|

|

September 13th, 2014

The 29th Annual Gun Rights Policy Conference will be held September 26-28, 2014 at the Hyatt Regency Airport Hotel in Chicago. This event will feature several national gun rights leaders as well as attorney Alan Gura, who argued the 2008 Heller case and the 2010 case of McDonald v. City of Chicago before the U.S. Supreme Court. Also on the schedule are attorney and Second Amendment scholar Stephen Halbrook, John Lott, author of More Guns = Less Crime, and Alan Gottlieb, founder of the Second Amendment Foundation (SAF).

The conference is jointly sponsored by the Second Amendment Foundation and Citizens Committee for the Right to Keep and Bear Arms. The 2014 GRPC will feature more than 60 speakers on subjects ranging from politics to personal protection. Attendance is FREE. Register on-line at www.saf.org.

29th Annual Gun Rights Policy Conference

WHO: National Gun Rights Leaders and Second Amendment Lawyers

WHAT: Speaking at the 29th Annual Gun Rights Policy Conference

WHEN: Saturday, Sept. 27 + Sunday, Sept. 28 (Evening Reception Sept. 26)

WHERE: Chicago O’Hare Airport Hyatt Regency, 9300 Bryn Mawr Ave, Rosemont, IL 60018

September 12th, 2014

Here’s the deal of the year if you need a quality, windage-adjustable front rest. Pay just $165.00 for a competition-grade rest that normally sells for well over four hundred bucks! You heard that right. Bullets.com is offering aluminum-base front rests, with flex-shaft remote windage adjustment, for just $165.00! Choose either the popular slingshot-style rest (model BE1005) or a triangle base version (model BE1004). These front rests previously retailed for $425.00 each (with windage drive). But Bullets.com is having an “overstock” sale so you can get blow-out pricing on both these rests. At these prices ($165.00) you can afford two rests — one for yourself and one for a shooting buddy.

Slingshot-Style Front Rest Now $165.00 (BE1005)

Here is the slingshot model BE1005. Note, the optional bag is NOT included in the $165.00 sale price.

Remote Windage Adjustment System

What looks like a cable connected to a knob is actually a flexible drive shaft. This connects to the front bag carrier assembly (windage top) and moves it left and right as you rotate the knurled knob. This allows you to conveniently (and precisely) adjust windage from any shooting position.

Triangle-Base Front Rest $165.00 (BE1004)

Here is the triangle-base model BE1004. Note: Optional front sand bag is sold separately.

Premium Rests at a Blow-Out Prices

These Bald Eagle front rests can be used on the bench or on the ground for prone shooting. Designed by a benchrest shooter and refined by a member of the U.S. F-Class Open Rifle Team, this rest system has been thoroughly tested and proven to be capable of quick, precise adjustments during string shooting. There are two different models available for $165.00 — Slingshot base or Triangle base. The Slingshot model has an elongated front leg to keep the rest stable as well as keep the Windage adjustment knob within easy reach. These Bald Eagle rests feature a flex-shaft-drive Windage System that allows you to quickly and easily adjust for changing wind conditions. Front bags are sold separately. Minor modifications are required for left-hand shooters.

September 12th, 2014

|

It’s been seven years since L.P. Brezny wrote the original Gun Digest Book of Long-Range Shooting. Much has changed in the long-distance shooting game in that time. Brezny addresses those developments in this completely updated Second Edition, set to be released September 25, 2014.

Highlights of Book of Long-Range Shooting (2nd Edition)

– Best new factory rifles for long-range shooting

– New calibers and loadings

– The best big bore, heavy bullet choices for 1,000 yards and beyond

– Recommended optics, accessories, chronographs, and techniques

– Popular new shooting sports: 3-Gun Competition and “Rifle Golf” |

|

Experienced firearms writer L.P. Brezny has completely updated his popular, original book on long-range rifles and shooting techniques. Readers will find up-to-date information on recent advances in long-range rifles and cartridge choices. The updated Second Edition offers hundreds of new photos and much new information on guns, optics, and ammunition.

Brezny also offers instructional “how-to” content for shooters looking to develop their technique. He draws from first-hand experience, as well as interviews with snipers and long-range competitors. Brezny discusses current military applied combat theory — new methods that help snipers achieve hits at ultra-long range. Last but not least, Brezny explores today’s popular competitive shooting events, including 3-gun competition and long distance “rifle golf.”

NOTE: This book has a lot of useful information, but it is written more for the tactical crowd than for long-range benchrest or F-Class shooters. This book is a good starting point if you want to get started in the long-range game. However, you’ll probably find more serious information about advanced reloading right here in the AccurateShooter.com archives. If you want to understand the fine points of long-range ballistics, then get Bryan Litz’s Applied Ballisitics for Long-Range Shooting (2d. Ed), now available in eBook as well as hard-cover format.

September 11th, 2014

The oldest remaining record in international shooting sports was the 581 score in 50m Free Pistol set way back in 1980 at the Moscow Olympics. After thirty-four long years, that record has finally been broken — by South Korea’s Jin Jong-oh. The South Korean, who earned gold medals in both the 2008 and 2012 Olympic Games, has been chasing this record for a long time, and now it is his. Congratulations to Jin Jong-oh. Well done!

Jin Jong-oh Shoots 583 in Free Pistol to Break 34-year-old Record

South Korean pistol ace Jin Jong-oh scored a combined 583 points on the way to winning the 50m Free pistol title in Granada on Tuesday. With his 583 score, Jin broke (by two points) the world record set by Russian Alexander Melentiev at the 1980 Olympics. This was the first individual world title for Jin, who won 50m pistol gold at the 2008 and 2012 Olympics and also added the 10m title at the London Games.

Records are “meant to be broken” they say. This was a long time coming. But Jin Jong-oh, the five-time Olympic medalist from South Korea, finally broke “The Record” — that historical 581-point world record set in 1980 by Alexander Melentiev of the USSR. Melentiev’s 50m mark was the longest-lasting shooting world record. Athletes from all over the world had been chasing that record for 34 years.

Yikes! Emmons’s Smallbore Match Rifles Lost in Paris…

Smallbore rifle events begin Wednesday with the Elimination Matches in Men’s Prone. Ready to compete is three-time Olympic medalist Matt Emmons, 2012 Olympian Michael McPhail, and Air Force Academy cadet David Higgins. A two-time Olympic medalist and three-time World Champion medalist in the event, Emmons arrived in Granada minus his two smallbore rifles courtesy of the Paris Charles De Gaulle airport, which seems to have lost or delayed many guns bound for the World Championships in Spain. Thankfully, Emmons has McPhail’s three-position gun available for the elimination. Emmons is familiar with that type of rifle so, hopefully, this will not be too great a set-back for Matt.

Want more info? CLICK HERE for ISSF World Championships results and schedules.

September 11th, 2014

We could say “It’s about time”… but let’s just praise the NSSF for taking this important step. We need more strong voices in Washington arguing on behalf of gun owners, and promoting the interests of those who craft, sell, and maintain accurate firearms.

On September 10, the National Shooting Sports Foundation (NSSF), the trade association for the firearms industry, opened its new office in The Hall of the States Building on Capitol Hill.

“We are the voice of the firearms and ammunition industry. The challenges we face as well as the positive opportunities that lie ahead require an enhanced and sustained presence in our nation’s capital,” said Lawrence G. Keane, NSSF Senior Vice President and General Counsel. “We are adding professional staff to our Washington-based Government Relations office in order to better serve our members in our mission to promote, protect and preserve hunting and the shooting sports.”

NSSF President Steve Sanetti, left, and Jeff Reh, NSSF Board of Governors Co-Vice Chairman and Beretta USA General Counsel, officially open NSSF’s new Washington, D.C., office.

Formed in 1961, NSSF has a membership of more than 10,000 manufacturers, distributors, retailers, shooting ranges, sportsmen’s clubs and publishers. For more info, visit nssf.org.

September 10th, 2014

Notice the narrow configuration of the Harry Jones Range. The 1000-yard targets are located below the tree line in the rear center of the picture.

Report by Jack Mulroy for IBS

This year’s IBS 1000-Yard National Match was held August 29-30 at the Harry Jones Range in Fairview, West Virginia. Attendance was good — there were 74 Light Gun shooters and 66 Heavy Gun competitors. After a tune-up day, the 1000-Yard Match for record started on Friday, August 29, and finished on Saturday, August 30, 2014. The 1000-Yard National Match is a three target Aggregate. You shoot three times for Light Gun and three times for Heavy Gun. I guess the reason you shoot at three targets is because anybody can get “lucky once” (such as a blind squirrel finding a nut). Shooting luck happens “when preparation and hard work meet opportunity”.

Mike Gaizaukas, World Record Shooter at Harry Jones Range on August 29, 2014

The overall Two-Gun Champion and match winner was Steve Waldrep with 32 rank points. Close behind, with 33 rank points, was Jim Bauer, who finished second overall. Waldrep dominated the Heavy Gun (HG) division, posting the best HG score and winning HG overall. Waldrep shot a .300 WSM Heavy Gun featuring Lawton action, Bartlein barrel, Byers stock, and Nightforce scope. Waldrep’s Light Gun was also chambered in .300 WSM. It had a Remington action, Bartlein barrel, McMillan stock, and Weaver scope. Jewell triggers on both guns.

Overall Winner Steve Waldrep (Left) with assist from Stanley Taylor (right)

In Light Gun division, James Isaacson put on an impressive show, winning LG overall and posting smallest LG group. Jim Bauer (second overall in the Two-Gun), posted the top LG score.

| Top Shooters by Division |

Two Gun Overall——— Steve Waldrep

Heavy Gun Overall——- Steve Waldrep

Heavy Gun Score——— Steve Waldrep

Heavy Gun Group——– Mike Gaizaukas

(1000-Yard World Record/2.871 inches) |

Light Gun Overall——– James Isaacson

Light Gun Group——— James Isaacson

Light Gun Score——— Jim Bauer |

Click Here for 2014 1K Nationals Complete Match Results (PDF).

World Record 2.871″ HG Group by Gaizaukus

Mike Gaizaukus shot the small HG group for the match — a stunning 2.871″ ten-shot group. Pending approval, Mike’s group should be a new IBS 1000-yard world record. Congrats to Mike for his record group. Mike’s record-setting gun featured a 1:10″-twist Krieger barrel chambered by Mark King in .300 WSM. Mike shot Berger 210gr VLDs with CCI BR2 primers.

The Harry Jones Range

Founded in 2008, this facility was named in memory of the former property owner Harry Jones who passed away a few years ago and is buried on top of the hill next to the range. Presently the property is being administered by Harry’s daughter, Jean Dawson. The property has been in the family since 1840. The 1000-yard shooting facility is a covered pavilion that has 13 shooting positions with ambidextrous concrete bench tops sitting on a concrete floor. Behind the pavilion is a covered ready line where the relays-in-waiting can stage their equipment. (For this shoot only 12 benches were used.)

Very Narrow Range — “Like Shooting Up a Holler”

The Harry Jones range is very unique — it’s very narrow in width, approximately 100 feet wide, and runs slightly uphill to the targets. As they say in West Virginia, “It’s like shooting up a Holler”. If there is such a thing as a “Wind God,” he’s alive and well at the Harry Jones Range. Some very good scores and groups have been recorded at this range (including a world record 2.871″ 10-shot group in this very match.) A longtime shooter friend of mine, Ralph, used to say when I would complain about the wind, “Jack, there is no such thing as wind, just sight adjustments”. Ralph was right, no matter what range you are shooting at, you have to deal with the wind through sight adjustments. Looks like Mike was “Right On” when he made his adjustments.

The management and membership of this range have come a long way in developing this range over the last few years. Trees had to be removed, gravel put down, buildings built, creek flow re-routed, target areas built, and shooting benches installed. But the effort was worth it — Harry Jones has become a very serviceable range that is a great place to shoot.

The Harry Jones range is not blessed with much “elbow room,” due to the configuration of the range, but through thoughtful placement of the firing line and ready area, the range is doable. At this match, there were 74 light gun and 66 heavy gun shooters. This match was well managed and ran smoothly, but parking space was at a premium. In my estimation the 2014 1000-Yard Nationals were at capacity with the number of shooters registered.

$27,000 Prize Table (with Lots of Scopes)

Roughly $27,000 worth of prizes were awarded at this year’s 1000-Yard match. Valuable prizes included Nightforce scopes, stocks, rests, bullets and more. Two of the nicest gifts presented at the match were a pair of quilts made by property owner Jean Dawson. Thanks Jean! That was a very generous gift that a shooter and his family will treasure for years. Many thanks should go to Stanley Taylor from Douglas Barrel for his time and energy in acquiring most of the prizes presented at the match.

Serious Artillery on Display — Rick Murphy’s Metal-Stocked Heavy Gun

The prettiest gun and gun rest at the match belonged to Rick Murphy of Adamsville, Tennessee. The barrel was originally 36 inches long, but was shortened to 30 inches. The gun now shoots much better after the reduction in barrel length. This Heavy Gun and rest set-up were probably the most expensive pieces of equipment at the 1000-Yard match. Rick has been working on this rig for the last three years and has put countless hours into the production of his gun and gun rest. Rick placed 13th in the Heavy Gun overall.

September 10th, 2014

Want to watch the ISSF World Shooting Championships taking place in Granada, Spain? ABC, CBS, FOX, or NBC won’t be airing the World Championships at all, but you can watch ISSF shooting action by way of internet “web-casting”.

Eurovision is providing extensive coverage of ISSF Championship events. Match footage (including live Finals coverage) is available online on the ISSF website (ISSF-Sports.org), and through the Eurovision App for Apple and Android devices. Highlights will also be uploaded to the ISSF YouTube Channel.

Free Eurovision App for Mobile Devices

The Eurovision Sports Live App makes it easy to watch live streaming video, replays, and highlights from the ISSF Shooting Championships. To download the App, go to the Eurovision download page or click the appropriate link below.

September 10th, 2014

October’s just around the corner — that means temperatures will be dropping soon in Northern climes. In a month or two, many of you will be putting your guns into storage for many months. To prevent rust from forming on your valuable firearms, you’ll want to control the temperature and humidity in your safe. By maintaining a warm temperature you can keep the relative humidity (in your safe) above the dew point and prevent moisture from condensing on your guns. One popular way to keep a safe warm is to use a Goldenrod. Though marketed as a “de-humidifier”, the Goldenrod tube is actually a simple electric heater. Placed in the bottom of your safe, the Goldenrod can help keep the relative humidity above the dew point.

Rope Lights — Light and Heat for Your Gun Safe

While Goldenrods work, they only provide heat, and Goldenrods typically retail for $20.00-$30.00. There is a less expensive solution that provides both light AND heat. A section of incandescent Rope Lighting will light up your safe AND warm the air. A 6-foot section of rope lighting costs about $6.00 at Lowes. The 6-foot strands can be linked together in longer chains. Rope Lighting can easily be installed in your safe with clips or velcro fasteners. One 6-foot long incandescent Rope Light draws about 18 watts of power — the same as an 18″ Goldenrod. Sheathed in plastic tubing, the incandescent Rope Lighting is slightly warm to the touch. A single 6-foot long strand of incandescent Rope Lighting maintains this Editor’s 23-cubic-foot indoor safe comfortably above 65° F all the time. (If you live in a colder area, or keep your safe in the garage, you may need a longer Rope Light, or a Rope Light in combination with a Goldenrod. Incandescent Rope Lights draw about 0.25 watts per bulb or about 3 watts per foot. Goldenrods draw about 12 watts per foot of length.)

Not All Rope Lighting is the Same — Incandescent vs. LED

Thus far, we’ve been talking about incandescent Rope Lights. For more money, you can also purchase energy-efficient LED ropes. LED Rope Lights draw much less electricity, but they won’t provide as much heat as incandescent Rope Lighting. It you use LED strands, you need to string longer sections to warm your safe. Or, just use LED strings for interior lighting only and then add a Goldenrod for heat.

Monitor Temp and Humidity with Thermometer/Hygrometer

To ensure that your safe’s interior is staying warm and dry, you can place a small temp/humidity sensor inside the safe. You can use either an Analog (dial-type) Thermometer-Hygrometer, or a battery-powered Thermometer-Hygrometer with digital read-out. Both digital and analog units can be purchased for $10 to $15 from internet vendors. Some of the digital units have dual temp sensors, so you can monitor the temperature both inside and outside your safe. That lets you gauge how well your safe-warming system is working.

WARNING: As with all electrical products, use caution with rope lighting. Follow manufacturer’s instructions. Avoid placing ropes in direct contact with paper or other flammable objects. Monitor surface temperatures.

September 9th, 2014

Randy Robinett, founder of BIB Bullets, is a highly respected custom bullet-maker. In recent years, Randy’s 30-caliber projectiles have won countless benchrest-for-score matches, and captured many National titles. If you want to “run with the big dogs” in score competition, campaigning a 30BR with BIB bullets is a very smart way to go. In this article, Randy talks about the process of creating highly uniform cores for benchrest bullets. Randy Robinett, founder of BIB Bullets, is a highly respected custom bullet-maker. In recent years, Randy’s 30-caliber projectiles have won countless benchrest-for-score matches, and captured many National titles. If you want to “run with the big dogs” in score competition, campaigning a 30BR with BIB bullets is a very smart way to go. In this article, Randy talks about the process of creating highly uniform cores for benchrest bullets.

This article originally started as an exchange of posts in Stan Ware’s Bench-Talk Forum. Stan, a gifted gunsmith, converted the Forum posts into an article, which first appeared on Stan’s Bench-Talk.com Website.

How to Make Benchrest-Quality Bullet Cores

by Randy Robinett, BIB Bullets

OK, Stan “made me do it”! A while back, Stan Ware asked if I’d submit a ditty on bullet-making. Here is the “picture is worth a few words” version. Below is a photo of a spool of lead wire. This is the first step in making benchrest-quality bullets. This spool of .250″ diameter lead wire will be cut into approximately 130 pieces, each about thirty inches long.

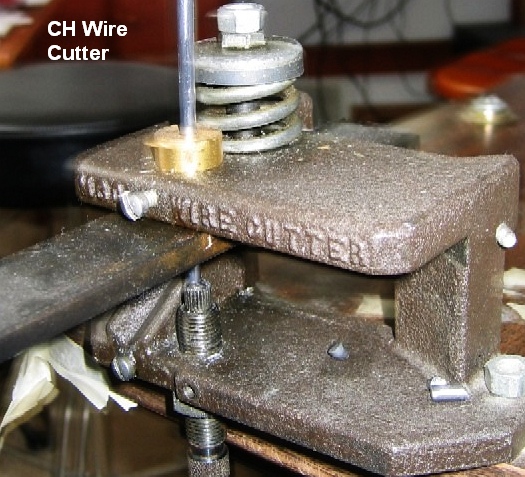

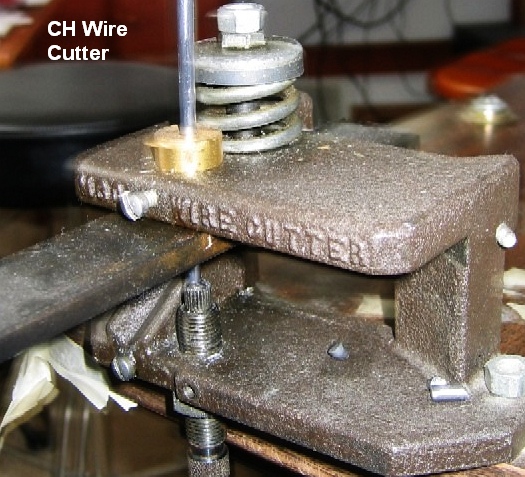

The Core Cutter

Here’s a really neat machine built by my Uncle and BIG MIKE. This is the core cutter. We made it using scrap steel and borrowed the crank shaft out of a 1966 Yamaha motorcycle to get the desired reciprocating-motion slide. When properly “juiced”, this machine can cut more than 3000 cores per hour.

As you doubtless deduced, the “sticks” are inserted, then fed via gravity — straightness is a virtue here! The crank, for now, is powered by the human hand. The bucket contents are the result of loading the cutter and turning the crank wheel. This photo shows cores for 112 grain, .30-caliber bullets. There are about 2500 cores to the bucket.

Here’s a close-up of the business end of the core cutter. Using recorded micrometer settings, this clever design allows us to get very repeatable length when changing through the length/weight cycle.

The photo below provides a closer look at the just-cut cores. Note the relatively clean shanks and square, unflared ends. This bucket contains roughly 2500 cores. By contrast, a tour of the Hornady plant will reveal cores being cut and squirted via a single operation, and deposited into 50-100 gallon livestock watering tanks!

Upon my first tour of a commercial plant, I lost all feelings of guilt about the cost of custom, hand-made bullets. When one totals the amount of labor, “feel” and “culling” that goes into them, custom hand-made bullets represent one of the best bargains on the planet!

At Hornady, each press produces 50-55,000 finished bullets per 10-hour shift. By contrast, a maker of hand-crafted bullets, at best, may make 3% of that number during a 10-hour span! Yep, hand-made benchrest-quality bullets are a labor of love and should be purchased with these criteria in mind: 1) QUALITY; 2) availability; 3) price. There is no reason for a maker of hand-made benchrest-quality bullets to negotiate on price. His time is worth what one receives from the bargain!

Core-Making Q & A

Randy’s original Bench-Talk Forum posts inspired some questions by Forum members. Here are Randy’s answers to spedific questions about core-making.

Question by Stan Ware: Randy, a post or two back you said the cores were cut into 30″ lengths first and straightened. Why do you cut to 30″ lengths? What is the reason for this?

Answer by Randy: Stan, the wire is cut into 30″ lengths (sticks) and then straightened, following which it is fed into the core cutter and cut into the individual individual “cores”. If you look at the core cutter photo above, you’ll see a stick of lead wire sticking up -it’s toward the right hand end of the contraption. The cut cores are also “ejected” by gravity — the white “tickler” brushes the cores as the slide moves forward and dislodges the core from the cutter bushing.

Q by GregP: Randy, How do you straighten the 30″ sticks? Roll them between metal plates?

Answer by Randy: Greg, BIG MIKE may kill me for letting out the secret. WE “roll” the wire between an aluminum plate, which is equipped with handles, and the “plate” which you can see in the pic of cutting the wire. The straightening is really a drag. Eventually, we will have the new cutter hooked up to a “feeder/straightener” and the wire will be cut into core slugs right off the roll! Well, that’s the Dream….

Question by Jim Saubier: How much of a nub do you use at the end of the 30″ section? I imagine that every section you will lose a little from the feed end. Your cutter looks real slick, we are using the manual deal and it isn’t quick by any means.

Answer by Randy: Jim, Since I cut all of the sticks using diagonal-cutting pliers, the ends are, indeed, waste. However, only about 1/8th inch on the beginning end — the final core may be too short. I have attached a pic of my old reliable CH cutter. I still use this cutter for .22-cal and 6mm cores and, occasionally, an odd lot of thirties. The CH cuts very square ends which are free of bulges and/or flaring.

Stan Ware Retires

Stan Ware has announced that he is retiring effective September 1, 2014. We are sad to see Stan hang up his tools. He was superbly capable smith who also always delivered the highest level of personal service to his customers. We worked with Stan on a couple projects and we have the highest regard for his skills, professionalism, and his dedication to doing the job right… the first time. We’re sorry to see Stan close shop at SGR Custom Rifles, but we wish him well in retirement and we hope he will enjoy his years of freedom with his friends and family members. Stan wants to thank all his customers: “The one thing I have found out in thirty-one years working for gun enthusiasts is that the are the finest people in the world to work for, and I mean that from the bottom of my heart.”

September 9th, 2014

One of our favorite Ruger bolt-action rifles is now available in a caliber better suited for varmint hunting. The versatile Ruger Gunsite Scout Rifle, previously offered in .308 Winchester only, is now chambered in .223 Rem / 5.56 NATO. This newest version of the Gunsite Scout Rifle features a hybrid chamber that shoots both 5.56x45mm NATO and .223 Remington. This rifle is light and compact. With a 16.1″ barrel, it weighs just 7.1 pounds without optics.

The .223 Scout Rifle is offered in both right- and left-hand versions, both with a 10-round detachable box magazine. You can choose either an all-stainless version ($1099.00 MSRP), with SS receiver and SS barrel, or a dark version ($1039.00 MSRP) with matte black alloy steel action and barrel. The bolt offers Mauser-style controlled round feed, with a lever-style safety on the rear of the bolt shroud. The rifle features a 16.1″, 1:8″-twist rate, barrel fitted with flash hider which can be removed to attach other 1/2-28 threaded barrel accessories. Interestingly, the magazine for .223/5.56 Scout Rifle is dimensionally the same as the mag for the .308 Scout Rifle. The .223/5.56 mag employs a plastic insert to feed the smaller cartridge properly.

American Rifleman Field Test of .223 Rem Scout Rifle

Adjustable Length of Pull Through Buttpad Spacers

The black laminate stock is fitted with sling swivel studs and features checkered grip and forearm. A soft rubber recoil pad with three 1/2″ spacers allows the length of pull (LOP) to be adjusted.

Ruger Scout Rifles feature a Mini-14-style protected, non-glare, post front sight and receiver-mounted, adjustable, ghost ring rear sight. The forward-mounted Picatinny rail lets you use a variety of optics including LER scout scopes that allow “both eyes open” target acquisition. Ruger provides scope rings for mounting conventional scopes on the integral M77-style mounts built into the Scout Rifle receivers.

|