|

|

December 25th, 2017

Image from HDfreewallpaper.net.

Holiday Greetings to Our Readers Holiday Greetings to Our Readers

Merry Christmas and Happy Holidays to all our readers and especially our 38,000+ Forum Members. This marks our 13th Christmas “in business”, and the site is stronger than ever thanks to our contributing Forum members and industry sponsors. AccurateShooter.com is now accessed by over 500,000 visitors every month, who enjoy our Feature Articles, Daily Bulletin, Shooters’ Forum, and our Facebook Page. Part of the reason for that success is the hard work of our hard-working staff and volunteer helpers.

Unsung Heroes Deserve Recognition

I want to acknowledge those guys who have really helped out the site. Number one is our Systems Admin, Jay Christopherson. Along with being a darn fine shooter, Jay is a computer guru who keeps the servers running smoothly and maintains our Forum. Jay has set up distributed computing and secure firewalls, making the site both speedier and more stable. We must acknowledge Boyd Allen and EdLongRange who tirelessly supply story leads for the Daily Bulletin. Thanks also go to Jeff Williams, our “Answerman” who fields miscellaneous questions from our readers. We have a great place to test rifles thanks to our valued friend (and designated trigger-puller) Joe Friedrich. Special thanks go to: Ed Mobley and Steve Lawrence of 65Guys.com; Bill, Editor of Rifleshooter.com; and Erik Cortina. These folks have worked with us on important product tests and contributed stories and videos. I also want to recognize our regular contributors, including Vince Bottomley, Jason Baney, Mark LaFevers, James Mock, and John Whidden. All these men (and many others) have all contributed much time and effort.

We also want to thank our major sponsors, without whose support the site could not provide the full AccurateShooter.com experience, with an active Forum, an archive of in-depth articles, and fresh content 365 days a year in our Daily Bulletin. We’re grateful to all our sponsors and advertisers. In particular, we want to acknowledge the major online retailers who have been strong supporters of this site for many years: Bullets.com (and Grizzly Industrial), Bruno Shooters Supply, Graf & Sons, EuroOptic, Midsouth Shooters Supply, Powder Valley Inc., and Precision Reloading. Their continuing support helps us keep up the flow of information and serve our readers and Forum members.

December 3rd, 2017

Rifleshooter.com built this tactical rifle (top image) with a Howa 1500 action, Shilen barrel, and MDT chassis. Below is a factory Howa 1500 Multi-Cam rifle.

Many of our readers are thinking of purchasing a Howa rifle or barreled action. These feature smooth-running actions with a good two-stage HACT trigger. But some folks have heard that it may be difficult to find stocks, or to fit an after-market barrel. That’s not true. There are many stock options available, and in this article, Bill of RifleShooter.com shows that it is easy to remove the factory-installed barrel with the right tools. We think a Howa makes a fine basis for a varmint rig or field rifle. Or you can build a tactical as Bill did. You can start with the factory barrel and when you want/need more accuracy, then have a gunsmith install a custom barrel from Krieger, Shilen, or other quality brand.

What You Need to Know About Howa 1500-series Rifles

Tech Feature by RifleShooter.com

Consider this article the “Howa 1500 Overview”. AccurateShooter.com’s editor mentioned there’s been a lot of interest in Howa rifles and barreled actions imported by Legacy Sports International. In addition to being able to buy a complete rifle from a dealer, Brownells sells barreled actions in a wide variety of calibers and configurations. In this post we are going to take a look at the Howa 1500 series.

Howa Rifles — General Background

Howa is a Japanese heavy machinery company. One of its product lines are firearms, which, are imported into the United States of America by two different companies, Legacy Sports International and Weatherby. Legacy sells the 1500 under the manufacturers name while Weatherby re-brands the guns as the Weatherby Vanguard. In general, the finishes on the Weatherby rifles are more refined than the LSI-imported 1500s.

General Evaluation of Howa 1500 Rifles

I’ve found Howa 1500s to be solid, entry-level rifles that are capable of sub-MOA accuracy out of the box. I’ve actually purchased two Howa rifles I’ve tested because I like them so much. The gun below, a Howa Mini-Action in 7.62×39 Russian, is one of my favorite factory guns to shoot. I’m running a Tract Optics Toric on it, these are solid little rifle scopes that offer great performance for the money.

Check out this three-shot group I drilled at 100 yards with the rifle above and 125-grain Sierras. It took a lot of work and load development to get there, but when it did, it worked well.

Howa 1500 HACT 2-Stage Trigger Howa 1500 HACT 2-Stage Trigger

Howa 1500s feature the very nice Howa HACT trigger. This is an adjustable, two-stage trigger, set for about 3 pounds (combined stages). Crisp and repeatable, this is an excellent trigger for a factory gun. There is no annoying Glock-style safety lever in the middle of the trigger blade. The 2-stage design and pull weight range works well for a hunting rifle or a rig for PRS competition. Rifleshooter.com says the Howa trigger is “one of the best factory triggers, along with Tikka. I’ve found the Howa trigger superior to a Remington 700 — the Howas doesn’t need to be replaced.

Writing for the Western Outdoor News, WONews.com, Steve Comus has field-tested the new HACT Trigger. Steve writes: “I always liked two-stage triggers, because of the way I could take-up the slack and then actually know when the rifle was going to go off. The take-up on the [HACT] trigger was fast and easy. The crisp, positive release when pressure was put on during the second stage [reminded me] of some of the target rifles I shot through the years.”

Howa Actions — Three Options

Howa offers three action lengths: Mini, Short, and Long. You can see the bolts for the three action lengths in the image below. The Mini-Action has similar external dimensions to the Remington Model Seven, however, the Mini-Action’s bolt does not travel as far to the rear. This is a mixed bag. The upside is you have a quicker action (shorter bolt throw). The downside is you are limited to shorter rounds such as the .223 Remington, 7.62×39mm Russian, and 6.5 Grendel. But if you need a bigger cartridge, just choose the standard or long action Howa variant.

Howa 1500 vs. Remington 700 — Important Differences

Is the Howa 1500 a Remington 700 clone, or some kind of improved Remington 700? No, not really. While the top radius of the Howa 1500 does match the Model 700, and they can both use the same two-piece scope bases, there area number of differences.

If you look at the Howa 1500 alongside the Remington 700 you’ll note the M700 is a round action, while the Howa is a flat-bottom action. In many ways the Howa’s bottom half reminds me of a push-feed Winchester. This means the chassis and stocks that support a Howa 1500 are not V-block based like you’ll find on a 700, instead they have a flat bottom. While the bolt of the Howa is similar in external appearance to the Model 700, it does offer some improvements, notably an M16-style extractor and a firing pin assembly that can be easily removed without tools.

Howa 1500 action screws are metric and are in a different location from the 700. The Howa 1500 has an integral recoil lug that accepts the front action screw, this means you have more of the front action screw engaging the action. WARNING: If you install it into a poorly-fitted stock or action you may bind it.

Can a Howa Action Be Used for a Custom Rifle Project?

Absolutely! You can either buy a barreled action from Brownells and throw it in a chassis system/stock of your choice or you can use a stripped action to build a custom rifle. If you are in the chassis market, MDT offers a wide variety of chassis in different price ranges. All have worked well for me.

How to Remove Howa Factory Barrel from Action

You may have heard internet grumblings about removing Howa barrels. Some keyboard commandos say they are extremely difficult to remove without a relief cut. Well Bill at Rifleshooter.com demonstrates that Howa barrels can be removed without trouble, provided you have the right tools. Watch this video:

Watch Howa Barrel Removal Video — Quick and Easy (Click Speaker Icon for Audio)

Q: Is it difficult to remove a barrel from a Howa 1500?

A: Not very. I’ve heard from some smiths that worked on Howas (years ago) that the factory barrels are difficult to remove. However of the half dozen or so Howa barrels that I’ve pulled, they’ve been very easy. I use a Brownells action wrench with the top piece for a Rem Model 700 and the flat bottom resting against the flat on the wrench.

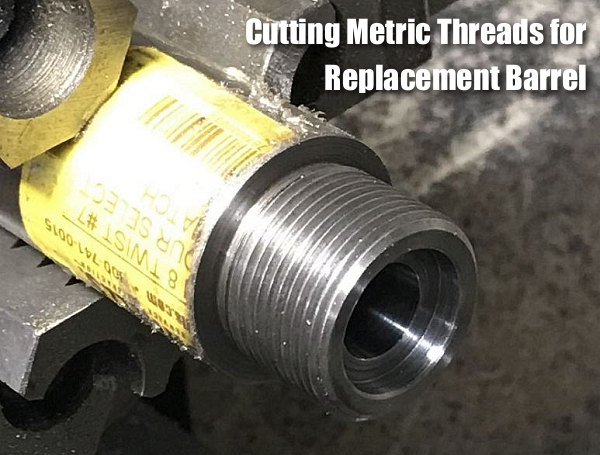

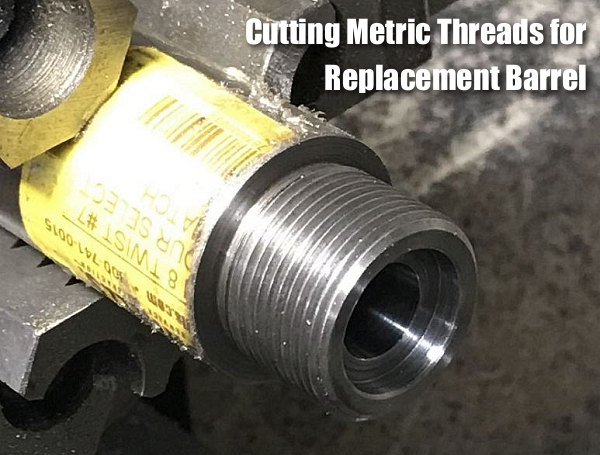

Howa Actions Require Metric Barrel Threads

It’s easy to thread a barrel for a Howa Action. You just have to cut metric threads — most lathes out there can cut them. I cut the threads below on a manual lathe using change gears. [Editor: John Whidden cuts metric tenon threads with a CNC lathe. “It’s easy,” John tells us, “No issue whatsoever.”]

Using Howa Actions for Custom Rifles

I have built a few customs with Howa actions. Below is one of my favorite, a .308 Winchester. It consists of a Howa 1500 action, Shilen Select Match Remington Varmint contour barrel, and Modular Driven Technologies (MDT) ESS chassis. Great rifle and it hammers!

To learn more about Howa rifles and actions, visit Legacy Sports International. To buy a Howa barreled action, visit Brownells.com.

To learn more about modular chassis systems for Howa rifles, visit MDTTAC.com

June 18th, 2017

RifleShooter.com built this rig with Howa 1500 barreled action and MDT ESS chassis. READ TEST HERE.

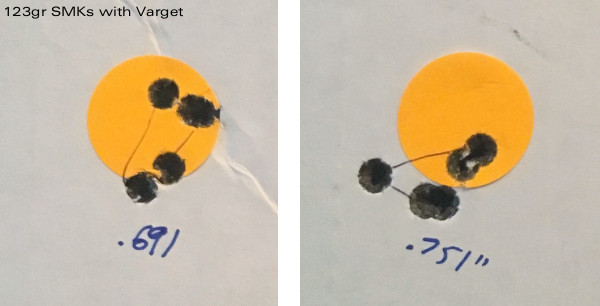

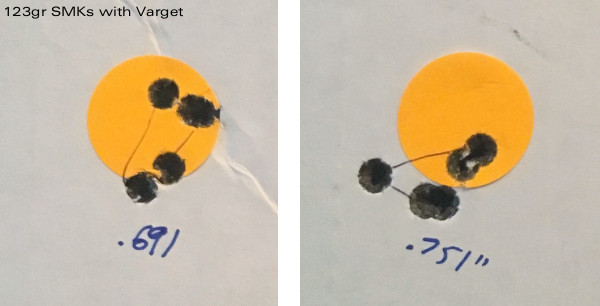

We’ve been telling folks that the Japanese Howa 1500 barreled actions are an attractive option for a hunting, varminting, or tactical rifle. Priced at under $450.00, these barreled actions include the excellent HACT two-stage trigger. These Howa 1500 actions are smooth-running (noticeably more so than some “major-brand” domestic receivers).

Our friends at RifleShooter.com recently acquired a Howa 1500 barreled action in 6.5 Creedmoor and installed it in an MDT ESS modular chassis. This project turned out well. The barreled action mated well to the ESS chassis, providing an ergonomic platform with comfortable grip, adjustable cheekpiece, and adjustable LOP. Most importantly the gun shot well. With virtually no load development, the project rifle delivered 3/4-MOA accuracy right out of the gate.

As tested with Hornady brass and Hodgdon Varget powder pushing Sierra 123gr MatchKings, the Howa 1500 MDT showed good accuracy right from the start. With more load development (and a few more rounds through the new barrel), half-MOA groups may be possible.

Brownells now sells barreled Howa actions in a variety of configurations. Rifleshooter.com acquired a Howa 1500 barreled action with a 24″ #6 contour barrel chambered in 6.5 Creedmoor. RifleShooter.com plans to test this barreled action in multiple modular chassis systems. That should provide an interesting comparison test, providing the pros and cons of various stock/chassis configurations.

RifleShooter.com’s Editor writes: “I was pleasantly surprised by the number of chassis and stock offerings for the Howa barreled action.” For this project rifle, RifleShooter.com chose the Modular Driven Technologies (MDT) Elite Sniper System (ESS) chassis, for the initial build.

Like MDT’s other chassis systems, the ESS uses any AR-15/M16 M4 pistol grip. The ESS departs from the rest of the MDT product line it does not use a standard AR-15/M16 M4 stock. Eliminating this interface allows for a design that does not increase the length of pull. The stock has an adjustable comb, adjustable length of pull, and horizontally adjustable recoil pad. Comb and LOP adjustments are accomplished with a hand wheel, plus a cap screw and clamp system.

RifleShooter.com’s Howa 6.5 Creedmoor rifle has the following components:

While the HACT 2-stage trigger is very good, RifleShooter.com’s Editor replaced the HACT with a Timney because he favors a single-stage design. The Timney adjusts lower than the HACT, allowing a crisp pull at ~1.5 pounds: “You’ll notice I swapped out the factory trigger in favor of a Timney. I’ve had great luck with their products and Timney’s Howa trigger was no exception. Adjusted to 1.5 pounds, it is a pleasure to shoot with.”

March 7th, 2017

Shooters contemplating purchase of a .338 LM rifle often ask: “What length barrel should I get?” Rifleshooter.com recently performed a test that provides interesting answers…

Our friends at RifleShooter.com like to slice and dice — barrels that is. They have done barrel length cut-down tests for popular calibers like the .223 Rem, 6.5 Creedmoor, and .308 Winchester. But now they’ve tackled something way bigger — the .338 Lapua Magnum, a true “Big Boomer”. Starting with a beefy 30″-long Pac-Nor Barrel, RifleShooter.com chopped the tube down in one-inch increments all the way down to 17 inches (that’s 14 different lengths). At each new (shorter) barrel length, velocity was measured with a MagnetoSpeed chronograph using two different loads, 250gr SMKs with H4831sc and 300gr SMKs with Retumbo. Four shots were fired at each length with each load, a total of 112 rounds.

Load #1: 250gr Sierra MK, Lapua brass, CCI #250 primer, H4831SC, OAL 3.720″.

Load #2: 300gr Sierra MK, Lapua brass, Win WLRM primer, Retumbo, OAL 3.720″.

The .338 Lapua Magnum is a jumbo-sized cartridge, that’s for sure…

Donor Barrel Sacrificed for Science

Rifleshooter.com’s Editor explains: “Brandon from Precision Addiction offered to send us his .338 barrel for our .338 Lapua Mag test. I took him up on his offer and he sent me his used Pac-Nor chrome-moly barrel with about 600 rounds though it. This thing was a beast! A heavy 1.350″ shank that ran straight for 6″, until tapering to 1″ at 30″ in length.”

Results Summary

.338 Lapua Magnum with 250gr Sierra MatchKings

After shortening the barrel from 30″ to 17″, total velocity reduction for the 250-grainers was 395 FPS, an average loss of 30.4 FPS per 1″ cut. The amount of velocity loss per inch rose as the barrel got shorter, with the biggest speed reduction, a loss of 55 FPS, coming with the cut from 18″ to 17″.

Start Velocity: 2942 FPS | End Velocity: 2547 FPS | Average Loss Per Inch: 30.4 FPS

.338 Lapua Magnum with 300gr Sierra MatchKings

Shooting the 300-grainers, total velocity reduction was 341 fps, an average of 26.2 FPS loss per 1″ cut (30″ down to 17″). However, the speed actually increased with the first cut from 30 inches to 29 inches. The tester noted: “The 300 SMK load showed a slight increase from 30″ to 29″. I’ve recorded this in other tests and it seems to be more common with a heavier load. I suspect it is primarily due to the small sample sizes being used along with the relative proximity of muzzle velocities in adjacent lengths.”

Start Velocity: 2833 FPS | End Velocity: 2492 FPS | Average Loss Per Inch: 26.2 FPS*

*Velocity rose with first cut. Velocities ranged from 2,871 FPS (29″) to 2,492 FPS (17″) for a total velocity loss of 341 FPS.

RifleShooter.com crunched the velocity numbers in some interesting ways. For example they analyzed rate of velocity loss, concluding that: “after the initial rate change, the rate of the change in velocity is fairly consistent.” (View Rate of Change Graph)

How Velocity Loss Alters Long-Range Ballistics

The testers wanted to determine how the velocity reductions “affect our ability to hit targets downrange”. So, Rifleshooter.com plotted changes in elevation and wind drift at all barrel lengths. This revealed something interesting — drift increased significantly below 26″ barrel length: “Above 26″ things look pretty good, below 22″ they change quickly.”

We highly recommend you read the whole story. Rifleshooter.com put in serious time and effort, resulting in solid, thought-provoking results. The data is presented in multiple tables and graphs, revealing inch-by-inch velocities, change “deltas”, and SDs at each length.

February 16th, 2017

6.5 Creedmoor vs. Other Mid-Sized 6.5mm Cartridges

The 6.5 Creedmoor is a very popular cartridge with the tactical and PRS crowd. This mid-size cartridge offers good ballistics, with less recoil than a .308 Winchester. There’s an excellent selection of 6.5mm bullets, and many good powder choices for this cartridge. When compared to the very accurate 6.5×47 Lapua cartridge, the 6.5 Creedmoor offers similar performance with less expensive brass options. For a tactical shooter who must sometimes leave brass on the ground, brass cost is a factor to consider. Here’s a selection of various 6.5mm mid-sized cartridges. Left to right are: 6.5 Grendel, 6.5×47 Lapua, 6.5 Creedmoor with 120gr A-Max, 6.5 Creedmoor with 142gr Sierra MK, and .260 Remington.

When asked to compare the 6.5 Creedmoor to the 6.5×47 Lapua, Rifleshooter.com’s Editor stated: “If you don’t hand load, or are new to precision rifle shooting, get a 6.5 Creedmoor. If you shoot a lot, reload, have more disposable income, and like more esoteric cartridges, get a 6.5×47 Lapua. I am a big fan of the 6.5×47 Lapua. In my personal experience, the 6.5×47 Lapua seems to be slightly more accurate than the 6.5 Creedmoor. I attribute this to the quality of Lapua brass.” But now that Lapua is producing top-quality 6.5 Creedmoor brass with small primer pockets, we could have a “second generation” 6.5 Creedmoor that rivals ANY mid-sized cartridge for efficiency AND accuracy. We will soon know how well the 6.5 Creedmoor cartridge performs with Lapua brass.

The first shipment of Lapua 6.5 Creedmoor brass has arrived in the USA. It features a small flash hole and small primer pocket. We have some for testing…

New Lapua 6.5 Creedmoor Brass Field Tests Soon

Our friends at 65Guys.com will be testing the new Lapua 6.5 Creedmoor brass next week. The goal will be to determine if Lapua’s new Small Primer Pocket/Small Flash Hole brass allows higher velocities than American-made brass (Hornady specifically). In addition the 6.5 Guys want to see how well the new Lapua brass holds up after dozen (or more) firing cycles. They’ll hammer the new brass pretty hard to see how it fares with repeated stout loads. Stay tuned…

Here are three tables from the Sierra Bullets Reloading Manual (5th Edition). IMPORTANT — This is just a sample!! Sierra has load data for many other 6.5mm bullet types, including FB, Spitzer, SBT, HPBT, and Tipped MK from 85 grains to 142 grains. To view ALL 6.5 Creedmoor DATA, CLICK HERE.

INDICATES MAXIMUM LOAD – USE CAUTION

LOADS LESS THAN MINIMUM CHARGES SHOWN ARE NOT RECOMMENDED.

INDICATES MAXIMUM LOAD – USE CAUTION

LOADS LESS THAN MINIMUM CHARGES SHOWN ARE NOT RECOMMENDED.

INDICATES MAXIMUM LOAD – USE CAUTION

LOADS LESS THAN MINIMUM CHARGES SHOWN ARE NOT RECOMMENDED.

January 1st, 2017

What do you get when you cut a 6.5 Creedmoor-chambered barrel down to just over 16 inches? A lot more velocity than you might think. Our friends at Rifleshooter.com recently did a barrel cut-down test with 6.5 Creedmoor test rifle, shortening the barrel from 27 to 16.1 inches in one-inch increments. Surprisingly, with a 142gr Sierra MK, the total velocity loss (as measured with a Magnetospeed) was just 158 FPS, an average of 14.4 FPS per inch of barrel length. With the lighter 120gr A-Max bullet, the total velocity loss was 233 FPS, or 21.8 FPS average loss per inch of barrel.

To perform this velocity test, our friend Bill, Rifleshooter.com’s editor, built up a 6.5 Creedmoor rifle using a Remington Model 7 action, 1:8″ twist Green Mountain CM barrel, and MDT LSS Chassis, all obtained from Brownells.com.

Test Procedure

Five (5) rounds of each type of cartridge were fired at each barrel length and the velocity data was recorded with a MagnetoSpeed V3 barrel-mounted chronograph. The rifle was then cleared and the barrel was cut back one inch at a time from 27″ to just over 16″. NOTE: During this winter test, the air temperature was a very chilly 23° F. One would expect higher velocities across the board had the outside temperature been higher.

The photo below shows how the barrel was cut down, inch-by-inch, using a rotary saw. The barrel was pre-scored at inch intervals. As the main purpose of the test was to measure velocity (not accuracy) the testers did not attempt to create perfect crowns.

6.5 Creedmoor vs. Other Mid-Sized 6.5mm Cartridges

The 6.5 Creedmoor is a very popular cartridge with the tactical and PRS crowd. This mid-size cartridge offers good ballistics, with less recoil than a .308 Winchester. There’s an excellent selection of 6.5mm bullets, and many powder choices for this cartridge. When compared to the very accurate 6.5×47 Lapua cartridge, the 6.5 Creedmoor offers similar performance with less expensive brass. For a tactical shooter who must sometimes leave brass on the ground, brass cost is a factor to consider. Here’s a selection of various 6.5 mm mid-sized cartridges. Left to right are: 6.5 Grendel, 6.5×47 Lapua, 6.5 Creedmoor with 120gr A-Max, 6.5 Creedmoor with 142gr Sierra MK, and .260 Remington.

When asked to compare the 6.5 Creedmoor to the 6.5×47 Lapua, Rifleshooter.com’s editor stated: “If you don’t hand load, or are new to precision rifle shooting, get a 6.5 Creedmoor. If you shoot a lot, reload, have more disposable income, and like more esoteric cartridges, get a 6.5×47 Lapua. I am a big fan of the 6.5×47 Lapua. In my personal experience, the 6.5×47 Lapua seems to be slightly more accurate than the 6.5 Creedmoor. I attribute this to the quality of Lapua brass.”

November 15th, 2016

Our friend Bill at Rifleshooter.com got his hands on some of Sierra’s brand new .30-Cal match bullets, the 195-grain Tipped Match Kings (TMKs). These feature an impressive 0.610 G1 BC above 2000 fps. We predict these new bullets will be popular with F-TR shooters shooting the .308 Winchester cartridge.

To see how the new 195gr TMKs perform, Bill loaded up some .308 Win ammo with IMR 4064, ranging from 40.5 grains up to 42.5 grains. That gave him a velocity range of 2438 FPS at the lowest charge weight, up to 2552 FPS at 42.5 grains. This was with a relatively short, 22-inch barrel. Best five-shot accuracy (and second lowest SD) was at 41.0 grains even, producing a 0.498 MOA five-shot group at 2480 fps (6.1 SD). CLICK HERE for full accuracy results.

I headed to the range on a brisk November day. Targets were 2″ orange dots at 100 yards. All shooting was done prone from a bipod with a rear bag. The Nightforce 3.5-15X scope was set at 15X. All ballistic information was recorded with a MagnetoSpeed barrel-mounted chronograph. Temperature was 54° F. Standard deviation for the loads ranged from 5.3 to 20.5 FPS. Average standard deviation was 12.5 FPS. Five-shot group sizes ranged from .521″ (.498 MOA, ) to 1.057″ (1.010 MOA). Average group size for all ten loads was .692″ (.661 MOA).

New 195gr TMK offers Impressive Long-Range Ballistics

Bill was also interested in how the ballistics of the new 195gr TMKs compared to other .30-cal projectiles. Even with a moderate, 2539 fps velocity, the new 195gr TMK showed less wind drift than other Sierras, thanks to its high 0.610 G1 BC. It also had a flatter trajectory beyond 600 yards than the 175gr and 190gr Sierra MatchKings. (The faster-flying 175gr TMK had slightly less drop at all yardages.)

Bill explains: “For comparison purposes, I selected the 42.0 grain load, with a muzzle velocity of 2,539 feet/second and an SD of 6.9. This load is compared to loads for the 190 SMK, 175 SMK, 175 TMK, and 168 Federal Gold Medal ammunition in the test rifle. In other words, these aren’t maximum loads, but loads that I have developed and would feel comfortable shooting a match with in the rifle shown (you may note the 190 SMK is fairly slow, but this is what the rifle liked). Also note that this rifle has a relatively short 22″ barrel compared to those you might find on a purpose built f-class rifle.”

Bill provides a full write-up on the Rifleshooter.com website complete with target photos and load details. If you are interested in these new 195-grainers, you should read the full report.

May 29th, 2016

We often receive questions from varmint hunters and AR shooters regarding barrel length. They want to know how much velocity they will loose if they run a shorter barrel in their .223-Rem rifle. Our friends at Rifleshooter.com did a test that provides some surprising answers to that question.

With barrels, one always wonders “Can a little more length provide a meaningful velocity gain?” To help answer that question, Rifleshooter.com performed an interesting test, cutting the barrel of a .223 Rem rifle from 26″ all the way down to 16.5″. The cuts were made in one-inch intervals with a rotary saw. At each cut length, velocity was measured with a Magnetospeed chronograph. To make the test even more interesting, four different types of .223 Rem/5.56 ammo were chron’d at each barrel length.

READ RifleShooter.com 5.56/.223 Barrel Cut-Down Test Article.

Test Barrel Lost 25.34 FPS Per Inch (.223 Rem Chambering)

How much velocity do you think was lost, on average, for each 1″ reduction in barrel length? The answer may surprise you. The average speed loss of the four types of .223/5.56 ammo, with a 9.5″ shortening of barrel length, was 240.75 fps total (from start to finish). That works out to an average loss of 25.34 fps per inch. (See inch-by-inch data HERE.)

| 5.56/.223 Barrel Cut-Down Speed Test 26″ to 16.5″ |

Start FPS at 26″ |

End FPS at 16.5″ |

Total Loss |

Average Loss Per Inch |

| UMC .223 55gr |

3182* |

2968 |

214 |

22.5 FPS |

| Federal M193 55gr |

3431 |

3187 |

244 |

25.7 FPS |

| Win m855 62gr |

3280 |

2992 |

288 |

30.3 FPS |

| Blk Hills .223 68gr |

2849 |

2632 |

217 |

22.8 FPS |

*There may have been an error. The 25″ velocity was higher at 3221 fps.

Rifleshooter.com observed: “Cutting the barrel from 26″ to 16.5″ resulted in a velocity reduction of 214 ft/sec with the UMC 223 55-grain cartridge, 244 ft/sec with the Federal M-193 cartridge, 288 ft/sec with the Winchester M855 cartridge and 217 ft/sec with the Back Hills 223 68-grain match cartridge.”

How the Test Was Done

The testers described their procedure as follows: “Ballistic data was gathered using a Magnetospeed barrel-mounted ballistic chronograph. At each barrel length, the rifle was fired from a front rest with rear bags, with five rounds of each type of ammunition. Average velocity and standard deviation were logged for each round. Once data was gathered for each cartridge at a given barrel length, the rifle was cleared and the bolt was removed. The barrel was cut off using a cold saw. The test protocol was repeated for the next length. Temperature was 45.7° F.”

CLICK HERE to Read the Rifleshooter.com Test. This includes detailed charts with inch-by-inch velocity numbers.

Much Different Results with 6mmBR and a Longer Barrel

The results from Rifleshooter.com’s .223/5.56 test are quite different than the results we recorded some years ago with a barrel chambered for the 6mmBR cartridge. When we cut our 6mmBR barrel down from 33″ to 28″ we only lost about 8 FPS per inch. Obviously this is a different cartridge type, but also our 6mmBR barrel end length was longer than Rifleshooter.com’s .223 Rem start length. Velocity loss may be more extreme with shorter barrel lengths.

April 24th, 2016

With barrels, one wonders “Can a little more length provide a meaningful velocity gain?” To answer that question, Rifleshooter.com performed an interesting test, cutting a .308 Win barrel from 28″ all the way down to 16.5″. The cuts were made in one-inch intervals with a rotary saw. At each cut length, velocity was measured with a Magnetospeed chronograph. To make the test even more interesting, four different types of .308 Win factory ammunition were chronographed at each barrel length.

READ RifleShooter.com .308 Win Barrel Cut-Down Test Article.

Test Barrel Lost 22.7 FPS Per Inch (.308 Win Chambering)

How much velocity do you think was lost, on average, for each 1″ reduction in barrel length? The answer may surprise you. With a barrel reduction from 28″ to 16.5″, the average speed loss of the four types of .308 ammo was 261 fps total. That works out to an average loss of 22.7 fps per inch. This chart shows velocity changes for all four ammo varieties:

Summary of Findings: The average velocity loss per inch, for all four ammo types combined, was 22.7 FPS. By ammo type, the average loss per inch was: 24.6 (Win 147 FMJ), 22.8 (IMI 150 FMJ), 20.9 (Fed GMM 168gr), and 22.5 (Win 180PP).

Interestingly, these numbers jive pretty well with estimates found in reloading manuals. The testers observed: “The Berger Reloading manual says for the 308 Winchester, ‘muzzle velocity will increase (or decrease) by approximately 20 fps per inch from a standard 24″ barrel’.”

How the Test Was Done

The testers described their procedure as follows: “Ballistic data was gathered using a Magnetospeed barrel mounted ballistic chronograph. At each barrel length, the rifle was fired from a front rest with rear bags, with five rounds of each type of ammunition. Average velocity and standard deviation were logged for each round. Since we would be gathering data on 52 different barrel length and ammunition combinations and would not be crowning the barrel after each cut, we decided to eliminate gathering data on group sizes. Once data was gathered for each cartridge at a given barrel length, the rifle was cleared and the bolt was removed. The barrel was cut off using a cold saw. The test protocol was repeated for the next length. Temperature was 47° F.”

CLICK HERE to Read the Rifleshooter.com Test. This includes detailed charts with inch-by-inch velocity numbers, multiple line charts, and complete data sets for each type of ammo. Rifleshooter.com also offers ballistics graphs showing trajectories with different barrel lengths. All in all, this was a very thorough test by the folks at RifleShooter.com.

Much Different Results with 6mmBR and a Longer Barrel

The results from Rifleshooter.com’s .308 barrel cut-down test are quite different than the results we recorded some years ago with a barrel chambered for the 6mmBR cartridge. When we cut our 6mmBR barrel down from 33″ to 28″, we only lost about 8 FPS per inch. Obviously this is a different cartridge type, but also our 6mmBR barrel end length was 5″ longer than Rifleshooter.com’s .308 Win start length. Velocity loss can be more extreme with shorter barrel lengths (and bigger cartridges). Powder burn rates can also make a difference.

March 28th, 2016

What do you get when you cut a 6.5 Creedmoor-chambered barrel down to just over 16 inches? A lot more velocity than you might think. Our friends at Rifleshooter.com recently did a barrel cut-down test with 6.5 Creedmoor test rifle, shortening the barrel from 27 to 16.1 inches in one-inch increments. Surprisingly, with a 142gr Sierra MK, the total velocity loss (as measured with a Magnetospeed) was just 158 FPS, an average of 14.4 FPS per inch of barrel length. With the lighter 120gr A-Max bullet, the total velocity loss was 233 FPS, or 21.8 FPS average loss per inch of barrel.

To perform this velocity test, our friend Bill, Rifleshooter.com’s editor, built up a 6.5 Creedmoor rifle using a Remington Model 7 action, 1:8″ twist Green Mountain CM barrel, and MDT LSS Chassis, all obtained from Brownells.com.

Test Procedure

Five (5) rounds of each type of cartridge were fired at each barrel length and the velocity data was recorded with a MagnetoSpeed V3 barrel-mounted chronograph. The rifle was then cleared and the barrel was cut back one inch at a time from 27″ to just over 16″. NOTE: During this winter test, the air temperature was a very chilly 23° F. One would expect higher velocities across the board had the outside temperature been higher.

The photo below shows how the barrel was cut down, inch-by-inch, using a rotary saw. The barrel was pre-scored at inch intervals. As the main purpose of the test was to measure velocity (not accuracy) the testers did not attempt to create perfect crowns.

6.5 Creedmoor vs. Other Mid-Sized 6.5mm Cartridges

The 6.5 Creedmoor is a very popular cartridge with the tactical and PRS crowd. This mid-size cartridge offers good ballistics, with less recoil than a .308 Winchester. There’s an excellent selection of 6.5mm bullets, and many powder choices for this cartridge. When compared to the very accurate 6.5×47 Lapua cartridge, the 6.5 Creedmoor offers similar performance with less expensive brass. For a tactical shooter who must sometimes leave brass on the ground, brass cost is a factor to consider. Here’s a selection of various 6.5 mm mid-sized cartridges. Left to right are: 6.5 Grendel, 6.5×47 Lapua, 6.5 Creedmoor with 120gr A-Max, 6.5 Creedmoor with 142gr Sierra MK, and .260 Remington.

When asked to compare the 6.5 Creedmoor to the 6.5×47 Lapua, Rifleshooter.com’s editor stated: “If you don’t hand load, or are new to precision rifle shooting, get a 6.5 Creedmoor. If you shoot a lot, reload, have more disposable income, and like more esoteric cartridges, get a 6.5×47 Lapua. I am a big fan of the 6.5×47 Lapua. In my personal experience, the 6.5×47 Lapua seems to be slightly more accurate than the 6.5 Creedmoor. I attribute this to the quality of Lapua brass.”

|

Holiday Greetings to Our Readers

Holiday Greetings to Our Readers

Howa 1500 HACT 2-Stage Trigger

Howa 1500 HACT 2-Stage Trigger