TECH Tip: How to Reduce Run-Out with Seating Dies

Each Wednesday, the U.S. Army Marksmanship Unit publishes a reloading “how-to” article on the USAMU Facebook page. A while back the USAMU’s reloading gurus looked at the subject of cartridge run-out and what can be done to produce straighter ammo. Tasked with producing thousands of rounds of ammo for team members, the USAMU’s reloading staff has developed smart methods for improving concentricity, even with budget=price dies. For other hand-loading tips, visit the USAMU Facebook page.

Minimizing Runout with Standard Seating Dies

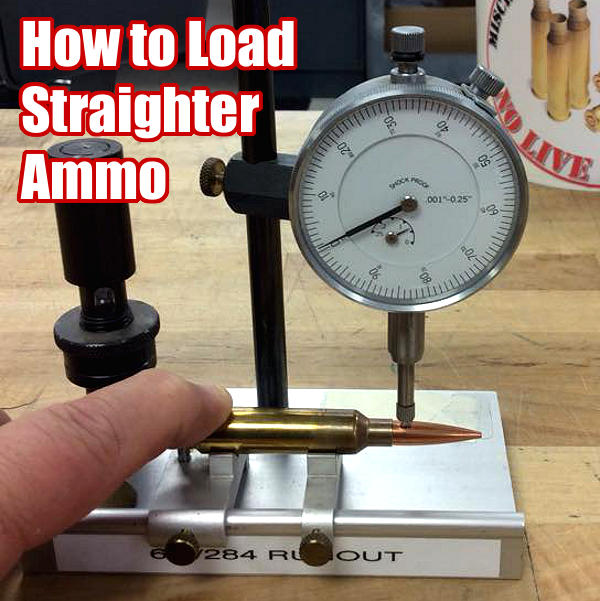

This USAMU article explains how to set up standard bullet seating dies dies to minimize Total Indicated Run-out (TIR). The loading process is described using a single-stage press since most handloaders have one. A high-quality run-out gauge is essential for obtaining consistent, accurate results.

Having sized, primed, and charged our brass, the next step is bullet seating. Many approaches are possible; one that works well follows. When setting up a standard seating die, insert a sized, trimmed case into the shellholder and fully raise the press ram. Next, back the seating stem out and screw the die down until the internal crimping shoulder touches the case mouth.

Back the die out ¼ turn from this setting to prevent cartridge crimping. Next, lower the press ram and remove the case. Place a piece of flat steel (or window glass, which is quite flat) on the shellholder and carefully raise the ram.

Place tension on the die bottom with the flat steel on the shellholder. This helps center the die in the press threads. Check this by gently moving the die until it is well-centered. Keeping light tension on the die via the press ram, secure the die lock ring. If one were using a match style, micrometer-type seating die, the next step would be simple: run a charged case with bullet on top into the die and screw the seating stem down to obtain correct cartridge OAL.

However, with standard dies, an additional step can be helpful. When the die has a loosely-threaded seating stem, set the correct seating depth but don’t tighten the stem’s lock nut. Leave a loaded cartridge fully raised into the die to center the seating stem in the die. Then, secure the stem’s lock nut. Next, load sample cartridges and check them to verify good concentricity.

One can also experiment with variations such as letting the seating stem float slightly in the die to self-center, while keeping correct OAL. The run-out gauge will show any effects of changes upon concentricity. However, this method has produced excellent, practical results as evidenced by the experiment cited previously. These results (TIR Study 2) will reproduced below for the reader’s convenience.

First, however, let’s examine run-out figures of some factory-loaded match ammunition. This should give readers who are new to TIR gauges some perspective about the TIR ranges one might encounter.

TIR Study 1: 50 rounds Lake City M852 Match 7.62mm

(168 gr. Sierra MatchKings)

0.000” – 0.001” = 2%

0.001” – 0.002” = 30%

0.002” – 0.003” = 16%

0.003” – 0.004” = 22%

0.004” – 0.005” = 14%

0.005” – 0.006” = 14%

0.006” – 0.007” = 0%

0.007” – 0.008” = 2%

TIR Study 2: 50 rounds of .308 match ammo loaded using carefully-adjusted standard dies, vs. 50 using expensive “Match” dies from the same maker.

Standard dies, TIR:

0.000” — 0.001” = 52%;

0.001”– 0.002” = 40%;

0.002”– 0.003” = 8%.

None greater than 0.003”.

Lesser-quality “Match” dies, TIR:

0.000”– 0.001” = 46%;

0.001” — 0.002” = 30%;

0.002” — 0.003” = 20%;

0.003” — 0.004” = 4%.

Note: both samples were loaded using the O-Ring method, i.e. with a rubber O-Ring placed under the locking ring of the Full-length sizing die to allow that die to float.

These tips are intended to help shooters obtain the best results from inexpensive, standard loading dies. Especially when using cases previously fired in a concentric chamber, as was done above, top-quality match dies and brass can easily yield ammo with virtually *no* runout, given careful handloading.

Similar Posts:

- How to Improve Case Concentricity with Standard Seating Dies

- How to Load Straighter Ammo with Reduced Cartridge Run-out

- Smart Advice for Reducing Run-Out with Standard Seating Dies

- Watch Out for Bullet Nose Contact in Short Seating Stems

- Always Check for Bullet Tip Contact with Seating Die Stems

Tags: Concentricity, Reloading, Run-Out, Seating Die, Seating Stem, TIR

O-Ring method is used only for FL die or for seating die too?

but what about competition seating dies, which have sliding sleeve that centers the case no matter of position of the whole die? this needs O-Ring method too for better performance?

I’ve found that the amount of neck resizing affects runout.

Think of it this way…

If you have 0.002″ clearance between neck and chamber of loaded round, you will be resizing maybe 0.004″, so you could theoretically get up to 0.004″ runout

If you have 0.010″ clearance between neck of loaded round and chamber, then you will be resizing 0.012″ and could theoretically end up with a max possible runout of 0.012″

So the less clearance between neck and chamber, the easier it is to produce concentric ammo.

I have tested some reloads out of my Lee dies that had .016” runout. Some of these rounds were difficult to chamber and after ejecting said round, abrasion marks were noticeable on the bullets where they were contacting the throat during chambering. Could this high level of run out cause pressure issues and/or accuracy issues?