|

|

December 6th, 2013

Report based on story by Ashley Brugnone, for The First Shot CMP Online Magazine

After a month of business, the CMP Custom Shop is already stacked to the ceiling with rifles needing customization and repair. With nearly 200 rifles already shipped to the Shop, the gunsmiths running the operation only anticipate more to come in the future. “Things are going great,” said John McLean, CMP Custom Shop manager. “We’re learning how to do everything we need to do in order to get things done as quickly for customers as we can, as well as do a good job.”

The Custom Shop opened its doors on October 1, 2013, offering upgrades, customization, refinishing, and other types of repair for U.S. Military-type rifles. The shop specializes in such rifles as the M1 Garand, M1 Carbine, 1903 and 1903A3 Springfield, the 1917 Enfield and the Krag. CMP will NOT be working on shotguns, pistols, revolvers, M14/M1A, AR15-style rifles or other commercially-produced modern rifles.

A M1917 U.S. Enfield was the first gun to pass through the doors of the custom shop. It was sent to be refinished by a contractor, spending nearly a month being restored. The rifle was then repaired by McLean and his crew and is just about ready to be returned to its owner. McClean explains: “The amount of time we work on pieces varies very widely. It could be five minutes worth of work to a couple days worth of work, depending on what the customer wants.”

John McLean works on a M1917 U.S. Enfield — the first of many rifles to arrive at the shop for repair.

Rifles needing repair can be shipped to the CMP Shop in Anniston, Alabama from anywhere in the country. Then, once repaired, these rifles are shipped back out to the owners. Shelves of rifles to be serviced are presently stacked to the ceiling of the Custom Shop, representing about 90 days’ worth of scheduled work for the CMP gunsmiths.

CMP Custom Shop Also Offers Training Classes

The space where the rifles are repaired, though meant as a machine shop, was also designed as a classroom. Benches facing a projection screen hanging on the wall to display slides and other instructional materials seat a class of about 20 people. Recently, the shop held its first CMP Advanced Maintenance Class (AMC), which involved both hands-on training. Students raved about this class: “Fantastic course. Can’t say enough good about it. Instructors were phenomenal”; “This was by far the very best firearms class I have ever taken.” The CMP Custom Shop will hold six more classes in 2014, However, registration is already full for all sessions.

For a list of services the shop provides, visit the CMP Custom Shop web page. For detailed CMP Custom Shop information, or specific questions, please contact John or Chris at customshop@thecmp.org or call (256) 835-8455, ext. 1113.

December 2nd, 2013

Forum member Jonathan L. (aka ‘Quest-QC’) was a member of the Canadian F-TR team at the F-Class World Championships in Raton, NM this fall. His handsome .308 Winchester rifle features some interesting hardware and a stunning African Padauk-wood stock stiffened with carbon fiber layers. We were impressed by the innovative, adjustable bag-rider assembly Jonathan fitted to the rear of his stock (scroll down for photo). With an Allen wrench, the vertical height and the slope (i.e. fore/aft angle) of the V-shaped bag-rider can be changed easily. This has many advantages. First, Jonathan can set his rifle to the most comfortable height (for his prone position) without using “lifters” under the rear bag. The system also gives him some gross elevation adjustment separate from the bipod. In addition, the angle adjustment allows the bag-rider to better match the geometry of the rear bag. Last but not least, by setting up the bag-rider with some drop (higher in front, lower in back), Jonathan can fine-tune his elevation (while aiming the gun) by simply sliding the rifle fore and aft.

Jonathan says: “This year was my second year shooting at 1000 yards and I managed to find a spot on Team Canada for the FCWC at Raton. Here is the rifle that brought me there…”

The rifle features a Kelbly Panda F-Class RB-LP action, 34″ Bartlein 1:11″-twist, Heavy Palma contour barrel. Fitted to the red-toned Padauk-wood stock is a 23.2 oz., StarShooter CF-SS light weight bipod with custom bench feet. On top is a March 8-80x56mm scope in Kelbly rings. Total weight of the rifle is 18 pounds, 1 oz., complete with the 24 oz. adjustable brass bag-rider at the back. The bag-rider block was modeled in 3D, then machined afterwards to use up the remaining weight available after all the other components. CLICK for StarShooter CF-SS Bipod Video.

African Padauk Wood is Very Stiff

Jonathan chose the red-toned African Padauk Wood because it is stiff for its weight: “The reason for choosing African Padauk is that the weight of the wood is the same as Maple but 45% more rigid.” The downside of Padauk, as Forum member Gstaylorg notes, is that it is a “very oily wood, which can make it somewhat difficult to finish with something like polyurethane. [Padauk] can generate a lot of bubbles and cause cracking problems around joints and/or seams.” Jonathan did note that he has observed a few bubbles in the auto clear coat on his stock. He plans to refinish the stock in the off-season.

Gun Is Extremely Accurate with Berger 200gr Hybrids

Jonathan says this rig was very accurate, at least until his barrel gave up the ghost. He says he has put 15 successive shots in about 1/4 MOA: “I managed to make it twice (1/4 MOA for 15) by taking my time between shots. You don’t want to overheat this barrel. I needed to provide a very strong effort (mentally) to be able to achieve such precision as the rifle is way better than me.” Jonathan shoots Berger 200gr Hybrid bullets (in the lands) with Hodgdon Varget powder, and Federal 205M primers, loaded into neck-turned Lapua .308 Win brass. He has also had good luck with Vihtavuori N150 powder in the past.

In compliance with F-Class rules, the adjustable bag-rider system would not be adjusted “on the fly” during record fire. The bag-rider’s vertical rise and fore/aft slope would be optimized before shooting, then locked in place. The bottom photo offers a good view of the V-shaped profile of the metal bag-rider. We have found that this kind of V-profile, closely matching the triangular profile of the rear ears, makes a rifle more secure in the rear bag and often allows the gun to track better.

November 27th, 2013

McMillan will still be making stocks and other components. However, it is selling off its gun-building business. Strategic Armory Corps (SAC) announced it has acquired McMillan Firearms Manufacturing, LLC. McMillan produces quality hunting and tactical rifles including the highly-regarded TAC-50, TAC-416, TAC-308, TAC-300/338, and the new Alias modular rifle system. McMillan produces a full line of hunting rifles, including the Custom Collection, Mountain Extreme Series, and Long Range Hunting Series. McMillan also builds competition and target rifles.

The McMillan Firearms acquisition carries out Strategic Armory Corps’ strategy of acquiring premium firearms manufacturing companies (SAC has previously purchased ArmaLite Inc. and Surgeon Rifles). “The acquisition of McMillan Firearms is consistent with our focus on acquiring the highest quality manufacturers of premium firearms,” said Mark Johnson, Strategic Armory Corps CEO. “This transaction provides the perfect product line complement to the ArmaLite and Surgeon Rifles product lines and will allow us to more effectively serve the needs of the custom bolt action rifle enthusiast.”

Kelly McMillan stated, “Both Ryan and I will continue on as long term consultants with McMillan Firearms. We are proud of our heritage and are confident that Strategic Armory Corps will continue to build the highest quality firearms for our valued customers”.

Strategic Armory Corps is based in Phoenix, Arizona and is a fast-growing firearms and ammunition company that serves the needs of the high end firearms enthusiast. In July of 2013, the company acquired ArmaLite, Inc. one of the oldest names in the AR-style sporting rifle segment of the industry.

Story lead from EdLongrange. We welcome reader submissions.

November 16th, 2013

Kirby Allen of Allen Precision Shooting, www.apsrifles.com, has developed a .30-caliber jumbo-sized magnum he calls the 300 Raptor. The 300 Raptor (center in photo) is based on Allen’s 338 Excalibur parent case (far right in photo), necked down to 30 cal with shoulder moved forward to increase case capacity. Allen states: “This is the largest capacity and performance .30 caliber magnum on the market that can be used in a conventional sized receiver.” Kirby Allen of Allen Precision Shooting, www.apsrifles.com, has developed a .30-caliber jumbo-sized magnum he calls the 300 Raptor. The 300 Raptor (center in photo) is based on Allen’s 338 Excalibur parent case (far right in photo), necked down to 30 cal with shoulder moved forward to increase case capacity. Allen states: “This is the largest capacity and performance .30 caliber magnum on the market that can be used in a conventional sized receiver.”

Shoot 200s at 3600 fps

Performance of Allen’s new 300 Raptor is impressive. Allen claims that “200gr Accubonds can be driven to nearly 3600 fps, 230gr Berger Hybrids to 3350 fps, and the 240gr SMK to right at 3300 fps. These loads offered case life in excess of 6-7 firings per case and many of my test cases have over 8 firings on each case so they are not an overly hot load showing the potential of this big .30 caliber.”

To showcase the new cartridge, Allen built up a prototype rifle with a McMillan A5 stock, Raptor LRSS Action with extended tenon, and a Jewell trigger. The first 300 Raptor Rifle is currently on its second barrel, a new 30″, 3-groove 1:9″-twist Lilja in a custom APS “Raptor Contour”. This distinctive dual-fluted contour runs full-diameter almost to the end of the stock, and then steps down and tapers to the muzzle, where a beefy Medium 3-port ‘Painkiller’ Allen Precision brake is fitted.

Story tip by EdLongrange. We welcome reader submissions.

November 14th, 2013

Wouldn’t it be great if you could apply a durable, two-part, commercial-grade coating on gun parts, with the ease of “rattle can” spraying. Until recently, you had to have some pro-grade equipment to apply multi-stage coatings. Now that has changed thanks to a new “can-in-a-can” developed in Europe. DuraCoat® can now be applied, in your choice of nine colors, from a single, convenient rattle can. The secret is the new type of twin-chamber can construction. An inner chamber holds the DuraCoat hardener (catalyst), while an outer chamber contains the DuraCoat color coating liquid. Wouldn’t it be great if you could apply a durable, two-part, commercial-grade coating on gun parts, with the ease of “rattle can” spraying. Until recently, you had to have some pro-grade equipment to apply multi-stage coatings. Now that has changed thanks to a new “can-in-a-can” developed in Europe. DuraCoat® can now be applied, in your choice of nine colors, from a single, convenient rattle can. The secret is the new type of twin-chamber can construction. An inner chamber holds the DuraCoat hardener (catalyst), while an outer chamber contains the DuraCoat color coating liquid.

The “can-in-a-can” design keeps the two elements completely separate until you are ready to apply the coating. It’s really quite ingenious. Duracoat’s owner, Steve Lauer, found this innovative dual-chamber aerosol can design in Europe. We believe his company, Lauer Custom Weaponry is the first to introduce this spray can technology in the American gun coating market.

Video Shows How to Apply DuraCoat with New Twin-Chamber Aerosol Can

DuraCoat is a two-part coating system. Once the DuraCoat is mixed with the hardener, a chemical reaction occurs. That is why the two fluids must be kept separated until it’s time to coat a project. When you’re ready, you mix the two products by pushing a plunger in the bottom of the can. This is done by attaching a red button to the bottom of the can. Push down on the can and you’ll here a “pop” that indicates the hardener can migrate into the main chamber. Shake the can for a couple minutes and you are good to go (provided the product to be coated has been prepped properly.) DuraCoat is a two-part coating system. Once the DuraCoat is mixed with the hardener, a chemical reaction occurs. That is why the two fluids must be kept separated until it’s time to coat a project. When you’re ready, you mix the two products by pushing a plunger in the bottom of the can. This is done by attaching a red button to the bottom of the can. Push down on the can and you’ll here a “pop” that indicates the hardener can migrate into the main chamber. Shake the can for a couple minutes and you are good to go (provided the product to be coated has been prepped properly.)

DuraCoat is Versatile

Duracoat can be used on carbon steel, stainless steel, aluminum, metal alloys, wood, plastic and many other surfaces. No baking or pre-heating is required. DuraCoat is not just a thin cosmetic layer like conventional paint. When properly applied, DuraCoat offers good abrasion resistance and very effective protection against corrosion. DuraCoat Aerosol is currently offered in nine (9) popular colors: Matte Black, Woodland Green, Parkerized Gray, OD Green, White, Combat Gray, Pink Lady, Magpul Flat Dark Earth, and Blackhawk Coyote Tan. View DuraCoat Color Chart.

November 13th, 2013

Steven Blair’s recent report on the .300 WSM for F-Class stirred quite a bit of interest. If you’re a serious F-Open competitor, you’ll definitely want to read that article, which covers the pros and cons of the .30-Cal WSM loaded with the ultra-high-BC 230gr Berger Hybrid bullets.

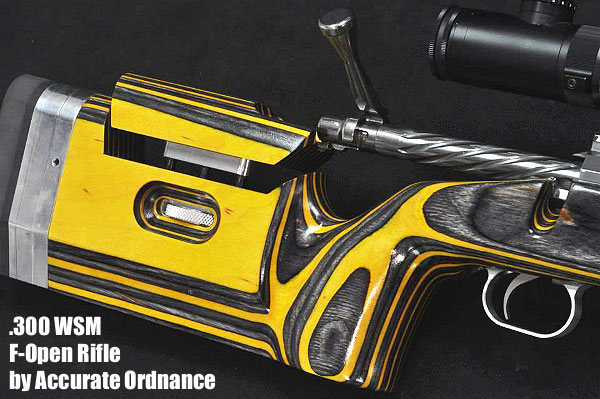

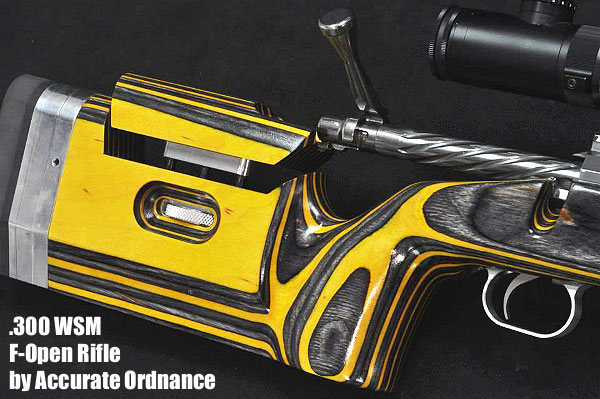

If you’re thinking about building a .300 WSM for F-Class, here’s a rig that can give you some design and hardware ideas. This eye-catching custom .300 WSM F-Open rig belongs to Forum member Keith T. (aka “KT”). With its striking “bumblebee” color scheme, it will certainly get noticed on the firing line.

Click Photos to see full-screen versions.

Bold Bumblebee .300 WSM for F-Class

Forum member Keith T. (aka “KT”) just got his hands on his new .300 WSM for F-Class and long-range competition. It’s a handsome brute, decked out in a “bumblebee” (yellow and black) laminated stock. Keith’s rifle features a Defiance Machine Deviant Long Magnum action (with Jewell trigger) in a Precision Rifle & Tool (PR&T) F-Class Lowboy stock. Keith has two 30″-long, 1:9″-twist barrels for the gun, one made by Brux Barrels, and the other by Bartlein. Both barrels have identical .300 WSM chambers cut with the same reamer. Keith will test both and then use the best-performing of the two in competition. Riding on top is a Nightforce 12-42x56mm Benchrest Model scope. All the work was done by Accurate Ordnance (AO), based in Winder, Georgia.

Keith reports: “This one took a while to get built due to parts availability issues, but I’m glad it’s done! Thanks to Accurate Ordnance and Nightforce and all their help.” NOTE: Accurate Ordnance tells us that a rifle like this can normally be completed in 6-8 weeks, once all key parts are in hand.

November 11th, 2013

Are you thinking thinking about a low-budget Remington 700 project? Perhaps you want to build a basic hunting rifle for a young family member. Or maybe you want to re-stock or re-barrel an old Rem 700 that’s sitting in the safe. Well here’s your opportunity. CDNN Investments has attained a large inventory of brand new “Take-Out” factory parts from Remington rifles. You’ll find triggers for $49.99, barrels for $49.99/$69.99, and synthetic stocks for $49.99/$59.99. If you already have a Rem 700 action, this will let you assemble a complete rifle for very little money. These are new Remington-made parts. NOTE: Though chambered as indicated, gunsmithing is required for installation of these barrels.

For more information, or to order, visit CDNNinvestments.com or call (800) 588-9500.

November 9th, 2013

Could your next metal scope rings, trigger guard, or muzzle brake be crafted with a 3D printing process? It’s possible. In fact, a wide variety of metal parts (even a complete handgun) can be printed using the latest 3D Direct Metal Laser Sintering (DMLS) process. The way this works is as follows: powdered metal is heated by a laser, causing the metal particles to fuse and solidify. This is progressively repeated, in vertically-stacked layers, until the entire metal part is complete. It’s like building a metal layer cake with the shape/size of each thin layer defined by a precise laser beam. The laser is guided by computer-controlled servos following a CAD “blueprint”.

This video demonstrates how metal parts are 3D printed using the DMLS process. This technology is offered by Solid Concepts, a leading rapid prototyping and manufacturing services company.

The Solid Concepts 1911 — World’s First 3D-Printed Metal Firearm

Solid Concepts has manufactured the world’s first 3D-printed metal gun using a laser sintering process and powdered metals. The gun, a .45 acp 1911 clone, has already handled 50 rounds of successful live-fire testing. A 1911 design was chosen because the “blueprint” is public domain. The gun is composed of thirty-three, 17-4 Stainless Steel and Inconel 625 components, crafted through the DMLS process. Even the carbon fiber-filled hand grips are 3D printed, using a Selective Laser Sintered (SLS) process.

Except for the springs, all the parts of this 1911 handgun were printed using the metal laser sintering process. Yes even the highly-polished slide, the barrel, the frame, and the hammer were printed. There are no forgings, castings, or conventionally-machined parts. With the exception of springs, all 30+ components in this prototype pistol were printed using Direct Metal Laser Sintering (DMLS) technology. Watch the video for a glimpse into the future of gun-making:

World’s First 3D-Printed Metal Gun Test Firing

Solid Concepts believes that its fully-functional, 3D-printed 1911 handgun proves the viability of 3D printing for gun parts, even highly-stressed components. Kent Firestone, V.P. of Additive Manufacturing at Solid Concepts, states: “We’re proving this is possible, the technology is at a place now where we can manufacture a gun with 3D metal printing. And we’re doing this legally. In fact, as far as we know, we’re the only 3D printing service provider with a Federal Firearms License (FFL). Now, if a qualifying customer needs a unique gun part in five days, we can deliver.”

Will we see complete 3D-printed metal guns on the market soon? That’s unlikely. It’s still more economical to produce complete guns the old-fashioned way. However, we may see 3D printing used for rapid prototyping. In addition, 3D metal printing has advantages for hard-to-machine parts with complex geometries. Solid Concepts reports that its 3D printed metal has fewer porosity issues than an investment cast part and better complexities than a machined part. It will be interesting to see what unfolds in the years ahead.

November 9th, 2013

The first edition of Modern Custom Guns hit bookstores 16 years ago. Next month Gun Digest will release the long-awaited Second Edition of Modern Custom Guns. This is a richly-illustrated, 8.2″x11″ hard-cover book, with approximately 200 color photos. Written by Tom Turpin and published by Gun Digest Books, this 208-page volume is now available for pre-order, with a December 11, 2013 release date. The first edition of Modern Custom Guns hit bookstores 16 years ago. Next month Gun Digest will release the long-awaited Second Edition of Modern Custom Guns. This is a richly-illustrated, 8.2″x11″ hard-cover book, with approximately 200 color photos. Written by Tom Turpin and published by Gun Digest Books, this 208-page volume is now available for pre-order, with a December 11, 2013 release date.

CLICK for FREE Preview of Modern Custom Guns

This 208-page Second Edition of Modern Custom Guns is not just a coffee-table book. In addition to the nice color photography, the book examines the processes and techniques used to craft ultra-high-end custom rifles. Author Turpin has interviewed many gifted rifle-makers and artisans who create showpiece rifles. Turpin explains how these craftsman work magic with wood and metal. Specific chapters are dedicated to: Stock-making, Metal-smithing, Actions, Barrels, Sights, Engraving/carving, and other topics. Chapter 10 spotlights two dozen master engravers, while Chapter 11 profiles 39 leading custom gun-builders. A helpful Appendix provides contact information for custom gun-makers and engravers.

About the Author – Tom Turpin has been a professional writer in the outdoor industry for over 40 years. He has written several hundred published articles, four books, and he is presently a contributing editor to the Gun Digest Annual.

In this new edition of Modern Custom Guns, Tom Turpin sought to showcase the exceptional craftsmanship found in high-end customs. Tom explains: “My preference runs to classic styling, and I follow the principle that if any one facet of a custom rifle immediately jumps out at you, it is surely overdone. Quiet elegance is best for me.”

October 29th, 2013

As a member of the World Champion Team USA F/TR squad, Paul Phillips regularly competes (and wins) at 1000 yards. Paul is also a long-range hunter. Here’s his story about developing his ultimate long-range hunting rifle. Chambered for the .338 Lapua Magnum, this rig is accurate out to 1800 yards.

The Long-Range Challenge By Paul Phillips

Being an avid big game rifle hunter, my goal was to build the most accurate long-range hunting rifle possible that would still be light enough to carry. My thought was to use the same type of high-quality components as what I used on my US F/TR Team Rifle, except in a bigger caliber — a caliber that would have plenty of knock-down power at very long ranges. After extensive research, including both ballistic data analysis, as well as discussion with top gunsmiths and champion long-range shooters, I chose the .338 Lapua Magnum. My past experience from being a member of a USMC Scout Sniper Platoon and a shooting member of two World Champion U.S. F-Class F/TR teams, I knew that this rifle was more than capable of performing the task. After establishing that the rifle had half-MOA accuracy at 600 yards, we wanted to see how far the rifle could maintain sub-MOA accuracy, to see what the cartridge and rifle could achieve. Could this gun shoot sub-MOA at a mile? That was our challenge.

Rifle Components and Gunsmithing

My rifle was built on a Stiller Tac-338 single-shot action. It has a 30″, 1:10″-twist Brux barrel, a McMillan A-5 stock with Magnum fill, a Sinclair Bipod, and a Remington X-Mark trigger set at two pounds. The rifle wears a Nightforce NXS 8-32x56mm scope in Nightforce rings on a +40 MOA rail. I chose David Tooley to install the barrel, custom brake, apply a Cerakote dark earth finish and bed the stock. After speaking with Mr. Tooley in great length, I chose his no-neck-turn match .338 Lapua chamber specifically designed for the 300 grain Berger Bullet. This rifle weighs 17 pounds and, with the muzzle brake, it recoils like a standard .308 Winchester.

Load Development and Accuracy Testing

I used the 600-yard range at the Midland County Sportsman’s Club. If I was going to have any chance of hitting small targets at a mile, I would need to find a load that could produce half-minute (0.5 MOA) or better accuracy. I found an accurate load that gave me consistent half-minute groups that chronographed at 2825 FPS. My load consisted of Lapua brass, Federal 215M Primer, Alliant Reloder 25, and Berger 300gr Hybrid OTM bullet. With the Berger 300-grainer’s listed 0.419 G7 BC, this load would be good enough to reach 1880 yards before going subsonic. This load’s calculated energy at one mile is 960 ft/pounds. This is similar to a .44 magnum pistol round at point-blank range.

With my +40 MOA scope rail, my 100-yard zero ended up with the elevation at the bottom of the tube and the windage just 2 MOA left of center. This left a full 65 Minutes of Elevation — enough to get out to 1800 yards. This gave me the capability to aim and shoot from 100 yards to 1800 yards with a projectile that is still supersonic at 1800.

Hitting a 10″ Balloon at One Mile

For a one-mile target, I chose a balloon inflated to 10″ in diameter. The balloon would be a challenging, reactive target that would show up well on video. I teamed up with a fellow long-range shooter, John Droelle and friend Justin Fargo to attempt this feat. Using my known 600-yard Zero, my ballistics program showed my come-up for 1783 yards to be 53 MOA. After two sighters that measured 4 inches apart, I adjusted up one minute from my spotter shot and nailed my 10″ balloon at one mile. This video was recorded with my iPhone attached to my 25-power Kowa spotting scope, so it may seem a lot closer than it really is. Below is a video of the shot. Needless to say I achieved my goal and was very excited.

Watch Hit on 10″-Diameter Balloon at One Mile with .338 Lapua Magnum

After my balloon shot, I let my friend Justin Fargo, a novice shooter, try his skills. Justin told me that he had never shot past 100 yards using a common deer rifle. Surprisingly, Justin not only kept all his shots under 1 MOA, he hit the 9-inch white circle in the middle of the target. This bullet hole measured only 4.3 inches from the center of where he was aiming. Truly amazing! The target below shows Justin’s shots at one mile. Note that All the hits are located within the 24-inch black circle.

What I Learned — With the Right Equipment, Even a Novice Can Make Hits at a Mile

The above results demonstrate that even a novice shooter with a high-quality, custom rifle and match-grade ammo can make extreme long range shots with great accuracy. It is very important to understand the ballistics of the bullet and the effect of wind drift to make precision, first-shot hits on your target. It is also important that you know your target, backstop and beyond when making these shots. To date, I have shot approximately 40 shots at a mile in calm conditions while averaging 3-shot groups between ½ to 1 MOA (1 MOA is about 18.5″ at that distance). My next experiment is to see how well these bullets perform traveling at subsonic speeds out to 1.5 – 2 miles. Stay tuned!

Special thanks to the following people that helped out with this project: Geoff Esterline, David Tooley, Dick Davis, John Droelle, Ray Gross and Bryan Litz.

Editor’s Comment: The point of this article is to show the kind of accuracy a precision rifle system can achieve, consistently, at extreme long range. Though this rifle will do duty as a hunting arm, Phillips is not advocating that a .338 LM be used to harvest animals at the full limit of its supersonic range. Because winds are hard to predict at extreme long range in a hunting situation, Phillips cautions that the practical distance at which he would shoot game with a rig like this is much, much shorter.

|

Kirby Allen of Allen Precision Shooting,

Kirby Allen of Allen Precision Shooting,

Wouldn’t it be great if you could apply a durable, two-part, commercial-grade coating on gun parts, with the ease of “rattle can” spraying. Until recently, you had to have some pro-grade equipment to apply multi-stage coatings. Now that has changed thanks to a new “can-in-a-can” developed in Europe.

Wouldn’t it be great if you could apply a durable, two-part, commercial-grade coating on gun parts, with the ease of “rattle can” spraying. Until recently, you had to have some pro-grade equipment to apply multi-stage coatings. Now that has changed thanks to a new “can-in-a-can” developed in Europe.

DuraCoat is a two-part coating system. Once the DuraCoat is mixed with the hardener, a chemical reaction occurs. That is why the two fluids must be kept separated until it’s time to coat a project. When you’re ready, you mix the two products by pushing a plunger in the bottom of the can. This is done by attaching a red button to the bottom of the can. Push down on the can and you’ll here a “pop” that indicates the hardener can migrate into the main chamber. Shake the can for a couple minutes and you are good to go (provided the product to be coated has been prepped properly.)

DuraCoat is a two-part coating system. Once the DuraCoat is mixed with the hardener, a chemical reaction occurs. That is why the two fluids must be kept separated until it’s time to coat a project. When you’re ready, you mix the two products by pushing a plunger in the bottom of the can. This is done by attaching a red button to the bottom of the can. Push down on the can and you’ll here a “pop” that indicates the hardener can migrate into the main chamber. Shake the can for a couple minutes and you are good to go (provided the product to be coated has been prepped properly.)