IBS 2021 1000-Yd Benchrest National Championship in Montana

Photo by Forum member Dave Way.

IBS 1000-Yard National Championship

IBS 1000-Yard National Championship

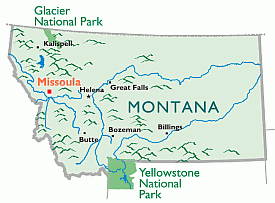

The IBS 1000-Yard Benchrest National Championship took place this past weekend, August 14-15, at the scenic Deep Creek Shooting Range outside Missoula, Montana. The Match was well attended, with 66 shooters in the Light Gun (LG) division, and 62 in Heavy Gun (HG). The venue was beautiful (as always), but conditions were challenging at times. One shooter noted: “The wind was brutal the last relay. Many shooters DQ’d”.*

Despite the tough conditions, there were some very impressive performances. Jason Walker took the Overall title, based on combined LG and HG standings. Shooting well in both classes, Jason (aka “LRPV” in our Shooters’ Forum) finished 3rd in LG and 6th in HG. Jason’s LG group size Agg was an impressive 4.357″. Nick Howlett was second Overall. Steve Simons won the LG division while James Bradley topped the HG field.

IBS 2021 1000-Yard Nat’l Championship Two-Gun Overall Results (LG + HG)

IBS 2021 1000-Yard Nat’l Championship Light Gun Overall Results

IBS 2021 1000-Yard Nat’l Championship Heavy Gun Overall Results**

| Top Five Two-Gun Overall

Jason Walker |

Top Five LG Overall

Steve Simons |

Top Five HG Overall

James Bradley |

Winners photo courtesy Jason Walker, 2021 IBS 1000-Yard Two-Gun Champion.

Gunsmith Alex Wheeler, who built many of the top-finishing rifles, noted: “Congratulations to the winners, you pulled your way to the top in some pretty tricky conditions. It was good to see every one again as well as meeting some in person for the first time.”

Equipment Used by Light Gun and Heavy Gun Competitors

The equipment lists, for both Light Gun and Heavy Gun, were heavily dominated by Krieger barrels. The Overall Winner and both LG and HG class winners used Kriegers. There were also many Bartlein barrels and Lilja barrels. But surprisingly, the equipment lists only showed 5 Brux barrels in Light Gun and 3 Brux barrels in Heavy Gun. BAT actions were the most common in both divisions, followed by Borden actions.

IBS 1000-Yd Light Gun Equipment List | IBS 1000-Yd Heavy Gun Equipment List

The vast majority of the shooters ran a 6mm cartridge in both Light Gun and Heavy Gun divisions. These were overwhelmingly 6mm Dashers and 6 BRAs. The 6 BRA (aka 6mmBR Ackley Improved) has a 40-degree shoulder like the Dasher, but with a longer neck. There were a half-dozen .300 WSMs in Heavy Gun division, and a couple 7mm RSAUMs, but the 6 Dashers and 6 BRAs dominated the field, even in HG.

Overall Winner Jason Walker was shooting two 6mm Dasher rifles. Both guns had BAT actions, Krieger barrels, and Nightforce scopes. Jason’s Heavy Gun had a Maxi-Tracker stock while his Light Gun had a PR&T LowBoy stock. In both rifles, he ran a 6mm Dasher loaded with Vapor Trail bullets pushed by Hodgdon Varget powder and CCI BR4 primers. Jay Cutright did the barrel work while Gordy Gritters worked on the PR&T stock. (NOTE: Jason changed to the LowBoy stock after the LG equipment list was submitted.)

Light Gun Overall winner Steve Simons was running a 6 BRA in Light Gun. Steve’s LG, smithed by Alex Wheeler, had a BAT action, Krieger barrel, Wheeler LRB stock, and Vortex scope. He loaded his 6 BRA cases with Vapor Trail bullets, Hodgdon H4895 powder, and CCI 450 Primers.

Heavy Gun Overall winner James Bradley was also running a 6 BRA in Heavy Gun. Again this had a BAT Action, Krieger barrel, Wheeler LRB stock, and Vortex scope. The rig was smithed by North Ridge Rifles. James shot Vapor Trail bullets, H4895 powder, and Federal 205M primers.

Looking back at the firing line from the target berm.

Deep Creek Range

The Deep Creek Range in Missoula, MT is one of the nicest places to shoot in the Intermountain West region. The range is located in the mountains within a few minutes drive of Missoula, and there is camping on-site. When conditions are good at Deep Creek, records get broken. To learn more about shooting at Deep Creek, contact Jamey Williams at jameydan[at]gmail.com.Here is an aerial view of the Deep Creek Range (Drone video by David Gosnell):

* One shooter at the match reported that: “Our last HV gun relay of the Match produced 11 DQs out of 13 competitors.” We have not confirmed this, but even if there were just a handful of DQs is is unfortunate for those HG competitors.

** This is the Heavy Gun Overall, as designated on the right top. However, the columns are erroneously titled “Light Gun”. If you compare the two linked results pages, you will see that they are NOT the same.

Effects Of Cartridge Over All Length (COAL) And Cartridge Base To Ogive (CBTO) – Part 2

Effects Of Cartridge Over All Length (COAL) And Cartridge Base To Ogive (CBTO) – Part 2