|

|

August 15th, 2023

Efficient cartridges make excellent use of their available powder and case/bore capacity. They yield good ballistic performance with relatively little recoil and throat erosion.

Cartridge Efficiency: A Primer (pun intended!) by USAMU Staff

The U.S. Army Marksmanship Unit (USAMU) published a series of reloading articles on its Facebook Page. In this article, the USAMU discusses cartridge case efficiency and its benefits. While this is oriented primarily toward NRA High Power Rifle and Long Range (1000-yard) competition, these factors also apply to medium/big game hunters. Assuming one’s rifle and ammunition are accurate, key considerations include ballistic performance (i.e., resistance to wind effects, plus trajectory), recoil, and throat erosion/barrel life.

Efficient cartridges make excellent use of their available powder and case/bore capacity. They yield good ballistic performance with relatively little recoil and throat erosion. A classic example in the author’s experience involved a featherweight 7x57mm hunting/silhouette rifle. When loaded to modern-rifle pressures, just 43-44 grains of powder pushed a 139gr bullet at 2900 fps from its 22” barrel. Recoil in this light rifle was mild; it was very easy to shoot well, and its performance was superb.

An acquaintance chose a “do everything” 7mm Remington Magnum for use on medium game at short ranges. A larger, heavier rifle, it used ~65 grains of powder to achieve ~3200 fps with similar bullets — from its 26″ barrel. Recoil was higher, and he was sensitive to it, which hampered his shooting ability.

Similarly efficient calibers include the 6mm BR [Norma], and others. Today’s highly-efficient calibers, such as 6mm BR and a host of newer developments might use 28-30 grains of powder to launch a 105-107gr match bullet at speeds approaching the .243 Winchester. The .243 Win needs 40-45 grain charges at the same velocity.

Champion-level Long Range shooters need every ballistic edge feasible. They compete at a level where 1″ more or less drift in a wind change could make the difference between winning and losing. Shooters recognized this early on — the then-new .300 H&H Magnum quickly supplanted the .30-06 at the Wimbledon winner’s circle in the early days.

The .300 Winchester Magnum became popular, but its 190-220gr bullets had their work cut out for them once the 6.5-284 and its streamlined 140-142gr bullets arrived on the scene. The 6.5-284 gives superb accuracy and wind performance with about half the recoil of the big .30 magnums – albeit it is a known barrel-burner.

Currently, the 7mm Remington Short Action Ultra-Magnum (aka 7mm RSAUM), is giving stellar accuracy with cutting-edge, ~180 grain bullets, powder charges in the mid-50 grain range and velocities about 2800+ fps in long barrels. Beyond pure efficiency, the RSAUM’s modern, “short and fat” design helps ensure fine accuracy relative to older, longer cartridge designs of similar performance.

Recent design advances are yielding bullets with here-to-fore unheard-of ballistic efficiency; depending on the cartridge, they can make or break ones decision. Ballistic coefficients (“BC” — a numerical expression of a bullet’s ballistic efficiency) are soaring to new heights, and there are many exciting new avenues to explore.

The ideal choice [involves a] balancing act between bullet BCs, case capacity, velocity, barrel life, and recoil. But, as with new-car decisions, choosing can be half the fun!

Factors to Consider When Evaluating Cartridges

For competitive shooters… pristine accuracy and ballistic performance in the wind are critical. Flat trajectory benefits the hunter who may shoot at long, unknown distances (nowadays, range-finders help). However, this is of much less importance to competitors firing at known distances.

Recoil is an issue, particularly when one fires long strings during competition, and/or multiple strings in a day. Its effects are cumulative; cartridges with medium/heavy recoil can lead to shooter fatigue, disturbance of the shooting position and lower scores.

For hunters, who may only fire a few shots a year, recoil that does not induce flinching during sight-in, practice and hunting is a deciding factor. Depending on their game and ranges, etc., they may accept more recoil than the high-volume High Power or Long Range competitor.

Likewise, throat erosion/barrel life is important to competitive shooters, who fire thousands of rounds in practice and matches, vs. the medium/big game hunter. A cartridge that performs well ballistically with great accuracy, has long barrel life and low recoil is the competitive shooter’s ideal. For the hunter, other factors may weigh more heavily.

Cartridge Efficiency and Energy — Another Perspective

Former Lapua staffer Kevin Thomas explains that efficiency can be evaluated in terms of energy:

“Cartridge efficiency is pretty straight forward — energy in vs. energy out. Most modern single-based propellants run around 178-215 ft/lbs of energy per grain. These figures give the energy potential that you’re loading into the rifle. The resulting kinetic energy transferred to the bullet will give you the efficiency of the round. Most cases operate at around 20-25% efficiency. This is just another way to evaluate the potential of a given cartridge. There’s a big difference between this and simply looking at max velocities produced by various cartridges.”

Share the post "Cartridge Efficiency — Factors to Consider"

December 13th, 2021

The NRA Blog has produced an interesting graphic guide to firearms function. This “How Guns Work” infographic shows the basics of bolt-action rifle operation and how a centerfire cartridge propels a bullet through a barrel during the “firing sequence”. There’s some good artistry here, with cutaway drawings letting you look inside an action and cartridge.

Enjoy this technical graphic. The NRA Blog says: “In celebration of cartridges big and small, we partnered with OutdoorHub to bring you a detailed look into how guns work. While the infographic will be most instructive to newcomers, we think avid shooters will find it interesting, too.”

Share the post "How Guns Work — Cartridge “Anatomy” and Firing Sequence"

September 28th, 2018

What is “Overbore”? That’s a question rifle shooters can debate to no end. This article from our archives proposes one way to identify “overbore cartridges”. We think the approach outlined here is quite useful, but we know that there are other ways to define cartridges with “overbore” properties. Whenever we run this article, it stimulates a healthy debate among our readers — and that is probably a good thing.

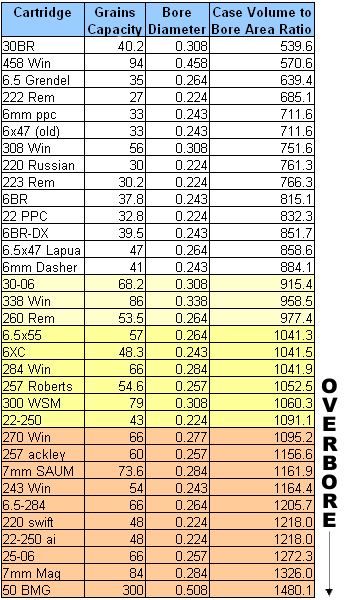

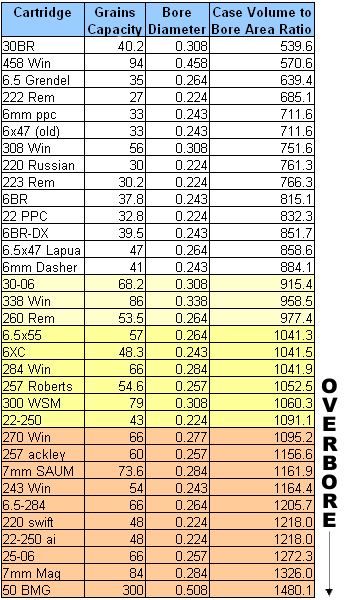

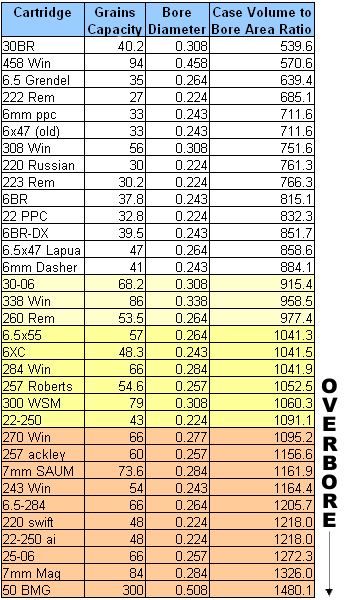

Forum Member John L. has been intrigued by the question of “overbore” cartridges. People generally agree that overbore designs can be “barrel burners”, but is there a way to predict barrel life based on how radically a case is “overbore”? John notes that there is no generally accepted definition of “overbore”. Based on analyses of a wide variety of cartridges, John hoped to create a comparative index to determine whether a cartridge is more or less “overbore”. This, in turn, might help us predict barrel life and maybe even predict the cartridge’s accuracy potential.

John tells us: “I have read countless discussions about overbore cartridges for years. There seemed to be some widely accepted, general rules of thumb as to what makes a case ‘overbore’. In the simplest terms, a very big case pushing a relatively small diameter bullet is acknowledged as the classic overbore design. But it’s not just large powder capacity that creates an overbore situation — it is the relationship between powder capacity and barrel bore diameter. Looking at those two factors, we can express the ‘Overbore Index’ as a mathematical formula — the case capacity in grains of water divided by the area (in square inches) of the bore cross-section. This gives us an Index which lets us compare various cartridge designs.”

OVERBORE INDEX Chart

So what do these numbers mean? John says: “My own conclusion from much reading and analysis is that cartridges with case volume to bore area ratio less than 900 are most likely easy on barrels and those greater than 1000 are hard on barrels.” John acknowledges, however, that these numbers are just for comparison purposes. One can’t simply use the Index number, by itself, to predict barrel life. For example, one cannot conclude that a 600 Index number cartridge will necessarily give twice the barrel life of a 1200 Index cartridge. However, John says, a lower index number “seems to be a good predictor of barrel life”.

John’s system, while not perfect, does give us a benchmark to compare various cartridge designs. If, for example, you’re trying to decide between a 6.5-284 and a 260 Remington, it makes sense to compare the “Overbore Index” number for both cartridges. Then, of course, you have to consider other factors such as powder type, pressure, velocity, bullet weight, and barrel hardness.

Overbore Cases and Accuracy

Barrel life may not be the only thing predicted by the ratio of powder capacity to bore cross-section area. John thinks that if we look at our most accurate cartridges, such as the 6 PPC, and 30 BR, there’s some indication that lower Index numbers are associated with greater inherent accuracy. This is only a theory. John notes: “While I do not have the facilities to validate the hypothesis that the case capacity to bore area ratio is a good predictor of accuracy — along with other well-known factors — it seems to be one important factor.”

Share the post "“Overbore” — A Practical Definition by the Numbers"

November 12th, 2017

Repeated firings at stout pressures can cause primer pockets to grow in diameter. This can create an unsafe condition if your primers are not seating properly. Are your primer pockets “good to go”, or have they been pushed to the point of no return? Do you really know? Many guys try to gauge primer pocket tightness by “feel”, as they seat the primer. But that method isn’t precise. Now there’s a better way…

The folks at Ballistictools.com have created a handy set of precision-machined gauges that let you quickly and accurately check your primer pockets. These gauges are offered in two sizes — for large and small primer pockets. A two-piece set of both large and small gauges costs just $19.99. These gauges let you quickly measure the depth of a primer pocket, and check if the crimp has been removed properly. Most importantly, the gauge tells you if the primer pocket has opened up too much. One side of the gauge has an enlarged diameter plug. If that “No-Go” side fits in the primer pocket, you should ditch the case — it’s toast. The folks at Ballistictools.com have created a handy set of precision-machined gauges that let you quickly and accurately check your primer pockets. These gauges are offered in two sizes — for large and small primer pockets. A two-piece set of both large and small gauges costs just $19.99. These gauges let you quickly measure the depth of a primer pocket, and check if the crimp has been removed properly. Most importantly, the gauge tells you if the primer pocket has opened up too much. One side of the gauge has an enlarged diameter plug. If that “No-Go” side fits in the primer pocket, you should ditch the case — it’s toast.

CLICK HERE to order Primer Pocket Gauge Set from Ballistictools.com.

Precision ground from O-1 tool steel, these primer pocket gauges serve multiple functions. The inventor of these tools explains:

I created the prototype of this tool for my own use in brass processing. I needed a way to quickly and easily measure primer pockets that was reliable and did not require wasting a primer. This tool has been indispensable for me and I would never go back to the old method of uncertainty and guessing.

One side of this gauge is the “go” side which quickly tells you the depth of a primer pocket, whether any crimp is properly removed, and whether the primer pocket is loose. If it feels loose on the “go” side, use the other end of the tool, the “no go” side, to test to see if the primer pocket is too loose to hold a primer. If the no-go slides into the pocket, then you know to junk that brass.

Product tip from Boyd Allen. We welcome reader submissions.

Share the post "Primer Pocket Gauge — Cool Tool Checks for Loose Pockets"

November 10th, 2017

Ever wondered what pistol, rifle, and shotgun ammo really looks like on the inside? Well, thanks to two clever friends, you can NOW see exactly what’s on the inside. Bernard Martinage and David Swanson, fellow NRA-certified firearms instructors, have created a new kind of training tool — cutaway ammo samples. The two men call their line of cutaways, AmVIEWnition. The sliced cartridges and shotshells are employed as visual/tactile training aids. These cutaways help new shooters understand ammo components and how cartridges and shotshells are engineered.

Bernard Martinage (L) and David Swanson (R) are the inventors of AmVIEWnition products — cutaway ammo samples for training.

Bernard told the NRA Blog: “In order to make teaching easier and increase trainee comprehension, I simply decided to cut bullets lengthwise and show them [students] what’s inside. It certainly sped up their understanding and it was cool to look at! I always liked inventing and creating things that solved problems or made life easier. So, doing it with firearm training was no different.” To learn more about the history of AmVIEWnition, read the NRA Blog’s Interview with Bernard Martinage.

Bernard and David also produce Barrel Cutaways and “Solo-Blast” 3-D Ballistics Models of projectile wound channels. Visit www.AmVIEWnition.com to see these products as well as the full line of pistol, rifle, and shotgun AmVIEWnition cutaways.

Share the post "Cutaway Ammo Samples for Training — AmVIEWnition"

November 7th, 2017

Click to View Large Size Poster.

Need something for the walls of your “man cave” or reloading room? The creators of the Cartridge Comparison Guide offer a nice poster showing 85 classic varmint and hunting cartridges. Along with cartridges (from 17 Mach2 all the way up to the 517 Nitro Express), this full-color 18″ x 24″ wall poster shows dozens of game animal types, including all the great African species. This unique Game & Ammo Hunting Poster opens reveals the range and breadth of game animals that can be hunted on the world stage, while providing a comprehensive sampling of proven cartridges for hunting these animals. Priced at $14.99, this poster was developed in cooperation with Hunter Education instructors.

In addition to the Game & Ammo Poster, ChamberIt.com offers 15 other large wall posters that display a variety of cartridge types. For example, the Rifleman’s Classic Poster, a full 38 inches wide and 27 inches tall, is the most comprehensive. This $15.99 poster displays 272 rifle cartridge types at true size (within 4/1000 of an inch). Cartridges shown range from .17 caliber all the way up to the big boomers (including some cannon shells). The Rifleman’s Classic Poster includes all American Standardized Rifle Cartridges (as of 2013) and many European rifle cartridges.

Rifleman’s Classic Poster

Click to view large size poster.

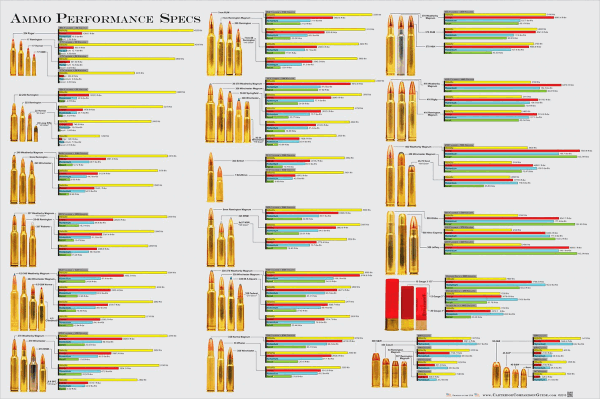

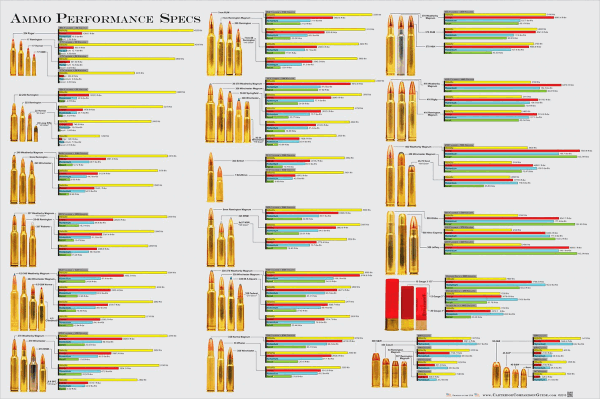

Ammunition Performance Specifications Poster

There is also an interesting Ammo Performance Specs poster. This shows dozens of popular hunting cartridges with the velocity, energy, momentum and recoil for each cartridge displayed in a bar graph.

This shows the actual size of the Ammo Performance Poster as displayed on a wall.

Share the post "Wall Poster Illustrates Hunting Cartridges and Game Species"

April 5th, 2017

Can you form a wildcat cartridge such as the 6 Dasher without expending primer, powders, and bullets? Absolutely. Using the hydro-forming method you can form improved cases in your workshop with no firing whatsoever, so there is no wear on your precious barrel. Watch this video to see how it’s done:

6 Dasher Case Hydro-Forming Demonstration:

Forum member Wes J. (aka P1ZombieKiller) has produced a helpful video showing how to form Dasher cases use the Hornady Hydraulic forming die kit. This includes a two-part die (body and piston), and a special shell holder. To form the case, you insert a primer in your virgin brass, top the case off with with a fluid (water or alcohol), then run the case up into the Hydro-forming die. A few stout whacks with a hammer and your case is 95% formed.

Hydro-Forming Procedure Step-by-Step: Hydro-Forming Procedure Step-by-Step:

1. Insert spent primer in new 6mmBR brass case.

2. Fill with water or alcohol (Wes prefers alcohol).

3. Wipe excess fluid off case.

4. Place case in special Hornady shell-holder (no primer hole).

5. Run case up into Hydraulic forming die.

6. Smack top piston of forming die 3-4 times with rubber mallet or dead-blow hammer.

7. Inspect case, re-fill and repeat if necessary.

8. Drain alcohol (or water) into container.

9. Remove primer (and save for re-use).

10. Blow-dry formed case. Inspect and measure formed case.

Wes achieves very uniform cartridge OALs with this method. He measured ten (10) hydro-formed 6 Dasher cases and got these results: two @ 1.536″; 2 @ 1.537″; and 6 @ 1.538″.

Three or Four Whacks Produces a 95%-Formed Case

With a Hornady hydro-forming die, hydraulic pressure does the job of blowing out the shoulders of your improved case. The process is relatively simple. Place a spent primer in the bottom of a new piece of brass. Fill the case with water, and then slip it into a special Hornady shell-holder with no hole in the middle. Then you run the case up into the forming die. Now comes the fun part. You gently insert a plunger (hydraulic ram) from the top, and give it three or four stiff whacks with a mallet (or better yet, a dead-blow hammer). Remove the plunger and you have a 95% formed case, ready to load.

Hornady supplies a shell holder made specifically for the hydro die; there’s no hole in the bottom of it. Just insert a spent primer into the primer pocket and you’re ready to go. The spent primer combined with the solid shell holder, keeps the water from seeping out of the primer pocket. The primer pushes out a little bit during this process, but it’s impossible for it to come out because of the way the shell holder is designed. The shell holder has a grove which allows the case to slide out of the shell holder even when the primer protrudes a bit. Hornady supplies a shell holder made specifically for the hydro die; there’s no hole in the bottom of it. Just insert a spent primer into the primer pocket and you’re ready to go. The spent primer combined with the solid shell holder, keeps the water from seeping out of the primer pocket. The primer pushes out a little bit during this process, but it’s impossible for it to come out because of the way the shell holder is designed. The shell holder has a grove which allows the case to slide out of the shell holder even when the primer protrudes a bit.

Story tip from Boyd Allen. We welcome reader submissions.

Share the post "TECH Tip: Video Shows How to Hydro-Form Cartridge Brass"

December 31st, 2016

The NRA Blog has produced an interesting graphic guide to firearms function. This “How Guns Work” infographic shows the basics of bolt-action rifle operation and how a centerfire cartridge propels a bullet through a barrel during the “firing sequence”. There’s some good artistry here, with cutaway drawings letting you look inside an action and cartridge.

Enjoy this technical graphic. The NRA Blog says: “In celebration of cartridges big and small, we partnered with OutdoorHub to bring you a detailed look into how guns work. While the infographic will be most instructive to newcomers, we think avid shooters will find it interesting, too.”

Share the post "How Guns Work — An Inside Look"

November 4th, 2016

Deep-Draw Ram Illustration from Demsey Mfg.

When we first ran this story a while back, it generated great interest among readers. By popular request, we’re reprinting this story, in case you missed it the first time around. — Editor

Precision shooters favor premium brass from Lapua, Norma, or RWS. (Lake City also makes quality brass in military calibers.) Premium brass delivers better accuracy, more consistent velocities, and longer life. Shooters understand the importance of good brass, but many of us have no idea how cartridge cases are actually made. Here’s how it’s done. Precision shooters favor premium brass from Lapua, Norma, or RWS. (Lake City also makes quality brass in military calibers.) Premium brass delivers better accuracy, more consistent velocities, and longer life. Shooters understand the importance of good brass, but many of us have no idea how cartridge cases are actually made. Here’s how it’s done.

The process starts with a brass disk stamped from strips of metal. Then, through a series of stages, the brass is extruded or drawn into a cylindrical shape. In the extrusion process the brass is squeezed through a die under tremendous pressure. This is repeated two or three times typically. In the more traditional “draw” process, the case is progressively stretched longer, in 3 to 5 stages, using a series of high-pressure rams forcing the brass into a form die. While extrusion may be more common today, RWS, which makes some of the most uniform brass in the world, still uses the draw process: “It starts with cup drawing after the bands have been punched out. RWS cases are drawn in three ‘stages’ and after each draw they are annealed, pickled, rinsed and subjected to further quality improvement measures. This achieves specific hardening of the brass cases and increases their resistance to extraordinary stresses.” FYI, Lapua also uses a traditional draw process to manufacture most of its cartridge brass (although Lapua employs some proprietary steps that are different from RWS’s methods).

After the cases are extruded or drawn to max length, the cases are trimmed and the neck/shoulder are formed. Then the extractor groove (on rimless cases) is formed or machined, and the primer pocket is created in the base. One way to form the primer pocket is to use a hardened steel plug called a “bunter”. In the photos below you see the stages for forming a 20mm cannon case (courtesy OldAmmo.com), along with bunters used for Lake City rifle brass. This illustrates the draw process (as opposed to extrusion). The process of draw-forming rifle brass is that same as for this 20mm shell, just on a smaller scale.

River Valley Ordnance explains: “When a case is being made, it is drawn to its final draw length, with the diameter being slightly smaller than needed. At this point in its life, the head of the draw is slightly rounded, and there are no provisions for a primer. So the final drawn cases are trimmed to length, then run into the head bunter. A punch, ground to the intended contours for the inside of the case, pushes the draw into a cylindrical die and holds it in place while another punch rams into the case from the other end, mashing the bottom flat. That secondary ram holds the headstamp bunter punch.

The headstamp bunter punch has a protrusion on the end to make the primer pocket, and has raised lettering around the face to form the headstamp writing. This is, of course, all a mirror image of the finished case head. Small cases, such as 5.56×45, can be headed with a single strike. Larger cases, like 7.62×51 and 50 BMG, need to be struck once to form a dent for the primer pocket, then a second strike to finish the pocket, flatten the head, and imprint the writing. This second strike works the brass to harden it so it will support the pressure of firing.”

Thanks to Guy Hildebrand, of the Cartridge Collectors’ Exchange, OldAmmo.com, for providing this 20mm Draw Set photo. Bunter photo from River Valley Ordnance.

Share the post "Mysteries Revealed — How Cartridge Brass is Made"

August 1st, 2016

What happens inside a rifle chamber and barrel when a cartridge fires can’t be seen by the naked eye (unless you are a Super-Hero with X-Ray vision). But now, with the help of 3D-style computer animation, you can see every stage in the process of a rifle round being fired.

In this amazing video, X-Ray-style 3D animation illustrates the primer igniting, the propellant burning, and the bullet moving through the barrel. The video then shows how the bullet spins as it flies along its trajectory. Finally, this animation shows the bullet impacting ballistic gelatin. Watch the bullet mushroom and deform as it creates a “wound channel” in the gelatin. This excellent video was commissioned by Czech ammo-maker Sellier & Bellot to demonstrate its hunting ammunition. The design, 3D rendering, and animation was done by Grafické studio VLADO.

Watch Video – Cartridge Ignition Sequence Starts at 1:45 Time-Mark

Video find by Seb Lambang. We welcome reader submissions.

Share the post "How Rifle Ammunition Works — Amazing CGI Animation"

May 19th, 2016

Hodgdon Powder Company (Hodgdon) offers a series of professionally produced how-to videos on its popular Reloading Data Center. These 3.5-minute videos present rifle, pistol, and shotshell reloading basics in an easy-to-understand,step-by-step format. These mobile-friendly, informative videos can also be viewed on a smart phone or tablet. Hodgdon Powder Company (Hodgdon) offers a series of professionally produced how-to videos on its popular Reloading Data Center. These 3.5-minute videos present rifle, pistol, and shotshell reloading basics in an easy-to-understand,step-by-step format. These mobile-friendly, informative videos can also be viewed on a smart phone or tablet.

To watch the reloading videos go to the Reloading Data Center at hodgdon.com. Click to the right/left of the displayed video to switch between pistol, rifle, and shotgun videos. Or, for your convenience, we have embedded the Rifle and Pistol videos here. Just click to watch!

Click to Watch Hodgdon Rifle Reloading Video:

Click to Watch Hodgdon Pistol Reloading Video:

In addition to these videos, Hodgdon’s Reloading Data Center (RDC) provides a wealth of information on Hodgdon®, IMR®, and Winchester® propellants. Along with reliable load data, you’ll find explanations of reloading basics, safety procedures, plus answers to frequently asked questions (FAQ).

Share the post "Hodgdon Goes Hollywood, Releasing How-To Reloading Videos"

March 26th, 2016

What is “Overbore”? That’s a question rifle shooters can debate to no end. This article from our archives proposes one way to identify “overbore cartridges”. We think the approach outlined here is quite useful, but we know that there are other ways to define cartridges with “overbore” properties. Whenever we run this article, it stimulates a healthy debate among our readers — and that is probably a good thing.

Forum Member John L. has been intrigued by the question of “overbore” cartridges. People generally agree that overbore designs can be “barrel burners”, but is there a way to predict barrel life based on how radically a case is “overbore”? John notes that there is no generally accepted definition of “overbore”. Based on analyses of a wide variety of cartridges, John hoped to create a comparative index to determine whether a cartridge is more or less “overbore”. This, in turn, might help us predict barrel life and maybe even predict the cartridge’s accuracy potential.

John tells us: “I have read countless discussions about overbore cartridges for years. There seemed to be some widely accepted, general rules of thumb as to what makes a case ‘overbore’. In the simplest terms, a very big case pushing a relatively small diameter bullet is acknowledged as the classic overbore design. But it’s not just large powder capacity that creates an overbore situation — it is the relationship between powder capacity and barrel bore diameter. Looking at those two factors, we can express the ‘Overbore Index’ as a mathematical formula — the case capacity in grains of water divided by the area (in square inches) of the bore cross-section. This gives us an Index which lets us compare various cartridge designs.”

OVERBORE INDEX Chart

So what do these numbers mean? John says: “My own conclusion from much reading and analysis is that cartridges with case volume to bore area ratio less than 900 are most likely easy on barrels and those greater than 1000 are hard on barrels.” John acknowledges, however, that these numbers are just for comparison purposes. One can’t simply use the Index number, by itself, to predict barrel life. For example, one cannot conclude that a 600 Index number cartridge will necessarily give twice the barrel life of a 1200 Index cartridge. However, John says, a lower index number “seems to be a good predictor of barrel life”.

John’s system, while not perfect, does give us a benchmark to compare various cartridge designs. If, for example, you’re trying to decide between a 6.5-284 and a 260 Remington, it makes sense to compare the “Overbore Index” number for both cartridges. Then, of course, you have to consider other factors such as powder type, pressure, velocity, bullet weight, and barrel hardness.

Overbore Cases and Accuracy

Barrel life may not be the only thing predicted by the ratio of powder capacity to bore cross-section area. John thinks that if we look at our most accurate cartridges, such as the 6 PPC, and 30 BR, there’s some indication that lower Index numbers are associated with greater inherent accuracy. This is only a theory. John notes: “While I do not have the facilities to validate the hypothesis that the case capacity to bore area ratio is a good predictor of accuracy — along with other well-known factors — it seems to be one important factor.”

Share the post "Defining “Overbore” Cartridges — The Great Debate"

|

The folks at

The folks at

Hydro-Forming Procedure Step-by-Step:

Hydro-Forming Procedure Step-by-Step: Hornady supplies a shell holder made specifically for the hydro die; there’s no hole in the bottom of it. Just insert a spent primer into the primer pocket and you’re ready to go. The spent primer combined with the solid shell holder, keeps the water from seeping out of the primer pocket. The primer pushes out a little bit during this process, but it’s impossible for it to come out because of the way the shell holder is designed. The shell holder has a grove which allows the case to slide out of the shell holder even when the primer protrudes a bit.

Hornady supplies a shell holder made specifically for the hydro die; there’s no hole in the bottom of it. Just insert a spent primer into the primer pocket and you’re ready to go. The spent primer combined with the solid shell holder, keeps the water from seeping out of the primer pocket. The primer pushes out a little bit during this process, but it’s impossible for it to come out because of the way the shell holder is designed. The shell holder has a grove which allows the case to slide out of the shell holder even when the primer protrudes a bit.

Precision shooters favor premium brass from

Precision shooters favor premium brass from