|

|

January 31st, 2023

So what does a “worn-out” barrel really look like? Tom Myers answered that question when he removed a 6.5-284 barrel and cut it down the middle to reveal throat wear. As you can see, there is a gap of about 5mm before the lands begin and you can see how the lands have thinned at the ends. (Note: even in a new barrel, there would be a section of freebore, so not all the 5mm gap represents wear.) There is actually just about 2mm of lands worn away. Tom notes: “Since I started out, I’ve chased the lands, moving out the seating depth .086″ (2.18 mm). I always seat to touch. My final touch dimension was 2.440″ with a Stoney Point .26 cal collet.” So what does a “worn-out” barrel really look like? Tom Myers answered that question when he removed a 6.5-284 barrel and cut it down the middle to reveal throat wear. As you can see, there is a gap of about 5mm before the lands begin and you can see how the lands have thinned at the ends. (Note: even in a new barrel, there would be a section of freebore, so not all the 5mm gap represents wear.) There is actually just about 2mm of lands worn away. Tom notes: “Since I started out, I’ve chased the lands, moving out the seating depth .086″ (2.18 mm). I always seat to touch. My final touch dimension was 2.440″ with a Stoney Point .26 cal collet.”

Except for the 2mm of wear, the rifling otherwise looks decent, suggesting that setting back and rechambering this barrel could extend its useful life. Tom reports: “This was something I just thought I’d share if anyone was interested. I recently had to re-barrel my favorite prone rifle after its scores at 1,000 started to slip. I only ever shot Sierra 142gr MatchKings with VV N165 out of this barrel. It is a Hart and of course is button-rifled. I documented every round through the gun and got 2,300 over four years. Since I have the facilities, I used wire EDM (Electro Discharge Machining) to section the shot-out barrel in half. It was in amazingly good shape upon close inspection.”

Tom could have had this barrel set back, but he observed, “Lately I have had to increase powder charge to maintain 2,950 fps muzzle velocity. So to set it back would have only increased that problem. [And] I had a brand new 30″ Krieger all ready to screw on. I figured it was unlikely I’d get another full season on the old barrel, so I took it off.”

February 16th, 2018

So what does a “worn-out” barrel really look like? Tom Myers answered that question when he removed a 6.5-284 barrel and cut it down the middle to reveal throat wear. As you can see, there is a gap of about 5mm before the lands begin and you can see how the lands have thinned at the ends. (Note: even in a new barrel, there would be a section of freebore, so not all the 5mm gap represents wear.) There is actually just about 2mm of lands worn away. Tom notes: “Since I started out, I’ve chased the lands, moving out the seating depth .086″ (2.18 mm). I always seat to touch. My final touch dimension was 2.440″ with a Stoney Point .26 cal collet.” So what does a “worn-out” barrel really look like? Tom Myers answered that question when he removed a 6.5-284 barrel and cut it down the middle to reveal throat wear. As you can see, there is a gap of about 5mm before the lands begin and you can see how the lands have thinned at the ends. (Note: even in a new barrel, there would be a section of freebore, so not all the 5mm gap represents wear.) There is actually just about 2mm of lands worn away. Tom notes: “Since I started out, I’ve chased the lands, moving out the seating depth .086″ (2.18 mm). I always seat to touch. My final touch dimension was 2.440″ with a Stoney Point .26 cal collet.”

Except for the 2mm of wear, the rifling otherwise looks decent, suggesting that setting back and rechambering this barrel could extend its useful life. Tom reports: “This was something I just thought I’d share if anyone was interested. I recently had to re-barrel my favorite prone rifle after its scores at 1,000 started to slip. I only ever shot Sierra 142gr MatchKings with VV N165 out of this barrel. It is a Hart and of course is button-rifled. I documented every round through the gun and got 2,300 over four years. Since I have the facilities, I used wire EDM (Electro Discharge Machining) to section the shot-out barrel in half. It was in amazingly good shape upon close inspection.”

Tom could have had this barrel set back, but he observed, “Lately I have had to increase powder charge to maintain 2,950 fps muzzle velocity. So to set it back would have only increased that problem. [And] I had a brand new 30″ Krieger all ready to screw on. I figured it was unlikely I’d get another full season on the old barrel, so I took it off.”

July 2nd, 2015

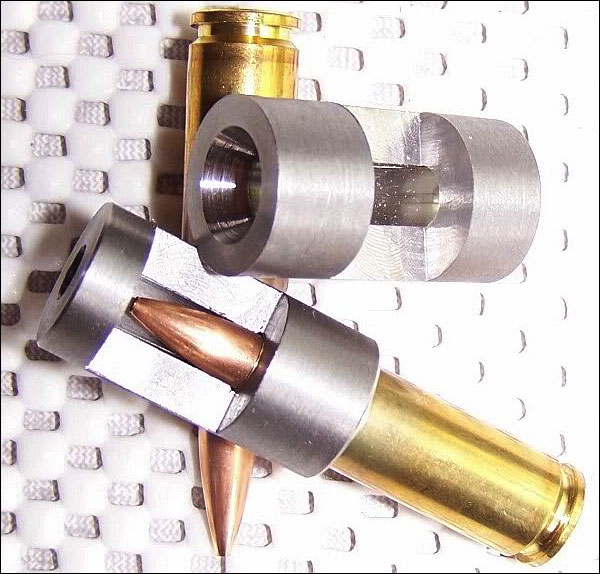

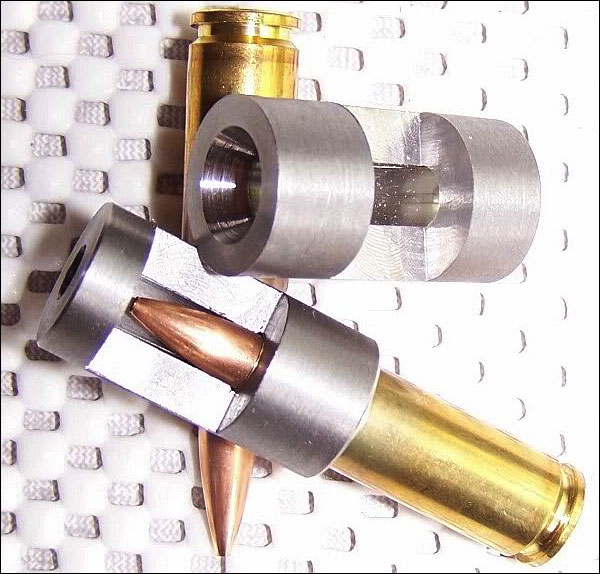

Forum member Rich DeSimone uses a handy “Stub Gauge” for setting shoulder “bump” and seating depth. The gauge is made from a section of barrel lopped off when the muzzle is crowned. The chambering reamer is run in about 1/4 of the way, enough to capture the neck and shoulder area of the case. Rich then uses his full-length die to “bump” a master case with the ideal amount of headspace for easy feeding and extraction. He takes that case and sets it in this Stub Gauge, and measures from the front of the gauge to the rim. He can then quickly compare any fired case to a his “master” case with optimal headspace. Since the gauge measures off the shoulder datum, this tells him how much to bump his fired brass. Forum member Rich DeSimone uses a handy “Stub Gauge” for setting shoulder “bump” and seating depth. The gauge is made from a section of barrel lopped off when the muzzle is crowned. The chambering reamer is run in about 1/4 of the way, enough to capture the neck and shoulder area of the case. Rich then uses his full-length die to “bump” a master case with the ideal amount of headspace for easy feeding and extraction. He takes that case and sets it in this Stub Gauge, and measures from the front of the gauge to the rim. He can then quickly compare any fired case to a his “master” case with optimal headspace. Since the gauge measures off the shoulder datum, this tells him how much to bump his fired brass.

In addition, the Stub Gauge can be used to set bullet seating-depth. Rich has a channel cut transversely on one side of the gauge, exposing the throat area. Since the interior of the gauge is identical to the chamber in his gun, this lets him see where a seated bullet engages the rifling. He can tinker with bullet seating length until he gets just the right amount of land contact on the bullet, confirmed visually. Then he measures the case OAL and sets his seating dies accordingly. This is much handier than using a Stoney Point Tool to measure distance to the lands. As your barrel’s throat wears, you may seat your bullets out further to “chase the lands”, but the gauge provides a constant land engagement point, in the barrel’s “as new” condition. By measuring the difference between the land contact point on the gauge and the actual contact point on your barrel, you can determine throat “migration”.

January 12th, 2014

Next time you have a barrel fitted, consider having your gunsmith create a “stub gauge” from a left-over piece of barrel steel (ideally taken from your new barrel blank). The outside diameter isn’t important — the key thing is that the stub gauge is created with the same reamer used to chamber your current barrel, and the stub must have the same bore diameter, with the same land/groove configuration, as the barrel on your rifle. When properly made, a stub gauge gives you an accurate three-dimensional model of the upper section of your chamber and throat. This comes in handy when you need to bump your case shoulders. Just slide a fired case (with spent primer removed) in the stub gauge and measure from base of case to the end of the gauge. Then, after bumping, re-measure to confirm how much you’ve moved the shoulder.

In addition, the stub gauge lets you measure the original length to lands and freebore when your barrel was new. This gives you a baseline to accurately assess how far your throat erodes with use. Of course, as the throat wears, to get true length-to-lands dimension, you need take your measurement using your actual barrel. The barrel stub gauge helps you set the initial bullet seating depth. Seating depth is then adjusted accordingly, based on observed throat erosion, or your preferred seating depth.

Forum member RussT explains: “My gunsmith [makes a stub gauge] for me on every barrel now. I order a barrel an inch longer and that gives him enough material when he cuts off the end to give me a nice case gauge. Though I don’t have him cut that nice-looking window in the side (as shown in photos). That’s a neat option. You can tell how much throat erosion you are getting from when it was new as well. For measuring initial seating depths, this is the most useful item on my loading bench next to calipers. Everyone should have a case gauge made by there smith if you have a new barrel put on.”

Forum member Lawrence H. has stub gauges made with his chamber reamers for each new barrel. He has his smith cut a port in the stub steel so Lawrence can actually see how the bullet engages the rifling in a newly-cut chamber. With this “view port”, one can also see how the case-neck fits in the chamber. Lawrence tells us: “My stub gauges are made from my barrels and cut with my chamber reamers. With them I can measure where my bullets are ‘touching the lands’ and shoulder bump dimensions. This is a very simple tool that provides accurate information.” To learn more about stub gauges, read this Forum Thread. The photos above and below show Lawrence’s stub gauges:

|

So what does a “worn-out” barrel really look like? Tom Myers answered that question when he removed a 6.5-284 barrel and cut it down the middle to reveal throat wear. As you can see, there is a gap of about 5mm before the lands begin and you can see how the lands have thinned at the ends. (Note: even in a new barrel, there would be a section of freebore, so not all the 5mm gap represents wear.) There is actually just about 2mm of lands worn away. Tom notes: “Since I started out, I’ve chased the lands, moving out the seating depth .086″ (2.18 mm). I always seat to touch. My final touch dimension was 2.440″ with a Stoney Point .26 cal collet.”

So what does a “worn-out” barrel really look like? Tom Myers answered that question when he removed a 6.5-284 barrel and cut it down the middle to reveal throat wear. As you can see, there is a gap of about 5mm before the lands begin and you can see how the lands have thinned at the ends. (Note: even in a new barrel, there would be a section of freebore, so not all the 5mm gap represents wear.) There is actually just about 2mm of lands worn away. Tom notes: “Since I started out, I’ve chased the lands, moving out the seating depth .086″ (2.18 mm). I always seat to touch. My final touch dimension was 2.440″ with a Stoney Point .26 cal collet.”

Forum member Rich DeSimone uses a handy “Stub Gauge” for setting shoulder “bump” and seating depth. The gauge is made from a section of barrel lopped off when the muzzle is crowned. The chambering reamer is run in about 1/4 of the way, enough to capture the neck and shoulder area of the case. Rich then uses his full-length die to “bump” a master case with the ideal amount of headspace for easy feeding and extraction. He takes that case and sets it in this Stub Gauge, and measures from the front of the gauge to the rim. He can then quickly compare any fired case to a his “master” case with optimal headspace. Since the gauge measures off the shoulder datum, this tells him how much to bump his fired brass.

Forum member Rich DeSimone uses a handy “Stub Gauge” for setting shoulder “bump” and seating depth. The gauge is made from a section of barrel lopped off when the muzzle is crowned. The chambering reamer is run in about 1/4 of the way, enough to capture the neck and shoulder area of the case. Rich then uses his full-length die to “bump” a master case with the ideal amount of headspace for easy feeding and extraction. He takes that case and sets it in this Stub Gauge, and measures from the front of the gauge to the rim. He can then quickly compare any fired case to a his “master” case with optimal headspace. Since the gauge measures off the shoulder datum, this tells him how much to bump his fired brass.