Saturday Movies: Loading at the Range — Gear and Methods

Today’s Saturday Video Showcase features informative videos about loading at the range. AccurateShooter.com contributor F-Class John shows efficient procedures for load development at the range, testing both powder charge and seating depth. And Ultimate Reloader’s Gavin Gear shows how to load in the field with a mechanical powder dispenser, small scale, and a high-tech hand press. We also include a video from a benchrest competitor in France loading his 6PPC, plus tips for loading at the range by Glen Zediker, author of the Handloading for Competition book.

Reloading at the Range with F-Class John

This excellent 25-minute video covers all aspects of loading at the range — case sizing, powder measuring/dispensing, priming, bullet seating and more. In the video, F-Class John also talks about transport of tools and how to develop loads at the range, as you test different powder charges and seating depths. Viewers have praised this video as one of F-Class John’s best ever. John employs a compact RCBS Summit press and an RCBS ChargeMaster. Highlights by time: 6:14 powder test with grain increments; 14:30 setting depth test; 16:18 test fire seating depth; 18:31 refine seating depth; 20:52 refined seating depth firing; 22:32 “take away” commentary.

Design and Function of Open Front RCBS Summit Press

Unlike other presses, the open front RCBS Summit moves the die up and down while the cartridge case remains stationary. The ambidextrous open-front design allows great access to your cases, and you can quickly change dies very quickly. The Summit has an all-steel linkage and cast iron frame. The Summit also offers compound leverage, a massive 2-inch diameter ram, full access through the front, a press adapter bushing, spent primer catcher, and wide 4.5-inch operating window for convenient access.

Ultimate Reloader Video of Loading at the Range

Sometimes the ONLY practical solution for load development is loading ammunition at the range. In this video Ultimate Reloader’s Gavin Gear demonstrates the loading process from start to finish, and covers what gear is required to “load where you shoot”. This applies to both loading at a covered range and loading in the field. In the video Gavin employs a bench-attached powder thrower and the impressive ($300) Buchanan Precision Machine (BPM) hand press.

Loading Between Matches — Precision Loading at a Pace

In this video, French benchrest competitor Carlos Pacheco loads ammo efficiently between relays at a Benchrest for Group match. He has a single-stage press clamped to a bench, and has a separate arbor press for bullet seating. 6PPC group-shooting competitors commonly tune their loads during the course of the competition, adjusting powder volumes to keep their rifles in optimal tune. Some competitors may also change bullet seating depth, but “tuning” is most commonly done with powder charge. Some benchrest-for-group competitors also believe that best accuracy is achieve with freshly-made ammo loaded before the brass necks take a set.

Loading at the Range — Then and Now

In benchrest shooting for Group, loading at the range has been de rigueur for decades. In the Score discipline, preloading is usually the custom. The main reason is that, in Score competition, only one Aggregate (warm-up match and five record targets) per day is usually shot. That would be less than 50 shots, assuming a few sighter shots. Also, the 30BR, the dominant Benchrest-for-Score cartridge, is very amenable to pre-loading.

By contrast, the Group discipline includes 21 targets (two warm-ups and twenty record targets) over a weekend, usually shot with 6PPC-chambered rifles. Many times, the 6PPC shooters may tweak their loads through the day given changing atmospheric conditions or simply trying to find the correct tune to “dot up”. This term, “Dot up”, means the shots are essentially going through the same hole, or closely so.

Loading at the range was a bit different when benchrest competition was in its infancy. The 1951 book, Modern Accuracy by Bob Wallack, is the best of the early benchrest books. Copies can be found, from time to time, on eBay or Alibris. It is a fascinating survey of benchrest as it existed more than six decades ago. In it, there is a photo of Wallack using the rear bumper of a car at the bench to clamp his reloading tools. Things have come a long way compared to the range loading set-ups of modern shooters. Here you can see Bob Wallack way back in 1950:

Good Article on Reloading at the Range by Glen Zediker

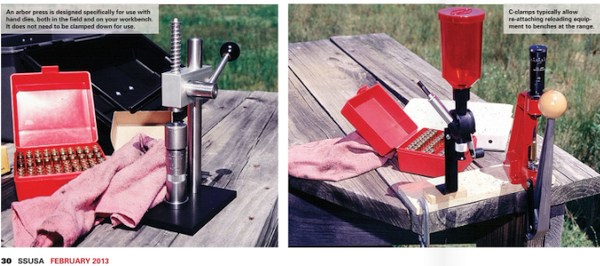

The February 2013 edition of Shooting Sports USA magazine has an interesting feature by Glen Zediker, who sadly passed away in October 2020. In this Transporting Success, Part I article, Zediker explains the advantages of loading at the range when you are developing new loads or tuning existing loads. Glen, the author of the popular Handloading for Competition book, discusses the gear you’ll need to bring and he explains his load development procedure. In discussing reloading at the range, Glen focuses on throwing powder and seating bullets, because he normally brings enough sized-and-primed brass to the range with him, so he doesn’t need to de-prime, re-size, and then re-prime his cases.

The February 2013 edition of Shooting Sports USA magazine has an interesting feature by Glen Zediker, who sadly passed away in October 2020. In this Transporting Success, Part I article, Zediker explains the advantages of loading at the range when you are developing new loads or tuning existing loads. Glen, the author of the popular Handloading for Competition book, discusses the gear you’ll need to bring and he explains his load development procedure. In discussing reloading at the range, Glen focuses on throwing powder and seating bullets, because he normally brings enough sized-and-primed brass to the range with him, so he doesn’t need to de-prime, re-size, and then re-prime his cases.

Zediker writes: “Testing at the range provides the opportunity to be thorough and flexible. You also have the opportunity to do more testing under more similar conditions and, therefore, get results that are more telling. Once you are there, you can stay there until you get the results you want. No more waiting until next time.”

Zediker starts with three-shot groups: “I usually load and fire three samples [with] a new combination. I’ll then increase propellant charge… based on the results of those three rounds, and try three more. I know that three rounds is hardly a test, but if it looks bad on that few, it’s not going to get any better.”

Glen reminds readers to record their data: “Probably the most important piece of equipment is your notebook! No kidding. Write it down. Write it all down.”

There’s More to the Story…

Editor’s Note: In Zediker’s discussion of loading at the range, he only talks about throwing powder and seating bullets. In fact, Glen opines that: “there is little or no need for sizing.” Well, maybe. Presumably, for each subsequent load series, Zediker uses fresh brass that he has previously sized and primed. Thus he doesn’t need to de-prime or resize anything.

That’s one way to develop loads, but it may be more efficient to de-prime, re-size, and load the same cases. That way you don’t need to bring 50, 80, or even 100 primed-and-sized cases to the range. If you plan to reload your fired cases, you’ll need a system for de-priming (and re-priming) the brass, and either neck-sizing or full-length sizing (as you prefer). An arbor press can handle neck-sizing. But if you plan to do full-length sizing, you’ll need to bring a press that can handle case-sizing chores. Such a press need not be large or heavy. Many benchresters use the small but sturdy RCBS Partner Press, an “O-Design” that costs about $119.99 on Amazon. You may even get by with the more basic Lee Precision Compact Reloading Press, shown in Zediker’s article. This little Lee press, Lee product #90045, retails for under $50.00.

Wind Box Shelters Scales When Reloading at Outdoor Ranges

Beat the Breezes with a Wind Box for your Scale

Forum member Boyd Allen has come up with a smart solution for reloaders who use scales outdoors — a windproof scale enclosure, aka “Wind Box”. Boyd explains: “Many guys have good set-ups for loading at the range, with clamping mounts for powder measure and press. But they lack a good enclosure for a scale. This is vitally important with beam scales because they have a lot of surface area to catch the wind. With much wind at all, the beam can oscillate to the point that is not really very usable. While a low-profile electronic scale may be less wind-sensitive, breezes DO affect weight read-outs on digital scales. And of course you always have the issue of blowing powder particles.”

Boyd Allen has used his Wind Box successfully for many seasons. He explains: “The essence of the idea is to have a scale set up in a box with a clear cover that can be opened and closed. On one side the trickler handle/control emerges through a ‘just big enough’ hole. You raise the cover, add a sub-target-weight thrown charge to the pan, and then close the cover. With the cover secure, the set-up is protected from the wind, and you can now trickle up to your desired charge. It works very well. The scale in the photo is an old Ohaus that I picked up. You can adapt this Wind Box design to any beam scale, or portable electronic scale. Simply adjust the dimensions to fit your particular scale and trickler.”

Saturday Movies range loading story concept and video links by Boyd Allen