|

|

May 31st, 2016

Nightforce’s 42x44mm fixed-power Benchrest scope mounted on James Mock’s 6mm Dasher.

Nightforce 42x44mm Comp Scope for Benchrest Shooters, by James Mock

Among long range shooters the name Nightforce has long commanded respect because of NF’s great optics and durability. However, the Benchrest disciplines that require either a 10-lb or 10.5-lb rifle had to forego the use of the Nightforce scopes because of their two+ pounds of weight. Some used the Benchrest model in the Heavy Varmint category (13.5-lb max weight) but not many in the Light Varmint, Sporter, or Hunter categories. That may change thanks to a new scope from Nightforce.

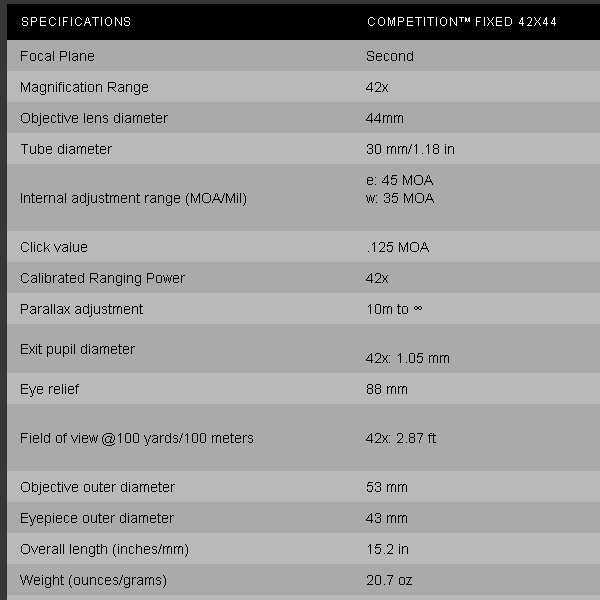

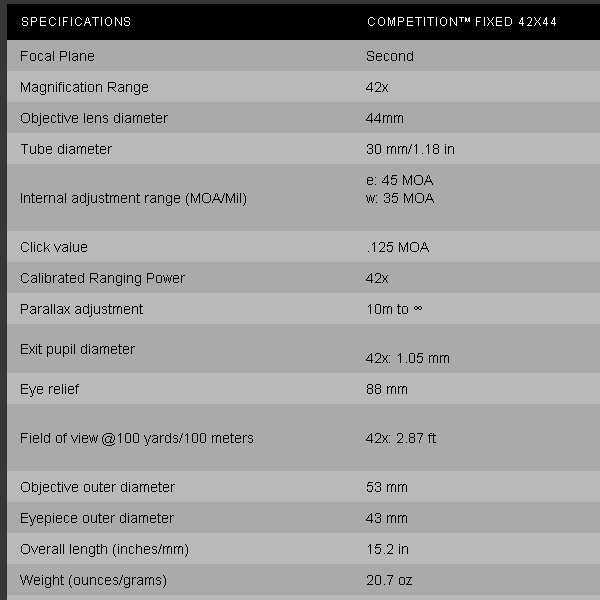

The folks at Nightforce Optics listened to benchrest shooters in the lighter classes and developed a new, light weight 42x44mm Competition Scope that weighs just 20.7 ounces. This scope comes as a fixed-power 42X and is without some of the “bells and whistles” of its larger cousins.

Key features of this scope important to Benchrest shooters are: ED glass, 42X power, 44mm objective lens, 88mm eye relief (~3.5 inches), 45 MOA elevation adjustment, 35 MOA windage, 10 MOA per revolution, 2.87-foot field of view at 100 yards, quick focus, click value of .125 inch, parallax adjustment from 10 meters (~33 ft.) to infinity, and an overall length of 15.2 inches. Also, you can set a “zero” easily. After obtaining conventional zero simply loosen one set screw per turret and set the dial at zero.

I received this scope on Monday, February 15th and mounted it on my BAT-action 6mm Dasher and zeroed it for a 600-yard match on Saturday, February 20th. My first impression of this scope was the amazing image produced by the ED glass. Although it is made with a 44mm objective lens (to save weight), one cannot say that the image is not clear. The image is outstanding from edge to edge and the image color is true. Nightforce offers two reticle options: the CTR-2 and CTR-3. Both reticles feature .016″ MOA vertical and horizontal lines, but the CTR-2 includes a .095 MOA center dot.

It took a small amount of faith to shoot the scope in a 600-yard match a few days after receiving it. Although I had shot only a few rounds with the scope mounted on my BAT Dasher, I knew that the Nightforce reputation was solid and my results would depend on the “nut” at the end of the rifle.

At the match, I fired a few shots to confirm zero and really appreciated the scope’s crisp 1/8th-MOA clicks. The adjustments were spot on at the 600-yard range and there was no problem getting my zero at the 600-yard distance. Remember, I had not shot at 600 yards with this scope, but I dialed in 11.5 MOA from my 100 yard zero and the resulting impact was correct. Each eight clicks delivered a precise one-MOA movement (about 6 inches) on the 600-yard target. The picture below is at the range as I was preparing for the first relay.

Our 600-yard match (non-registered) features 20 record rounds fired on the IBS target with steel gongs for sighters. The winter mirage can be brutal in this part of the country, but the Nightforce handled it without problems. Before the match was over, the left to right wind caused me to dial in two minutes (~12 inches) of windage and the scope was precise and I posted my 3rd best score with 191/200. The very fine .095″ dot allows for great precision in aiming.

Actual target shot by James Mock at 300 yards using Nightforce 42x44mm scope. James won the match.

My next match to use the scope was a 300-yard score match on March 5th. I had one chance to zero my rifle for this match and again I had no trouble changing the zero with the crisp, repeatable adjustments of this fine scope. The day was cool with bright sunshine and switchy tail winds. The new Nightforce handled the conditions very well, even with the horrible mirage. We shot two, 10-shot targets on the IBS 300-yard target. I shot 99-3X on the first and 99-3X on the second to win the match by one point over Mitch Young. Above is my second target, and the new scope let me see every shot through the mirage. There were many others who said that they could not see their bullet holes.

|

Summary of Nightforce 42x44mm Review

This 42x44mm optic is everything that I want in a scope. The 1/8th-MOA adjustments are crisp and repeatable. The center dot is small (.095 MOA). The image is sharp and clear all the way to the edges, and the ED glass provides a sensational image. The turret markings are distinct and there are 10 MOA per revolution. And you get all this in a scope that weighs 20.7 ounces with a 44mm objective lens. The low weight makes this scope viable for all benchrest classes. I believe the short range Benchrest shooters will welcome this scope and pay the sales price of $1742.00 (MSRP is $1795.00). Good shooting — James Mock |

|

Share the post "Nightforce 42x44mm Competition Scope Review by James Mock"

August 2nd, 2014

Brux Barrels, based in Lodi, Wisconsin, has earned a reputation for producing great-shooting tubes. Brux-made barrels have won their fair share of matches, and set some notable records in the process. Last year, Rodney Wagner shot the smallest five-shot, 600-yard group (.0349″) in the history of rifle competition, using a Brux barrel chambered for the 6mm Dasher. Brux Barrels, based in Lodi, Wisconsin, has earned a reputation for producing great-shooting tubes. Brux-made barrels have won their fair share of matches, and set some notable records in the process. Last year, Rodney Wagner shot the smallest five-shot, 600-yard group (.0349″) in the history of rifle competition, using a Brux barrel chambered for the 6mm Dasher.

Folks often ask us why Brux barrels shoot so well. “What’s the secret?” they ask. We can only answer with what Brux explains on its own website: “To make a cut-rifled barrel you have to start off with the proper ingredients: the best steel available, skill, and experience. Since there are really only two main suppliers of barrel-quality steel, the skill and experience is what really makes a barrel maker stand out.” Here is how Brux’s co-owners, Norman Brux and Ken Liebetrau, explain all the procedures involved in making a Brux cut-rifled barrel:

| Brux Barrel-Making Process, Start to Finish

We start out with either 4150 chrome-moly or 416R stainless steel double stress-relieved bar stock. The bar stock starts out at 1-9/32″ in diameter and 20-24 feet long so we cut it to length.

Step two is to rough-contour the outside of the barrel blank in a lathe.

Thirdly, the blank gets mounted into a Barnes gun drill. The cutter bit has holes through which oil or coolant is injected under pressure to allow the evacuation of chips formed during the cutting process. This is called “oil-through” or “coolant-through”. Without this, you wouldn’t want to even attempt drilling a hole 30” long and under ¼” in diameter. The combination of a 3600rpm and good flushing allows us to drill a beautifully straight and centered hole .005” under “land” diameter at a rate of 1” per minute.

Clean the barrel.

Next the blank is sent back to the lathe to machine the finished contour of the outside.

Clean the barrel again.

Now, the blank is sent on to the Pratt & Whitney reamer in which an “oil through” reaming tool is used to cut away the extra .005” left in the drilling process. The reamer makes an extremely accurate bore size and after it is finished the bore will have a better surface finish and will be at the proper “land” diameter.

Clean the barrel again.

In the sixth step we hand lap each barrel to remove any slight tool marks that may have been left by the reamer and inspect every one with a bore scope. If the barrel doesn’t meet our standards for surface finish and tolerance it doesn’t get any further.

Clean the barrel again.

The barrels then go onto the rifling machine which is responsible for cutting the all so familiar grooves in the bore. A caliber/land configuration-specific rifling head is used to progressively shave away small amounts of steel to form the rifling grooves. This is accomplished by simultaneously pulling the rifling head through the reamed blank as the blank is spun at a controlled rate. After each cut, the blank is rotated 90 degrees (for a four-land configuration) and after one full rotation (360 degrees) the rifling head is slightly raised to shave off the next bit of material. This process is repeated until we reach groove diameter.

Clean the barrel again.

Lastly, the barrel is hand-lapped again (to ensure a smooth bore), and a final inspection is performed with the bore scope.

The barrel is cleaned one last time, wrapped, packed, and shipped to [the customer]. |

Anyone reading this detailed description of the Brux barrel-making process will doubtless come away with a new appreciation for the time, effort, and dedication required to produce a premium match-grade cut-rifled barrel. Obviously, there are no easy shortcuts and great attention to detail is required each step of the way. As shooters we’re lucky that we have barrel-makers so dedicated to their craft.

Credit James Mock for steering us to this Barrel Making 101 feature on the Brux website.

Share the post "How Brux Barrels are Made — Precision Start to Finish"

January 4th, 2013

Review by James D. Mock

Around the first of November, I received a call from Boyd Allen. During one our conversations about all things Benchrest, he mentioned that Barnes made conventional match bullets. This I did not know. Most hunters are familiar with the excellent Barnes premium hunting bullets, but many like me did not know that they make match bullets also, marketed as “Match Burners”.

After contacting the good folks Barnes to request some Match Burners for a review in Precision Shooting Magazine, I received a box of 6mm 68gr match bullets and a box of 6mm 105gr VLDs. By the time I got these, I learned that Precision Shooting would no longer print a magazine. After contacting the good folks Barnes to request some Match Burners for a review in Precision Shooting Magazine, I received a box of 6mm 68gr match bullets and a box of 6mm 105gr VLDs. By the time I got these, I learned that Precision Shooting would no longer print a magazine.

These bullets sat around the house for quite some time, but I finally got around to testing them. First of all I weighed many of the bullets and found that the nominal 68gr bullets averaged 68.07 grains and the 105s averaged 105.08 grain. The 68gr bullets were .845 inches long and measured .2432 on the body and .2435 on the pressure ring of these flat-base bullets. The VLDs measured 1.192 inches long with a diameter of .2433 at the largest point and the boat tail measured .180 long with a diameter at the base of .210.

Flat-Base 68gr Match Burners Prove Very Accurate

Although I shot the 68gr bullets in some fairly “strong” conditions, they performed well as you can see below. I loaded the rounds with 28.4 grains of the new Accurate LT-32 powder (from Western Powders).

Above is a target with three 3-shot groups shot with the 68-grainers. I chose the following seating depths: (from left to right) .020 off jam*; .010 off jam; and .005 off jam. Since then I have shot a few more groups, and have been pleasantly surprised.

Barnes Match Burner 105gr VLDs Perform Well

For the 105 VLDs I chose my Dasher with a 26.5″ Bartlein gain twist (1:8.25″ to 1:7.75″). Like the 68gr bullets, these VLDs were a pleasant surprise. I plan to shoot these bullets again as soon as the weather improves.

*Editor’s Note: The term “Jam” (or “Jam Length”) is used to describe a maximum practical bullet seating dimension, typically measured from base to bullet ogive. As James uses the term, “Jam” means the maximum functional length to which he can seat a bullet in his brass, with his selected neck tension, before the bullet starts to move backwards in the case (in the direction of casehead) when he closes the bolt. Thus, if James specifies a load that is “.010 off Jam”, this means that James has seated the bullet ten-thousandths shorter than maximum functional length in his gun. His bullets are still engaged in the rifling at “.010 off Jam”, and probably still touching the rifling at “.020 off Jam”. The “Jam” length is specific to James’ barrel and brass. In different barrels, “Jam Length” can vary according to numerous factors — bore dimensions, land configuration, neck tension, bullet geometry et cetera.

Share the post "James Mock Tests “Match Burner” Bullets from Barnes"

May 31st, 2012

Forum member (and respected shooting journalist) James Mock has provided a follow-up report on the recently concluded Firearm Industry Super Shoot. Forum member (and respected shooting journalist) James Mock has provided a follow-up report on the recently concluded Firearm Industry Super Shoot.

First, James wanted to give credit to this year’s overall winner, Jeff Summers. James writes: “Jeff Summers persevered through the four days and came away with a HV Grand and a two-gun win at Super Shoot XL. This was his second Super Shoot win. For those who do not know Jeff, he is from eastern Tennessee (Oak Ridge area). He shot a BAT action and Bartlein 1:14″-twist barrel. He is a bag squeezer and shoots homemade bullets. Also, he smiths his own rifles”.

Harpenau Wins Light Varmint Grand

James also wanted to spotlight some talented new shooters, including a schoolboy who represents the next generation of benchrest shooters. James reports: “Many think that the top shoots are the exclusive domain of the old grizzled shooters, but that is not always the case. In the Super Shoot this year, Mark Harpenau (left, below) won a yardage and the Light Varmint Grand Aggregate (10.5-lb Class). Mark has been shooting only three years. Also, young Wyatt Peinhardt (right, below) finished first in the youth group and in the top fifty among all 270 shooters! It is good to see new faces in Benchrest.”

Photos by James Mock.

Share the post "Super Shoot — Deserving Two-Gun Champion and New Talent"

July 30th, 2010

Valdada 36X Scope, First Report: Benchrest shooter and noted gun writer James Mock recently tested Valdada’s new 36X Benchrest scope on his PPC. Valdada scopes are made by IOR (Industry Optic Romania) in Bucharest, Romania. James was impressed with the scope — and it certainly didn’t hurt his performance any. With the Valdada on top of his PPC, James nailed a 0.150″ three-shot group at 200 yards during testing earlier this week. Below you’ll find Mock’s first impressions of the Valdada 36X, along with photos of the scope mounted on his rifle. James — Thanks for sharing this! Valdada 36X Scope, First Report: Benchrest shooter and noted gun writer James Mock recently tested Valdada’s new 36X Benchrest scope on his PPC. Valdada scopes are made by IOR (Industry Optic Romania) in Bucharest, Romania. James was impressed with the scope — and it certainly didn’t hurt his performance any. With the Valdada on top of his PPC, James nailed a 0.150″ three-shot group at 200 yards during testing earlier this week. Below you’ll find Mock’s first impressions of the Valdada 36X, along with photos of the scope mounted on his rifle. James — Thanks for sharing this!

NEW Valdada 36X Benchrest Scope NEW Valdada 36X Benchrest Scope

by James Mock

Yesterday, I received one of Valdada’s new 36X BR scopes for testing. My initial tests proved that Valdada may have a winner. The scope has 7-layer coating on their German glass optics for a superb image. The 1/8th-minute clicks are positive and they repeat well. The reticle is a 1/8th MOA floating dot with 1 MOA hash marks for both windage and elevation. The scope has a very smooth worm gear parallax side adjustment that is marked in meters. Overall I am impressed with the initial testing. The suggested retail is around $1295.00, but I don’t know what the “street price” will be. Here are a couple pictures that show the scope mounted on My BAT-actioned rifle, currently fitted with a PPC barrel.

Share the post "Optics: James Mock Tests New IOR Valdada 36X Benchrest Scope"

|

After contacting the good folks Barnes to request some Match Burners for a review in Precision Shooting Magazine, I received a box of 6mm 68gr match bullets and a box of 6mm 105gr VLDs. By the time I got these, I learned that Precision Shooting would no longer print a magazine.

After contacting the good folks Barnes to request some Match Burners for a review in Precision Shooting Magazine, I received a box of 6mm 68gr match bullets and a box of 6mm 105gr VLDs. By the time I got these, I learned that Precision Shooting would no longer print a magazine.

Forum member (and respected shooting journalist) James Mock has provided a follow-up report on the recently concluded Firearm Industry Super Shoot.

Forum member (and respected shooting journalist) James Mock has provided a follow-up report on the recently concluded Firearm Industry Super Shoot.

Valdada 36X Scope, First Report: Benchrest shooter and noted gun writer James Mock recently tested Valdada’s new 36X Benchrest scope on his PPC. Valdada scopes are made by IOR (Industry Optic Romania) in Bucharest, Romania. James was impressed with the scope — and it certainly didn’t hurt his performance any. With the Valdada on top of his PPC, James nailed a 0.150″ three-shot group at 200 yards during testing earlier this week. Below you’ll find Mock’s first impressions of the Valdada 36X, along with photos of the scope mounted on his rifle. James — Thanks for sharing this!

Valdada 36X Scope, First Report: Benchrest shooter and noted gun writer James Mock recently tested Valdada’s new 36X Benchrest scope on his PPC. Valdada scopes are made by IOR (Industry Optic Romania) in Bucharest, Romania. James was impressed with the scope — and it certainly didn’t hurt his performance any. With the Valdada on top of his PPC, James nailed a 0.150″ three-shot group at 200 yards during testing earlier this week. Below you’ll find Mock’s first impressions of the Valdada 36X, along with photos of the scope mounted on his rifle. James — Thanks for sharing this! NEW Valdada 36X Benchrest Scope

NEW Valdada 36X Benchrest Scope