For Less Run-Out, Try Rotating Your Cases During Bullet Seating

Here is a simple technique that can potentially help you load straighter ammo, with less run-out (as measured on the bullet). This procedure costs nothing and adds only a few seconds to the time needed to load a cartridge. Next time you’re loading ammo with a threaded (screw-in) seating die, try seating the bullet in two stages. Run the cartridge up in the seating die just enough to seat the bullet half way. Then lower the cartridge and rotate it 180° in the shell-holder. Now raise the cartridge up into the die again and finish seating the bullet.

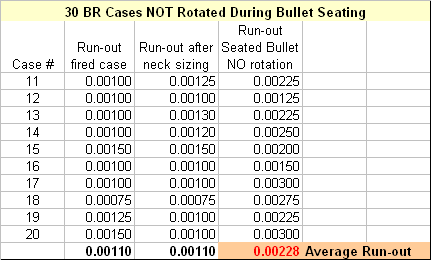

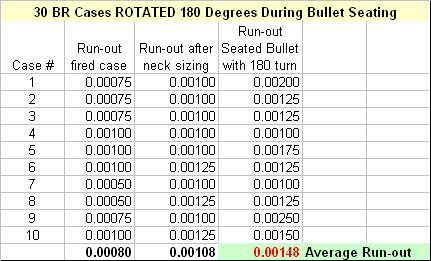

Steve, aka “Short Range”, one of our Forum members, recently inquired about run-out apparently caused by his bullet-seating process. Steve’s 30BR cases were coming out of his neck-sizer with good concentricity, but the run-out nearly doubled after he seated the bullets. At the suggestion of other Forum members, Steve tried the process of rotating his cartridge while seating his bullet. Steve then measured run-out on his loaded rounds. To his surprise there was a noticeable reduction in run-out on the cases which had been rotated during seating. Steve explains: “For the rounds that I loaded yesterday, I seated the bullet half-way, and turned the round 180 degrees, and finished seating the bullet. That reduced the bullet runout by almost half on most rounds compared to the measurements from the first test.”

READ Bullet Seating Forum Thread »

Steve recorded run-out measurements on his 30 BR brass using both the conventional (one-pass) seating procedure, as well as the two-stage (with 180° rotation) method. Steve’s measurements are collected in the two charts above. As you can see, the run-out was less for the rounds which were rotated during seating. Note, the change is pretty small (less than .001″ on average), but every little bit helps in the accuracy game. If you use a threaded (screw-in) seating die, you might try this two-stage bullet-seating method. Rotating your case in the middle of the seating process won’t cost you a penny, and it just might produce straighter ammo (nothing is guaranteed). If you do NOT see any improvement on the target, you can always go back to seating your bullets in one pass. READ Forum Thread..

Similar Posts:

- Tech Tip: Try Rotating Cartridge During Bullet Seating Process — This Might Reduce Bullet Run-Out

- Reduce Run-Out — Try Rotating Your Cases During Bullet Seating

- Try Rotating Cases During Bullet Seating to Reduce Run-Out

- For Reduced Runout, Rotate Your Cases During Bullet Seating

- For Better Bullet Seating — Try Lapping Inside of Seating Stems

Tags: 30 BR, Case Run-out, Concentricity, Dies, Hand Die, Reloading

Guess what? It’s even more beneficial to do it during the case forming process. Lift the handle partially, rotate the case 90 degrees and size the case a second time.

Been doing the rotating bullet seating idea for several years now, but I do it in 3 steps instead of two. And it makes a big difference.

Was taught to do this by my Uncle back in the 60’s . A former Army sniper , who proved to a hard-headed teen that it was beneficial , if done properly . I rotate the case in 6,7, or 8 increments as I press the bullet . Loaded rounds come out .001 or less . Takes longer , but I think it’s worth the time investment .