Case Diagnostics — Find the Flaws in Your Cases

Inspect your cases — every time you reload. A tiny flaw could lead to a split neck, case-head separation or worse. The Sierra Blog has a good article this week on case inspection, with many eye-catching examples. Sierra Bullets Ballistic Technician Duane Siercks shows a variety of problem cases and explains the issues he found. Duane states: “Careful case examination is one of the most important safety aspects of the reloading process.”

CLICK HERE to Read Full Article on the Sierra Bullets Blog

We recommend that you read the full article. Here are three examples…

Incipient Case-Head Separation

This is a Winchester .308 Win case that has a real issue. This case has a very obvious incipient case head separation in the process of becoming a complete failure.

This is most commonly caused by over-sizing the case causing there to be excess headspace on the case. After a few firings and subsequent re-sizing, this case is just about ready to come completely apart. Proper die adjustment is certainly a requirement here. Of course this case is not safe to reuse.

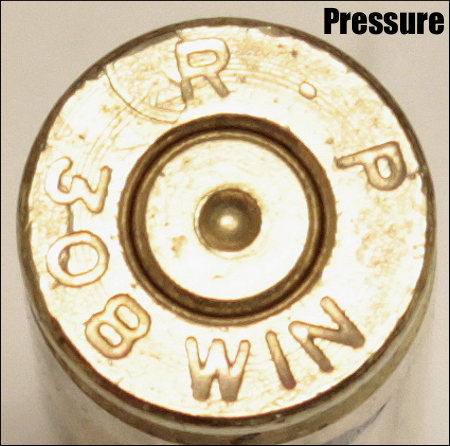

Excessive Pressure (Load Too Hot)

If you will notice in the picture of the case rim, there are two pressure signs to notice. First, look at the primer. It is basically flattened to about the max of what could be considered safe. If this was the only pressure sign noted, I would probably be fine with this load, but would constantly keep an eye on it especially if I was going to use this load in warmer temperatures. This load could easily cross into the “excess pressure” realm very quickly.

There is another sign of pressure that we cannot ignore. If you’ll notice, there is an ejector mark apparent that is located over the “R” of the R-P headstamp. This absolutely tells us that this load would not have been in the safe pressure range. If there were any of these rounds loaded, they should not be fired and should be dis-assembled. This case should not be reloaded.

Split Case-Neck

Here we have an R-P .22-250 case that has died the death. Everything looks fine with this case except the neck is split. This case must be tossed.

A split neck is a normal occurrence that you must watch for. It is caused by work-hardening of the brass. Brass cases get harder with age and use. Brand new cases that are stored for a period of time can become hard enough that they will split like this case within one to two firings. I have had new factory loads do the same thing. Then as we resize and fire these cases repeatedly, they tend to get harder and harder. Eventually they will split. The life of the case can be extended by careful annealing practices. This is an issue that would need to be addressed in an article by itself. Of course this case is no longer usable.

In the classes that I teach, I try to use examples like this to let the students see what they should be looking for. As always, if we can assist you, whether you are new to reloading or very experienced, contact us here at Sierra Bullets by phone at 1-800-223-8799 or by email at sierra [at] sierrabullets.com.

“Brand new cases that are stored for a period of time can become hard enough that they will split like this case within one to two firings.”

Any input on how long in storage it takes this to happen?

I don’t know specifically, but I do know that that time period is a LOT shorter if the brass is stored anywhere near an ammonia-containing solvent.

Is there a jig made that can help smooth out “ejector scars” on the casing base? I see this alot but never hear anyone addressing it.