|

|

November 17th, 2018

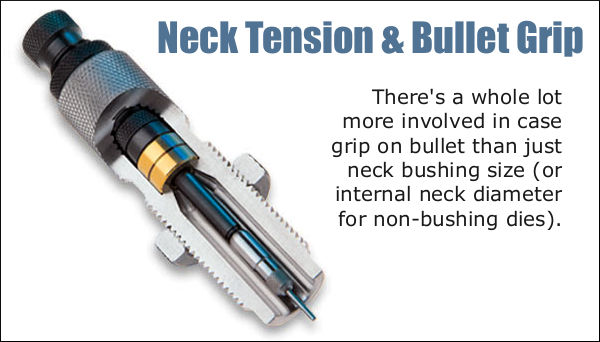

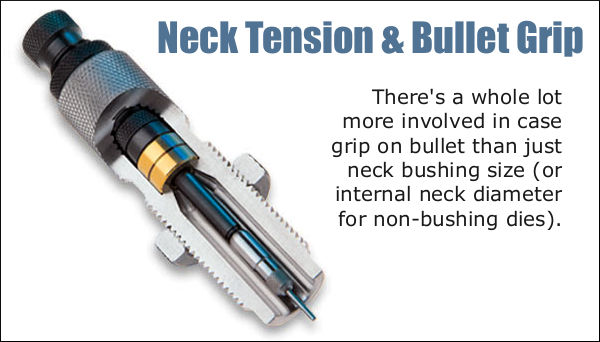

Many novice hand-loaders believe that neck bushing Inside Diameter (ID) size is the only important factor in neck tension. In fact, many different things will influence the grip on your bullet and its ability to release from the case neck. To learn more about neck tension and “case grip”, take the time to read this article carefully. We bet you’ll gain knowledge that will let you load more accurate ammo, with better ES/SD.

Neck Tension (i.e. Grip on Bullets) Is a Complex Phenomenon

While we certainly have considerable control over neck tension by using tighter or looser bushings (with smaller or bigger Inside Diameters), bushing size is only one factor at work. It’s important to understand the multiple factors that can increase or decrease the resistance to bullet release. Think in terms of overall brass-on-bullet “grip” instead of just bushing size (or the internal neck diameter in non-bushing full-length sizing dies).

Bullet grip is affected by many things, such as:

1. Neck-wall thickness.

2. Amount of bullet bearing surface (shank) in the neck.

3. Surface condition inside of neck (residual carbon can act as a lubricant; ultrasonic cleaning makes necks “grabby”).

4. Length of neck (e.g. 6mmBR neck vs. 6mm Dasher).

5. Whether or not the bullets have an anti-friction coating.

6.The springiness of the brass (which is related to degree of work-hardening; number of firings etc.)

7. The bullet jacket material.

8. The outside diameter of the bullet and whether it has a pressure ridge.

9. Time duration between bullet seating and firing (necks can stiffen with time).

10. How often the brass is annealed.

11. Amount (length) of neck sized (e.g. you can size only half the neck).

12. Interior diameter of bushing, or neck section of non-bushing die.

— and there are others…

One needs to understand that bushing size isn’t the beginning and end of neck tension questions, because, even if bushing size is held constant, the amount of bullet “grip” can change dramatically as the condition of your brass changes. Bullet “grip” can also change if you alter your seating depth, and it can even change if you ultrasonically clean your cases.

In our Shooters’ Forum a reader recently asked: “How much neck tension should I use?” This prompted a Forum discussion in which other Forum members recommended a specific number based on their experience, such as .001″, .002″, or .003″. These numbers, as commonly used, correspond to the difference between case-neck OD after sizing and the neck OD of a loaded round, with bullet in place. In other words, the numbers refer to the nominal amount of interference fit (after sizing). In our Shooters’ Forum a reader recently asked: “How much neck tension should I use?” This prompted a Forum discussion in which other Forum members recommended a specific number based on their experience, such as .001″, .002″, or .003″. These numbers, as commonly used, correspond to the difference between case-neck OD after sizing and the neck OD of a loaded round, with bullet in place. In other words, the numbers refer to the nominal amount of interference fit (after sizing).

While these commonly-used “tension numbers” (of .001″, .002″ etc.) can be useful as starting points, neck tension is actually a fairly complex subject. The actual amount of “grip” on the bullet is a function of many factors, of which neck-OD reduction during sizing is just one. Understanding these many factors will help you maintain consistent neck tension as your brass “evolves” over the course of multiple reloadings.

Seating Depth Changes Can Increase or Decrease Grip on Bullet

You can do this simple experiment. Seat a boat-tail bullet in your sized neck with .150″ of bearing surface (shank) in the neck. Now remove the bullet with an impact hammer. Next, take another identical bullet and seat it with .300″ of bearing surface in another sized case (same bushing size/same nominal tension). You’ll find the deeper-seated bullet is gripped much harder.

Neck-Wall Thickness is Important Too Neck-Wall Thickness is Important Too

I have also found that thinner necks, particularly the very thin necks used by many PPC shooters, require more sizing to give equivalent “grip”. Again, do your own experiment. Seat a bullet in a case turned to .008″ neckwall thickness and sized down .003″. Now compare that to a case with .014″ neckwall thickness and sized down .0015″. You may find that the bullet in the thin necks actually pulls out easier, though it supposedly has more “neck tension”, if one were to consider bushing size alone.

In practical terms, because thick necks are less elastic than very thin necks, when you turn necks you may need to run tighter bushings to maintain the same amount of actual grip on the bullets (as compared to no-turn brass). Consequently, I suspect the guys using .0015″ “tension” on no-turn brass may be a lot closer to the guys using .003″ “tension” on turned necks than either group may realize.

Toward a Better Definition of Neck Tension

As a convenient short-cut, we tend to describe neck tension by bushing size alone. When a guy says, “I run .002 neck tension”, that normally means he is using a die/bushing that sizes the necks .002″ smaller than a loaded round. Well we know something about his post-sizing neck OD, but do we really have a reliable idea about how much force is required to release his bullets? Maybe not… This use of the term “neck tension” when we are really only describing the amount of neck diameter reduction with a die/bushing is really kind of incomplete.

My point here is that it is overly simplistic to ask, “should I load with .001 tension or .003?” In reality, an .001″ reduction (after springback) on a thick neck might provide MORE “grip” on a deep-seated bullet than an .003″ reduction on a very thin-walled neck holding a bullet with minimal bearing surface in the neck. Bushing ID is something we can easily measure and verify. We use bushing size as a descriptor of neck tension because it is convenient and because the other important factors are hard to quantify. But those factors shouldn’t be ignored if you want to maintain consistent neck tension for optimal accuracy.

Consistency and accuracy — that’s really what this all about isn’t it? We want to find the best neck tension for accuracy, and then maintain that amount of grip-on-bullet over time. To do that you need to look not only at your bushing size, but also at how your brass has changed (work-hardened) with time, and whether other variables (such as the amount of carbon in the neck) have changed. Ultimately, optimal neck tension must be ascertained experimentally. You have to go out and test empirically to see what works, in YOUR rifle, with YOUR bullets and YOUR brass. And you may have to change the nominal tension setting (i.e. bushing size) as your brass work-hardens or IF YOU CHANGE SEATING DEPTHS.

Remember that bushing size alone does not tell us all we need to know about the neck’s true “holding power” on a bullet, or the energy required for bullet release. True bullet grip is a more complicated phenomenon, one that is affected by numerous factors, some of which are very hard to quantify.

November 18th, 2016

Do you use bushings to size your case-necks? Are you assuming that your bushings are actually round on the inside, with a hole that’s centered-up properly? Well you may be in for an unpleasant surprise, based on what our friend Jim de Kort recently discovered. Jim was concerned about the run-out on his brass. His cases went into his bushing-equipped FL die pretty straight, but came out of the die with up to .004″ run-out. “What gives?”, Jim wondered. “Could the problem be the bushings themselves?”

To answer that question, Jim decided to examine his bushings. Using an Accuracy One Wheel-drive concentricity gauge, Jim checked out some of his neck bushings. What he discovered may surprise you…

Neck Bushing Flaws Revealed

Trust no one… — Jim de Kort

Jim writes: “I measured the concentricity of my 6BR rounds today. I noticed they went into the neck-bushing equipped full-length sizing die with less than .001″ deviation but came out with .003-.004″. The culprit, it appears, was the bushing itself. Without it the cases stayed within .0005″ to .001″ deviation, so something was happening with the bushing.

One bushing had .00025″ deviation on the outside, yet almost .003″ on the inside, so it is crooked. But even when using a bushing that is within .001″ I still get .003″ runout after sizing. I repeated the same procedure for my 6×47 and got the same results. When using the bushing, concentricity suffers a lot.”

Before we bash the bushing-makers, we must acknowledge that many different things can contribute to excessive run-out and/or mis-alignment of case-necks. We don’t have all the answers here, and Jim would be the first to say that some mysteries remain. Still, these are interesting results that give all precision hand-loaders something to think about.

Jim Borden of Borden Accuracy also offers this tip: “Check the trueness of the face of the die cap. That has more to do with trueness than the bushing. Also check perpendicularity of hole in bushing to top surface. When I was making dies, the cap was made by threading and facing the threaded tenon in same setup.”

Editor’s Comment: Many people have great results with neck-bushing dies, but Jim isn’t the only fellow who has seen some very odd results. I personally employ honed, non-bushing dies for many of my chamberings. These non-bushing dies (with the necks honed for .002-.003″ neck tension) produce extremely straight ammo, with run-out consistently under .0015″.

January 30th, 2016

Craters may look interesting on the moon, but you don’t want to see them on your primers. Certain mechanical issues that cause primer craters can also cause primer piercing — a serious safety problem that needs to be addressed. If you have a gun that is cratering primers (even at moderate pressure levels), there is a solution that works with many rifles — send your bolt to Greg Tannel to have the firing pin hole bushed. Craters may look interesting on the moon, but you don’t want to see them on your primers. Certain mechanical issues that cause primer craters can also cause primer piercing — a serious safety problem that needs to be addressed. If you have a gun that is cratering primers (even at moderate pressure levels), there is a solution that works with many rifles — send your bolt to Greg Tannel to have the firing pin hole bushed.

Shooters who convert factory actions to run 6BRs, 6PPCs or other high-pressure cartridges should consider having the firing pin bushed. These modern cartridges like to run at high pressures. When running stout loads, you can get cratering caused by primer flow around the firing pin hole in the bolt face. The reason is a little complicated, but basically the larger the hole, the less hydraulic pressure is required to crater the primer. A limited amount of cratering is normally not a big issue, but you can reduce the problem significantly by having a smith fit a bushing in the firing pin hole. In addition to reduced cratering, bushing the firing pin often produces more consistent ignition.

This is a highly recommended procedure that our editors have had done to their own rifles. Greg Tannel (Gre-Tan Rifles) is an expert at this procedure, and he does excellent work on a wide variety of bolts. Current price for a bushing job, which includes turning the firing pin to .062″, is $80.00, or $88.00 with USPS Priority Mail return shipping.

If you have a factory rifle, a bushed firing pin is the way to go if you are shooting the high-pressure cartridges such as 6PPC, 6BR, 6-6.5×47 and 6.5×47. This is one of the most cost-effective and beneficial upgrades you can do to your factory rifle. For more info on the Firing Pin Bushing process, visit GreTanRifles.com, or email greg [at] gretanrifles.com. (After clicking the link for GreTanRifles.com, Click on “Services” > “Shop Services” > “Bolt Work”, and you’ll see a listing for “Bush Firing Pin Hole & Turn Pin”. Select “View Details”.)

Firing Pin Hole Bushing by Greg Tannel Firing Pin Hole Bushing by Greg Tannel

Work Done: Bush firing pin hole and turn pin.

Functions: Fixes your cratering and piercing problems.

Price: $80.00 + $8.00 return shipping

Total Price: $88.00

Actions for which Bushing is Offered: Remington, Winchester, Savage multi-piece pin, Sako, Kimber, Nesika, Stiller, BAT Machine, Kelbly, Lawton, Surgeon, Borden, Wichita, Hall, Ruger, Howa, Weatherby, Dakota, Pacific Tool, Phoenix, and Defiant bolt action rifle or pistol.

Actions for which Bushing is NOT Available: Case hardened receivers, ARs, Accuracy International (AI), Barnard, Big Horn, Cooper, Desert Tactical Arms, Kimber, Rosenthal, New Savage single piece pin, Rim fires, Falling block, Break open, Lever, Pump rifles, 1903-A3, CZ, Mauser.

How to send your bolt in to be bushed:

You can send your bolt snail mail, priority mail, or UPS (Please do not use FEDEX as it sometimes has delivery delays). Pack your bolt carefully and ship to: Gre’-Tan Rifles, 24005 Hwy. 13, Rifle CO 81650. Please include your name, phone number, and return shipping address.

Due to the high volume of work, turn around is 5 to 8 weeks on bushing a bolt. Three or more bolts will be sent back to you UPS and we will have to calculate shipping. We can overnight them at your expense. You can pay by check, money order, or credit card. For more information visit GretanRifles.com.

December 29th, 2014

In our Shooters’ Forum a reader asked: “How much neck tension should I use?” This prompted a Forum discussion in which other Forum members recommended a specific number based on their experience, such as .001″, .002″, or .003″. These numbers, as commonly used, correspond to the difference between case-neck OD after sizing and the neck OD of a loaded round, with bullet in place. In other words, the numbers refer to the nominal amount of interference fit (after sizing). In our Shooters’ Forum a reader asked: “How much neck tension should I use?” This prompted a Forum discussion in which other Forum members recommended a specific number based on their experience, such as .001″, .002″, or .003″. These numbers, as commonly used, correspond to the difference between case-neck OD after sizing and the neck OD of a loaded round, with bullet in place. In other words, the numbers refer to the nominal amount of interference fit (after sizing).

While these commonly-used “tension numbers” (of .001″, .002″ etc.) can be useful as starting points, neck tension is actually a fairly complex subject. The actual amount of “grip” on the bullet is a function of many factors, of which neck-OD reduction during sizing is just one. Understanding these many factors will help you maintain consistent neck tension as your brass “evolves” over the course of multiple reloadings.

Neck Tension (i.e. Grip on Bullets) Is a Complex Phenomenon

While we certainly have considerable control over neck tension by using tighter or looser bushings (with smaller or bigger Inside Diameters), bushing size is only one factor at work. It’s important to understand the multiple factors that can increase or decrease the resistance to bullet release. Think in terms of overall brass-on-bullet “grip” instead of just bushing size.

One needs to understand that bushing size isn’t the beginning and end of neck tension questions, because, even if bushing size is held constant, the amount of bullet “grip” can change dramatically as the condition of your brass changes. Bullet “grip” can also change if you alter your seating depth significantly, and it can even change if you ultrasonically clean your cases.

Bullet grip is affected by many things, such as:

- 1. Neck-wall thickness.

- 2. Amount of bearing surface (shank) in the neck.

- 3. Surface condition inside of neck (residual carbon can act as a lubricant; ultrasonic cleaning makes necks “grabby”).

- 4. Length of neck (e.g. 6BR neck vs. 6BRX).

- 5. Whether or not the bullets have an anti-friction coating.

- 6. The springiness of the brass (which is related to degree of work-hardening; number of firings etc.)

- 7. The bullet jacket material.

- 8. The outside diameter of the bullet and whether it has a pressure ridge.

- 9. The time duration between bullet seating and actual firing (necks can stiffen with time).

- 10. How often the brass is annealed

— and there are others…

Seating Depth Changes Can Increase or Decrease Grip on Bullet

You can do this simple experiment. Seat a boat-tail bullet in your sized neck with .150″ of bearing surface (shank) in the neck. Now remove the bullet with an impact hammer. Next, take another identical bullet and seat it with .300″ of bearing surface in another sized case (same bushing size/same nominal tension). You’ll find the deeper-seated bullet is gripped much harder.

Neck-Wall Thickness is Important Too Neck-Wall Thickness is Important Too

I have also found that thinner necks, particularly the very thin necks used by many PPC shooters, require more sizing to give equivalent “grip”. Again, do your own experiment. Seat a bullet in a case turned to .008″ neckwall thickness and sized down .003″. Now compare that to a case with .014″ neckwall thickness and sized down .0015″. You may find that the bullet in the thin necks actually pulls out easier, though it supposedly has more “neck tension”, if one were to consider bushing size alone.

In practical terms, because thick necks are less elastic than very thin necks, when you turn necks you may need to run tighter bushings to maintain the same amount of actual grip on the bullets (as compared to no-turn brass). Consequently, I suspect the guys using .0015″ “tension” on no-turn brass may be a lot closer to the guys using .003″ “tension” on turned necks than either group may realize.

Toward a Better Definition of Neck Tension

As a convenient short-cut, we tend to describe neck tension by bushing size alone. When a guy says, “I run .002 neck tension”, that normally means he is using a die/bushing that sizes the necks .002″ smaller than a loaded round. Well we know something about his post-sizing neck OD, but do we really have a reliable idea about how much force is required to release his bullets? Maybe not… This use of the term “neck tension” when we are really only describing the amount of neck diameter reduction with a die/bushing is really kind of incomplete.

My point here is that it is overly simplistic to ask, “should I load with .001 tension or .003?” In reality, an .001″ reduction (after springback) on a thick neck might provide MORE “grip” on a deep-seated bullet than an .003″ reduction on a very thin-walled neck holding a bullet with minimal bearing surface in the neck. Bushing ID is something we can easily measure and verify. We use bushing size as a descriptor of neck tension because it is convenient and because the other important factors are hard to quantify. But those factors shouldn’t be ignored if you want to maintain consistent neck tension for optimal accuracy.

Consistency and accuracy — that’s really what this all about isn’t it? We want to find the best neck tension for accuracy, and then maintain that amount of grip-on-bullet over time. To do that you need to look not only at your bushing size, but also at how your brass has changed (work-hardened) with time, and whether other variables (such as the amount of carbon in the neck) have changed. Ultimately, optimal neck tension must be ascertained experimentally. You have to go out and test empirically to see what works, in YOUR rifle, with YOUR bullets and YOUR brass. And you may have to change the nominal tension setting (i.e. bushing size) as your brass work-hardens or IF YOU CHANGE SEATING DEPTHS.

Remember that bushing size alone does not tell us all we need to know about the neck’s true “holding power” on a bullet, or the energy required for bullet release. True bullet grip is a more complicated phenomenon, one that is affected by numerous factors, some of which are very hard to quantify.

May 4th, 2014

Harrell’s Precision sells “semi-custom” full-length bushing dies for the PPC and 6BR chamberings. While the Harrell brothers do not cut the die to spec, they carry a large selection of dies made with slightly different internal dimensions. When you send in your fired brass, the Harrells choose a die from inventory with just the right amount of sizing (diameter reduction) at the top and bottom of the case. Given the quality, and precise fit, Harrell’s full-length dies are a good value at $75.00 plus shipping. Harrell’s Precision sells “semi-custom” full-length bushing dies for the PPC and 6BR chamberings. While the Harrell brothers do not cut the die to spec, they carry a large selection of dies made with slightly different internal dimensions. When you send in your fired brass, the Harrells choose a die from inventory with just the right amount of sizing (diameter reduction) at the top and bottom of the case. Given the quality, and precise fit, Harrell’s full-length dies are a good value at $75.00 plus shipping.

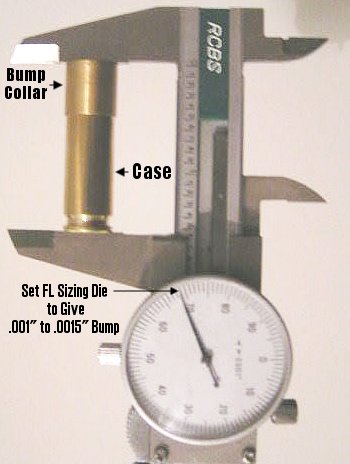

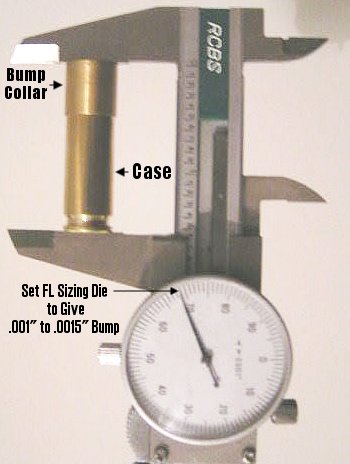

Bump Measuring Collar Bump Measuring Collar

The Harrell brothers provide a nice bonus item with each full-length die — a neat, little shoulder bump measuring device as shown in the photo at right. Hornady/Stoney Point sells a stand-alone tool that does the same job, but the Harrell’s bump collar is simpler and faster. To measure your shoulder bump, simply place the Harrell’s bump collar over the upper section of your deprimed case (before sizing) and measure the OAL with your calipers. The collar should seat on the shoulder without any wobble. After taking the measurement, then size the case in your full-length die, replace the collar and repeat the measurement. You want to set your die so the shoulder moves back about .001″ to .0015″ for most applications. (With semi-auto guns you may want more bump — .003″ or more.)

When measuring for shoulder bump, you need to remove the primers first. Our friend Boyd Allen explains: “Use a decapping tool or die to remove the fired primer before taking the initial measurement. When working to thousandths, even the raised edge of a crater or a slightly raised primer can throw you off by a significant amount.”

January 7th, 2013

RCBS has a new made-in-USA single-stage reloading press. With its innovative “moving die/static cartridge” design, the new RCBS Summit Press definitely demonstrates “out of the box” thinking. Unlike other presses, the case does not move. Rather, the reloading die comes down to the case. With the press bolted on your reloading bench, all operations of the Summit take place ABOVE the bench-top. RCBS has a new made-in-USA single-stage reloading press. With its innovative “moving die/static cartridge” design, the new RCBS Summit Press definitely demonstrates “out of the box” thinking. Unlike other presses, the case does not move. Rather, the reloading die comes down to the case. With the press bolted on your reloading bench, all operations of the Summit take place ABOVE the bench-top.

The new Summit Press features a rugged cast-iron frame with all-steel linkages. The press is very strong with minimal flex and slop in use. This allows you to “bump” your case shoulders and seat bullets with great precision and repeatability. The handle can be switched from right to left side (good for southpaws), and the open-front design provides good access, facilitating quick die changes. The 4.5-inch opening allows you to work with tall cases. Beneath the shell-holder is a spent primer catcher.

The new Summit press has a beefy 2-inch diameter ram, with compound linkages for plenty of leverage. A zerk fitting is included for easy lubrication. The press will accept larger bushings for oversize 1-inch dies.

Summit Press for $207.94

The new Summit Press (RCBS item #09290) lists for $269.95. However, Midsouth Shooters Supply offers the Summit Press for $207.94. An optional short handle costs $15.27 at Midsouth ($19.95 MSRP).

RCBS Summit Press Features: RCBS Summit Press Features:

• Bench-top operation

• Massive 2-inch diameter ram

• Ambidextrous handle

• Compound leverage

• 4.50-inch operating window

• Spent primer catcher

• Full frontal access

• Accepts bushings for 1″ die bodies

• Press adapter bushing

• Zerk lubrication fitting

• Made in USA

Product tip by EdLongrange. We welcome reader submissions.

January 3rd, 2013

In our Shooters’ Forum a reader recently asked: “How much neck tension should I use?” This prompted a Forum discussion in which other Forum members recommended a specific number based on their experience, such as .001″, .002″, or .003″. These numbers, as commonly used, correspond to the difference between case-neck OD after sizing and the neck OD of a loaded round, with bullet in place. In other words, the numbers refer to the nominal amount of interference fit (after sizing). In our Shooters’ Forum a reader recently asked: “How much neck tension should I use?” This prompted a Forum discussion in which other Forum members recommended a specific number based on their experience, such as .001″, .002″, or .003″. These numbers, as commonly used, correspond to the difference between case-neck OD after sizing and the neck OD of a loaded round, with bullet in place. In other words, the numbers refer to the nominal amount of interference fit (after sizing).

While these commonly-used “tension numbers” (of .001″, .002″ etc.) can be useful as starting points, neck tension is actually a fairly complex subject. The actual amount of “grip” on the bullet is a function of many factors, of which neck-OD reduction during sizing is just one. Understanding these many factors will help you maintain consistent neck tension as your brass “evolves” over the course of multiple reloadings.

Neck Tension (i.e. Grip on Bullets) Is a Complex Phenomenon

While we certainly have considerable control over neck tension by using tighter or looser bushings (with smaller or bigger Inside Diameters), bushing size is only one factor at work. It’s important to understand the multiple factors that can increase or decrease the resistance to bullet release. Think in terms of overall brass-on-bullet “grip” instead of just bushing size.

One needs to understand that bushing size isn’t the beginning and end of neck tension questions, because, even if bushing size is held constant, the amount of bullet “grip” can change dramatically as the condition of your brass changes. Bullet “grip” can also change if you alter your seating depth significantly, and it can even change if you ultrasonically clean your cases.

Bullet grip is affected by many things, such as:

- 1. Neck-wall thickness.

- 2. Amount of bearing surface (shank) in the neck.

- 3. Surface condition inside of neck (residual carbon can act as a lubricant; ultrasonic cleaning makes necks “grabby”).

- 4. Length of neck (e.g. 6BR neck vs. 6BRX).

- 5. Whether or not the bullets have an anti-friction coating.

- 6. The springiness of the brass (which is related to degree of work-hardening; number of firings etc.)

- 7. The bullet jacket material.

- 8. The outside diameter of the bullet and whether it has a pressure ridge.

- 9. The time duration between bullet seating and actual firing (necks can stiffen with time).

- 10. How often the brass is annealed

— and there are others…

Seating Depth Changes Can Increase or Decrease Grip on Bullet

You can do this simple experiment. Seat a boat-tail bullet in your sized neck with .150″ of bearing surface (shank) in the neck. Now remove the bullet with an impact hammer. Next, take another identical bullet and seat it with .300″ of bearing surface in another sized case (same bushing size/same nominal tension). You’ll find the deeper-seated bullet is gripped much harder.

Neck-Wall Thickness is Important Too Neck-Wall Thickness is Important Too

I have also found that thinner necks, particularly the very thin necks used by many PPC shooters, require more sizing to give equivalent “grip”. Again, do your own experiment. Seat a bullet in a case turned to .008″ neckwall thickness and sized down .003″. Now compare that to a case with .014″ neckwall thickness and sized down .0015″. You may find that the bullet in the thin necks actually pulls out easier, though it supposedly has more “neck tension”, if one were to consider bushing size alone.

In practical terms, because thick necks are less elastic than very thin necks, when you turn necks you may need to run tighter bushings to maintain the same amount of actual grip on the bullets (as compared to no-turn brass). Consequently, I suspect the guys using .0015″ “tension” on no-turn brass may be a lot closer to the guys using .003″ “tension” on turned necks than either group may realize.

Toward a Better Definition of Neck Tension

As a convenient short-cut, we tend to describe neck tension by bushing size alone. When a guy says, “I run .002 neck tension”, that normally means he is using a die/bushing that sizes the necks .002″ smaller than a loaded round. Well we know something about his post-sizing neck OD, but do we really have a reliable idea about how much force is required to release his bullets? Maybe not… This use of the term “neck tension” when we are really only describing the amount of neck diameter reduction with a die/bushing is really kind of incomplete.

My point here is that it is overly simplistic to ask, “should I load with .001 tension or .003?” In reality, an .001″ reduction (after springback) on a thick neck might provide MORE “grip” on a deep-seated bullet than an .003″ reduction on a very thin-walled neck holding a bullet with minimal bearing surface in the neck. Bushing ID is something we can easily measure and verify. We use bushing size as a descriptor of neck tension because it is convenient and because the other important factors are hard to quantify. But those factors shouldn’t be ignored if you want to maintain consistent neck tension for optimal accuracy.

Consistency and accuracy — that’s really what this all about isn’t it? We want to find the best neck tension for accuracy, and then maintain that amount of grip-on-bullet over time. To do that you need to look not only at your bushing size, but also at how your brass has changed (work-hardened) with time, and whether other variables (such as the amount of carbon in the neck) have changed. Ultimately, optimal neck tension must be ascertained experimentally. You have to go out and test empirically to see what works, in YOUR rifle, with YOUR bullets and YOUR brass. And you may have to change the nominal tension setting (i.e. bushing size) as your brass work-hardens or IF YOU CHANGE SEATING DEPTHS.

Remember that bushing size alone does not tell us all we need to know about the neck’s true “holding power” on a bullet, or the energy required for bullet release. True bullet grip is a more complicated phenomenon, one that is affected by numerous factors, some of which are very hard to quantify.

November 15th, 2012

We were recently asked: “What size neck bushing is best for Lapua 6mmBR brass in a ‘no-turn’ chamber?” The questioner planned to purchase a Redding Type ‘S’ full-length sizing die with neck bushings. The quick answer is that one should probably get 0.265, 0.266, and 0.267 bushings and see what works best. We were recently asked: “What size neck bushing is best for Lapua 6mmBR brass in a ‘no-turn’ chamber?” The questioner planned to purchase a Redding Type ‘S’ full-length sizing die with neck bushings. The quick answer is that one should probably get 0.265, 0.266, and 0.267 bushings and see what works best.

Using current “Blue Box” Lapua brass, a loaded 6BR round with an unturned neck will typically run about 0.2680-0.2685 (depending on the bullet). A 0.266 neck bushing, after springback, will give about 0.0015 tension which can work well in a bolt gun. NOTE: With the older “Brown Box” Lapua Brass, the neckwalls are slightly thicker, so you may want to start with a .267 bushing. Remember, however, that with either older or newer Lapua brass you may want to experiment. Some bullets prefer more tension than others. And, you may find that it is useful to tweak neck tension slightly if you make major changes in seating depth during load development. In a gas gun, such as an AR15, you probably want .003 or more tension.

Alternative to Bushings — Honed Full-Length dies

Conventional, non-bushing full-length sizing dies can create ultra-accurate ammo with very low run-out. For some applications, we prefer a non-bushing FL die over a bushing die — so long as the neck tension is correct. But many FL dies have an undersized neck diameter so you end up with excess neck tension, and you work the brass excessively. Forster offers a simple, inexpensive solution — honing the neck diameter to whatever size you want.

If you purchase a Forster non-bushing, full-length sizing die, Forster will hone the neck dimension to your specs for $12.00 extra (plus shipping). This way you can have a FL die that provides the right amount of tension for your particular load. (The max amount of diameter change Forster can do is about .008″) Forster dies are relatively inexpensive so you can afford to have a couple of FL dies with necks honed to different diameters — such as 0.266″ and 0.267″ for a no-turn 6mmBR. The die itself is fairly inexpensive — currently Sinclair Int’l charges $33.99 for a Forster 6mmBR full-length sizing die (Forster Part # 018121).

Forster FL dies, necks honed to .265″, .266″, and .267″.

Steve Rasmussen of IowaHighPower.com gave this a try. In fact, he had three dies made — each with a different neck dimension. Here’s his report: “My original Forster 6BR FL die sized the necks down a lot [to about 0.260″]. I sent my die in and asked if they could supply two more FL dies (for three total) to have the necks honed to 0.265″, 0.266″, and 0.267″.” In addition to the purchase cost of two more FL-sizing dies, Steve paid $36 ($12 per die) for the three dies to be honed, plus about $12 for return shipping.

The table below shows the neck diameter range of 10 sized cases using each die. [NOTE: This is with older “Brown Box” Lapua brass!] Brass springback after sizing is running 1 to 1.3 thousandths. My loaded rounds are running 0.2697-0.2699 using Lapua I bought last year. So far the dies are working well. I sized 80 cases with the 0.266″ necked die. The shoulder is running 0.4582″ and 0.300″ up from the base is 0.4684". I spun 20 of ‘em and 16 had a runout of one thousandth (0.001) and the other 4 at 1.5 thousandths (0.0015).”

| Die Diameter |

Sized Brass |

Springback |

Neck Tension |

| 0.267 Die |

0.2683-0.2684 |

0.0013 |

0.0014 |

| 0.266 Die |

0.2672-0.2674 |

0.0013 |

0.0025 |

| 0.265 Die |

0.2659-0.2660 |

0.0010 |

0.0039 |

September 24th, 2012

Gear Review by Boyd Allen Gear Review by Boyd Allen

Just about everyone knows that Wilson and Redding make neck-sizing bushings. But few shooters seem to be aware that RCBS produces bushings. In fact, RCBS does make quality neck-sizing bushings, including very nice Tungsten Disulfide-coated bushings.

As a companion product for their Gold Medal bushing-style dies, RCBS produces its own line of sizing bushings, that have a couple of notable features. First, along with plain steel bushings, RCBS offers bushings with a distinctive, dark gray Tungsten Disulfide (WS2) anti-friction coating. Redding offers bushings in bare “white” steel or with a gold-colored Titanium-Nitride anti-friction coating. Wilson bushings are plain steel with a shiny silver finish. Though the Redding and Wilson plain steel bushings may look like stainless, remember that these un-coated bushings need to be kept oiled or they WILL rust. In normal use, you shouldn’t have to worry about rust on the Tungsten Disulfide-coated RCBS bushings.

Comparing coated bushings, Redding’s gold TiN-coated bushings look pretty, but the WS2 anti-friction coating on RCBS bushings seems to work as well. Tungsten Disulfide (WS2) has an extremely low coefficient of friction — 0.03 compared to 0.6 for Titanium Nitride. Accordingly, the RCBS WS2-coated bushings can work with minimal neck lubrication. When I actually sized necks with the RCBS WS2-coated bushings, the “smoothness” of the neck-sizing operation seemed on a par with other quality, coated bushings.

Another notable difference with the RCBS bushings (compared to other brands) is that RCBS stamps the bushing size onto the outside of the bushing, rather than on the top. RCBS puts the bushing diameter on a reduced-diameter band that runs around the circumference of each RCBS bushing. I think that this is a good idea because it eliminates the possibility that raised edges from the stamping itself might interfere with proper bushing alignment*. (Remember that the top of the bushing — where size marks are stamped by other bushing-makers — contacts the retaining cap in the die during sizing.) Putting the size marks on the outside also makes it easy to distinguish RCBS bushings from other bushing brands.

The other feature that I like is the shape of the entry chamfer on the bottom of the RCBS bushing. This chamfer is large and angular, rather than curved. This is only a guess, but I think that it may do a better job of letting the bushing align itself with the case as it is inserted into the die, and do a better job on brass from chambers that allow more neck expansion. (The picture shows the smaller chamfer at the top of the bushing.)

That about wraps it up, with the exception of one small point. While MidwayUSA has a wide selection of RCBS bushings, other retailers need to do a better job of stocking these bushings. I got mine from RCBS, but you may have trouble finding them in many online catalogs, or on dealers’ shelves. Hopefully this small review will help to increase awareness of RCBS bushings, and more retailers will carry them.

*As you probably know, stamping displaces metal, some of which is raised above the level of the surface that was stamped. Although it can be argued that shooters have gotten some pretty spectacular results in spite of any cocking of neck bushings caused by their being stamped on top, I am sure that a lot of us would prefer to have things as straight as they can be, and moving the stamping to a recessed band that runs around the outside of the bushing helps accomplish this.

March 6th, 2012

We are often asked: “What size neck bushing is best for Lapua 6mmBR brass in a ‘no-turn’ chamber?” The questioner planned to purchase a Redding Type ‘S’ full-length sizing die with neck bushings. The quick answer is that one should probably get both 0.265 and 0.266 bushings and see what works best. With the current “blue box” Lapua brass, a loaded 6BR round with an unturned neck will typically run about 0.268″ (depending on the bullet). A 0.266″ neck bushing, after springback, will give about 0.0015″ tension which can work well in a bolt gun. In a gas gun, we recommend running .003″ (or more) neck tension. We are often asked: “What size neck bushing is best for Lapua 6mmBR brass in a ‘no-turn’ chamber?” The questioner planned to purchase a Redding Type ‘S’ full-length sizing die with neck bushings. The quick answer is that one should probably get both 0.265 and 0.266 bushings and see what works best. With the current “blue box” Lapua brass, a loaded 6BR round with an unturned neck will typically run about 0.268″ (depending on the bullet). A 0.266″ neck bushing, after springback, will give about 0.0015″ tension which can work well in a bolt gun. In a gas gun, we recommend running .003″ (or more) neck tension.

Alternative to Bushings — Honed Full-Length dies

Conventional, non-bushing full-length sizing dies can create ultra-accurate ammo with very low run-out. For some applications, we prefer a non-bushing FL die over a bushing die — so long as the neck tension is correct. But many FL dies have an undersized neck diameter so you end up with excess neck tension, and you work the brass excessively. Forster offers a simple, inexpensive solution — honing the neck diameter to whatever size you want.

If you purchase a Forster non-bushing, full-length sizing die, Forster will hone the neck dimension to your specs for about $10.00 extra. This way you can have a FL die that provides the right amount of tension for your particular load. Forster dies are relatively inexpensive so you can afford to have a couple of FL dies with necks honed to different diameters — such as 0.265″ and 0.266″ for a no-turn 6mmBR. The die itself is very affordable — currently Sinclair Int’l charges $33.95 for a Forster 6mmBR full-length sizing die (item FP6BRFL).

Forster FL dies, necks honed to .265″, .266″, and .267″.

Steve Rasmussen of IowaHighPower.com gave this a try. In fact, he had three dies made — each with a different neck dimension. Here’s his report: “My original Forster 6BR FL die sized the necks down a lot, less than 0.260″, .256″ if I recall correctly. I sent my die in and asked if they could supply two more FL dies (for three total) to have the necks honed to 0.265″, 0.266″, and 0.267″. The cost was $10 for my supplied die and $38.50 plus $10.00 honing fee for each additional die. Return shipping was $11.00 via USPS Priority Mail.”

The table below shows the neck diameter range of ten (10) sized cases using each die. Brass springback after sizing runs 1 to 1.3 thousandths. Steve was using the older, “brown box” Lapua brass with thicker necks so he needed the .267″ bushing. The older Lapua 6mmBR brass measures about 0.2695″ with bullet in place. Steve explained: “My loaded rounds are running 0.2697-0.2699 using [brown box] Lapua 6BR brass. So far the dies are working well. I sized 80 cases with the 0.266″ necked die. The shoulder is running 0.4582″ and 0.300″ up from the base is 0.4684″. I spun 20 of ‘em and 16 had a runout of one thousandth (0.001) and the other 4 at 1.5 thousandths (0.0015).” That shows that these honed Forster FL dies produce exceptionally straight sized cases.

| Die Diameter |

Sized Brass |

Springback |

Neck Tension |

| 0.267 Die |

0.2683-0.2684 |

0.0013 |

0.0014 |

| 0.266 Die |

0.2672-0.2674 |

0.0013 |

0.0025 |

| 0.265 Die |

0.2659-0.2660 |

0.0010 |

0.0039 |

|

In our Shooters’ Forum a reader recently asked: “How much neck tension should I use?” This prompted a Forum discussion in which other Forum members recommended a specific number based on their experience, such as .001″, .002″, or .003″. These numbers, as commonly used, correspond to the difference between case-neck OD after sizing and the neck OD of a loaded round, with bullet in place. In other words, the numbers refer to the nominal amount of interference fit (after sizing).

In our Shooters’ Forum a reader recently asked: “How much neck tension should I use?” This prompted a Forum discussion in which other Forum members recommended a specific number based on their experience, such as .001″, .002″, or .003″. These numbers, as commonly used, correspond to the difference between case-neck OD after sizing and the neck OD of a loaded round, with bullet in place. In other words, the numbers refer to the nominal amount of interference fit (after sizing). Neck-Wall Thickness is Important Too

Neck-Wall Thickness is Important Too

Craters may look interesting on the moon, but you don’t want to see them on your primers. Certain mechanical issues that cause primer craters can also cause primer piercing — a serious safety problem that needs to be addressed. If you have a gun that is cratering primers (even at moderate pressure levels), there is a solution that works with many rifles — send your bolt to

Craters may look interesting on the moon, but you don’t want to see them on your primers. Certain mechanical issues that cause primer craters can also cause primer piercing — a serious safety problem that needs to be addressed. If you have a gun that is cratering primers (even at moderate pressure levels), there is a solution that works with many rifles — send your bolt to  Firing Pin Hole Bushing by Greg Tannel

Firing Pin Hole Bushing by Greg Tannel

Bump Measuring Collar

Bump Measuring Collar

RCBS Summit Press Features:

RCBS Summit Press Features:

Gear Review by Boyd Allen

Gear Review by Boyd Allen