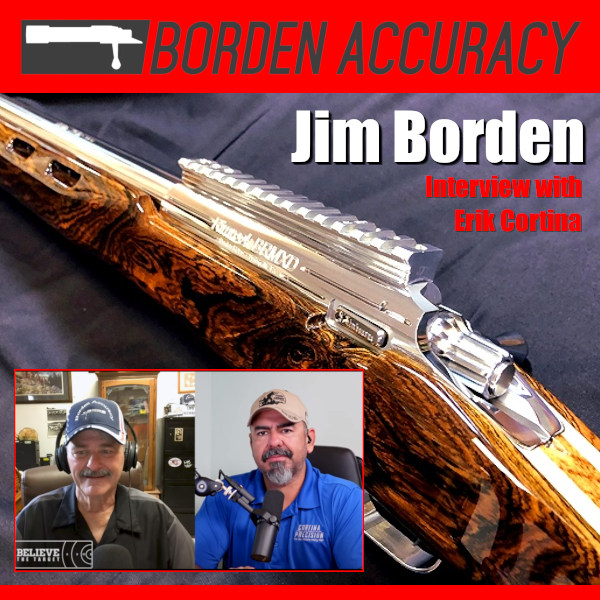

Great Interview with Action Maker/Rifle Builder Jim Borden and Erik Cortina

Every wondered how modern rifle actions are designed and crafted? Want to know the fine details of firing pin function and bolt lock-up? Then you should definitely watch this highly informative YouTube video. Top F-Class shooter Erik Cortina of Cortina Precision interviews Jim Borden, an engineer whose Borden Accuracy company produces some of the best rifle actions ever made. This is one of the better Erik Cortina video interviews. You’ll learn quite a bit from watching the video. The full video runs over two hours, so you may want to watch in segments over a couple of days.

Viewers have praised this interview, saying it has a wealth of information:

Gunsmith Alex Wheeler observed: “I consider Jim a friend even though we have never met. Definitely one of the guys that really gets actions. There’s not as many of them as you would think. He was the first timed action out there that had good ignition, at least in my opinion. It was a great interview. I do hope he has him on again.”

“Agreed. Jim is full of information and really does a good job on his actions. This [Cortina] interview with Jim Borden was excellent.” — Jud96

“I really like Jim’s explanations on why ductility is so important in an action. Especially in the critical areas that basically form 90 degree surfaces, such as where bolt lugs meet the bolt body. There is a lot of great info in this interview.” — Jackie Schmidt

“I have enjoyed all of Erik’s interview videos, which are very informative. But I agree [that] this interview with Jim Borden is the best. I learned a lot. Thank you Erik and Jim!” — Alexander-M

About Jim Borden and Borden Accuracy

About Jim Borden and Borden Accuracy

Jim began shooting high power silhouette and benchrest matches in the mid 1970s while working for a Fortune 500 company as an engineer. In the early 1980s he began building rifles for himself and then for others. Jim has a background as a gunsmith, machinist, registered mechanical engineer, engineering instructor, project manager, hunter, and benchrest competitor.

In benchrest competition Jim has set ten world records and won 11 National Championships thereby earning induction into the Benchrest Hall of Fame. Jim also served six terms as President of the International Benchrest Shooters (IBS).

Jim operates Borden Rifles/Borden Accuracy with his wife Joan, sons Jim Junior and John, daughter Andrea Mecca and son-in-law John (Mike) Mecca. Jim is also an outstanding photographer. Below is a stunning eagle image photographed by Jim Borden.

Borden Accuracy — A Success Story

Borden Accuracy/Borden Rifles has been a source for precision benchrest and hunting rifles for many years. Jim started doing his own gunsmithing while competing in benchrest and High Power silhouette matches. Jim launched his business in 1987, working nights and weekends while still employed at P&G. The business became full-time in 1995 with Jim and his wife Joan doing the work. The business was expanded in 1999 with the construction of the new Springville, PA facility and the addition of sons Jim Jr. and John to the staff. Daughter Andrea Mecca joined the staff in May 2016 as machinist and machine operator and Son-in-law John Mecca came onboard in January 2000.Jim and company began making Rimrock benchrest and Rimrock hunting actions in 2001. They added Borden Alpine and Timberline actions in 2006. These actions are made in an advanced manufacturing facility which has three CNC vertical machining centers, 1 CNC lathe and 2 CNC turning centers, three manual lathes, a manual knee mill, a surface grinder, a cylindrical grinder and wire EDM machine. To learn more, visit BordenRifles.com, call 570-965-2505, or send email to info [at] bordenrifles.com.

Neck-sizing dies resize only the neck of the case. The benefit of sizing only the neck is that the brass is “worked” very little, reducing the amount of changes to the brss. [We recommend full-length sizing for all applications after the first couple of firings, and semi-auto brass should be full-length sized every time!] Sinclair recommends that neck-sized-only cartridges should not be used any in other rifle besides the one they were originally fired from [unless they are also FL-sized], or in any action other than a bolt-action.

Neck-sizing dies resize only the neck of the case. The benefit of sizing only the neck is that the brass is “worked” very little, reducing the amount of changes to the brss. [We recommend full-length sizing for all applications after the first couple of firings, and semi-auto brass should be full-length sized every time!] Sinclair recommends that neck-sized-only cartridges should not be used any in other rifle besides the one they were originally fired from [unless they are also FL-sized], or in any action other than a bolt-action.

In response to a Bulletin article about

In response to a Bulletin article about

Eye Protection — Lesson Learned

Eye Protection — Lesson Learned Editor’s Comment: Among competitive pistol shooters, the use of safety eyewear is universal. You’ll never see Rob Leatham, Julie Golob, or Jerry Miculek competing without eye protection — for good reason. The handgun sports’ governing bodies effectively enforce mandatory eye protection policies. We wish the same could be said for competitive rifle shooting. We often see benchrest, High Power, and F-Class competitors shooting without eye protection. We’ve heard all the excuses, yet none of them trump the safety considerations involved.

Editor’s Comment: Among competitive pistol shooters, the use of safety eyewear is universal. You’ll never see Rob Leatham, Julie Golob, or Jerry Miculek competing without eye protection — for good reason. The handgun sports’ governing bodies effectively enforce mandatory eye protection policies. We wish the same could be said for competitive rifle shooting. We often see benchrest, High Power, and F-Class competitors shooting without eye protection. We’ve heard all the excuses, yet none of them trump the safety considerations involved.