|

|

September 27th, 2010

Many shooters expend considerable time and effort to coat their bullets with friction-reducing compounds such as Boron Nitride (HBN), Molybdenum Disulfide (Moly), and Tungsten Disulfide (WS2 or ‘Danzac’). Many of these same shooters believe that coated bullets permit longer strings of fire between barrel cleanings. Also, there is some evidence that coated bullets may extend barrel life (though this remains controversial).

What if you could enjoy all the benefits of coated bullets without the effort? When you think about it, why not apply the anti-friction coating to the barrel itself, rather than the bullets? That is the thinking behind salt-bath nitriding of barrels. This nitriding process creates a very slick, very hard surface coating on the steel in the bore. The coating is only 10-20 microns thick (so it doesn’t cause pressure problems). But that coating is enough to reduce friction, and just possibly, extend useful barrel life.

John Whidden, Camp Perry Long-Range National Champion in 2007, 2008, and 2010, recently had one of his Broughton 6mm match barrels nitrided by Joel Kendrick. Joel does the salt-bath nitriding for MMI TruTec. Whidden reports he “is happy as he can be with the barrel” after the nitriding process. After nitriding, the stainless Broughton 5C barrel was “every bit as accurate as before, and noticeably easier to clean”, according to John. Also, John reports that he did NOT have to change his load after the barrel was nitrided (which left it with a handsome black, semigloss finish). Whidden says, “after cleaning, the barrel takes about 3-4 rounds to settle in… that’s the same as before.” This barrel shot very well before nitriding, and after nitriding, John used it successfully at Camp Perry in the 2009 Wimbleton Cup competition.

Overall, John tells us “Everything looks good. No accuracy loss, and easier cleaning.” He is pleased enough that he has sent more barrels to Joel Kendrick for nitride processing. John also said that he’s heard that nitrided barrels in some of the big caliber rifles, such as the .338 Lapua Magnum, are showing “significantly enhanced” barrel life.

To learn more about salt-bath nitriding for barrels, or to place a processing order with MMI-TruTec, email joelkndrck [at] aol.com, or call Joel at (704) 616-6442. Joel, a past 600-yard Shooter of the Year, is very knowledgeable about both shooting and the nitriding process. He can give you well-informed answers to your questions. Price for nitriding depends on quantity — call Joel for pricing details.

May 8th, 2010

Thanks to Savage’s signature barrel nut system, it’s easy for Savage rifle owners to swap barrels without gunsmith assistance. With a pre-fit barrel from Pac-Nor or Shilen you can easily re-barrel your rifle and set the headspace with go/no-go gauges. In addition to a barrel vise, you’ll need a specialized barrel nut wrench to swap Savage barrels. Now through 5/31/2010, MidwayUSA has the Wheeler Engineering Savage Barrel Nut Wrench on sale for just $22.99, marked down from $38.49 (a $15.50 savings — roughly 40%). For comparison, Brownell’s charges $47.90 for the Sharp Shooter Supply Savage barrel nut wrench.

The double-ended Wheeler Savage Barrel Nut Wrench (item #288765) allows easy removal of the barrel nut on Savage model 10, model 110, and model 12 series rifles. Made from 3/16″ steel, the Wheeler tool features two 1/2″ square drive holes for a swing bar or torque wrench.

February 1st, 2010

Many of our readers know Joel Kendrick, one of America’s top mid-range shooters. Joel is a two-time IBS 600-yard Shooter of the Year, and we have featured Joel’s match-winning 6×44 as one of our Guns of the Week. Joel now works with MMi-Trutec, specializing in the salt-bath nitriding process. This is a surface-hardening procedure for steel that creates a super-hard, low friction layer for the top 10-20 microns of the metal. Barrels treated with salt-bath-nitriding show much improved wear resistance and reduced friction.

For match rifles, varmint rifles, and hunting rifles, the most significant benefits of salt-bath nitriding are enhanced barrel life, and easier cleaning. Joel’s own F-Class rifle has a nitrided stainless barrel with over 5000 rounds — and it still holds 1/4 MOA at 100 yards. Other well-known shooters, such as John Whidden, have observed that nitrided barrels can shoot longer strings of fire between cleanings, with no reduction of accuracy. What is the cost of nitriding? As Joel explains in the video below, nitriding a single barrel costs $60.00, but there is a minimum first-time lot charge of $200.00. If you submit multiple barrels at the same time, the price per barrel can be reduced significantly. For more info, visit the MMI-Trutec website or contact Joel Kendrick by phone (704) 616-6442, or via email: joelkndrck [at] aol.com .

Is there a downside to nitriding? First, the nitriding process results in a BLACK matte or satin finish. If you like the natural silver finish of stainless steel, you shouldn’t nitride your barrel. Second, and most importantly, the salt-bath-nitriding process creates a surface so hard that you can NOT re-cut the chamber with normal reaming tools. Therefore, before nitriding, the barrel must be finished chambered. Basically the barrel should be fully finished, crowned, chambered and headspaced before nitriding. NOTE: MMi Trutec CAN mask the crown during nitriding so that the barrel can be re-crowned at a later time.

January 27th, 2010

Chip Lohman, Managing Editor of Shooting Sports USA Magazine, has authored an excellent article on barrel maintenance and cleaning. Chip’s article, Let the BARREL Tell You — Match Barrel Care, Part I, appears in the January 2010 edition of Shooting Sports USA, which is FREE online, in a digital e-zine format. Chip Lohman, Managing Editor of Shooting Sports USA Magazine, has authored an excellent article on barrel maintenance and cleaning. Chip’s article, Let the BARREL Tell You — Match Barrel Care, Part I, appears in the January 2010 edition of Shooting Sports USA, which is FREE online, in a digital e-zine format.

Chip Lohman is a talented writer, an NRA-Certified Instructor, and an active shooter. Like most writers, he maintains a healthy sense of curiosity. The debate about the proper care of a match barrel is a hot one, spiked with folklore and old wives’ tales, Lohman said. He and his staff set out to set the record straight: “We tried to interject some science into the discussion of cleaning a match barrel,” he explained. In his article, Lohman writes:

Why worry about a little barrel fouling when the throat is subjected to a brutal 5,600° F volcano at 55,000 PSI? To investigate these and other questions about taking care of a match barrel, we spoke with a dozen experts and share their knowledge in this first of a series of articles.

After listening to folks who shoot, build barrels or manufacture cleaning solvents for a living, we concluded that even the experts each have their own unique recommendations on how to care for a match barrel. But they all agree on one thing— the gun will tell you what it likes best. Because the life expectancy of a match barrel is about 1,500 to 2,500 rounds, the objectives of cleaning one should include: preserve accuracy, slow the erosion and remove fouling—all without damaging the gun. This article doesn’t claim that one cleaning method is better than the next. Rather, we set out to interject a little science into the discussion and to share some lessons learned from experts in the field.

CLICK HERE to read complete Barrel Care Article in Shooting Sports USA

CLICK HERE to read latest February 2010 Edition of Shooting Sports USA

January 4th, 2010

You never want to run the barrel of a precision rifle too hot. Excessive barrel heat kills accuracy, increases copper fouling, and can cause rapid barrel throat wear. Over the years people have devised various means to cool their barrels — from electric fans to dunking in tubs of ice water.

But how do you know if your barrel is too hot? Consider a “non-contact” thermometer that reads your barrel’s “infrared signature”. The $20.00 Kintrex pocket-sized, non-contact IR thermometer is ideal for shooters at the range or in the prairie dog fields. But how do you know if your barrel is too hot? Consider a “non-contact” thermometer that reads your barrel’s “infrared signature”. The $20.00 Kintrex pocket-sized, non-contact IR thermometer is ideal for shooters at the range or in the prairie dog fields.

Just 3.2″ long, and weighing a mere 1.3 ounces, the waterproof Kintrex IRT0401 (IP67) is small enough to carry in your pocket, and will easily stow in any range bag/box. The unit measures from -67 to 428 °F (-55 to 220 °C). Given the low cost and compact size, we highly recommend you get one of these units.

KINTREX IRT0401 Compact Waterproof (IP67) Infrared Thermometer

Kintrex is a respected manufacturer that also makes larger hand-held IR thermometers for industrial and shop applications. Priced at just $19.95 on Amazon.com, the tiny Kintrex is one new gadget that every serious shooter should have. Given the cost of replacing barrels these days, can you afford NOT to have a good temp gauge for your match or varmint barrel?

If you have more room in your range kit, and want a larger unit with longer battery life for daily shop duty, we recommend the Kintrex IRT0421. A top-selling tool, this $47.08 unit has a full-sized pistol grip and features laser targeting for ultra-precise temp-gauging. It records temps from -76 °F all the way up to 932 °F (-60 to 500 °C). Black & Decker also offers the versatile TLD100 IR thermometer, which can be used for thermal leak detection in the home as well.

December 12th, 2009

Bruno Shooters Supply is running a holiday sale on Krieger 6mm Gain Twist (GT) barrels. Short-range GT barrels cost $249.95 while long-range GT barrels are $269.00. Gain twist barrels have performed very well in recent short-range benchrest matches and long-range shooters have started to experiment with them in faster twists for the longer bullets. Bruno Shooters Supply is running a holiday sale on Krieger 6mm Gain Twist (GT) barrels. Short-range GT barrels cost $249.95 while long-range GT barrels are $269.00. Gain twist barrels have performed very well in recent short-range benchrest matches and long-range shooters have started to experiment with them in faster twists for the longer bullets.

Many Gain-Twist Options Offered

For short-range benchrest rigs, Heavy Varmint, Light Varmint, or Medium contour 6mm slow-twist GT barrels are offered in 15-14.2 twist, 14.6-13.8 twist, or 14.2-13.4 twist, all with a 27″ length, and a $249.95 price. For tactical, 600-yard, or long-range, Krieger 6mm GT barrels are offered in 8.75-8.3 twist rate for $269.00. Available contours are: #14, 15, 16 Palma; Heavy Varmint (1.250″ x .900″); and 1.250″ straight. Length is 31″ on the fast-twist 6mm barrels. Bruno’s also offers 29″-long, 1.450″ straight-diameter gain twist Krieger barrels for rail guns. These cost $315.00. For more info, visit Brunoshooters.com or call Bruno’s at (623) 587-7641.

November 1st, 2009

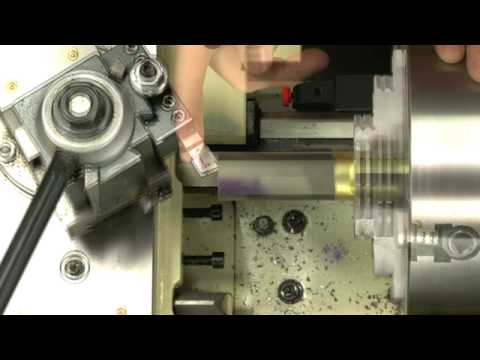

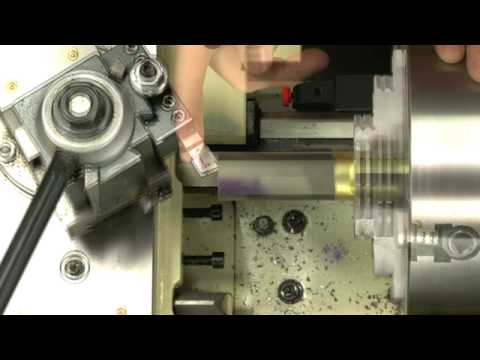

Larry Potterfield, owner and founder of MidwayUSA, has created some basic gunsmithing videos that are worth watching. These show some key aspects of rifle metal-working, such as crowning a barrel. Be aware that these videos are really just teasers — they don’t illustrate most of the critical preparatory steps a skilled gunsmith will do, such as leveling his lathe precisely, and indicating the barrel very, very carefully. Nonetheless, there are some good, basic tips in the videos, which should be informative for all shooters, whether they do their own smithing or not. Please note that benchrest smiths may employ more advanced methods.

VIDEO One: Cutting and Crowning a Barrel (Radiused Crown)

VIDEO Two: Threading and Chambering an Octagon Barrel

VIDEO Three: Trueing the Bolt Face on a Mauser 98

August 2nd, 2009

Tony Boyer is, without question, the greatest short-range Benchrest for Group shooter who has ever lived. In a rare interview for the August 2009 issue of Precision Shooting magazine, Tony shares many of his “secrets of success” with his friend (and fellow benchrester) James Mock. James also interviews Tony’s wife Faye, a superb shooter in her own right. Tony Boyer is, without question, the greatest short-range Benchrest for Group shooter who has ever lived. In a rare interview for the August 2009 issue of Precision Shooting magazine, Tony shares many of his “secrets of success” with his friend (and fellow benchrester) James Mock. James also interviews Tony’s wife Faye, a superb shooter in her own right.

This Boyer interview is now, for a limited time, available online. CLICK HERE to READ INTERVIEW. Every short-range and mid-range benchrest shooter should read this article word for word, at least twice. Tony reveals insights that may surprise you, and will certainly enlighten you. You may be surprised that Tony is now shooting a .268″ neck.

And in the article Tony challenges many commonly-held ideas. For example he doesn’t think vertical is mostly load-related: “Most shooters think that vertical groups are caused by too light a powder charge. This may be true, but more often than not, the rifle has more to do with this than the load. If the rifle is muzzle heavy, this can cause vertical. Also, the way the action is set in the stock can cause vertical as can handling problems…such as shouldering the rifle.”

Barrel Quality is All-Important

What is the main secret to Benchrest accuracy? Throughout the interview, Boyer stresses the importance of barrel quality. Tony can quickly identify barrels with winning potential. He has “developed a system that takes no more than 30 rounds to determine if it is going to shoot”. Tony needs that kind of efficiency because he burns through barrels very quickly: “Contrary to what many say, I rarely shoot a barrel more than 600 rounds in competition. I can remember only one barrel that exceeded 1200 rounds.”

When asked if there was one paramount “secret” he could share to help new shooters, Tony replied: “If you have the means, buy as many barrels as possible. A great barrel is the real secret of this game. There are barrels out there that shoot better than they should. They have been given the name ‘hummer’. I can assure you that they exist.”

June 12th, 2009

In the shooting sports, safety always has to be your number one priority. Even if you have a safe load, if the barrel is obstructed in any way, such as with mud in the barrel, a squib bullet, or a bore-sighting tool left in the barrel, the barrel can blow up, pealing back like a banana skin. Serious injury or even death can result. Below is an amazing video showing a catastrophic barrel failure caused, presumably, by a barrel obstruction — probably mud or dirt. You can see the barrel blow apart, starting at time mark 0:25 seconds.

The rifle is a Browning stainless A-Bolt, caliber unknown. We don’t know for sure, but the barrel probably became obstructed when the shooter allowed the gun to rest muzzle down on the ground, so some mud collected in the bore. Below, we’ve grabbed five frames from the key section of the video. You can see the barrel split into two segments. This shooter, who was NOT wearing eye protection, was uninjured. He is is lucky that the action held and no metal shards blew backwards.

May 17th, 2009

John Krieger is widely recognized as one of the wizards of barrel-making. Krieger cut-rifled barrels are widely recognized as among the best you can buy. You’ll find Krieger barrels winning in all major disciplines, from “point-blank” benchrest to 1000-yard prone matches. John Krieger, and his staff of highly-skilled employees, are strongly committed to quality manufacturing and customer satisfaction. When asked to describe his “business philosophy”, John stated: “Everybody in the company has one concern. That’s just to make the best barrels we can make — hopefully the best barrels that have ever been made — and to try and keep (as much as humanly possible) every customer happy.” John Krieger is widely recognized as one of the wizards of barrel-making. Krieger cut-rifled barrels are widely recognized as among the best you can buy. You’ll find Krieger barrels winning in all major disciplines, from “point-blank” benchrest to 1000-yard prone matches. John Krieger, and his staff of highly-skilled employees, are strongly committed to quality manufacturing and customer satisfaction. When asked to describe his “business philosophy”, John stated: “Everybody in the company has one concern. That’s just to make the best barrels we can make — hopefully the best barrels that have ever been made — and to try and keep (as much as humanly possible) every customer happy.”

During the NRA Annual Meeting, we had a chance to chat with John Krieger. John shared his views on a variety of technical topics, ranging from gain twist rifling, to advances in steel quality and manufacturing methods. John answered questions about barrel contours, barrel fluting, and stress relieving. John also provided some sage advice on how to protect your barrel’s crown during the cleaning process.

|

Chip Lohman, Managing Editor of Shooting Sports USA Magazine, has authored an excellent article on barrel maintenance and cleaning. Chip’s article,

Chip Lohman, Managing Editor of Shooting Sports USA Magazine, has authored an excellent article on barrel maintenance and cleaning. Chip’s article,

But how do you know if your barrel is too hot? Consider a “non-contact” thermometer that reads your barrel’s “infrared signature”. The $20.00 Kintrex pocket-sized, non-contact IR thermometer is ideal for shooters at the range or in the prairie dog fields.

But how do you know if your barrel is too hot? Consider a “non-contact” thermometer that reads your barrel’s “infrared signature”. The $20.00 Kintrex pocket-sized, non-contact IR thermometer is ideal for shooters at the range or in the prairie dog fields.

Tony Boyer is, without question, the greatest short-range Benchrest for Group shooter who has ever lived. In a rare interview for the August 2009 issue of

Tony Boyer is, without question, the greatest short-range Benchrest for Group shooter who has ever lived. In a rare interview for the August 2009 issue of

John Krieger is widely recognized as one of the wizards of barrel-making.

John Krieger is widely recognized as one of the wizards of barrel-making.