|

|

March 30th, 2021

Image by ModernArms, Creative Common License.

by Philip Mahin, Sierra Bullets Ballistic Technician

This article first appeared in the Sierra Bullets Blog

If you asked a group of shooters to explain the difference between CUP and PSI, the majority would probably not be able to give a precise answer. But, for safety reasons, it’s very important that all hand-loaders understand these important terms and how they express cartridge pressures.

The ANSI / SAAMI group, short for “American National Standard Institute” and “Sporting Arms and Ammunition Manufacturers’ Institute”, have made available some time back the voluntary industry performance standards for pressure and velocity of centerfire rifle sporting ammunition for the use of commercial manufacturers. [These standards for] individual cartridges [include] the velocity on the basis of the nominal mean velocity from each, the maximum average pressure (MAP) for each, and cartridge and chamber drawings with dimensions included. The cartridge drawings can be seen by searching the internet and using the phrase ‘308 SAAMI’ will get you the .308 Winchester in PDF form. What I really wanted to discuss today was the differences between the two accepted methods of obtaining pressure listings. The Pounds per Square Inch (PSI) and the older Copper Units of Pressure (CUP) version can both be found in the PDF pamphlet.

CUP Pressure Measurement CUP Pressure Measurement

The CUP system uses a copper crush cylinder which is compressed by a piston fitted to a piston hole into the chamber of the test barrel. Pressure generated by the burning propellant causes the piston to move and compress the copper cylinder. This will give it a specific measurable size that can be compared to a set standard. At right is a photo of a case that was used in this method and you can see the ring left by the piston hole.

PSI Pressure Measurement

What the book lists as the preferred method is the PSI (pounds per square inch or, more accurately, pound-force per square inch) version using a piezoelectric transducer system with the transducer flush mounted in the chamber of the test barrel. Pressure developed by the burning propellant pushes on the transducer through the case wall causing it to deflect and make a measurable electric charge.

Q: Is there a standardized correlation or mathematical conversion ratio between CUP and PSI values?

Mahin: As far as I can tell (and anyone else can tell me) … there is no [standard conversion ratio or] correlation between them. An example of this is the .223 Remington cartridge that lists a MAP of 52,000 CUP / 55,000 PSI but a .308 Winchester lists a 52,000 CUP / 62,000 PSI and a 30-30 lists a 38,000 CUP / 42,000 PSI. It leaves me scratching my head also but it is what it is. The two different methods will show up in listed powder data[.]

So the question on most of your minds is what does my favorite pet load give for pressure? The truth is the only way to know for sure is to get the specialized equipment and test your own components but this is going to be way out of reach for the average shooter, myself included. The reality is that as long as you are using printed data and working up from a safe start load within it, you should be under the listed MAP and have no reason for concern. Being specific in your components and going to the load data representing the bullet from a specific cartridge will help get you safe accuracy. [With a .308 Winchester] if you are to use the 1% rule and work up [from a starting load] in 0.4 grain increments, you should be able to find an accuracy load that will suit your needs without seeing pressure signs doing it. This is a key to component longevity and is the same thing we advise [via our customer service lines] every day. Till next time, be safe and enjoy your shooting.

Share the post "Know Your Terminology — CUP vs. PSI"

February 13th, 2020

by James Calhoon

(First Printed in Varmint Hunter Magazine, October, 1995)

In the course of talking to many shooters, it has become clear to me that the manufacturers of primers have done a less than adequate job of educating reloaders on the application of their primers. Everybody seems to realize that some primers are “hotter” than others and some seem to shoot better for them than others, but few reloaders know that primers have different pressure tolerances.

Primer Pressure Tolerance

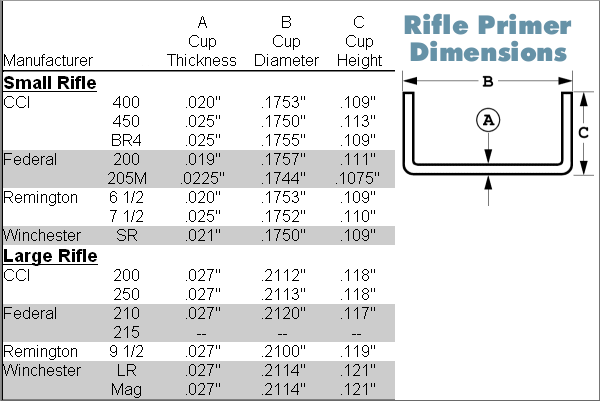

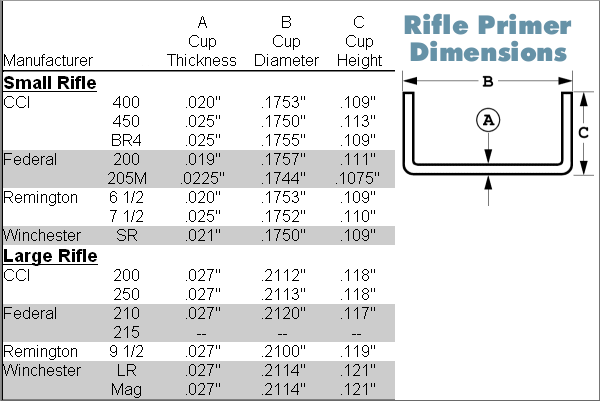

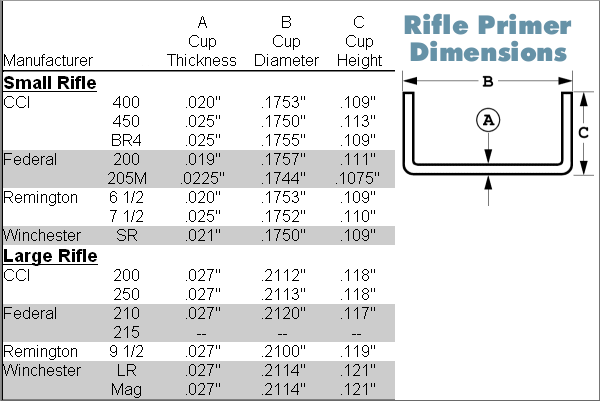

When loading a .223 to the maximum, I was getting primer piercing before I reached case overloading. I don’t know what prompted me to try CCI 450s instead of the 400s which I had been using, but I did. Presto! No more piercing! Interesting!? A primer that has a hotter ignition and yet withstands more pressure! Thats when I decided that it was time to do a dissection of all primers concerned. The chart below shows my results.

NOTE: These primer dimensions were measured many years ago. There may be some differences in current production specifications.

By studying the numbers (Cup “A” thickness), one can see which primers in the small rifle sections should be more resistant to primer cratering and/or piercing. Primer cup diameters are all similar and appear to follow a specification, but check out the cup thickness in the small rifle primers (Dimension “A”). Some cups are quite a bit thicker than others: .025″ for CCI 450 vs. .0019″ for Fed 200. Large rifle primers all appear to have the same cup thickness, no matter what the type. (As a note of interest, small pistol primers are .017″ thick and large pistol primers are .020″ thick.)

If you are shooting a 22 Cooper, Hornet, or a Bee, the .020″ cup will perform admirably. But try using the .020″ cup in a 17 Remington and you will pierce primers, even with moderate loads.

Considering that cup thickness varies in the small rifle primers, it is obvious that primer “flatness” cannot solely be used as a pressure indicator.

Another factor which determines the strength of a primer cup is the work-hardened state of the metal used to make the primer cup. Most primers are made with cartridge brass (70% copper, 30% zinc), which can vary from 46,000 psi, soft, to 76,000 psi tensile strength when fully hardened. Note that manufacturers specify the hardness of metal desired, so some cups are definitely “harder” that others.

What does all this mean to the reloader?

- Cases that utilize small rifle primers and operate at moderate pressures (40,000 psi) can use CCI 400, Federal 200, Rem 6 1/2, or Win SR. Such cases include 22 CCM, 22 Hornet and the 218 Bee. Other cases that use the small rifle primer can use the above primers only if moderate loads are used. Keep to the lower end of reloading recommendations.

– Cases that utilize small rifle primers and operate at higher pressures (55,000 psi) should use CCI 450, CCI BR4, Fed 205 and Rem 7 1/2.

– All the large rifle primers measured have the same thickness. Therefore choose based on other factors, such as accuracy, low ES/SD, cost, cup hardness, and uniformity.

Hope this clears up some primer confusion. If you want more information about primers, priming compounds, or even how to make primers, the NRA sells an excellent book called “Ammunition Making” by George Frost. This book tells it like it is in the ammo making industry.

Share the post "Primers and Pressure Tolerances — How Primers Vary"

September 27th, 2015

Image by ModernArms, Creative Common License.

by Philip Mahin, Sierra Bullets Ballistic Technician

This article first appeared in the Sierra Bullets Blog

The ANSI / SAAMI group, short for “American National Standard Institute” and “Sporting Arms and Ammunition Manufacturers’ Institute”, have made available some time back the voluntary industry performance standards for pressure and velocity of centerfire rifle sporting ammunition for the use of commercial manufacturers. [These standards for] individual cartridges [include] the velocity on the basis of the nominal mean velocity from each, the maximum average pressure (MAP) for each, and cartridge and chamber drawings with dimensions included. The cartridge drawings can be seen by searching the internet and using the phrase ‘308 SAAMI’ will get you the .308 Winchester in PDF form. What I really wanted to discuss today was the differences between the two accepted methods of obtaining pressure listings. The Pounds per Square Inch (PSI) and the older Copper Units of Pressure (CUP) version can both be found in the PDF pamphlet.

CUP Pressure Measurement CUP Pressure Measurement

The CUP system uses a copper crush cylinder which is compressed by a piston fitted to a piston hole into the chamber of the test barrel. Pressure generated by the burning propellant causes the piston to move and compress the copper cylinder. This will give it a specific measurable size that can be compared to a set standard. At right is a photo of a case that was used in this method and you can see the ring left by the piston hole.

PSI Pressure Measurement

What the book lists as the preferred method is the PSI (pounds per square inch or, more accurately, pound-force per square inch) version using a piezoelectric transducer system with the transducer flush mounted in the chamber of the test barrel. Pressure developed by the burning propellant pushes on the transducer through the case wall causing it to deflect and make a measurable electric charge.

Q: Is there a standardized correlation or mathematical conversion ratio between CUP and PSI values?

Mahin: As far as I can tell (and anyone else can tell me) … there is no [standard conversion ratio or] correlation between them. An example of this is the .223 Remington cartridge that lists a MAP of 52,000 CUP / 55,000 PSI but a .308 Winchester lists a 52,000 CUP / 62,000 PSI and a 30-30 lists a 38,000 CUP / 42,000 PSI. It leaves me scratching my head also but it is what it is. The two different methods will show up in listed powder data[.]

So the question on most of your minds is what does my favorite pet load give for pressure? The truth is the only way to know for sure is to get the specialized equipment and test your own components but this is going to be way out of reach for the average shooter, myself included. The reality is that as long as you are using printed data and working up from a safe start load within it, you should be under the listed MAP and have no reason for concern. Being specific in your components and going to the load data representing the bullet from a specific cartridge will help get you safe accuracy. [With a .308 Winchester] if you are to use the 1% rule and work up [from a starting load] in 0.4 grain increments, you should be able to find an accuracy load that will suit your needs without seeing pressure signs doing it. This is a key to component longevity and is the same thing we advise [via our customer service lines] every day. Till next time, be safe and enjoy your shooting.

Share the post "CUP vs. PSI — Do You Understand the Difference?"

September 14th, 2015

Our friend Grant Guess recently had a “close encounter” with a bad primer. An apparently defective primer caused part of the casehead on one of his rounds to blow out. This, in turn, allowed high pressure gas to vent through the damaged primer pocket. Take a good look, boys and girls. This is yet another very good reason to wear safety glasses. The cartridge was a 6.5-06, handloaded in necked-down Winchester-headstamp .270 Win brass. Grant reports:

“I had a blow through between the primer and the primer pocket today. The action was really smoking and I got a face full of gas. This was a reasonably light charge. Thank God for safety glasses.

I should also mention that it appears there is a 3/64 hole that is halfway between the primer and the primer pocket. Like it burned a small jet hole through both of them.”

Could this happen to you? It just might. On seeing this damaged case, one of Grant’s Facebook friends, Chris D., observed: “Search the internet, you will see a lot of these pin hole ‘in the corner’ failures. Obviously Winchester has some issues with the LR primers.”

Careful Examination Reveals Apparent Primer Defect

After this incident, Grant examined the damaged case: “I pinned the flash hole and it is not over-sized or under-sized. The primer clearly has an area where it had a defect. At [50,000 CUP], it doesn’t take much of a defect to cause issues. There was a slight bit of pucker-factor on the next shot….”

Share the post "Primer Pocket Rocket — Good Reason to Wear Safety Glasses"

April 18th, 2015

When you look at a loading manual with load data, you will usually see pressure ratings for stated load. Sometimes these are listed in PSI numbers, which most people correctly understand to be Pounds per Square Inch of pressure. However, powder-makers also commonly list pressure in CUP numbers. CUP stands for Copper Unit of Pressure. You may be asking — “What exactly is a CUP, and what is the origin of that unit of measurement?” You may also be wondering — “What’s the difference between CUP pressures and PSI pressures?” On Hodgdon’s Facebook Page, you’ll find answers to these questions. When you look at a loading manual with load data, you will usually see pressure ratings for stated load. Sometimes these are listed in PSI numbers, which most people correctly understand to be Pounds per Square Inch of pressure. However, powder-makers also commonly list pressure in CUP numbers. CUP stands for Copper Unit of Pressure. You may be asking — “What exactly is a CUP, and what is the origin of that unit of measurement?” You may also be wondering — “What’s the difference between CUP pressures and PSI pressures?” On Hodgdon’s Facebook Page, you’ll find answers to these questions.

Q: What is CUP?

A: Copper Unit of Pressure (CUP) is a measurement used in the ammunition industry to determine the chamber pressure created by a cartridge load. Originally, a precisely formed copper slug was placed in a fixture over the chamber. When the cartridge was fired, the amount of crushing measured on the slug allowed engineers to determine the pressure.

These days, modern electronic transducers provide faster, more accurate measurements of chamber pressures in pounds per square inch (PSI). CUP and PSI are measured to different scales and are NOT interchangeable.

Hodgdon Reloading Data Center Sample

Share the post "Copper Unit of Pressure (CUP) Defined by Hodgdon"

October 13th, 2014

by Philip Mahin, Sierra Bullets Ballistic Technician

This article first appeared in the Sierra Bullets Blog

The ANSI / SAAMI group, short for “American National Standard Institute” and “Sporting Arms and Ammunition Manufacturers’ Institute”, have made available some time back the voluntary industry performance standards for pressure and velocity of centerfire rifle sporting ammunition for the use of commercial manufacturers. [These standards for] individual cartridges [include] the velocity on the basis of the nominal mean velocity from each, the maximum average pressure (MAP) for each, and cartridge and chamber drawings with dimensions included. The cartridge drawings can be seen by searching the internet and using the phrase ‘308 SAAMI’ will get you the .308 Winchester in PDF form. What I really wanted to discuss today was the differences between the two accepted methods of obtaining pressure listings. The Pounds per Square Inch (PSI) and the older Copper Units of Pressure (CUP) version can both be found in the PDF pamphlet.

Image by ModernArms, Creative Common License.

CUP Pressure Measurement CUP Pressure Measurement

The CUP system uses a copper crush cylinder which is compressed by a piston fitted to a piston hole into the chamber of the test barrel. Pressure generated by the burning propellant causes the piston to move and compress the copper cylinder. This will give it a specific measurable size that can be compared to a set standard. At right is a photo of a case that was used in this method and you can see the ring left by the piston hole.

PSI Pressure Measurement

What the book lists as the preferred method is the PSI (pounds per square inch or, more accurately, pound-force per square inch) version using a piezoelectric transducer system with the transducer flush mounted in the chamber of the test barrel. Pressure developed by the burning propellant pushes on the transducer through the case wall causing it to deflect and make a measurable electric charge.

Q: Is there a standardized correlation or mathematical conversion ratio between CUP and PSI values?

Mahin: As far as I can tell (and anyone else can tell me) … there is no [standard conversion ratio or] correlation between them. An example of this is the .223 Remington cartridge that lists a MAP of 52,000 CUP / 55,000 PSI but a .308 Winchester lists a 52,000 CUP / 62,000 PSI and a 30-30 lists a 38,000 CUP / 42,000 PSI. It leaves me scratching my head also but it is what it is. The two different methods will show up in listed powder data[.]

So the question on most of your minds is what does my favorite pet load give for pressure? The truth is the only way to know for sure is to get the specialized equipment and test your own components but this is going to be way out of reach for the average shooter, myself included. The reality is that as long as you are using printed data and working up from a safe start load within it, you should be under the listed MAP and have no reason for concern. Being specific in your components and going to the load data representing the bullet from a specific cartridge will help get you safe accuracy. [With a .308 Winchester] if you are to use the 1% rule and work up [from a starting load] in 0.4 grain increments, you should be able to find an accuracy load that will suit your needs without seeing pressure signs doing it. This is a key to component longevity and is the same thing we advise [via our customer service lines] every day. Till next time, be safe and enjoy your shooting.

Share the post "CUP vs. PSI — What’s The Difference in Pressure Measurements"

March 5th, 2012

by James Calhoon

(First Printed in Varmint Hunter Magazine, October, 1995)

In the course of talking to many shooters, it has become clear to me that the manufacturers of primers have done a less than adequate job of educating reloaders on the application of their primers. Everybody seems to realize that some primers are “hotter” than others and some seem to shoot better for them than others, but few reloaders know that primers have different pressure tolerances.

Primer Pressure Tolerance

When loading a .223 to the maximum, I was getting primer piercing before I reached case overloading. I don’t know what prompted me to try CCI 450s instead of the 400s which I had been using, but I did. Presto! No more piercing! Interesting!? A primer that has a hotter ignition and yet withstands more pressure! Thats when I decided that it was time to do a dissection of all primers concerned. The chart below shows my results.

By studying the numbers (Cup “A” thickness), one can see which primers in the small rifle sections should be more resistant to primer cratering and/or piercing. Primer cup diameters are all similar and appear to follow a specification, but check out the cup thickness in the small rifle primers (Dimension “A”). Some cups are quite a bit thicker than others: .025″ for CCI 450 vs. .0019″ for Fed 200. Large rifle primers all appear to have the same cup thickness, no matter what the type. (As a note of interest, small pistol primers are .017″ thick and large pistol primers are .020″ thick.)

If you are shooting a 22 Cooper, Hornet, or a Bee, the .020″ cup will perform admirably. But try using the .020″ cup in a 17 Remington and you will pierce primers, even with moderate loads.

Considering that cup thickness varies in the small rifle primers, it is obvious that primer “flatness” cannot solely be used as a pressure indicator.

Another factor which determines the strength of a primer cup is the work-hardened state of the metal used to make the primer cup. Most primers are made with cartridge brass (70% copper, 30% zinc), which can vary from 46,000 psi, soft, to 76,000 psi tensile strength when fully hardened. Note that manufacturers specify the hardness of metal desired, so some cups are definitely “harder” that others.

What does all this mean to the reloader?

- Cases that utilize small rifle primers and operate at moderate pressures (40,000 psi) can use CCI 400, Federal 200, Rem 6 1/2, or Win SR. Such cases include 22 CCM, 22 Hornet and the 218 Bee. Other cases that use the small rifle primer can use the above primers only if moderate loads are used. Keep to the lower end of reloading recommendations.

– Cases that utilize small rifle primers and operate at higher pressures (55,000 psi) should use CCI 450, CCI BR4, Fed 205 and Rem 7 1/2.

– All the large rifle primers measured have the same thickness. Therefore choose based on other factors, such as accuracy, low ES/SD, cost, cup hardness, and uniformity.

Hope this clears up some primer confusion. If you want more information about primers, priming compounds, or even how to make primers, the NRA sells an excellent book called “Ammunition Making” by George Frost. This book tells it like it is in the ammo making industry.

Share the post "Primers and Pressure Analysis by James Calhoon"

|

CUP Pressure Measurement

CUP Pressure Measurement

When you look at a loading manual with load data, you will usually see pressure ratings for stated load. Sometimes these are listed in PSI numbers, which most people correctly understand to be Pounds per Square Inch of pressure. However, powder-makers also commonly list pressure in CUP numbers. CUP stands for Copper Unit of Pressure. You may be asking — “What exactly is a CUP, and what is the origin of that unit of measurement?” You may also be wondering — “What’s the difference between CUP pressures and PSI pressures?” On Hodgdon’s

When you look at a loading manual with load data, you will usually see pressure ratings for stated load. Sometimes these are listed in PSI numbers, which most people correctly understand to be Pounds per Square Inch of pressure. However, powder-makers also commonly list pressure in CUP numbers. CUP stands for Copper Unit of Pressure. You may be asking — “What exactly is a CUP, and what is the origin of that unit of measurement?” You may also be wondering — “What’s the difference between CUP pressures and PSI pressures?” On Hodgdon’s