|

|

July 22nd, 2023

Widener’s Reloading & Shooting Supply recently published a helpful introduction to reloading powders. Widener’s online Guide to Smokeless Powders shows the various types of powders, and explains how the differences in powder kernel/flake size and shape, and burn rate affect performance. We recommend you visit Widener’s website and read the Powder Guide in full.

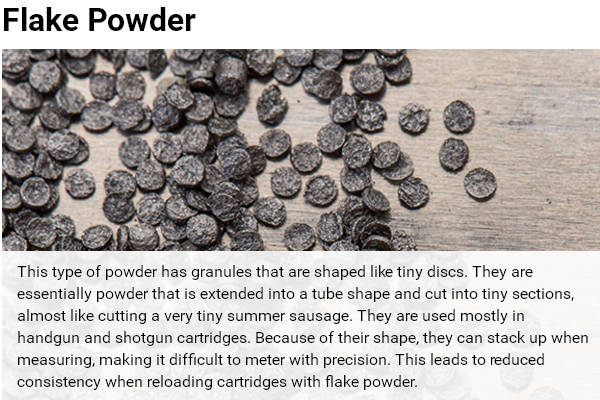

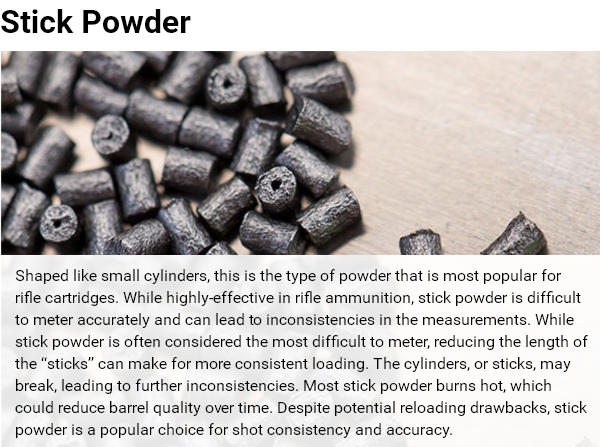

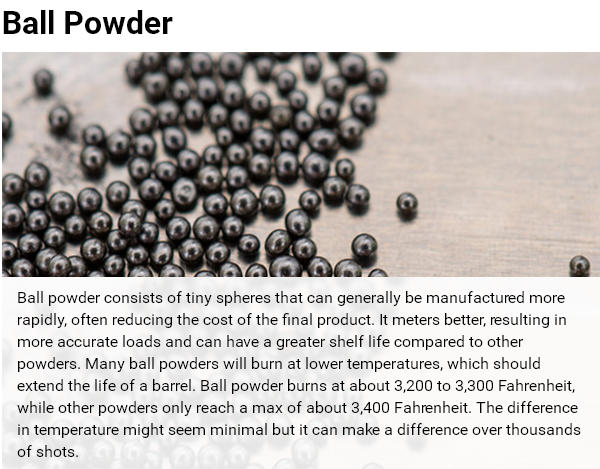

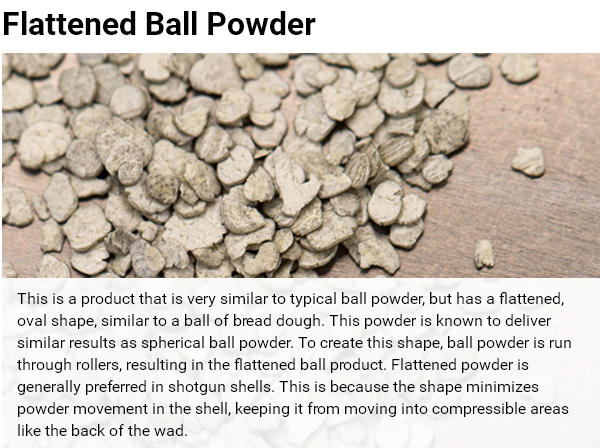

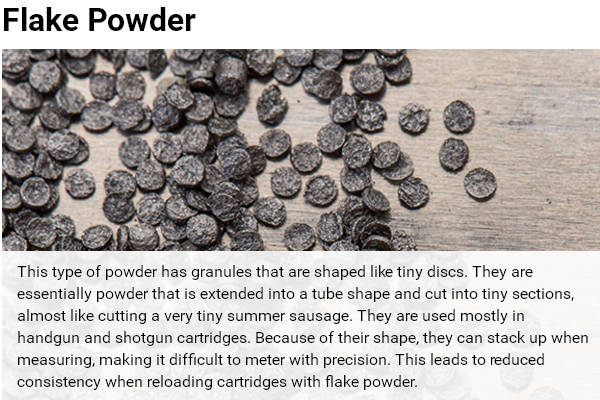

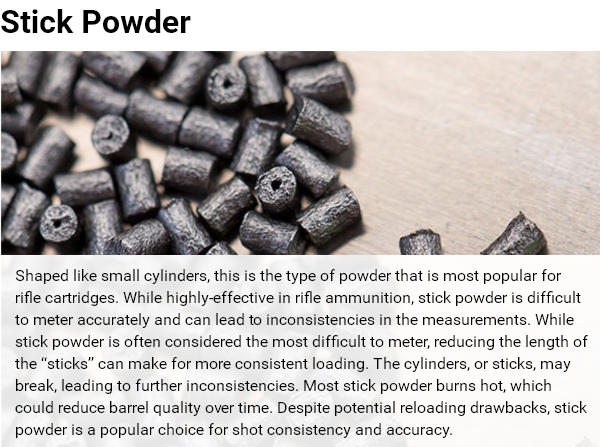

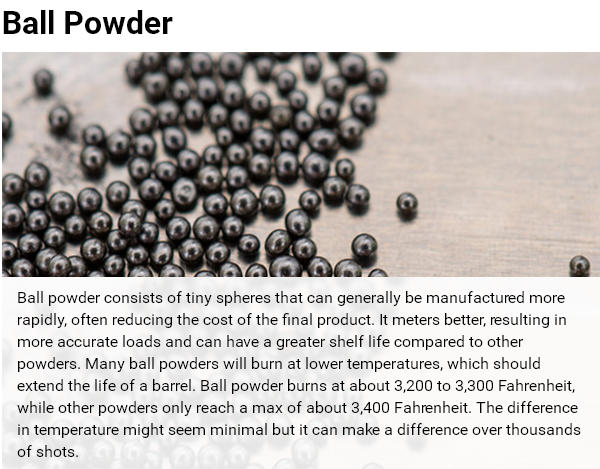

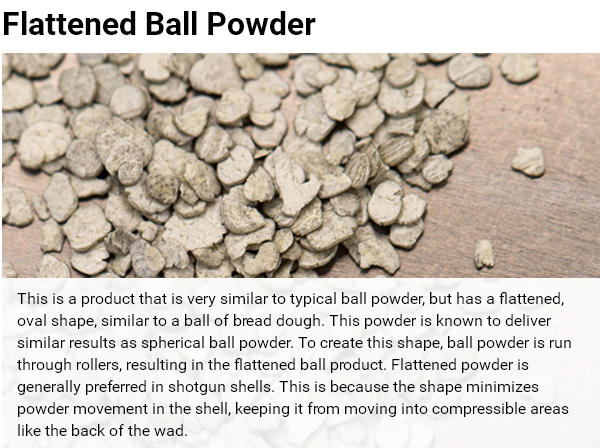

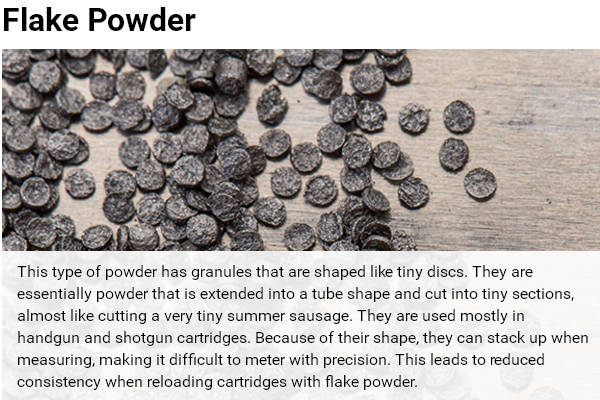

Take a close look at these illustrations which show the key differences between the four main powder types: extruded (stick) powder, ball (spherical) powder, flattened ball powder, and flake powder.

Burn Rate Basics

Widener’s Guide to Smokeless Powders also has a useful discussion of Burn Rate (a confusing topic for many hand-loaders). Wideners explains: “While a gun powder explosion in the cartridge seems instantaneous, if you slow it down you will actually find that each powder has a different ‘burn rate’, or speed at which it ignites.” This video shows powders with two very different burn rates. Watch closely.

Different burn rates suit different cartridge types notes Widener’s: “In general a fast-burning powder is used for light bullets and low-speed pistols and shotguns. Medium-rate powders are used for magnum pistols, while high-velocity, large bore rifle cartridges will need slow powders[.]

It should be noted that burn rate does not have a standardized unit of measurement. In fact, burn rate is really only discussed in comparison to other powders; there is no universal yardstick. Specifics will change by cartridge and bullet types[.]”

Share the post "Stick, Flake, and Ball — Do You Know Your Powder Properties?"

November 10th, 2016

Widener’s Reloading & Shooting Supply recently published a helpful introduction to reloading powders. Widener’s online Guide to Smokeless Powders shows the various types of powders, and explains how the differences in powder kernel/flake size and shape, and burn rate affect performance. We recommend you visit Widener’s website and read the Powder Guide in full.

Take a close look at these illustrations which show the key differences between the four main powder types: extruded (stick) powder, ball (spherical) powder, flattened ball powder, and flake powder.

Burn Rate Basics

Widener’s Guide to Smokeless Powders also has a useful discussion of Burn Rate (a confusing topic for many hand-loaders). Wideners explains: “While a gun powder explosion in the cartridge seems instantaneous, if you slow it down you will actually find that each powder has a different ‘burn rate’, or speed at which it ignites.” This video shows powders with two very different burn rates. Watch closely.

Different burn rates suit different cartridge types notes Widener’s: “In general a fast-burning powder is used for light bullets and low-speed pistols and shotguns. Medium-rate powders are used for magnum pistols, while high-velocity, large bore rifle cartridges will need slow powders[.]

It should be noted that burn rate does not have a standardized unit of measurement. In fact, burn rate is really only discussed in comparison to other powders; there is no universal yardstick. Specifics will change by cartridge and bullet types[.]”

Share the post "Widener’s Guide to Smokeless Powders"

November 5th, 2016

NOTE: Despite the “BLK” in the name, this is a NOT a black powder substitute. This is a modern smokeless powder suitable for a wide variety of popular cartridges.

Hodgdon has announced a new “faster” variant of its popular CFE 223 powder. That’s good news for shooters of small varmint cartridges. Hodgdon’s new CFE BLK (named after the .300 AAC Blackout cartridge) has a faster burn rate than the original CFE 223. That makes CFE BLK ideal for small cartridges such as the .17 Hornet and .221 Fireball. The original CFE 223 propellant was formulated for reduced copper fouling (“CFE” in the name refers to “Copper Fouling Eraser”). New CFE BLK shares this reduced fouling technology which was developed originally for the U.S. military. Many of our Forum members have tried CFE 223 and confirmed that is performs “as advertised” — with less copper fouling that most other propellants. That’s a big benefit for varmint shooters, who may put hundreds of rounds through a barrel in a single day on the varmint fields.

Optimized for the .300 AAC Blackout cartridge, CFE BLK works great for .300 Blackout loads in AR-type rifles throughout the range of bullet weights. Moreover, CFE BLK is perfect for subsonic, reduced loads. In addition, Hodgdon reports that CFE BLK performs superbly in many smaller-capacity cartridges, in particular varmint cartridges such as the .17 Hornet, .17 Ackley Hornet, .218 Bee, .221 Fireball. CFE BLK is also well-suited for the 6.8 Remington SPC and the 7.62X39 Russian cartridge.

CFE BLK Meters Well and Burns Clean

CFE BLK is a spherical (ball) powder. Hodgdon reports the CFE BLK meters well, allowing reloaders to throw very consistent charges every time: “This fine powder meters like a dream and leaves no copper residue, extending accuracy for longer shooting periods, and making clean-up quick and easy.”

CFE BLK Should Be on Dealers’ Shelves in January 2017

Starting in January, 2017, CFE BLK powder will be available in both one-pound (1-lb.) and eight-pound (8-lb.) containers. Check with leading vendors such as Bruno’s, Midsouth, and Powder Valley. By the end of 2016, you should find complete load data for CFE BLK on the Hodgdon Reloading Data Center at www.HodgdonReloading.com.

Share the post "New Hodgdon CFE BLK Powder — Great for Small Cartridges"

November 24th, 2009

Hornady recently announced its new line of Superformance Hunting Ammo. Loaded with GMX solid bullets and SST jacketed bullets, the new ammo is faster than conventional hunting ammunition. Hornady claims that, “across the board”, Superformance ammo is 100-200 fps faster than other factory hunting ammo with similar bullet weights. Hornady recently announced its new line of Superformance Hunting Ammo. Loaded with GMX solid bullets and SST jacketed bullets, the new ammo is faster than conventional hunting ammunition. Hornady claims that, “across the board”, Superformance ammo is 100-200 fps faster than other factory hunting ammo with similar bullet weights.

We had a lengthy discussion yesterday with Dave Emary, Hornady’s Senior Ballistician. Dave shared some of the secrets of the new Superperformance ammo, and explained how Hornady is achieving such high velocities. The key, as we suspected, is that Hornady is using new propellants — powders that are not yet available for sale. These new propellants are BALL POWDERS custom-made to Hornady’s specs. Hornady actually commissioned multiple new spherical formulations, in various speed ranges. Then Hornady blends these ball powders to suit particular cartridges and loads. So, each type of Superformance ammo (e.g. 243 Win with 95gr SST and 300 Win Mag with 165gr GMX) represents a custom blend of the new ball propellants of various burn ranges. Hornady tailors the powder blend to achieve maximum velocity, accuracy, and low temp sensitivity for each load.

Hornady is NOT using Alliant’s Reloder 17. However, in some respects, Hornady’s new ball powders behave like Reloder 17 — by “flattening the right side of the pressure curve”. Rather than hitting a high peak pressure and then dropping off dramatically in energy, Reloder 17 sustains high pressure behind the heel of the bullet for a longer in-barrel time. Hornady’s new powders do the same thing — they deliver high energy behind the bullet for more milliseconds as the bullet travels down the bore. This is the main reason Superformance ammo delivers high velocity — the new powders are maintaining higher energy levels for a longer period of time. Additionally, being ball powders that pack tightly, the new propellants can be loaded to a high density in the case — an advantage with medium-sized cartridges such as the 6.5 Creedmoor.

| Here is how Hornady has achieved high velocities with its new Superformance ammunition:

1) Superformance ammo uses advanced new Ball Powders (not yet for sale).

2) The powders are BLENDED, with different “recipes” for different cartridges.

3) The new powders maintain high-energy longer in barrel (like Reloder 17).

4) The new powders burn almost completely, reducing ejecta, for less exit pressure, and less felt recoil.

5) Superformance ball propellants pack very densely, so more grains of powder can fit inside a case, compared to typical extruded stick powders. |

High Progressivity Powders High Progressivity Powders

In addition to high sustained energy, Emary noted, the new propellants exhibit very high “progressivity”. What this means, in practical terms, is that the new propellants achieve almost 100% burn by the end of the cycle. So, virtually all of the mass of the powder has changed to gas by the time the bullet exits the muzzle. As a result, Emary explained “with Superformance propellants you have less ejecta leaving the muzzle. With some other extruded powders, you’ll get unburned or partly burned sticks leaving the muzzle”. Why does that matter? Dave explains there are a couple major benefits to high progressivity. First, you get “every last ounce of energy” out of each powder kernel. Second, because less unburned ejecta is driven out the barrel, the amount of recoil is reduced, particularly for the large magnum cases.

Dave explains: “In the past, small arms performance has been limited by the powder’s ability to completely burn by the time the bullet exits the muzzle. To attempt to get higher performance, high charge weights of a slow burning powder were used to attempt to maximize muzzle velocity. Powders were not progressive enough to allow these heavy charges of slow powder to be completely burned by the time the bullet left the muzzle, especially with lighter-weight bullets. The end result was very modest increases in velocity with heavy recoil and many times unacceptable accuracy. Superformance powders solve this problem because of their ability to completely burn by bullet muzzle exit…. This results in a much higher percentage of the available powder energy being transferred to the projectile, rather than being blown out the end of the barrel as unburned powder[.]”

In practical terms, Emary stated, the high energy and high progressivity of the new propellants permit many cartridges to deliver “real-world” performance equaling that of larger cartridges loaded with conventional powders. For example, according to Dave, “the 6.5 Creedmoor is performing on a par with a Rem .260.” Dave cited the example of his own 6.5 Creedmoor hunting rifle: “It shoots as flat as a .260 and the accuracy is as good or better.”

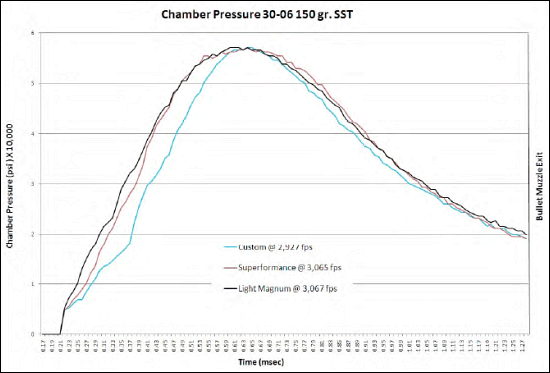

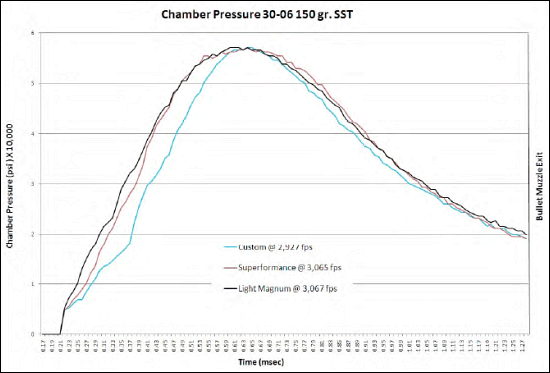

Dave has authored a detailed report that shows how 30-06 Superformance ammo can match the velocities of Hornady’s “light magnum” 30-06 ammo loaded with conventional powders. The Superformance 30-06 achieved similar velocities, with equivalent peak pressures, while using 6 grains less powder. This is illlustrated in the graph below.

Dave’s report states: “[The chart] shows a comparison of Chamber Pressure vs. Time for Custom, Superformance and Light Magnum ammunition in 30-06 loaded with a 150 gr SST bullet. As can be seen from the graph, all loads produced approximately the same pressure but have widely different charge weights and velocity performance. There is considerably more area under the curve for both Superformance and Light Magnum. This is where the increase in performance comes from. One detail to note is that the Superformance chamber pressure has dropped to at or below that of the Custom ammunition by the time the bullet exits the muzzle. This shows the highly progressive burning characteristics of the powder and its ability to completely burn. As noted above, the charge weights which go along with the different loads and the performance achieved with them are quite different. Custom is loaded with 58.5 grs of powder, Superformance 61.0 grs and Light Magnum 67.0 grs. Superformance ammunition produces significantly higher velocities than Custom with only a small amount more powder and the same velocity as Light Magnum with significantly less powder.”

Superformance Ammo for Match Shooters May Be Next

Right now Hornady is marketing its Superformance line as hunting ammunition only. However, Hornady recognizes that the new propellant technology could benefit match shooters as well. Dave told us that Hornady has begun development of a 6.5 Creedmoor Superformance round using the 140gr A-Max bullet.

Share the post "Hornady's Emary Shares Superformance Ammo Secrets"

January 18th, 2009

Alliant Powder is well-known among precision shooters. Reloder 15 has set many world records in the 6BR and 6BR Improved cartridges, and the new Reloder 17 powder offers dramatically increased velocities in cartridges such as the 6XC and .284 Winchester.

At SHOT Show 2009, Alliant unveiled its new Power Pro™ series of canister, spherical powders. There are five (5) new powders: Magnum Pistol, Varmint Rifle, Medium Rifle, Large Rifle, and Magnum Rifle. Each powder has a burn rate optimized for the particular application (Medium Rifle is a bit slower than RL15, Large Rifle rate is similar to H4350, Magnum is similar to H4831). Alliant claims that “Power Pro powders deliver improved velocity and density for more efficient reloading and help reloaders duplicate certain factory loaded ammunition.” Alliant engineer Dick Quensenberry said reloaders can expect to get +50 fps more from the Power Pro series than with most other, comparable ball powders.

New Powder for 50-Caliber Applications New Powder for 50-Caliber Applications

Alliant also recently introduced Reloder 50, a new powder designed for long-range, 50 caliber rifle shooters. Burn rate is “a little slower than Winchester 860.” The powder is showing excellent lot-to-lot consistency and the load density is optimized for the 50 BMG and similar cases. Like Reloder 17, Reloder 50 employs a process which staturates/penetrates the kernels with the burn rate controlling chemical. This should allow a longer, flatter pressure curve, allowing more velocity than conventional powders can deliver. Alliant says that Reloder 50 offers “superior velocity and the ability to burn cleaner (with less residue).” Reloder 50 will be available in both 1-lb (#150527) and 8-lb (#150528) containers.

On the Horizon — More Alliant Powders like Reloder 17

Reloder 17, made in Switzerland by Nitro Chemie, is a unique propellant that offer a smoother, longer energy release because the burn rate controlling chemicals are saturated into the kernels rather than just applied to the outside. This can provide extra energy over the course of the burn, with the result that Reloder 17 can deliver more velocity than any other powder with a similar burn rate and density. The demonstrated high performance of Reloder 17 has created demand for similar formulations, but with faster or slower burn rates. The good news is that Alliant’s Reloder 50 (see above) has the new burn rate control chemsitry, and Alliant is working right now on at least two new powders that will use the Nitro Chemie’s new powder technology. One powder (Reloder 16?) will be faster than RL 17, and one will be slower — possibly in the H1000 range. Stay tuned to AccurateShooter.com for future updates.

Share the post "SHOT Show Report: Alliant's Five New Power Pro Ball Powders"

|

Hornady recently announced its new line of

Hornady recently announced its new line of  High Progressivity Powders

High Progressivity Powders

New Powder for 50-Caliber Applications

New Powder for 50-Caliber Applications