|

|

December 28th, 2014

This article originally appeared in Sinclair Intl’s Reloading Press Blog, which has been merged into the Gun Tech Section on Sinclair’s website, www.SinclairIntl.com

Steps to Minimize Bullet Run-Out

Poor bullet run-out can cause poor and inconsistent accuracy, and variations in bullet velocities. The truer the loaded round, the more consistent your results will be on paper and across the chronograph.

Measuring Concentricity Measuring Concentricity

We all know that low run-out is the goal. But how can you tell if your run-out is high or low? Run-out is generally measured in thousandths of an inch with a concentricity gauge. There are many concentricity gauges to choose from that work well. Some work on loaded rounds only, some have a bullet straightening feature, and a few work on both loaded rounds and empty cases for checking case neck concentricity. The tool of choice for the Sinclair Reloading Tech Staff is the Sinclair Concentricity Gauge (Part # 09-175).

This tool is a mainstay on my bench, and it is used about as much as I use my reloading press! The tool uses two sets of bearings that are set on lateral, length-adjustable anodized aluminum blocks to accommodate cartridges from .221 Fireball-sized cases up to .50 BMG. The indicator is set on a height adjustable swiveling base on a stand that can be used for checking bullet or case neck run-out. The adjustable blocks ride aligned in a precision-milled slot. The entire set up is on an anodized base plate that gives excellent support during the process that is crucial to operation and accuracy. Basically the operation consists of placing a loaded round (for checking bullet run-out) or an empty case (for case run-out) on the bearings with the indicator end touching the chosen point to be measured. The case is easily spun with one finger as the indicator measures the amount of run-out. Once this process has been done a few times it is a fast and accurate means of measurement. In terms of indicator type being used, whether dial or digital, I actually prefer a standard dial indicator over the digital type. My reason for this choice is that you can see the needle jump when run-out is present. I believe this to be easier and faster than looking at digital numbers while measuring. In the video below, Sinclair’s Bill Gravatt shows how to use the Sinclair Concentricity Gauge correctly.

Sizing Steps to Minimize Run-Out

One of the most common steps in the reloading process that contributes to bullet run-out occurs is the sizing operation. If improper techniques are used or there are issues with the sizing die set up, a once perfectly concentric case can become out of whack. By using the proper dies for your application, properly setting up the die/shell holder or floating the de-capping/expander assembly, you can eliminate problems before they happen.

Many of us on the technical staff choose the Redding Type-S series of dies. These are full-Length or neck sizing dies that utilize a removable/changeable neck bushing (sold separately) to size the neck according to your application. These dies are machined with true precision and quality in mind. The Type-S dies come with a standard de-capping assembly with a caliber-specific expander ball in place. In addition to this an undersized retainer to hold the de-capping pin is included with the die. In my experience with these dies I use the standard expander ball with new, unfired brass on the initial re-size. I will then use the undersized retainer in place of the expander ball with brass that has been fired. I have found this step crucial in my reloading regiment to minimize bullet run out. The use of the expander ball can cause a few thousandths of run-out when the case is being pulled back out of the sizing die. With the undersized retainer in place the only thing that touches the neck of the case in sizing is the bushing. If you prefer to use an expander ball, Redding offers caliber specific carbide floating expander balls that fit on the de-capping rod. This free floating expander ball will self center on the case neck, and reduce the amount of run-out that can be caused by a standard expander ball. Many of us on the technical staff choose the Redding Type-S series of dies. These are full-Length or neck sizing dies that utilize a removable/changeable neck bushing (sold separately) to size the neck according to your application. These dies are machined with true precision and quality in mind. The Type-S dies come with a standard de-capping assembly with a caliber-specific expander ball in place. In addition to this an undersized retainer to hold the de-capping pin is included with the die. In my experience with these dies I use the standard expander ball with new, unfired brass on the initial re-size. I will then use the undersized retainer in place of the expander ball with brass that has been fired. I have found this step crucial in my reloading regiment to minimize bullet run out. The use of the expander ball can cause a few thousandths of run-out when the case is being pulled back out of the sizing die. With the undersized retainer in place the only thing that touches the neck of the case in sizing is the bushing. If you prefer to use an expander ball, Redding offers caliber specific carbide floating expander balls that fit on the de-capping rod. This free floating expander ball will self center on the case neck, and reduce the amount of run-out that can be caused by a standard expander ball.

When setting up a Type-S sizing die, set the neck bushing into the die with the numbers facing down toward the body of the die. Tighten the de-capping assembly until it contacts the bushing and then back it off ¼ of a turn. This allows the bushing to free float in the die. You should be able to hear the bushing rattle if you shake the die. Having the bushing free floating self centers the neck, and again minimizes any run-out that can occur.

If you prefer other brands of sizing dies there are a few tricks that people use to minimize run-out as well. Many reloaders claim that the use of an O-ring at the base of the de-capping assembly lock nut will float the assembly and help self center during sizing. Another trick that has been used is to remove the retaining pin on the shell holder slot on the press ram, and use an O-ring in its place to hold the shell holder in place. This allows the shell holder to self center during sizing as well.

Seating Steps to Minimize Run-Out

Run-out issues can arise during the bullet seating process. To reduce run-out during seating, use a high-quality die with a sliding sleeve. The sliding sleeve perfectly aligns the case with the bullet to be seated. Good examples of these dies are the Redding Competition Micrometer bullet seating dies, Forster Ultra Seaters, or RCBS Competition Seating dies. All of these dies utilize a micrometer top to precisely set seating depth. They are all very high quality dies that have tight tolerances to maximize bullet straightness during seating.

We receive many questions about seating long pointed bullets such as the Berger VLD or Hornady A-Max. One problem that the reloader faces with longer bullets is that they are so long that the standard seating stem is not machined deep enough to contact these bullets properly. The point of the bullet “bottoms out” in the stem and the result is off-center seating and/or rings and dents on the bullet nose. If you plan on using such bullets, you should purchase a “VLD” style seating stem, which is cut to accommodate the longer bullets. The use of this stem results in truer seating of the bullet without leaving a ring or marring the tip of the bullet.

Besides using a traditional press and threaded seating die, another great way to get a true bullet seat is by using an arbor press and Wilson chamber-type seating die. These dies are cut to very tight tolerances and have proven themselves as the main choice for bench rest enthusiasts. The design of the die positively aligns the case with the bullet as they are both captured by the die before the bullet is pushed straight into the case by the stem. These seating dies are available with the standard seating cap and stem or an additional micrometer top can be added for precise adjustment. Wilson also offers a stainless seating die with an integral micrometer seating head.

Finally another trick used by many in the seating process is to turn the case while the bullet is being seated. Some people claim this will keep things straight. What they do is raise the ram in increments while seating and rotate the case in the shellholder in increments of 90 degrees from the original starting while the bullet is being seated. Personally I have tried this and have seen no significant difference at all. However you may be the judge of this one. It makes sense, and maybe I should try this a little more before I rule it out.

After the Rounds Are Loaded — Batch Sorting by Concentricity Levels

No matter how meticulous you are, and no matter how good your components and tools are, run-out will still show up. Reloaders can drive themselves crazy trying to make each and every loaded round a true “0” in run-out. You will still see some minimal amount no matter what you do. Set yourself a standard of maximum allowable run-out for your loads. For instance for my Long Range 600- and 1000-yard F-Class loads I like to see .002” or less. I average .0015” and see a few in the range up to .004”. I spin each loaded round on my Sinclair Concentricity Gauge and sort them by run-out. Those that run over .002” I use for sighters or practice. Though achieving zero run-out (on every round) isn’t possible, minimizing run-out can definitely help your performance. Not only will your loads shoot better but you will have one less thing to worry about when you are lining up the sights on the target.

December 26th, 2014

East Coast buried in a winter whiteout? No problem — grab your snow shovel and go shooting. Here’s how hardy Forum Member Nick (aka “ChevyTruck 83″) coped with winter’s fury back in December 2012. Never underestimate the resourcefulness of a dedicated AccurateShooter Forum member….

We admire the fortitude of Forum Member Nick who braved wintry December weather to enjoy a day at the range in his native Pennsylvania. A little snow on the ground couldn’t stop this intrepid shooter, who brought snow shovel and arctic gear to his range session. Folks, here’s a true “hardcore” fan of shooting! Despite the “relentless snow”, Nick reports that “at least it wasn’t windy”. Nick shot a variety of long guns, including his .22LR rimfires, a .223 Rem, and a .308. Not daunted by the cold, Rick said it was fun to “play like a kid once in a while.” That’s the spirit! We admire the fortitude of Forum Member Nick who braved wintry December weather to enjoy a day at the range in his native Pennsylvania. A little snow on the ground couldn’t stop this intrepid shooter, who brought snow shovel and arctic gear to his range session. Folks, here’s a true “hardcore” fan of shooting! Despite the “relentless snow”, Nick reports that “at least it wasn’t windy”. Nick shot a variety of long guns, including his .22LR rimfires, a .223 Rem, and a .308. Not daunted by the cold, Rick said it was fun to “play like a kid once in a while.” That’s the spirit!

Nick reports: “There was no wind to speak of — just relentless snow. I’ll tell you what — it’s awesome to get out and play like a kid once in a while.”

Nick’s foray into the winter wonderland really puts things in perspective for “fair-weather” shooters. After viewing Nick’s Forum thread about his snowy range session, fellow Forum member DennisH observed: “I will never complain about our super hot sugar cane fields in south Louisiana ever again! We can hold matches 12 months a year. I have NEVER had, owned, or used a snow shovel.”

December 26th, 2014

During the Christmas season we get together with our families and enjoy the fellowship of our relatives and dear friends. For many, this holiday is a time to pause and look inwards — to examine how we can improve our relations with loved ones, and lead happier, more fulfilling lives together. To that end, consider the message of a Native-American parable, the Tale of Two Wolves.

The Tale of Two Wolves

An old Cherokee chief was teaching his grandson about life. “A fight is going on inside me,” he said to the boy. “It is a terrible fight and it is between two wolves.”

“One is evil: he is anger, envy, sorrow, regret, greed, arrogance, self-pity, guilt, resentment, inferiority, lies, false pride, superiority, self-doubt, and ego.

The other is good: he is joy, peace, love, hope, serenity, humility, kindness, benevolence, empathy, generosity, truth, compassion, and faith.

This same fight is going on inside you — and inside every other person, too.”

The grandson thought about it and then asked his grandfather, “Which wolf will win?”

The old chief answered . . .

“The one you feed.”

December 25th, 2014

Holiday Greetings to Our Readers Holiday Greetings to Our Readers

Merry Christmas and Happy Holidays to all our readers and especially our 26,480+ Forum Members. This marks our tenth Christmas “in business”, and the site is stronger than ever thanks to our members and industry sponsors. AccurateShooter.com (and 6mmBR.com) are now accessed by over 150,000 unique users every week. Part of the reason for that success is the hard work of our volunteer helpers.

Unsung Heroes Deserve Recognition

I want to acknowledge some guys who have really helped out the site. Number one is JayChris, our IT guy — he keeps the servers running smoothly and maintains our Forum. We just updated the Forum software this week and Jay pulled that off without a hitch. Thanks also go to Jeff Williams, our “Answerman” who fields miscellaneous questions from our readers. We have a great place to test rifles thanks to our good buddy (and designated trigger-puller) Joe Friedrich. I also want to recognize our regular contributors, including German Salazar, Jason Baney, Robert Whitley, Mark LaFevers, and Vince Bottomley. And special thanks to Boyd Allen and EdLongRange who tirelessly supply story leads for the Daily Bulletin. These guys (and many others) have all contributed much time and effort.

You can download this photo as a FREE computer wallpaper from Wallpaperhere.com.

We also want to thank our major sponsors, without whose support the site could not provide the full AccurateShooter.com experience, with an active Forum, an archive of in-depth articles, and fresh content 365 days a year in our Daily Bulletin. We’re grateful to all our sponsors and advertisers.

December 25th, 2014

What do you get when you combine red Cerakote and barrel fluting? Well, a candy-cane AR barrel — just in time for the holidays. This unique barrel was created by Black Hole Weaponry in St. Helens Oregon. No this is not a Photoshop job. This barrel is really finished this way (as you can see in the close-up). Thanks to Anette Wachter, aka 30 Cal Gal, for finding this festive firearm fitting.

December 25th, 2014

One of the most popular features of our Shooters’ Forum is the Official ‘Pride & Joy’ Rifle thread. There you’ll find dozens of interesting rifles, with photos and descriptions supplied by proud owners. Today we’re spotlighting one of the more interesting ‘Pride & Joy’ rifles unveiled this year, a Mosin Nagant “senior citizen”. This 72-year-old Russian bolt gun is not like any Mosin Nagant you’ve ever seen before. It has been brought into the 21st Century with a handsome target stock and some first-class upgrades, including Lothar Walther barrel and Timney trigger. Here’s a look at a very nice Russian rifle, belonging to Forum member Ben C. (aka “Grimstod”):

CLICK TO See Full-Screen Photo:

Video Shows Rifle Shooting Sub-Half-MOA from Bipod (in the Snow):

Name of rifle: Smyert Mk3 (Modified Mosin Nagant)

Make: Izhmekh/Izhevsk (“Izzy”) High Wall

Model: 91/30 | Year: 1942

Components and Specifications:

Barrel: Lothar Walther 26″

Contour: 1.18″ straight

Chambering: 7.62x54R, .310 bore

Stock: Bluegrass Tactical (Gen 1 & 2)

Trigger: Timney with Bluegrass trigger shoe

Magazine: Finnish No-Jam magazine |

Scope mount: Rock Solid (looks like an action sleeve)

Scope: SWFA 20x42mm MRAD

Gunsmith: Sheppard

Bolt handle: Rock Solid with Surgeon tactical handle

Bipod: Versa Pod

Total Weight: 18.6 lbs |

Grimstod’s Mosin Nagant Custom Shoots Under 0.5 MOA From Bipod

Even in harsh winter conditions, the rifle shot well. (I guess we should expect that for a Russian gun). The photo below shows a group shot from bipod. (The video shows Grimstod’s snow-bound range session). Grimstod calculated the group at 0.394 MOA measuring from outside edge to edge. Using our On-Target software, which measures center to center of most distant shots, we came up with 0.428 MOA. Still that’s impressive for an ancient action being shot in the dead of winter with snow falling. To learn more about this rifle (and view photos of the build process), visit the SurplusRifleForum.com.

December 24th, 2014

We recently featured the “Hornady Number One”, a showcase rifle featureing a CAD-designed, machine-cut stock. While many viewers liked that one-of-a-kind Hornady rifle, others lamented the absence of hand-shaped curves on the Hornady’s angular stock. So, for fans of curvy, hand-crafted rifles, we’re presenting this homage to a truly great stock-maker, Doan Trevor, an artist in the old style.

Doan Trevor is a master gunsmith and stock-maker who works in the old style. He still hand-crafts stocks from start to finish, and does all the metal-work on the custom rifles he builds. Starting with highly-figured woods, Doan carves and shapes his stocks largely by hand, with meticulous attention to detail. Each rifle he builds is optimized for its intended discipline, and custom-fitted for the customer.

With the help of his talented wife Sue (who does the photography and builds the web pages), Doan has created a wonderful website, DoanTrevor.com, that is a feast for the eyes. You can see beautiful wood-stocked rifles being hand-crafted. Doan also illustrates how he creates custom metal parts, and how he beds barreled actions into the finished stocks.

Set aside a few minutes and visit Doan’s website. Be sure to click on the site’s secondary pages: Rifle Building, Woodworking, and Metalworking. You’ll find dozens of high-quality photos and fascinating information on gun-building.

For more information, visit DoanTrevor.com, or call (505) 890-0368, 10am-5pm M-F.

Doan Trevor RifleBuilding

4119 Lanceleaf Ct NW

Albuquerque, NM 87114

505-890-0368

December 24th, 2014

More and more shooters are “wet-tumbling” their brass (in liquid) with reusable polishing media, rather than using dry media in a vibratory tumbler. The “wet-cleaning” method works best with a rotary tumbler fitted with a water-tight, horizontal drum to hold your brass, cleaning solution, and stainless, pin-type media. The rotary tumbler of choice has been the Thumler’s Tumbler Model B Heavy-Duty. That is a great, sturdy machine, but now you have a more affordable option.

Frankford Arsenal has introduced a “Platinum Series” rotary tumbler designed to clean cartridge brass with liquid and stainless media.The watertight, polymer drum rides on four rollers which rotate the drum around its horizontal axis. Two filters are provided so you can quickly separate your brass and media. A built-in timer allows you to set tumbling sessions up to three hours. Frankford Arsenal says its new product will clean up to 1000 cases of .223 Rem brass. That’s impressive capacity.

|

The Frankford Arsenal rotary tumbler is sold by major retailers including Grafs.com and Cabelas. You’ll find the best prices online.

Amazon Deal

Update 12/28/2015: The Amazon special has expired. As with all sales, timing is everything. Check the link at right for current pricing. You can also check with other vendors such as Midsouth Shooters Supply. |

|

How to Wet-Clean Your Brass in a Rotary Tumbler

On our main Accurateshooter.com website, you’ll find a comprehensive review of the STM system for cleaning cartridge brass with stainless media. To clean brass with stainless media, start with five pounds of small stainless pins sold by StainlessTumblingMedia.com. Place these along with a gallon of water, a little liquid cleaner, and two pounds of cartridge brass in a rotary tumbler, and run the machine for one to four hours. CLICK HERE for Brass Cleaning System Review On our main Accurateshooter.com website, you’ll find a comprehensive review of the STM system for cleaning cartridge brass with stainless media. To clean brass with stainless media, start with five pounds of small stainless pins sold by StainlessTumblingMedia.com. Place these along with a gallon of water, a little liquid cleaner, and two pounds of cartridge brass in a rotary tumbler, and run the machine for one to four hours. CLICK HERE for Brass Cleaning System Review

Forum Member Tests STM System

Our reviewer, Forum member Jason Koplin, purchased the STM media and a new Thumler’s Tumbler. He then tested the STM cleaning procedure on his own brass, including some extremely dirty and tarnished “range pick-up” brass. Jason was thoroughly impressed with how well the STM process worked — as you can see from the “before and after” photos below. Brass which looked like it was ready for the scrap heap was restored to “like-new” appearance. The process works equally well on both rifle brass and pistol brass. Jason observed that one surprise benefit of the STM cleaning procedure is a big reduction in noise. Jason said the water-filled rotary tumbler was much quieter than his vibratory tumblers.

December 23rd, 2014

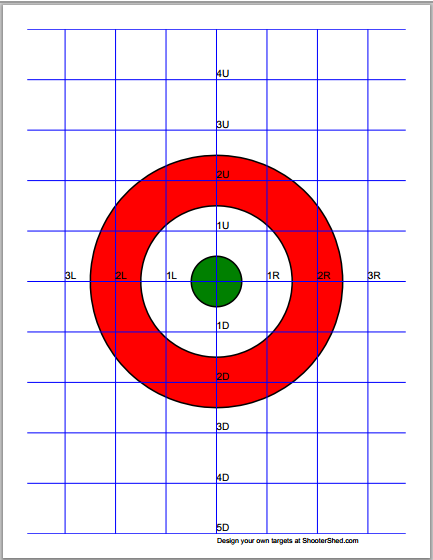

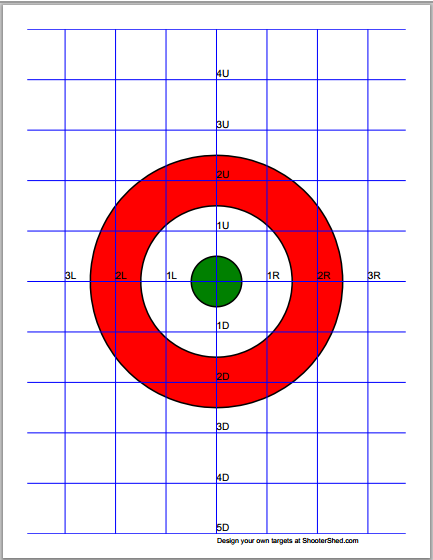

Are you creative? Do you like to design and customize things? Then you’ll love the Target Generator from the folks at ShooterShed.com. This free, interactive webpage allows you to design a variety of fun targets, including grids, benchrest-type Score Shooting targets, sight-in targets, and even playing card targets. Choose the paper size and orientation (vertical or horizontal), then select the number of target elements on the page. For example, you could have four (4) bulls or 52 playing cards. You can include a grid on the target, or tell the program to include load information blocks. For bullseye targets, you can control the number, color, and spacing (diameter) of the rings. LINK to TARGET GENERATOR.

|

|

The program provides a preview of each target you generate. If you like a particular design, save the file, and then print as many targets as you want. Check it out, this program is fun and handy to use. Here are five (5) targets your Editor created this morning just for this article. With a bit of practice, you can be generating your own custom targets in minutes. Have fun.

About the Creator of the Target Generator

The excellent Target Generator program was created by Rod Brown of Sheridan, Wyoming. Rod tells us: “I build custom rifles and coach shooters. I’ve got a 100-yard range out my back door. I shoot short- and long-range benchrest competitively around the country. I’m a full-time software development consultant and an FFL holder. When I’m not developing custom software for my clients, I’m usually fiddling in the shop, building a custom benchrest rifle, traveling to a match, chambering a barrel, or reloading some ammunition.

Story tip from Boyd Allen. We welcome reader submissions.

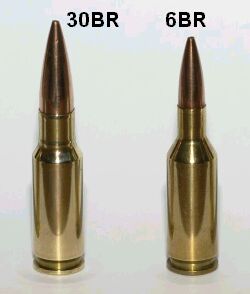

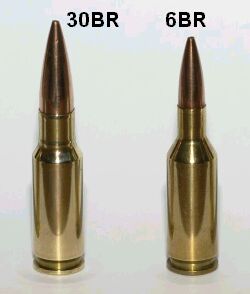

December 23rd, 2014

Forum member Toby Bradshaw is one lucky dude. He recently acquired a “previously owned” 30BR benchrest rifle from fellow forum member Al Nyhus. This 17-year-old gun has to be a candidate for “Second-Hand Rifle of the Year.” You see, Al’s cast-off 30BR still shoots tiny little dots — as its new owner discovered. Al Nyhus reports: “That gun won literally piles of trophies, plaques and patches for me. It will win any time and any where for ‘ya if you hit the flags right.”

Here are the first three-shot groups out of the gun, during load testing by its new owner. Yeah, we would take that. Needless to say, Toby is delighted with his “hand-me-down” purchase. If only all new benchrest rifles could shoot this way!

Bradshaw Bags a 17-Year-Old Panda-Actioned 30BR from Al Nyhus

Toby tells us: “I took advantage of Al Nyhus’s move from score shooting to drag racing, and picked up his ’97 vintage Panda 30BR. I hauled my gear to the range to zero the Leupold 45x that I put in the Kelbly high rings, and to produce three snug cases to send to the Harrells for a FL bushing die. I expanded and neck-turned a few gold box 6BR culls, leaving just 0.001 clearance in the chamber to produce a fitted neck, since I don’t yet have a sizing die (but did get a Wilson seater die from Al). I have 1000 118gr 7-ogive bullets on order from Ronnie Cheeks, but I bought 200 Berger 115gr FB to do some fireforming and practice until the Cheeks bullets arrive.

I bore-sighted, adjusted the scope to the first bullet hole, and verified the adjustment with a second shot in the middle of the 100-yard score target sheet (visible in the photo).

After running an H4198 pressure test without any drama, I loaded the once-fireformed brass with a stout load of H4198, bullets still at the jam, and shot two 3-shot groups with a 2-click scope adjustment in between. You can see the results above. I’d say that’s not bad for a ‘used’ rifle with no real load development on my part.”

Toby Bradshaw’s story about his “hand-me-down” 17-year-old rifle reinforces what we’ve been saying for a long time about the little 30BR cartridge. Necked-up from the parent 6mmBR Norma case, the 30BR is, without question, one of the most inherently accurate cartridges ever invented. And it is forgiving…. Toby Bradshaw’s story about his “hand-me-down” 17-year-old rifle reinforces what we’ve been saying for a long time about the little 30BR cartridge. Necked-up from the parent 6mmBR Norma case, the 30BR is, without question, one of the most inherently accurate cartridges ever invented. And it is forgiving….

Compared to the other dominant short-range accuracy cartridge, the 6 PPC, the 30BR tends to be less finicky, and easier to tune. The 30BR offers broad accuracy nodes. Also, we often find that 30BRs are relatively insensitive to seating depth. It’s not uncommon for a good 30 BR to shoot quality bullets equally well at a variety of seating depths, both in the lands and out of the lands.

|

Measuring Concentricity

Measuring Concentricity

Many of us on the technical staff choose the Redding Type-S series of dies. These are full-Length or neck sizing dies that utilize a removable/changeable neck bushing (sold separately) to size the neck according to your application. These dies are machined with true precision and quality in mind. The Type-S dies come with a standard de-capping assembly with a caliber-specific expander ball in place. In addition to this an undersized retainer to hold the de-capping pin is included with the die. In my experience with these dies I use the standard expander ball with new, unfired brass on the initial re-size. I will then use the undersized retainer in place of the expander ball with brass that has been fired. I have found this step crucial in my reloading regiment to minimize bullet run out. The use of the expander ball can cause a few thousandths of run-out when the case is being pulled back out of the sizing die. With the undersized retainer in place the only thing that touches the neck of the case in sizing is the bushing. If you prefer to use an expander ball, Redding offers caliber specific carbide floating expander balls that fit on the de-capping rod. This free floating expander ball will self center on the case neck, and reduce the amount of run-out that can be caused by a standard expander ball.

Many of us on the technical staff choose the Redding Type-S series of dies. These are full-Length or neck sizing dies that utilize a removable/changeable neck bushing (sold separately) to size the neck according to your application. These dies are machined with true precision and quality in mind. The Type-S dies come with a standard de-capping assembly with a caliber-specific expander ball in place. In addition to this an undersized retainer to hold the de-capping pin is included with the die. In my experience with these dies I use the standard expander ball with new, unfired brass on the initial re-size. I will then use the undersized retainer in place of the expander ball with brass that has been fired. I have found this step crucial in my reloading regiment to minimize bullet run out. The use of the expander ball can cause a few thousandths of run-out when the case is being pulled back out of the sizing die. With the undersized retainer in place the only thing that touches the neck of the case in sizing is the bushing. If you prefer to use an expander ball, Redding offers caliber specific carbide floating expander balls that fit on the de-capping rod. This free floating expander ball will self center on the case neck, and reduce the amount of run-out that can be caused by a standard expander ball.

We admire the fortitude of Forum Member Nick who braved wintry December weather to enjoy a day at the range in his native Pennsylvania. A little snow on the ground couldn’t stop this intrepid shooter, who brought snow shovel and arctic gear to his range session. Folks, here’s a true “hardcore” fan of shooting! Despite the “relentless snow”, Nick reports that “at least it wasn’t windy”. Nick shot a variety of long guns, including his .22LR rimfires, a .223 Rem, and a .308. Not daunted by the cold, Rick said it was fun to “play like a kid once in a while.” That’s the spirit!

We admire the fortitude of Forum Member Nick who braved wintry December weather to enjoy a day at the range in his native Pennsylvania. A little snow on the ground couldn’t stop this intrepid shooter, who brought snow shovel and arctic gear to his range session. Folks, here’s a true “hardcore” fan of shooting! Despite the “relentless snow”, Nick reports that “at least it wasn’t windy”. Nick shot a variety of long guns, including his .22LR rimfires, a .223 Rem, and a .308. Not daunted by the cold, Rick said it was fun to “play like a kid once in a while.” That’s the spirit!

Holiday Greetings to Our Readers

Holiday Greetings to Our Readers

On our main

On our main

Toby Bradshaw’s story about his “hand-me-down” 17-year-old rifle reinforces what we’ve been saying for a long time about the little 30BR cartridge. Necked-up from the parent 6mmBR Norma case, the 30BR is, without question, one of the most inherently accurate cartridges ever invented. And it is forgiving….

Toby Bradshaw’s story about his “hand-me-down” 17-year-old rifle reinforces what we’ve been saying for a long time about the little 30BR cartridge. Necked-up from the parent 6mmBR Norma case, the 30BR is, without question, one of the most inherently accurate cartridges ever invented. And it is forgiving….