century Arbor Press has decades of tool-making experience, and he has designed tools for many “big-name” companies. 21st Century stands behind the product with a lifetime warranty for the original purchaser. The Arbor Press is currently offered in four different versions, with two post heights (8.5″ or 10.5″), and two baseplate sizes (small 3″ x 4″ or large 4″ x 5″). Prices start at $94.99 for the 8.5″ post and small baseplate. CLICK HERE for more info.

21st Century Shooting

www.21stCenturyShooting.com

(260) 273-9909

This review originally appeared in RiflemansJournal.com in 2010. 21st Century Shooting Inc., a site advertiser, supplied an Arbor Press for testing and evaluation.

December 4th, 2012

In his Riflemans Journal Blog, German Salazar has authored an excellent article on IMR 4320 — The Forgotten Powder. German tested IMR 4320 and found that it produced outstanding results both in the .308 Winchester and the 30-06. This means that shooters have another very effective propellant option for their .308 and 30-06 match rifles. With H4895 and Varget being hard to obtain lately, you may want to give IMR 4320 a try. In his Riflemans Journal Blog, German Salazar has authored an excellent article on IMR 4320 — The Forgotten Powder. German tested IMR 4320 and found that it produced outstanding results both in the .308 Winchester and the 30-06. This means that shooters have another very effective propellant option for their .308 and 30-06 match rifles. With H4895 and Varget being hard to obtain lately, you may want to give IMR 4320 a try.

German writes: “IMR 4320 falls right between 4895 and 4064 on the burn rate scale for most cartridges — in other words, right where Varget falls. Yet, despite having a very useful burn rate, 4320 has languished for decades while newer powders of similar burn rate have gained in popularity. I was interested in seeing what current production IMR 4320 would do in the .308 with the 155gr Palma bullets. My interest was sparked by the obvious fact that Varget and H4895 have been very hard to get lately while IMR 4320 sits on the shelves.”

German loaded up some .308 Win loads with IMR 4320 and moly-coated Sierra 155gr Palma bullets. German’s “practical max” load delivered 2990 fps in his long-barreled Palma rifle. This is certainly competitive speed-wise.

German observed that: “IMR 4320 has very small granules and throws very consistently from the powder measure — it is very much like Reloder 15 in granule size — so for those who prefer to throw charges it’s a good choice.”

Satisfied with the chron results, German loaded more rounds with the two most promising charge weights and used them in a 500-yard prone match at Ben Avery (ambient temps were 60s-80s F). Here is his report:

“As in the chrono tests, all IMR 4320 loads were with moly-coated Sierra 155 Palma bullets, Winchester brass and PMC primers. Powder charges should be reduced at least 1.0 grain for bare bullets. The load with 45.0 grains of IMR 4320 gave me a 199-12X with the single 9 being a high shot just off the 10 ring line at 12:00. Overall, I would rate that load as good, very useable for the intended purpose of 500 or 600 yard shooting (it’s 2844 fps) but no better than my H4895 load for that purpose.

Next I fired the heavier 47.0 grains ‘practical max’ load and that was an eye opener. The score was 200-15X in conditions that were windier than those in which the first load was fired. Elevation was noticeably tighter and shots were exactly on call. This load gives 2990 fps, so it has real potential as a Palma load. While no 500-yard test can ensure results at 1000, given the MV and reasonably low SD of this load as well as the good performance at 500, I won’t hesitate to shoot it at 1000 at the first opportunity. Warning: this was a STRONG LOAD and may not be safe in your gun.

Overall, I’m very satisfied with what I’ve seen in these past few days from IMR 4320 and plan to shoot it in some of our upcoming Palma and 1000-yard matches with the 155s. It appears to be a very useful alternative to some of the harder to get powders.”

CLICK HERE to Read Complete IMR 4320 Story (includes chron data and match test results).

October 8th, 2012

This 2010 story is reprinted at readers’ request.

In the past few years, tubeguns have really taken over in high power circles. At many matches you’ll see more tubeguns than conventional prone rifles, and a high percentage of those tubeguns will have been built using an Eliseo (Competition Machine) CSS chassis kit.

Step-By-Step Guide to Stock Set-Up

If you are a new tubegun shooter, or if you are planning a tubegun build this winter, German Salazar has prepared a comprehensive set-up guide for Eliseo tubeguns. Eliseo’s CSS chassis system affords a myriad of adjustments. Initially, one can be overwhelmed by all the variables: Length of Pull, Length to Sights, Length to Handstop, Cheekpad Height, Buttstock Offset, Buttstock Cant Angle, Handstop Angle, and Forearm Rotation.

In his Guide to Configuring the Eliseo Tubegun, Salazar shows how to adjust the Tubegun so that a shooter’s prone position is stable, repeatable, and comfortable. Salazar covers each adjustment, step by step. If you follow his instructions, starting with setting Length of Pull, you should find that your hold becomes more stable, the gun moves less from shot to shot, and your eye position relative to the sights is improved. In his Guide to Configuring the Eliseo Tubegun, Salazar shows how to adjust the Tubegun so that a shooter’s prone position is stable, repeatable, and comfortable. Salazar covers each adjustment, step by step. If you follow his instructions, starting with setting Length of Pull, you should find that your hold becomes more stable, the gun moves less from shot to shot, and your eye position relative to the sights is improved.

German explains the set-up process: “Adjusting the stock is a process that you must work at and it builds on itself. As you get one adjustment right, the others begin to fall into place. Our hope is that you take from this article a system for adjusting the stock, not an exact set of dimensions; and that you understand that it will take continuous work over a period of time to really refine the adjustments. Your goal is not to obtain a ‘perfect set of dimensions’ but rather a perfect feel that accomplishes the three objectives of stability, durability and comfort and the knowledge of how to change the adjustments to achieve those objectives under varying conditions such as sloped firing lines or other terrain features.”

Read More at RiflemansJournal.com

German Salazar runs the excellent Rifleman’s Journal website, where you will find dozens of informative articles like this story.

March 10th, 2012

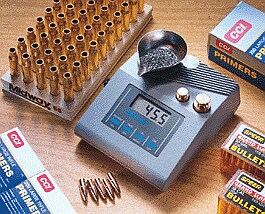

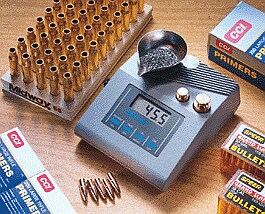

Here’s a tip that can help you score higher at matches and get more predictable results when weighing loads with an electronic scale. Kelly Bachand, a top prone shooter and electrical engineering major at the Univ. of Washington, tells us that all digital scales can drift. Therefore Kelly recommends re-calibrating electronic scales often. In addition — and this is key — Kelly recommends that you shoot the ammo in the exact order in which it was loaded. Arrange your loaded ammo in a box in the order of loading and shoot it first-loaded to last-loaded. (Or, if you prefer, shoot it last-loaded to first-loaded.) The important thing is to maintain the order and not mix everything up. That way, if your scale drifts, the effect of drift on charge weight will be incremental from one loaded round to the next, so point of impact change should be negligible. Conversely, if you shoot your last-loaded round right after your first-loaded round, the effect of scale drift is at its maximum, so powder charge varience is maximized. And that can produce a different point of impact (POI) on the target. Here’s a tip that can help you score higher at matches and get more predictable results when weighing loads with an electronic scale. Kelly Bachand, a top prone shooter and electrical engineering major at the Univ. of Washington, tells us that all digital scales can drift. Therefore Kelly recommends re-calibrating electronic scales often. In addition — and this is key — Kelly recommends that you shoot the ammo in the exact order in which it was loaded. Arrange your loaded ammo in a box in the order of loading and shoot it first-loaded to last-loaded. (Or, if you prefer, shoot it last-loaded to first-loaded.) The important thing is to maintain the order and not mix everything up. That way, if your scale drifts, the effect of drift on charge weight will be incremental from one loaded round to the next, so point of impact change should be negligible. Conversely, if you shoot your last-loaded round right after your first-loaded round, the effect of scale drift is at its maximum, so powder charge varience is maximized. And that can produce a different point of impact (POI) on the target.

Tips on Loading with Electronic Scales

by Kelly Bachand

If you use a digital scale to measure powder charges, recalibrate the scale often. I like to do this about every 25 rounds or so. Additionally, most electronic scales rely on eddy currents for their precision. Eddy currents are easily disrupted by static electricity so keep a cloth or ground strap nearby to remove any static currents should the scale start acting up; I usually just use a fabric softener sheet that has gone through the dryer once.

Shoot Ammo in Order of Loading

I shoot my rounds in the same order or reverse order as I load them. If the charge weight varies due to scale drift during use, the difference will be gradual if I shoot in the same order as production (or reverse order). I should be able to adjust for the slight varience in charge weight without having any wildly high or low shots (see the charts below for a graphical demonstration). I usually load my ammunition just 100 rounds at a time. Give yourself plenty of time and remember that you will make your best ammunition when you are fully awake and alert.

This graph demonstrates the effect a .01% (that’s 1/100th of 1 percent) difference in scale measurement would have over the course of 100 rounds assuming the desired load is somewhere between 46 and 47 grains. The final round made would have almost 1% less (or more) powder than the first, that’s almost an 0.5 grain difference from the first. If shot back to back, these rounds will invariably have different points of impact on the target.

This graph demonstrates the same .01% difference in scale measurement but this time with a recalibration every 25 rounds. By recalibrating the scale every 25 rounds the furthest a weighed charge ever gets from the original is less than 0.25%. Again if the charge being weighed is between 46 and 47 grains then the 26th round made would vary from the 1st by .12 grains. Even that small difference would likely show on target.

Either way it is important to note that if the bullets are shot in the same (or reverse) order as they are made, the biggest difference from bullet to bullet in this example is less than .01 grains.

March 2nd, 2012

In today’s economy, Free is good. Here’s a list of older shooting books that can be downloaded for FREE from Google Books. This list, created by German Salazar, includes many classic treatises on marksmanship that still have value for today’s competitive shooters. In addition, we’ve included illustrated firearm histories, such as Townsend Whelen’s fascinating book, The American Rifle, and The Gun and its Development (9th Ed.), by William Wellington Greener. In today’s economy, Free is good. Here’s a list of older shooting books that can be downloaded for FREE from Google Books. This list, created by German Salazar, includes many classic treatises on marksmanship that still have value for today’s competitive shooters. In addition, we’ve included illustrated firearm histories, such as Townsend Whelen’s fascinating book, The American Rifle, and The Gun and its Development (9th Ed.), by William Wellington Greener.

In the list below, the title link will take you to the Google Books page for each book. You can read the entire book online, or you can download it to your computer as a PDF file* and save it (or print it). You can also create your own Google Library and save the books there for access from any computer.

The Bullet’s Flight From Powder to Target, Franklin W. Mann, 1909, 384 pages.

Irish Riflemen in America, Sir Arthur Blennerhassett Leech, 1875, 216 pages.

The American Rifle, Townsend Whelen, 1918, 637 pages.

Suggestions to Military Riflemen, Townsend Whelen, 1909, 243 pages.

Modern Rifle Shooting From the American Standpoint, W. G. Hudson, 1903, 155 pages.

The Gun and its Development, William Wellington Greener, 1907 (9th Ed.) 846 pages. The Gun and its Development, William Wellington Greener, 1907 (9th Ed.) 846 pages.

Manual for Rifle Practice: Including Suggestions for Practice at Long Range, George Wood Wingate, 1879, 303 pages.

How I Became a Crack Shot — With Hints to Beginners, W. Milton Farrow, 1882, 204 pages.

Cartridge Manufacture, Douglas Thomas Hamilton, 1916, 167 pages.

Description and Rules for the Management of the United States Rifle, Caliber .30, Model of 1903, United States Army Ordnance Dept., 1904 (5th rev. 1914), 72 pages.

CLICK HERE for more FREE, downloadable Classic Shooting Titles.

*To download a book, first click the title from the list above. Then, once you’re at the Google book site, look for the icon that looks like a gear in the upper right-hand corner. Click that and a pull-down menu will appear. Select “Download PDF” from the menu — this will bring up a security question to make sure you are a human. Respond to the security question correctly and your normal download prompt will appear. Choose a location to hold your new e-book, and click “save”.

February 9th, 2011

Gear Review: 21st Century Neck Turner

by Germán A. Salazar

A new neck-turning tool with easy adjustments, super-high quality of manufacturing and an ergonomic design sounds like a good thing to me. If you also like good tools and like to keep up with developments in the field, read on (most of the pictures can be enlarged by clicking on them).

I recently received the new Neck-Turning Tool made by John at 21st Century Shooting. I always enjoy seeing John’s work because he really has a good grasp on how a tool should be designed to work effectively and this tool certainly fits that mold. The basic requirements of a good neck turner are: (a) accurate adjustments, (b) good blade design, (c) ergonomic design and (d) a well thought-out system of ancillary items. Let’s look at each of those areas and give the tool a test drive.

Handy Cut-Depth Adjustment Dial Handy Cut-Depth Adjustment Dial

The 21st Century neck turner has a unique dial adjustment for the depth of the cut which makes small adjustments simple and fast. Each full number represents 0.001″ of cutter movement, and the fine lines in between let you zero in on the exact neck wall thickness that you need. The dial is simply turned in until the desired neck thickness is reached. If you go too far, it’s best to turn it out a full turn, then back in once again; this reduces the effect of any backlash that might exist in the threads. I found the dial easy to use and had no trouble getting to my usual thickness setting of 0.0125″.

Excellent Carbide Cutter Blade Design Excellent Carbide Cutter Blade Design

At its core, a neck turner is a cutting tool and good blade design is what sets any good cutting tool apart from the competition. Here, John really shows his ability as a designer and manufacturer. The blade supplied on my tool is carbide and cuts brass effortlessly, however, that’s not the real point of interest. Many neck turners have blades with less than ideal nose radius and create a “threading” effect on the neck unless the tool is fed over the brass at a very slow rate. The 21st Century blade has a good radius at the transition to the shoulder angle which allows for a smooth cut with a reasonable feed rate.

The shoulder angle is another well thought-out feature as it is a very close match to the actual shoulder angle of the case. This allows you to bring the cutter a bit further into the shoulder without weakening it and definitely avoid the subsequent occurrence of the donut of thick brass at the base of the neck. (When ordering, 21st Century lets you specify one of four (4) different cutter shoulder angles to match your particular cartridge: 20°, 30°, 35°, and 40°.) The photo of the case in the cutter shows the cutter making solid contact with the shoulder after a substantial cut on the neck, yet the shoulder was really just lightly touched. I backed the cutter off a bit from this setting for the final adjustment. If you tend to use heavy bullets which extend below the base of the neck, this feature alone makes John’s tool worthwhile.

Turning necks is tedious, especially if you’re turning a large number of cases as High Power shooters generally do. Accordingly, a design that takes ergonomics into consideration is highly appreciated. Note the slight hourglass shape of the tool, that really lets your hand take a grip that counters the natural tendency of the tool to turn with the rotation of the case, especially when turning with a power case driver. The size of the tool itself also helps; if you’ve used one of the smaller tools on the market, you know just how tired your hand can get from trying to hold on to it after a while! I turned 70 case necks in two sessions with the 21st Century tool and my hand and fingers remained comfortable throughout. Turning necks is tedious, especially if you’re turning a large number of cases as High Power shooters generally do. Accordingly, a design that takes ergonomics into consideration is highly appreciated. Note the slight hourglass shape of the tool, that really lets your hand take a grip that counters the natural tendency of the tool to turn with the rotation of the case, especially when turning with a power case driver. The size of the tool itself also helps; if you’ve used one of the smaller tools on the market, you know just how tired your hand can get from trying to hold on to it after a while! I turned 70 case necks in two sessions with the 21st Century tool and my hand and fingers remained comfortable throughout.

However good the turner may be, it doesn’t work alone. Any neck turner needs a matching expander. The 21st Century expander is a nicely designed unit that allows you to change expander sizes with no tools by simply unscrewing the cap of the die body and dropping in the appropriate expander.

K&M Arbor Adapters Available K&M Arbor Adapters Available

I’ve been using a K&M turner for some years now and have accumulated turning arbors (mandrels) in various sizes. John knows that’s the case for many of us, so he makes affordable adapter bushings for his tool that allow the use of K&M turner arbors. That’s a nice feature that will allow me to save the price of a few arbors and expanders. The adapter for K&M arbors costs $12.00.

Although I use a cordless screwdriver to turn the case, I still like to have a manual option for case turning. Sometimes the cordless driver dies with just a few cases left to go in a session and I know that, one day, when I most need it, it’ll just quit altogether. John’s case handle for manual case turning is another well-designed, ergonomic piece that shows his careful, thoughtful approach to tool design. He even makes a version of it for the .50 BMG if your tastes in cartridges run on the large side!

Neck-Turning Tool and Accessory Order Information

Order the Neck Turner and accessories through www.21stCenturyShooting.com, or call (260) 273-9909. The 21st Century neck-turning tool, by itself, costs $78.00, including a carbide cutter (standard size). You can chose among four different cutter shoulder angles, to match your particular cartridge: 20°, 30°, 35°, and 40°. Additional carbide cutters cost $26.00-$28.00. Caliber-specific turning arbors and expander mandrels are priced at $7.95 each. The standard size Universal Case-Holding Handle (photo above), costs $16.95.

You can also purchase a complete Neck-Turning Tool Kit from 21st Century. This $112.99 package includes everything you need: You can also purchase a complete Neck-Turning Tool Kit from 21st Century. This $112.99 package includes everything you need:

Neck Turning Tool w/cutter

Turning Arbor

Expander Mandrel

Expander Die Body

Loading Die Locking Ring

Neck Turning Universal Handle

Disclosure: 21st Century Shooting, an advertiser on this website, provided a neck turner tool and accessories to German Salazar for testing and evaluation.

September 12th, 2009

Our current “Cover Story” for the website is about the 6XC Cartridge. German Salazar, a top prone shooter who has won the Arizona NRA Long-Range Championship using the 6XC, reveals how to get the most accuracy out of the cartridge. German discusses brass options, recommended bullets for long-range competition, and German also discusses the pros and cons of various 6XC dies.

CLICK HERE for 6XC Cartridge Review by German Salazar.

The 6XC cartridge was developed by David Tubb, and it has captured multiple Camp Perry Championships. Now that Norma brass is available, the 6XC is an outstanding choice for shooters looking for an ultra-accurate, easy-recoiling cartridge that offers more “horsepower” than the 6BR or 6BR Improved. Team Norma, shooting factory-loaded 6XC ammo, captured the 2007 300m world championship. This was the first time in many years that a cartridge other than the 6BR has won “all the marbles” in international 300m competition. And just last week, the Swedish Team of Anders Brolund, Johan Gustafsson, and Mikael Larsson won the 2009 European 300m Championship shooting the Norma 6XC.

Forum members and 6XC shooters Mudcat and German Salazar are both very happy with their choice of chamberings. German tells us:

“The 6XC is a great long-range cartridge, it needs no excuses and can hold its own against any other LR cartridge. I prefer to use Norma 6XC brass, but 22-250 brass can be used by running through a 6XC full-length die and then fire-forming. It will look pretty nasty at first, but it will shoot just fine even fire-forming.

I principally use the 6XC for 1000-yard prone shooting (sometimes at 600). The main bullet I use is the Berger 115 VLD (in a 30″ Krieger with 1:7.5″ twist). The best powder I’ve found for the Berger 115 in the 6XC is H4831sc. Velocity is in the 3000 fps range. I principally use the 6XC for 1000-yard prone shooting (sometimes at 600). The main bullet I use is the Berger 115 VLD (in a 30″ Krieger with 1:7.5″ twist). The best powder I’ve found for the Berger 115 in the 6XC is H4831sc. Velocity is in the 3000 fps range.

Whether the 6XC is ideal for any given person depends on a lot of factors. I tend to shoot fast and keep the rifle in my shoulder. Accordingly, a low-recoil cartridge suits me because it doesn’t require any repositioning of the rifle or rebuilding of position during a 22-shot string. I know how to read wind, so whether a cartridge drifts a few inches more or less than another isn’t really a concern to me, I learn the cartridge’s behaviour and work with what I’ve got. The 6XC shines because it is ACCURATE at 1000 yards and without that, you’ve got nothing. Accuracy, low recoil, reasonable wind drift, good component availability, decent barrel life, what else is there to want in a long-range cartridge?”

Mudcat concurs that the 6XC is a great cartridge for High Power Competition:

“I am not sure there really are ‘downsides’ for the 6XC. Well, maybe barrel life, if you are used to shooting a 223 or 308. I have fired about 15,000 rounds of 6XC over the last couple of years and havent really found a negative. My 6XC barrels get an easy 2,000 rounds. In fact, most get upwards of 3,000 before I move them to strictly off-hand and rapid-fire use. (I am a High Power shooter, not a Benchrester.)

Propellant — Powder choices are excellent. However, contrary to what German has found, I can’t get H4831sc to get me the velocity that the H4350 can. I have found only two powders that deliver more speed than H4350.

Cases — Just use Winchester 22-250 cases as they last 20+ firings and you never have to trim them. I use Winchester 22-250 brass rather than any of the Tubb or Norma offerings — they are just too soft for my liking. With the Winchester, I know what I am dealing with and know I will get at least 20 firings out of it, on average. And, I never have to trim it. While I have a Giraud power trimmer, I would just as soon not do it.

Bullets — Well, 6mm bullets are out there for about anything you want to shoot.

Velocity — The 6XC offers plenty of speed. Is 3000+ fps with a 115 enough for you? I certainly hope so.

Accuracy — I can’t out shoot the 6XC round. About any decent load will work just fine. Shoot, all my 300-yard and less ammo is loaded on a Dillon 650! Overall, I agree with German, the 6XC will definitely hold its own and I am not sure that my 6.5×284 running 142s at 2950 fps actually drifts much less than the 115 VLDs.”

March 9th, 2009

Interior Secretary Ken Salazar, affirming a decision of the U.S. Fish and Wildlife Service (USFWS), has removed the gray wolf from protection under the Endangered Species Act (ESA). However, this ONLY applies to Idaho, Montana, the Western Great Lakes, and some (but not all) areas of Washington, Oregon, and Utah. Wolves in other parts of the 48 states, including the Southwest states, remain endangered and are not affected by Salazar’s ruling. Wolf hunters should check carefully to ensure that the area(s) where they intend to hunt are not subject to ESA controls. Wolves in Wyoming remain specifically protected. Interior Secretary Ken Salazar, affirming a decision of the U.S. Fish and Wildlife Service (USFWS), has removed the gray wolf from protection under the Endangered Species Act (ESA). However, this ONLY applies to Idaho, Montana, the Western Great Lakes, and some (but not all) areas of Washington, Oregon, and Utah. Wolves in other parts of the 48 states, including the Southwest states, remain endangered and are not affected by Salazar’s ruling. Wolf hunters should check carefully to ensure that the area(s) where they intend to hunt are not subject to ESA controls. Wolves in Wyoming remain specifically protected.

Hunters are advised to wait before planning a hunt. Salazar’s ruling could be stalled by litigation from environmental groups. The Sierra Club has announced: “Aggressive wolf-killing practices, coupled with genetic isolation and plans to institute hunts in Idaho and Montana, could push wolf numbers dangerously low and reverse decades of recovery work. The Sierra Club, along with other conservation groups, plans to challenge the wolf delisting decision in court.”

Praise for Interior Secretary’s Decision

Safari Club International President Merle Shepard hailed the announcement, saying “This decision is the right one and we commend Secretary Salazar for reaching it so quickly. Delisting the gray wolf came about as a result of years of effort involving the states, tribes, landowners, academic researchers, sportsmen and other conservation groups, the Canadian government and many other partners.”

In making the announcement, Secretary Salazar reviewed the numbers behind the decision. “When it was listed as endangered in 1974, the wolf had almost disappeared from the continental United States. Today, we have more than 5,500 wolves, including more than 1,600 in the Rockies,” Salazar said. Gray wolves were previously listed as endangered in the lower 48 states, except in Minnesota where they were listed as threatened. The USFWS oversees three separate recovery programs for the gray wolf; each has its own recovery plan and recovery goals based on the unique characteristics of wolf populations in each geographic area.

|

An arbor press’ basic function is simple enough: exert sufficient downward pressure on the die to either size the case neck or seat the bullet depending on which die is in use. It isn’t a mechanically challenging function. So why do we use an arbor press and what should be look for in one? Consistent operation, sensitive feel, quality of design and machining are the hallmarks of a good arbor press and this one from 21st Century comes away with good marks in all areas.

An arbor press’ basic function is simple enough: exert sufficient downward pressure on the die to either size the case neck or seat the bullet depending on which die is in use. It isn’t a mechanically challenging function. So why do we use an arbor press and what should be look for in one? Consistent operation, sensitive feel, quality of design and machining are the hallmarks of a good arbor press and this one from 21st Century comes away with good marks in all areas.

High Quality Machining and Parts Finishing

High Quality Machining and Parts FinishingEditors’ Note: The designer of the 21st Century Arbor Press has decades of tool-making experience, and he has designed tools for many “big-name” companies. 21st Century stands behind the product with a lifetime warranty for the original purchaser. The Arbor Press is currently offered in four different versions, with two post heights (8.5″ or 10.5″), and two baseplate sizes (small 3″ x 4″ or large 4″ x 5″). Prices start at $94.99 for the 8.5″ post and small baseplate. CLICK HERE for more info.

In his

In his

In his

In his  Here’s a tip that can help you score higher at matches and get more predictable results when weighing loads with an electronic scale. Kelly Bachand, a top prone shooter and electrical engineering major at the Univ. of Washington, tells us that all digital scales can drift. Therefore Kelly recommends re-calibrating electronic scales often. In addition — and this is key — Kelly recommends that you shoot the ammo in the exact order in which it was loaded. Arrange your loaded ammo in a box in the order of loading and shoot it first-loaded to last-loaded. (Or, if you prefer, shoot it last-loaded to first-loaded.) The important thing is to maintain the order and not mix everything up. That way, if your scale drifts, the effect of drift on charge weight will be incremental from one loaded round to the next, so point of impact change should be negligible. Conversely, if you shoot your last-loaded round right after your first-loaded round, the effect of scale drift is at its maximum, so powder charge varience is maximized. And that can produce a different point of impact (POI) on the target.

Here’s a tip that can help you score higher at matches and get more predictable results when weighing loads with an electronic scale. Kelly Bachand, a top prone shooter and electrical engineering major at the Univ. of Washington, tells us that all digital scales can drift. Therefore Kelly recommends re-calibrating electronic scales often. In addition — and this is key — Kelly recommends that you shoot the ammo in the exact order in which it was loaded. Arrange your loaded ammo in a box in the order of loading and shoot it first-loaded to last-loaded. (Or, if you prefer, shoot it last-loaded to first-loaded.) The important thing is to maintain the order and not mix everything up. That way, if your scale drifts, the effect of drift on charge weight will be incremental from one loaded round to the next, so point of impact change should be negligible. Conversely, if you shoot your last-loaded round right after your first-loaded round, the effect of scale drift is at its maximum, so powder charge varience is maximized. And that can produce a different point of impact (POI) on the target.

In today’s economy, Free is good. Here’s a list of older shooting books that can be downloaded for FREE from Google Books. This list, created by German Salazar, includes many classic treatises on marksmanship that still have value for today’s competitive shooters. In addition, we’ve included illustrated firearm histories, such as Townsend Whelen’s fascinating book, The American Rifle, and The Gun and its Development (9th Ed.), by William Wellington Greener.

In today’s economy, Free is good. Here’s a list of older shooting books that can be downloaded for FREE from Google Books. This list, created by German Salazar, includes many classic treatises on marksmanship that still have value for today’s competitive shooters. In addition, we’ve included illustrated firearm histories, such as Townsend Whelen’s fascinating book, The American Rifle, and The Gun and its Development (9th Ed.), by William Wellington Greener.

Turning necks is tedious, especially if you’re turning a large number of cases as High Power shooters generally do. Accordingly, a design that takes ergonomics into consideration is highly appreciated. Note the slight hourglass shape of the tool, that really lets your hand take a grip that counters the natural tendency of the tool to turn with the rotation of the case, especially when turning with a power case driver. The size of the tool itself also helps; if you’ve used one of the smaller tools on the market, you know just how tired your hand can get from trying to hold on to it after a while! I turned 70 case necks in two sessions with the 21st Century tool and my hand and fingers remained comfortable throughout.

Turning necks is tedious, especially if you’re turning a large number of cases as High Power shooters generally do. Accordingly, a design that takes ergonomics into consideration is highly appreciated. Note the slight hourglass shape of the tool, that really lets your hand take a grip that counters the natural tendency of the tool to turn with the rotation of the case, especially when turning with a power case driver. The size of the tool itself also helps; if you’ve used one of the smaller tools on the market, you know just how tired your hand can get from trying to hold on to it after a while! I turned 70 case necks in two sessions with the 21st Century tool and my hand and fingers remained comfortable throughout.

I principally use the 6XC for 1000-yard prone shooting (sometimes at 600). The main bullet I use is the Berger 115 VLD (in a 30″ Krieger with 1:7.5″ twist). The best powder I’ve found for the Berger 115 in the 6XC is H4831sc. Velocity is in the 3000 fps range.

I principally use the 6XC for 1000-yard prone shooting (sometimes at 600). The main bullet I use is the Berger 115 VLD (in a 30″ Krieger with 1:7.5″ twist). The best powder I’ve found for the Berger 115 in the 6XC is H4831sc. Velocity is in the 3000 fps range.

Interior Secretary Ken Salazar, affirming a decision of the U.S. Fish and Wildlife Service (USFWS), has removed the gray wolf from protection under the Endangered Species Act (ESA). However, this ONLY applies to Idaho, Montana, the Western Great Lakes, and some (but not all) areas of Washington, Oregon, and Utah. Wolves in other parts of the 48 states, including the Southwest states, remain endangered and are not affected by Salazar’s ruling. Wolf hunters should check carefully to ensure that the area(s) where they intend to hunt are not subject to ESA controls. Wolves in Wyoming remain specifically protected.

Interior Secretary Ken Salazar, affirming a decision of the U.S. Fish and Wildlife Service (USFWS), has removed the gray wolf from protection under the Endangered Species Act (ESA). However, this ONLY applies to Idaho, Montana, the Western Great Lakes, and some (but not all) areas of Washington, Oregon, and Utah. Wolves in other parts of the 48 states, including the Southwest states, remain endangered and are not affected by Salazar’s ruling. Wolf hunters should check carefully to ensure that the area(s) where they intend to hunt are not subject to ESA controls. Wolves in Wyoming remain specifically protected.