|

|

April 6th, 2014

The National Shooting Sports Foundation (NSSF) has taken over the Ruger Rimfire Challenge program. Now called the NSSF Rimfire Challenge, the program retains the format that has made it so popular. This remains a two-gun timed competition with rimfire rifles and pistols. Shooters engage steel targets at relatively close distances. The matches are for young and old alike, all skill levels, with mentoring by experienced shooters. The emphasis is on fun and safety.

The use of .22 caliber pistols, revolvers and rifles make the Rimfire Challenge more affordable than most centerfire matches. “The affordability of this program is something that participants really like and keeps them coming back,” said Zach Snow, NSSF’s Manager of Shooting Promotions. “Event fees are affordable as well.”

For participants, NSSF Rimfire Challenge offers categories for everyone — Open and Limited Divisions, plus Special Recognition competitions. To learn more about on program equipment, rules, courses of fire, scheduled matches and the first NSSF Rimfire World Championship, visit NSSF.org/Rimfire.

NSSF Rimfire Challenge Basics

- This is a two-gun event so you need a rifle and a handgun (which can be either a semi-auto pistol or revolver).

- Bolt-action rifles and lever-action rifles are allowed, but self-loading (semi-auto) rifles are most popular because they can shoot quickly.

- It is suggested that your firearms hold at least ten rounds each, as there is no reloading allowed during the actually stages.

- It is a good idea to have five (5) magazines per gun (5 each for rifle and pistol). That way you don’t have to reload between stages. If you have a 10-shot revolver, you can reload manually, or use speed loaders.

- At Rimfire Challenge Matches, each competitor get five (5) runs through each target stage.

- Eye and ear protection is required on the range at all times. This is true for spectators as well as competitors.

NSSF Rimfire Challenge Courses of Fire | NSSF Rimfire Challenge Rulebook

Many different stage designs can be employed at Rimfire Challenge matches. Here are two examples from the NSSF Rimfire Challengs Suggested Courses of Fire:

April 6th, 2014

As a cartridge case is reloaded multiple times, burnt powder residue and carbon builds up on the inside of the case. Unless the case interior is cleaned in some fashion, eventually you’ll see a reduction in case capacity. One of our Forum members from Australia wonders about the effects of reduced case capacity: “If the capacity of the case decreases as the crud builds up, then it effectively reduces the chamber size. Wouldn’t that change the pressure produced from that of an equivalent clean case?”

Ultrasonic Cleaning Example:

Interesting Test of Case Capacity Changes

Forum member Fred Bohl has actual test results that can help answer the above question. Fred proved that, over a 20-reload cycle, the case capacity of uncleaned cases did, indeed, decline a small amount. However, surprisingly, this did not seem to affect the actual chronographed velocity of the load. ES did increase, but Fred believes the higher ES was due to changes in case-neck tension, rather than due to the slight reduction in case capacity.

Fred reports: “Back when beginning to use ultrasonic case cleaning, part of the motivation was to get the inside clean based on the assumption that allowing burnt residue to build up inside cases would affect capacity, and, ultimately, performance. An experiment was done to test this hypothesis. The load used, 30.5 grains of RL15 behind 107gr SMKs in a 6mmBR, was selected for best group and lowest ES in prior load development. It turned out to be 92% of initial case capacity and neither “full” or compressed. (I would suspect that different powders, load weight, and total case capacity might produce very different results.)

We took 30 cases of identical initial capacity and tracked three lots of 10 each:

LOT 1: No Internal cleaning

LOT 2: Cleaned with media in tumbler

LOT 3: Cleaned with Ultrasound machine

Each case (in each lot) was shot and reloaded 20 times. The simplified results after 20 reloads of each lot were as follows:

Lot 1 (not cleaned) – 0.3 to 0.4 gr. loss of capacity, 5 to 8 fps greater ES.

Lot 2 (tumble cleaned) – 0.1 to 0.3 gr. loss of capacity, 4 to 6 fps greater ES.

Lot 1 (ultrasonic cleaned) – no loss of capacity, no detectable change in ES.

FINDINGS

There was no detectable correlation of velocity change to the lots. An oddity was that on very hot days Lot 1 velocities were, occasionally, slightly higher. [Editor’s note: That does suggest that the carbon build-up inside the uncleaned cases might cause a slight increase in pressure that shows up on hot days. Fred has posted that “A local shooter reported doing the 20 reload, no clean test on a .308 that gave a loss of capacity of 2.0 grains, doubled ES and signficant velocity changes. However, I don’t have any details on his load weight or powder.”]

NOTE: From results of another ongoing test, I believe the above differences in ES are probably due more to variance in bullet grip tension than case capacity. The ultrasound cleaned cases (LOT 3) did maintain the lowest ES, but we are not 100% sure of the reasons why. More consistent bullet seating might be the reason.

[Editor’s comment: Jason found that with his ultrasonically-cleaned cases, the inside of the necks got so “squeaky clean” that he needed to use dry lube in the necks. Jason uses the $10.95 dry lube kit from Neconos.com. This applies ultra-fine Moly powder to the neck using small carbon steel balls]

April 6th, 2014

by Bill Gravatt

(This article was written when Bill was President of Sinclair International, Inc.)

Chamber casting is an easy task for the handloader to perform. A chamber casting is valuable if you run across a firearm that you believe has a custom barrel on it and you want to find out the dimensions of the chamber. Some gunsmiths will chamber a barrel and not mark it properly with the neck dimension or the exact cartridge name or specifications. We also get calls from some customers that have military firearms without cartridge stampings on the barrel; this will help these shooters identify their chambering.

Another reason to make a chamber casting would be for a die manufacturer to manufacture custom dies for you. A chamber casting is often required when fired cases are not available. Some reloaders will make a chamber casting that shows them the exact configuration of the throat and leade so they can determine what bullets to try. Shooters using cast bullets will make a cast so they can choose a mould that better fits their throat taper and grove/lands diameter.

A product called Cerrosafe is the most common, reliable, and the safest material to use for making chamber castings. Cerrosafe is a metal alloy that has some unique properties which make it ideal for chamber casting. First, it has a relatively low melting point of 158 to 190° Fahrenheit. This makes it easy for the handloader to melt the Cerrosafe in his home shop. Second, it shrinks slightly during cooling which allows it to be extracted from the chamber easily. It then re-expands to the chamber’s original size after about one hour at room temperature. After cooling for about 200 hours, the chamber cast will expand to about .0025″ larger than the actual chamber size. Most good reloading die makers are used to working from Cerrosafe chamber casts.

As we said, using Cerrosafe is fairly easy and comes with complete instructions.

Making a Cerrosafe Chamber Cast — Step by Step:

1. First, clean and dry the chamber and barrel thoroughly.

2. Disassemble the firearm as necessary to gain access to the chamber.

3. Insert a tight fitting cleaning patch with a jag into the bore from the muzzle end to form a plug for the Cerrosafe. The patch should be positioned in the bore, just forward of the throat by approximately ½” to 1”.

4. Heat a Cerrosafe ingot in a small ladle. A heavy cast iron bullet caster’s ladle works fine or a plumber’s ladle. Any source of heat will do (a small propane torch will work fine).

5. Pour the Cerrosafe into the chamber until a little mound forms at the rear of the chamber. Too much and it can become more difficult to remove the cast from the chamber. If this happens, simply heat the barrel a little and re-melt the Cerrosafe. Don’t worry, your barrel gets a bit hotter than 190 degrees during firing.

6. The chamber can be difficult to access, so some people find it easier if they make a pouring tube out of steel, brass, or aluminum tubing to funnel the Cerrosafe into the chamber.

7. After the Cerrosafe has hardened, the chamber casting can be pushed out of the chamber coming from the muzzle end using a cleaning rod or a wooden dowel. It is recommended that you push it out within a half-hour of casting the chamber. We usually push our cast out within a few minutes. If the cast does not push out easily, insert a cleaning rod from the muzzle and tap the rod handle with the palm of your hand to start the cast out of the chamber. You can put a paper towel in the action to catch the cast or lay the rifle on the bench with a towel or bench mat underneath it to catch the cast as it falls from the action. This will prevent damage to the cast.

8. Take your measurements shortly after one hour of cast, and then put the casting away until you need it again. A medicine container or something similar makes a great container. If you are going to keep the cast be sure to mark the cast or the storage container so you know which rifle it came from. If you have no need to keep the cast you can re-melt the Cerrosafe and use it again when you need to make another cast. |

This article originally appeared in Sinclair International’s The Reloading Press Blog.

April 6th, 2014

Free is good. Especially when “free” is the real deal, meaning no purchase required, no strings attached. And that’s what we’ve got here. Now through April 30, 2014, Harbor Freight is offering six products, absolutely free (with coupon). You can get a tape measure, flashlight, multimeter, tarp, screwdriver set, or scissors. Just print the coupon and take it to the store. You don’t have to buy anything else — but there is a limit of ONE ITEM per day per customer. So you can’t go to the store and get all six items on the same day. (But you could return multiple times and get a different item). NOTE: Before you print out these coupons, click the images below to display the 100% scale version. The coupons below have been downsized to fit our Daily Bulletin — this may make the bar codes harder to scan.

Click coupon images to get larger version for printing

Product tip from EdLongrange. We welcome reader submissions.

April 5th, 2014

One of our readers, Joshua Targownik, is a very talented photographer. Last year he captured an evocative series of photos at the 2013 California State Palma Championships, hosted at the Coalinga range. Joshua reports: “I shot all these images on good old-fashioned medium format black and white film”. We like Joshua’s images — they have a classic “old school” look which seems to suit the Palma (Full-bore) discipline. The black and white photography seems appropriate to the world of iron sights, leather shooting coats, and “hard-holding” marksmen.

Images by Joshua Targownik. To see more of Joshua’s photos, visit TargoPhoto.com.

Click Image to see full screen version

CLICK HERE to View Full PHOTO GALLERY (17 images).

April 5th, 2014

If you have recently placed credit card orders with Wideners.com, you should check for unauthorized charges and other suspicious activity related to your credit card(s). You may also want to contact your card issuer. The reason is that web security breaches have “allowed [unauthorized] access to some customer credit card information.” After an initial security breach in February of this year, there was another breach in the past few days. If you have recently placed credit card orders with Wideners.com, you should check for unauthorized charges and other suspicious activity related to your credit card(s). You may also want to contact your card issuer. The reason is that web security breaches have “allowed [unauthorized] access to some customer credit card information.” After an initial security breach in February of this year, there was another breach in the past few days.

Here is a statement published

on the Wideners.com website:

Just prior to February 16th, there was a brute force attack on the site that we now believe allowed access to some customer credit card information. Fortunately, we keep very few customer records in our on-line database. Since there is very little information on the site, exposure is minimized just in case something like this ever happens. We were alerted to this potential breach by a few customers, and we are fortunate that it was so small.

When our internet provider later discovered the attack, we immediately took action to prevent unauthorized access. Since that time, we have further tightened security. We have also performed internal audits to insure all our in-house systems are free of problems.

At this point, we believe we have identified only a few customers who were affected by the incident, and we have done everything possible to prevent recurrence of this activity. If you suspect you have had a problem due to doing business with us, please let us know immediately. We sincerely apologize for any difficulty this has caused.

Sincerely,

Stan Widener

President, Widener’s Reloading & Shooting Supply, Inc.

Update 4-4-14: For the period 3-31-14 to 4-3-14 our website provider’s website was compromised and credit card information for those dates may have been obtained by unauthorized users.

We have been in meetings all day long with a host of computer experts and programmers and our web provider. The breach from overseas has been finally been identified and eliminated as of 4:00 EST. Our web provider now declares that the website is secure.

Story Tip from EdLongrange. We welcome reader submissions.

April 5th, 2014

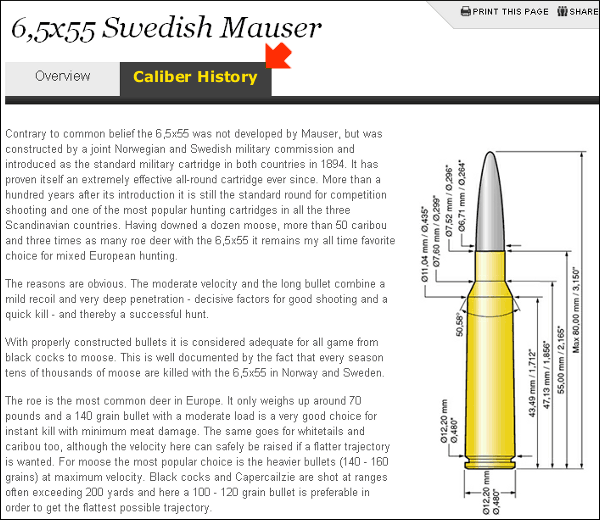

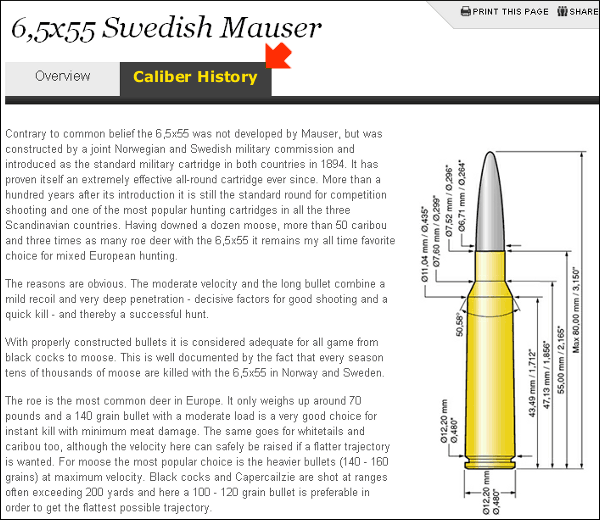

On the Norma website, in the products area, you’ll find dozens of illustrated cartridge profiles. Many of these have been augmented with “Caliber Histories” providing background information, both historical and practical. These entries will benefit those interested in the origins and development of popular hunting and match cartridges. Many of the “Caliber Histories” also include information on bullets and twist rates. On the Norma website, in the products area, you’ll find dozens of illustrated cartridge profiles. Many of these have been augmented with “Caliber Histories” providing background information, both historical and practical. These entries will benefit those interested in the origins and development of popular hunting and match cartridges. Many of the “Caliber Histories” also include information on bullets and twist rates.

CLICK HERE to access the Hunting Products page on Norma’s website. There, on the left, you’ll see a vertical list of 58 different cartridges. Click on any cartridge name and you’ll see an illustrated “overview”. For most (but not all) listed cartridges, there is also a gray tab labeled “Caliber History”. Click that tab to see a cartridge diagram and a few paragraphs explaining the cartridge’s lineage and design features. For example, the .280 Remington Caliber History explains: “This cartridge was constructed in 1957 for Remington’s model 740 Autoloader. It is basically a .30-06 necked down to accept 7mm bullets, but the shoulder was moved forward a little in order to prevent the cartridge from being loaded into .270 Win. rifles by mistake.” Many of the Caliber History entries offer recommended bullet weights and barrel twist rates. Shown below is the 6.5×55 Swede’s Caliber History:

Article tip by EdLongrange. We welcome reader submissions.

April 4th, 2014

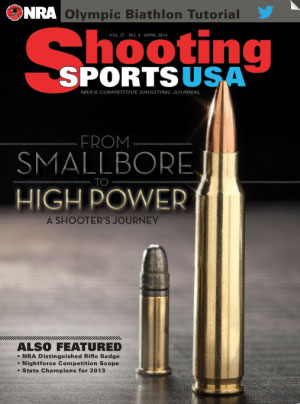

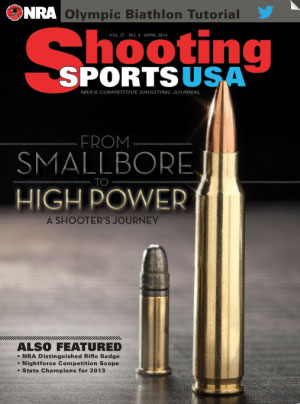

The April 2014 Digital Edition of Shooting Sports USA is now available online (for free). This month’s issue has many articles of interest to competitive shooters. The cover story From Smallbore to High Power, profiles Col. Denise Loring, an international smallbore competitor who recently made the transition to High Power shooting. This is an excellent article. The April 2014 Digital Edition of Shooting Sports USA is now available online (for free). This month’s issue has many articles of interest to competitive shooters. The cover story From Smallbore to High Power, profiles Col. Denise Loring, an international smallbore competitor who recently made the transition to High Power shooting. This is an excellent article.

Col. Loring “compares and contrasts” smallbore and High Power, providing fascinating insights into the differences between the disciplines: “I was very nervous about having only two sighters for NRA High Power matches. Then, I heard about the CMP style of HP where there are no sighters and could not believe you could shoot a match without them. We have unlimited sighters in smallbore and I took full advantage of that aspect. In NRA conventional smallbore you can even return to the sighter bull once you have begun shooting for record.”

Biathlon — Shooting at 180 Beats Per Minute

There is also an interesting feature on Biathlon shooting. This tutorial covers the basics of this challenging Olympic sport that combines Nordic skiing and smallbore position shooting. This in-depth article profiles the top athletes, explains the rules, and provides interesting details of the hardware: “Most athletes use a Fortner (straight-pul bolt) action, although traditional bolt-action guns are allowed. The rulebook regulates biathlon rifles by minimum width, trigger resistense, dimensions and shape[.] Magazines may be spot-checked before or after an event to ensure they contain only five rounds[.]”

The April issue of Shooting Sports USA also includes a complete round-up of 2013 State Champions for all NRA shooting disciplines, from BB Gun to Black Powder Cartridge Rifles.

April 4th, 2014

Last year, to catch up with demand for its most popular products, Hornady temporarily halted production of a significant number of bullet types and ammunition products. Some shooters were upset because they were no longer able to get their favorite bullets. Well, here’s some good new guys — Hornady has resumed production of a number of bullet types, and four ammo varieties. Last year, to catch up with demand for its most popular products, Hornady temporarily halted production of a significant number of bullet types and ammunition products. Some shooters were upset because they were no longer able to get their favorite bullets. Well, here’s some good new guys — Hornady has resumed production of a number of bullet types, and four ammo varieties.

CLICK LINK to View Updated 2014 Production List.

Highlighted items have been removed from suspension.

http://www.hornady.com/assets/files/support/CurrentProductionList.pdf

We scanned over the updated production list (linked above), and we found these highlighted items, which should now be back in production. As Hornady may update the list with new items, we suggest you contact Hornady if your favorite projectile is not yet back in production.

|

Bullets Restored to 2014 Production

22492 22 CAL .224 52 GR A-MAX®

2250 22 CAL .224 53 GR HP MATCH

22281 22 CAL .224 60 GR V-MAX®

2278 22 CAL .224 68 GR BTHP MATCH

27352 270 CAL .277 140 GR SST®

27402 270 CAL .277 150 GR SST®

27200 270/6.8 .277 110 GR BTHP W/C

28402 7MM .284 162 GR A-MAX®

28405 7MM .284 162 GR BTHP MATCH

30311 30 CAL .308 140 GR MFX (308MX)

30310 30 CAL .308 140 GR MONOFLEX®

30370 30 CAL .308 150 GR GMX®

3072 30 CAL .308 180 GR BTSP

3560 9.3 CAL .366 286 GR SP-RP |

Ammo Restored to 2014 Production

8218 AMMO 300 WIN MAG 195 GR BTHP

8115 AMMO 30-06 SPRG 165 GR BTSP

4747 470 CAL .474 500 GR DGX®

82741 AMMO 45-70 GOVT 250 GR MFX LVR |

April 4th, 2014

Here’s a way you can support competitive shooting, while getting a tax deduction. Donations to the NRA Competitive Shooting & National Championships Endowment can be tax-deductible. Started in 2007 by then NRA President John Siegler, the Endowment provides direct funding for shooting programs, including the NRA National matches at Camp Perry. This is a permanent Endowment, with investment income channeled to shooting programs.

According to the NRABlog: “Donations go right into the fund and stay there. They are never touched. 85% of the earnings (or interest) generated by the fund are dispersed to the Competitive Shooting Division for their yearly budget. The other 15% goes back into the principal. By never touching the principal, and reinvesting a portion of the earnings, the endowment will always grow. Simple as that.”

You can contribute in one of two ways — as a gift or as a tax-deductible donation. No matter what path you choose, the money still goes towards the overall cost of running the competitions. To make a contribution to the fund, download the Competitive Shooting & National Championships Endowment flyer, fill out the form and send it to:

NRA Treasurer’s Officer

11250 Waples Mill Road

Fairfax, Virginia 22030

“Once [the Endowment] is big enough, it could pay for all of competitive shooting. That’s something every competitor would benefit from.” — Dennis Willing, NRA Competitive Shooting Director.

|

If you have recently placed credit card orders with

If you have recently placed credit card orders with

Last year, to catch up with demand for its most popular products, Hornady temporarily halted production of a significant number of bullet types and ammunition products. Some shooters were upset because they were no longer able to get their favorite bullets. Well, here’s some good new guys — Hornady has resumed production of a number of bullet types, and four ammo varieties.

Last year, to catch up with demand for its most popular products, Hornady temporarily halted production of a significant number of bullet types and ammunition products. Some shooters were upset because they were no longer able to get their favorite bullets. Well, here’s some good new guys — Hornady has resumed production of a number of bullet types, and four ammo varieties.