New Flameless Induction (Electrical) Annealer from Giraud

Click Photo for full screen view of machine.

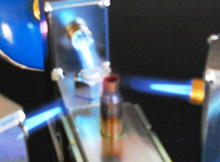

Forget flames — induction may be the future of cartridge annealing. Induction heating, using an electrical current passing through a coil, can be controlled with great precision (you can dial in the “dwell time” to a small fraction of a second). With a high-wattage power source, induction annealing is also very fast. A cartridge case can be done in two seconds or less. Combine that with an automatic case feeding system and you have a true assembly-line process capable of cranking out hundreds of precision-annealed cases per hour. Sound too good to be true? Well Giraud Tool recently announced its new Electro-Induction cartridge annealing system. This combines Giraud’s proven hopper-type case feeding system with a powerful Fluxeon Annealer. Watch the video below to see how it works.

Watch Giraud Induction Annealer Batch-Process Cases (900+ cases/hour)

Including case-shuttle time, a case is annealed and processed approximately every 4 seconds (rate based on the video demonstration). At that rate, if you keep the hopper full, you could anneal over 900 cases per hour. Even if you don’t need that production capacity, this system allows unattended annealing of your cartridge brass while you do other tasks — such as weighing powder charges or seating bullets.

We know some of you guys are now thinking “OK — I want one. What’s it going to cost?” Giraud has not listed a price yet for a complete induction annealing system. Giraud’s torch-equipped, hopper-fed annealing rig starts at $470.00. We expect that integrating the “Annie” induction unit by Fluxeon will add $500 to the price. By itself, the “Annie” induction annealer costs $449.00 on Fluxeon’s online store. But that $449.00 Fluxeon price does not include long-reach cables and adapters for the hopper feed.

Forum member and long-range shooter Jerry Brandon has launched a new company,

Forum member and long-range shooter Jerry Brandon has launched a new company,

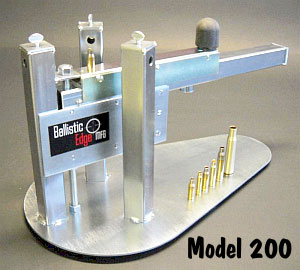

For PPC, 6mmBR, and .308-sized cases, you can use the Model 200, the Model 300, or the Model 400. The Model 200 is a simple, one-at-a-time annealer that works remarkably well using a sliding arm. Simply slide the case into the flame, then slide it out after the required dwell time. For the average reloader, the Model 200 may be more than adequate. If, however, you plan to anneal hundreds of cases a week, you may want to consider the beautifully-machined Model 400 carousel, which will anneal 100 cases in less than 15 minutes. The Model 400 features both .308-size and magnum/ultra magnum-size holes to accept both .47X and .56X diameter cases. Just choose the correct size hole and adjust the torch height to match your case. The .75″-thick shell-plate top acts as a heat-sink to protect the lower case body. View the Model 400 carousel annealer in the video below.

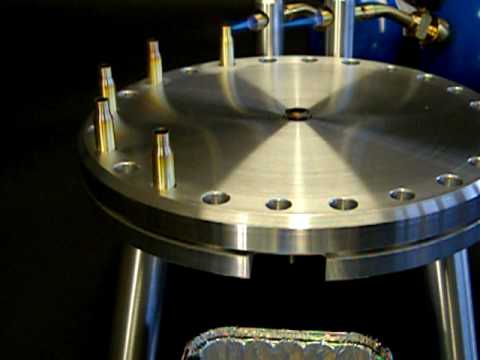

For PPC, 6mmBR, and .308-sized cases, you can use the Model 200, the Model 300, or the Model 400. The Model 200 is a simple, one-at-a-time annealer that works remarkably well using a sliding arm. Simply slide the case into the flame, then slide it out after the required dwell time. For the average reloader, the Model 200 may be more than adequate. If, however, you plan to anneal hundreds of cases a week, you may want to consider the beautifully-machined Model 400 carousel, which will anneal 100 cases in less than 15 minutes. The Model 400 features both .308-size and magnum/ultra magnum-size holes to accept both .47X and .56X diameter cases. Just choose the correct size hole and adjust the torch height to match your case. The .75″-thick shell-plate top acts as a heat-sink to protect the lower case body. View the Model 400 carousel annealer in the video below.