|

|

July 12th, 2019

Good news for rimfire shooters! Lapua will open a new rimfire test center in Ohio in the fall of 2019. At this new facility, which will replicate Lapua’s current rimfire test center in Arizona, shooters can test various lots of Lapua rimfire ammunition to determine what shoots best in their firearms. The new location will have a full 100 meter testing tunnel, with electronic target readouts for both 50 meters and 100 meters. Customers have the option to send their rifles in for testing or schedule an onsite appointment to participate and view the test process.

“We’re taking our established practices and testing capabilities from our Mesa, AZ location to our new, second location in Ohio, offering customers state-of-the-art rimfire ammunition testing,” said Adam Braverman, Director of Sales and Marketing.

Patterned after the world-renowned Lapua Service Center in Schönebeck, Germany, the new Ohio facility will give shooters the chance to test various types and lots of rimfire ammunition, in their own firearms, under ideal conditions. Customers interested in performing ammo tests at either USA Lapua Rimfire Test locations (Arizona or Ohio), may call (480) 898-2731 or email rimfiretest@capstonepg.com .

Lapua announced: “Lapua … is proud to announce our second USA Lapua Rimfire Test Center at the Cardinal Shooting Center in Marengo, Ohio. The new Lapua Rimfire Test Center will offer competitive shooters and consumers alike the opportunity to match individual lots of Lapua ammunition to their match rifles and pistols. The new East Location will officially open in late Fall of 2019. All of the capabilities of the new test center will replicate our current Lapua Rimfire Test Center in Mesa, AZ.”

“We’re excited to partner with Lapua and bring this facility and test capabilities to our current and potential customers,” stated Jim Henderson, Director of Competitions at the Cardinal Shooting Center, “We feel this will help many consumers, as well as junior and collegiate teams…”

About Lapua

Lapua produces bullets, brass, and loaded rimfire and centerfire ammunition for civilian and professional use. Lapua is a part of the Capstone Precision Group, exclusive U.S. distributor for Berger, Lapua, Vihtavuori and SK-Rimfire products. For more information, visit Lapua.com.

June 25th, 2019

A few season back, our friend Kevin Thomas acquired a bit of living history — a reproduction Model 1873 Trapdoor Springfield. Here is Kevin’s story of his new rifle and the legacy it carries. A few season back, our friend Kevin Thomas acquired a bit of living history — a reproduction Model 1873 Trapdoor Springfield. Here is Kevin’s story of his new rifle and the legacy it carries.

Today marks the 143rd Anniversary of Lt.Col. George Armstrong Custer’s historic ride into the valley of the Little Big Horn, along with 200+ men of the U.S. Seventh Cavalry. June 25, 1876 did not go well, as Custer and his men became a well-known, sad footnote in U.S. history. [Editor: Well it was sad for Custer fans. Native Americans have a different perspective.]

For years now, I’ve wanted one of the rifles Custer and his men carried that day, a Model 1873 Trapdoor Springfield, chambered for the 45/70 cartridge. I finally acquired one, when I walked into a gunstore a while back and saw a handsome repro Trapdoor sitting peacefully on the shelf. It called to me.

Somewhere in the distance, I could hear the bugle calls, the Sioux and Cheyenne war cries and the thundering of cavalry across the plain. It simply had to go home with me, and so it did. It seemed an especially insistent demand with this being the 138th anniversary and all, so I took it along to our regular Wednesday night practice session. All I can say is, I’m glad we don’t have to do rapid-fire with one of these in our matches today, because they do have a mule-like kick to them!

The Trapdoors were a cost saving measure that the Armory came up with at the end of the Civil War, to convert muzzle-loading Springfield muskets into breech-loading cartridge arms. A quick look will give several dead giveaways that many of the parts on the “new” rifle were actually interchangeable with the old 1861 and 1863 Springfield muskets. The parts that were altered or newly fabricated were relatively minor changes.

Above, you can see where these rifles got their name. Loading was done by flipping a lever which opened up a trap door that provided access to the chamber. Flipping that same lever and opening the trap door then ejected the case after firing.

Here is the opposite side, trapdoor open. The ring and slide on the side of the stock was to facilitate an attachment point for a lanyard that the troopers wore over their shoulders. Remember, they often used these while at a full gallop, not an easy feat!

January 23rd, 2019

SHOT Show 2019 kicked off Tuesday, with tens of thousands of exhibitors, media members, and invitees streaming into the Sands EXPO Center in Las Vegas. This firearms industry trade show just gets bigger every year. We visited many of our favorite vendors including Capstone Precision Group (Berger, Lapua, SK, Vihtavuori), McMillan Fiberglass Stocks, Zeiss Optics, Redding Reloading, SIG Sauer, Smith & Wesson, Anschutz, and Target Vision/Longshot.

Here are some quick highlights from Day One of SHOT Show, a little bit of everything: Rifles, pistols, ammo, reloading gear, and some notable shooters.

Capstone Precision Group: Berger, Lapua, SK and Vihtavuori

Capstone Precision Group showcased new products from its four companies: Berger Bullets, Lapua, SK, and Vihtavuori. Lapua showcases cartridge brass and loaded ammo, including new 6.5 Creedmoor ammo with the ultra-consistent Scenar-L bullets. Capstone also told us to expect large quantities of brass to be arriving in the USA soon, including the high-demand 6mmBR brass.

Berger will release new loaded ammo in Lapua brass. Options will include 6mm Creedmoor, which should be popular with the PRS crowd. In addition, Berger will offer an impressive new line of solid projectiles. These ultra-high-BC ELF Match Solids have optimal shapes to stay supersonic at longer ranges. They are an impressive option for the Extreme Long Range game.

McMillan — 6012-Yard Shot with ELR Rifle

At the McMillan booth, members of the Global Precision Group (GPG) Team showcased an impressive .416 Barrett ELR rifle. Team leader Paul Phillips explained how the team managed (on the 22nd shot) to hit a 48″x32″ target at the incredible distance of 6012 yards. Our friend Derek Rodgers, reigning F-TR World Champion, told us that this shows how the ELR sport has evolved. The rifle features a McMillan ELR Beast stock with a Bartlein Barrel on a massive BAT 50 action.The .416 Barrett rounds were loaded with 550 grain Cutting Edge bullets.

A Tacom Charlie/Delta TARAC prism system was fitted in front of the Nightforce scope, allowing the team to put over 625 MOA of elevation on the shot while still being able to see the target. The ballistics numbers for this 6012-yard shot are pretty mind-boggling: 625 MOA of elevation was required, and the bullet was in the air for 17.1 seconds!

New Products from LongShot Target Cameras (aka TargetVision)

Our first stop at the show was at the LongShot Target Cameras booth. Here we met with company founder, Clay Rhoden, the bright young man who has created the best-performing wireless target cameras on the market. Most folks know Rhoden’s company as TargetVision, but Clay said they are re-branding as LONGSHOT Target Cameras, to help emphasize the extreme range capabilities of his latest systems (the top tier Longshot cameras can operate out to one mile and beyond). Clay showed us two new products, the latest target camera (with easy-to remove battery pack), and a special camera that will transmit video from a spotting scope to your mobile devices. See the latest products at www.longshotcameras.com.

Light-Weight Camo Hunting Rifles from Weatherby

Hunters can spend hundreds of dollars on the latest camouflaged clothing in order to blend in to their environment, so why do gun makers continue to produce shiny hunting rifles? Well, this is one thing Weatherby has gotten right with the latest Weatherby Mark V ultra lightweight rifles. The rifle has the option of a rugged, matte Cerakote finish on action, bolt, and barrel, effectively eliminating glare. And did I mention it’s light weight? The full rifle weights a mere 5.75 pounds for non-magnum calibers. Weatherby guarantees sub-MOA accuracy with factory ammunition out of the box. Add a decent lightweight scope and this rifle is ready for a long backcountry hunt.

Hot New Sub-Compacts from SIG Sauer, Kimber, Walther

For shooters who carry concealed or simply prefer a more compact pistol, three new handguns really stood out at shot show 2019: the SIG Sauer P365, Walther CCP M2, and the Kimber EVO. All three guns had a similar weight and feel at roughly 1” width, 6” length, and 1 lb when empty. The P365 has an advantage with a 10 + 1 round capacity, compared to the 7/8 of the EVO and CCP M2, but the CCP M2 is more competitively priced with an MSRP starting at $469. Retail for the P365 starts at $599 and the Kimber a surprising $925. Expect to see these guns in stores between spring and summer of 2019.

Smith & Wesson — Handguns Galore and New T/C Performance Center LRR

Smith & Wesson is not just a handgun company. It markets rifles under its own brand name as well as via its Thompson Center Arms (T/C) division. At SHOT Show 2019 we saw the T/C Performance Center LRR (Long Range Rifle). With a $1211.00 MSRP, this offers great “bang for the buck” for shooters competing in PRS production division. These rigs feature a modular aluminum chassis, 24″ barrel, and adjustable cheekpiece. Available chamberings include .243 Win, 6.5 Creedmoor, and .308 Win. And of course S&W continues to make great wheelguns, include some very BIG magnum revolvers:

At the Anschutz Booth with Company President, Jochen Anschutz

The German company Anschutz remains a world leader in rimfire rifles. The company’s match rifles have captured countless Gold Medals in Olympic target shooting and biathlong competition. Here company President Jochen Anschutz (left) shows the latest Biathlon rifle, featuring the impressive Fornter straight-pull action. With Jochen is Steven Bolter, North America Custom Shop Director. We were pleased to hear that Anschutz will be offering a new line of 17 HM2 (Mach2) rifles soon. That is an effective varmint round that’s considerable less expensive than 17 HMR.

January 16th, 2019

Who doesn’t want to save money? If you can get a significant discount, you should really take advantage of that opportunity. Guys, we’ve been tracking prices on shooting sports products at vendors around the country. Sad to say, we’ve seen price increases across the board in 2019. Reloading components, loading tools, stocks, targets, electronic gadgets — you name it, the price trend is moving upwards. Thankfully our friends at Precision Reloading are holding the line. Even better, Precision Reloading is running a really significant promotion right now.

Take Note! For today and tomorrow, January 16 and January 17, you can get 15% OFF All ORDERS over $100.00. That’s right, save 15% on your purchases at Precision Reloading with Code 15OFF. If you buy a $400.00 item that could save you $60.00. Yes, this applies to pretty much everything in stock at Precision Reloading, including all major brands below (and dozens more including Lapua, Berger, Forster, Hodgdon, Nosler, RCBS, Redding, Sierra etc.).

If you need bullets, brass, powder, dies, presses, powder dispensers, check out this sale. It’s a very good deal. Use Code 15OFF at check-out to save 15% on your orders over $100.00.

January 14th, 2019

PRS and NRL shooters, as well as game hunters, now have new ultra-accurate Berger and Lapua factory ammo for the popular 6mm Creedmoor and 6.5 Creedmoor chamberings. For shooters who do not have the time or equipment to hand-load, these new factory ammo options promise outstanding performance. We fully expect that these new offerings from Berger and Lapua will set new standards for accuracy and ballistic uniformity among commercial ammunition for the 6mm Creedmoor and 6.5 Creedmoor. Lapua’s match ammo for the similar 6.5×47 Lapua cartridge has shown outstanding accuracy with ES/SD numbers rivaling high-quality hand-loads. (SEE 6.5x47L Test Results).

New Lapua 6.5 Creedmoor Target and Lead-Free Hunting Ammunition

Lapua has added the popular 6.5 Creedmoor cartridge to its line of Scenar-L Target ammo and its Naturalis Hunting ammunition offerings. The 6.5m Creedmoor 136 grain Scenar-L offers a high ballistic coefficient (BC) for long-range competitive target shooting, yet maintains SAAMI configuration for flawless function through all factory or custom rifle magazines. Lapua ammo will also be loaded with the excellent 123 grain OTM Scenar. One of our favorite bullets, the 123-grainer offers faster velocities (and less recoil) than its bigger brother, and may be the best choice for many PRS stages.

6.5 Creedmoor ammo loaded with the 140 grain Lapua Naturalis provides hunters a lead-free option for hunting in areas that ban lead bullets. Designed and manufactured from pure copper, Naturalis bullets will reliably retain 90-100% of their original weight. Lapua’s Naturalis projectiles produce consistent, controlled expansion at the widest velocity range on the market.

New Berger 6mm Creedmoor Target and Hunting Ammo

New 6mm Creedmoor Target Ammunition is loaded with Berger 105 grain Hybrid Target bullets, the “go-to” for PRS shooters and long-range accuracy enthusiasts alike. Built using premium-grade Lapua cartridge cases, Berger’s 6mm Creedmoor Target Ammunition provides the discriminating shooter the highest quality components and sub-MOA accuracy “off-the-shelf”, unequaled by the competition.

New Berger 6mm Creedmoor Hunting Ammunition is loaded with 95 grain Hybrid Classic Hunter bullets in premium Lapua brass. These top-flight components deliver lethal precision and sub-MOA accuracy — impressive for hunting ammo. The hybrid ogive design of the Classic Hunter projectile is the same as Berger Hybrid Target bullets, while allowing for SAAMI length configurations for efficiency in the field and reliable functioning through magazines.

December 1st, 2018

Since 2010, Lapua has shipped its quality cartridge brass in sturdy blue plastic boxes. Here’s a handy tip for you — don’t toss the plastic boxes when you load up your brass! These are double-duty containers. If you’re not familiar with “Blue Box” Lapua brass, you may not realize that the boxes are designed to serve as 50-round carriers for your loaded ammo and fired cases. (Yes we know some folks who’ve been tossing out their blue boxes without knowing how the boxes work as caddies.)

Snapped in place under the box lid is a rectangular plastic grid that fits in the bottom of the box. Pop the grid loose and slide it into the box with the smooth side facing up. Side supports molded into the lower section hold the grid in place.

Voilà, instant Ammo Box! Each grid contains holes for fifty (50) loaded rounds or empty cases. The convertible plastic container/ammo box is a great idea that Lapua executed very nicely. Now you have even more motivation to purchase your cartridge brass from Lapua.

USER TIPS: When transporting ammo you may want to put some foam over the loaded rounds. That will protect the bullet tips. Also, with shorter cartridges, this will help keep your loaded ammo and fired cases from moving around. You can also tape the FREE Redding Ammo Box Labels on the underside of the lids to list your load information.

September 29th, 2018

After Norm Harrold won the 2018 F-Open National Championship in Raton, New Mexico, setting a new 1000-yard National Record in the process, many of our Forum members wanted to see Norm’s championship-winning rifle, and learn more about Norm’s experience at the Nationals. Read on for coverage of Norm’s equipment and .284 Shehane ammo. Scroll down and you’ll find a detailed video showing how McMillan builds the advanced Kestros ZR stocks, like the one Norm used at Raton.

Norm posted: “I made it home from Raton 2018 F-Class Nationals and what an unbelievably amazing week I had. I was blessed enough to bring home a new F-Open 1000-yard record and the National Championship! Our Team McMillan took second in Mid-range and fourth overall in Long Range. I am so thankful and blessed to have this opportunity and to be able to do it with such a stand-up group of competitors and lifelong friends. Thanks to all our sponsors: McMillan Fiberglass Stocks, Nightforce Optics, Kelbly’s [Actions], Bartlein Barrels, and Berger Bullets.”

Gun and Load: Norm’s F-Open rig features a McMillan Kestros ZR stock and Bartlein barrel chambered for the .284 Shehane, which has a bit more case capacity than a standard .284 Winchester. Norm loaded Berger 184gr 7mm bullets in Lapua brass. Norm revealed his load in an Erik Cortina YouTube Video. Fellow shooter Erik Cortina joked — “the minute this video goes live, the 184s will be hard to find”. Norm says “Stock up guys — they shoot good!”

Here Norm Harrold shows his shooting form. Note how low the McMillan Kestros ZR forearm sits on Norm’s SEB NEO front rest. Norm also uses a large footprint rear bag for enhanced stability.

Harrold Shoots 200-22X to Smash 1000-Yard F-Open Record

On a rainy day at Raton, Norm shot brilliantly to set a new F-Open National Record: 200-22X at 1000 yards. (The previous record was 200-17X.) How could he get 22 Xs for a 20-shot string? Under NRA rules, if you shoot all Xs for the full string, you are allowed to keep shooting for as long as you can put shots in the X-Ring. Norm almost missed the chance to extend his X-Count. After his 20th shot, Norm recalled, “I said ‘I’m done, give me my target’, but … my shooting partner said ‘No! Keep shooting!’” So Norm did, drilling two more Xs to set the new National Record.

Kelly McMillan Shows Design and Construction of the Kestros ZR:

In this video, Kelly McMillan explains the design features and construction methods for the Kestros ZR, a fiberglass Kestros with aluminum extension rails in the front. Kelly explains “how and why we made the stock the way we did” and he shows how to retro-fit standard Kestros stocks with the new front rails. On the ZR the rails are anchored to a reinforced area for extra rigidity. In addition, the cantilevered rails are milled to be perfectly parallel. If you shoot F-Class we strongly recommend you watch this video.

Kelly McMillan showed us the prototype Kestros ZR at the 2018 Berger Southwest Nationals.

September 12th, 2018

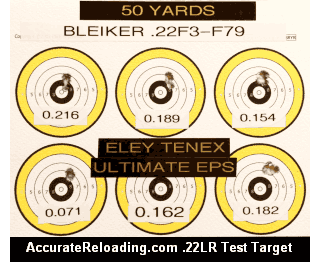

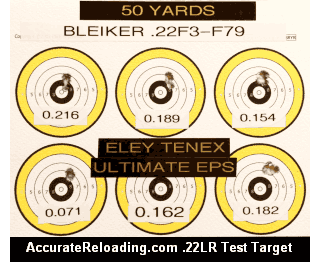

We first featured this story in 2010, but the results of this rimfire ammo test have been of such widespread interest that we try to bring the test to readers’ attention every year.

In 2010, the staff of AccurateReloading.com Forum completed a massive .22LR Rimfire Ammunition Testing Project. Some 55 different types of ammo were tested, using a highly-accurate Swiss-made Bleiker rifle, with a 2-stage trigger. All ammo varieties were tested at 50 yards, 75 yards, and 100 yards, shooting five, 5-shot groups at each distance. Though these tests were completed some time ago, many readers have requested a “reprint” of the ammo rankings, so we’ve republished this data below. In 2010, the staff of AccurateReloading.com Forum completed a massive .22LR Rimfire Ammunition Testing Project. Some 55 different types of ammo were tested, using a highly-accurate Swiss-made Bleiker rifle, with a 2-stage trigger. All ammo varieties were tested at 50 yards, 75 yards, and 100 yards, shooting five, 5-shot groups at each distance. Though these tests were completed some time ago, many readers have requested a “reprint” of the ammo rankings, so we’ve republished this data below.

The results are fascinating to say the least (and perhaps eye-opening). The tester observed: “I got some amazing groups, and some which are, frankly, absurdly bad! This has re-enforced what I had experienced with 22 ammo in the past — that is being consistently inconsistent.”

While we strongly caution that .22LR rimfire ammo may work well in one gun and not another, and ammo performance can be improved through the use of barrel tuners, the AccurateReloading.com research provides invaluable guidance for smallbore shooters. Overall, the testers burned through over 4,000 rounds of ammo, and you can see the actual test targets online. To read all the test reports, and view target photos visit AccurateReloading.com.

The lists below rank the average accuracy (by brand) of five, 5-shot groups shot at 50, 75, and 100 yards. CLICK HERE for Complete Test Results with target photos.

| 50-Yard Results |

75-Yard Results |

100-Yard Results |

0.162 Eley Tenex Ultimate EPS

0.164 Lapua Midas Plus

0.177 Lapua Polar Biathlon

0.187 Eley Match EPS

0.193 Eley Match

0.203 Lapua Midas M

0.215 Lapua Center X

0.216 Western Value Pack

0.229 Lapua Signum

0.241 Lapua Master L

0.243 Eley Pistol Match

0.256 Olin Ball

0.256 Akah X-Zone

0.261 Lapua Midas L

0.261 Lapua Master M

0.263 Eley Tenex Semi Auto

0.270 Lapua Super Club

0.272 Eley Tenex

0.303 Lapua Standard Plus

0.312 CCI Standard Velocity

0.319 RWS R 50

0.319 Eley Standard

0.328 SK High Velocity

0.339 Eley Club Xtra

0.340 Winchester T22

0.356 Federal Champion

0.362 Eley Subsonic HP

0.371 CCI Mini Mag

0.376 Federal American Eagle

0.377 Norinco Target

0.380 Sellier & Bellot Club

0.384 Eley Club

0.387 Eley Sport

0.388 Totem

0.392 Swartklip Match Trainer

0.398 Federal Gold Medal

0.403 Swartklip HV

0.409 Eley Match Xtra Plus

0.424 Sellier & Bellot Std

0.443 Remington Target

0.461 Lapua Crow HP

0.475 Eley Silhouex

0.479 Magtech

0.498 Eley High Velocity

0.513 Winchester Super X

0.516 Kassnar Concorde

0.539 CCI Blazer

0.560 Winchester Supreme Pistol

0.576 Norinco Pistol Revolver

0.593 SK Standard

0.611 Sellier And Bellot HP

0.626 SK Standard HP

0.686 Logo HV

0.956 Pobjeda Target |

0.274 Lapua Center X

0.283 Lapua Standard Plus

0.295 Eley Tenex Ultimate EPS

0.307 Lapua Midas M

0.329 Lapua Master M

0.346 Eley Match

0.373 Lapua Polar Biathlon

0.399 RWS R 50

0.432 Lapua Midas L

0.448 Eley Tenex Semi Auto

0.467 Eley Match EPS

0.474 Lapua master L

0.491 Eley Match Xtra Plus

0.494 CCI Standard

0.496 Eley Subsonic HP

0.507 Eley Sport

0.512 Federal American Eagle

0.513 SK High Velocity

0.514 Eley Standard

0.516 Eley Tenex

0.516 Lapua Crow HP

0.532 Western Value Pack

0.533 Fed. Champion Target

0.535 Lapua Midas Plus

0.564 Akah X Zone

0.566 Olin Ball

0.573 Eley Club Xtra

0.616 Lapua Signum

0.631 Winchester T22

0.639 Swartklip HV HP

0.641 Eley Club

0.642 Eley Silhouex

0.647 CCI Mini Mag

0.679 Eley Pistol Match

0.682 Swartklip Match Trainer

0.690 Federal Gold Medal

0.692 Remington HV

0.703 Lapua Super Club

0.720 Winchester Super X

0.738 Eley High Velocity

0.759 Kassnar Concorde

0.765 Sellier And Bellot Club

0.770 Winch. Supreme Pistol

0.770 Norinco target

0.775 CCI Blazer

0.802 Norinco Pistol Revolver

0.841 LVE Logo HV

0.855 Sellier & Bellot Std

0.871 Magtech

0.923 Sellier & Bellot HP

0.934 SK Standard HP

1.017 Remington Target

1.257 Totem Standard

1.442 SK Standard

1.578 Pobjeda target |

0.455 Eley Match

0.510 Lapua Midas Plus

0.549 Lapua Midas M

0.611 Lapua Polar Biathlon

0.611 Eley Tenex Ultimate EPS

0.619 Eley Match EPS

0.622 Eley Club

0.630 Lapua Center X

0.631 RWS R50

0.679 Eley Tenex Semi Auto

0.694 Lapua Midas L

0.729 Eley Tenex

0.739 Lapua Master L

0.753 Lapua Super Club

0.785 Lapua Master M

0.831 Eley Sport

0.851 Eley Match Xtra

0.859 Lapua Standard Plus

0.867 Akah X-Zone

0.877 Eley Pistol Match

0.907 Norinco Target

0.924 Eley Silhouex

0.939 CCI Standard

0.952 Eley Subsonic HP

0.963 Magtech

0.970 Olin Ball

0.978 Kassnar Concorde

0.995 Eley Club Xtra

1.009 Western Value Pack

1.032 Federal Champion

1.087 Norinco Pistol Revolver

1.100 CCI Mini Mag

1.112 Lapua Crow HP

1.143 Winchester T22

1.142 Federal Gold Medal

1.144 federal American Eagle

1.156 Swartklip Hollo Point

1.165 Lapua Signum

1.170 Swartklip Match Trainer

1.175 Fed. Champion Value Pk

1.182 SK high Velocity

1.201 Totem

1.224 Winchester Super X

1.358 Eley Standard

1.367 Remington High Velocity

1.375 CCI Blazer

1.414 Eley High Velocity

1.450 Remington Target

1.504 LVE Logo

1.813 SK Standard

1.879 S&B Club

1.947 S&B Hollow Point

2.073 SK Standard HP

2.221 S&B Standard

2.266 Pobjeda Target |

April 25th, 2018

Capstone Precision Group will conduct four informative seminars about competitive shooting during the 2018 NRA Annual Meetings & Exhibits. These seminars, designed as introductions to various shooting disciplines, will be led by top competitors. The 147th Annual NRA Convention runs May 3-6, 2018 at the Kay Bailey Hutchinson Convention Center in Dallas, Texas. Visit Capstone at Booth #4517 to learn more about competitive shooting from the experts. The seminars will be held each day in Booth #4517, May 4, 5, and 6 on the schedule listed below.

F-Class Shooting – 10:00-10:30

Join members of the USA Rifle Team to learn about F-Class, what you need to get started and what resources are available to help you learn more. This session will be held by the leaders of the United States F-Open and F-TR Rifle Teams. Made up of over 40 members, the team will be traveling to South Africa in 2021 to represent our country.

F-TR Team USA won the 2017 F-TR World Championship.

Precision Rifle Series (PRS) Shooting – 1:30-2:00

The Precision Rifle Series is one of the fastest growing competitive disciplines. Join two of the top series shooters to learn about all PRS has to offer and how you can join in on the fun. This session is led by Matthew Brousseau of Team Lapua and Missy Gilliland of Team Berger. Matthew is currently #1 in the series, and Missy has won numerous women’s and Top 10 daily awards.

F-TR Team USA won the 2017 F-TR World Championship.

Juniors in Competitive Shooting – 10:45-11:15

Do you have a son or daughter who is interested in competitive shooting? Attend our Juniors in Competitive Shooting educational session to learn how get them started on the right foot. Madison Bramley and her father Dan will lead this discussion. At just 14, Madison has already competed and represented the US around the country, as well as Ireland and Canada.

Madison Bramley at Berger SWN. Erik Cortina Facebook Photo.

Women in Competitive Shooting – 2:15-2:45

This is designed specifically for women who are interested in shooting competitively. Missy Gilliland of Team Berger and Gabby Pitre of Team VihtaVuori will talk about how they got their start in the competitive world and how you can get involved. Missy is a PRS shooter, and Gabby competes in Long Range, Mid-Range, and High Power Across the Course (XTC), so this session will cover many topics.

Missy Gilliland photo courtesy Bushnell.com.

High Power Shooting – 3:00-3:30

Are you interested in High Power Rifle competitions? Let us break down the competition, what you need to get started and how you can get involved with our High Power seminar led by Gabby Pitre and Kevin Thomas. Gabby is a member of Team VihtaVuori and has been competing since she was eight years old. Kevin Thomas is a Capstone employee, and has years of experience both shooting and teaching High Power shooting skills. Both have won distinguished badges and been awarded President’s Hundred, among other accomplishments.

About Capstone Precision Group

Capstone Precision Group is the exclusive U.S. distributor of Berger Bullets, Lapua Components and Munitions, Vihtavuori Propellants, and SK Rimfire products. Capstone Precision Group is a part of Nammo Group.

April 2nd, 2018

Vihtavuori markets a full line of quality, European-made powders for rifles and pistols. Finland-based Vihtavuori is operated by the same parent company, Nammo, that owns Lapua and Berger Bullets. If you haven’t tried Vihtavuori powders yet, you may be pleasantly surprised. For loading .45 ACP, our favorite powder is VV N320 — it burns clean and is very accurate. Likewise, VV makes excellent powders for rifle applications — from small varmint cartridges to large magnums.

New Reloading Data Released

Vihtavuori offers free reloading data on its website, and through a free Mobile App. And now those resources are even more complete… Vihtavuori offers free reloading data on its website, and through a free Mobile App. And now those resources are even more complete…

Last week, Vihtavuori added new reloading data for ten different cartridge types, including some of the most popular pistol and rifle cartridges. You’ll find new pistol data for 9mm Luger and .45 ACP, and extensive new load data for .223 Rem, .260 Rem, .308 Win, and .30-06 Springfield (among others). Overall the 2018 data update features over 20 new bullets, with more than 140 new lines! All new data is also available in FREE Vihtavuori Reload App for iOS and Android. The updated online information supplements Vihtavuori’s Reloading Databases, which have dedicated sections for Rifle Cartridges, Pistol Cartridges, and Cowboy Action.

New Reloading Data is available for these TEN cartridge types:

Story tip from EdLongrange. We welcome reader submissions.

|

A few season back, our friend Kevin Thomas acquired a bit of living history — a reproduction Model 1873 Trapdoor Springfield. Here is Kevin’s story of his new rifle and the legacy it carries.

A few season back, our friend Kevin Thomas acquired a bit of living history — a reproduction Model 1873 Trapdoor Springfield. Here is Kevin’s story of his new rifle and the legacy it carries.

In 2010, the staff of

In 2010, the staff of