|

|

March 27th, 2022

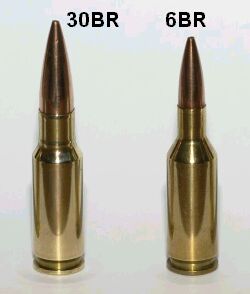

They say that a man can never have too much money or too much time. Darrell Jones would add that a man can never have too many BR-based rifles. Darrell had a fleet of BRs, in 22BR, 6mm BR, 6.5 BR, 7 BR, and 30 BR. But he was intrigued by the potential of a rifle in the .257 caliber. Could it shoot as well as a 6mm BR? Could it challenge the more popular calibers in the highly competitive 600-yard benchrest game? Through careful research and component selection, Darrell created a 25 BR rifle that proves the viability of the 25 BR as a competition round. Pushing 115gr high-BC Berger bullets at 2837 fps, Darrell’s 25 BR “Peppermint” won first place in its very first match.

The Barely Bigger BR — Exploring the .25 Caliber Option

Rifle Report by Darrell Jones

I decided to build a 25 BR after several weeks of deliberation and ruling out a .257 Ackley Improved. Part of my dilemma was that I wanted to shoot F-Class competition at 600 yards, and I was unsure about the accuracy potential of the 25 BR. However, I currently have several BRs chambered in 22 BR, 6BR, 6.5 BR, 7 BR, and 30 BR and they all shoot exceptionally well at 600 yards. This lead me to believe a 25 BR should deliver fine accuracy, just like its other BR siblings. Why wouldn’t a 25 BR shoot accurately provided that I built it with the right components? The feasibility saga began. I began searching diligently for custom 25-caliber bullets. Unfortunately, there are not many 25-caliber custom bullet makers. I actually found only two custom bulletsmiths who produce the 25s. I did look at Fowlers and then looked at Bergers. Both Jeff Fowler and Berger made 110-grain flat-base bullets when I was looking. [Editor — this 110gr bullet is no longer listed by Berger]. The Berger 110gr FB bullets (.414 ballistic coefficient) shot very well out of my 12-twist 25-06 Ackley. However, I wanted to shoot a heavier bullet if possible. Berger makes a 25-caliber 115gr VLD boat-tail with a high ballistic coefficient. This needs a 10-twist barrel.

Panda Action, McMillan Stock, Weaver T-36

As you can see, I went with a Panda polished action and a weighted McMillan BR stock painted metallic silver with red candy cane stripes thus the name “Peppermint”. This gun actually does double duty now as a 25 BR and 6 PPC switch barrel. When I want to run the gun as a 6 PPC for short range, I simply screw on the PPC barrel, then swap in a bolt (fitting the PPC bolt face) from another Panda action I own. That’s one advantage of owning custom Kelbly actions! Don’t even think about exchanging bolts between factory guns. Kelbly rings and a Weaver T-36 fixed-power scope handle the optical duties while a Jewell trigger set at one ounce takes care of the firing mechanism.

Chambering for the .25 Caliber BR Wildcat

I wanted a chamber that would let me shoot both the 110s and the 115s. I took some time surfing the net looking for rental reamers that had suitable throat dimensions. I found that Elk Ridge Reamer Rentals had a 25 BR pilot reamer available. I called and Elk Ridge faxed me a reamer diagram that indicated it was designed to tight SAMMI specs. I asked how often was the reamer used and was told “not very often”.

I did want a minimum no-turn neck optimized for Lapua brass. The drawing indicated that the reamer would cut a .281″ neck and a throat of 1.0315″. This was very close to ideal, though I did have to turn two thousandths off the necks of Lapua 6BR brass after I necked it up. I resized using a .277″ bushing and the loaded rounds came out to be .279″. Realizing that this was in the ball park, I decided to go with the Elk Ridge Reamer and build a 25 BR that could shoot 110gr or 115gr bullets. Now the question was where to get a match-grade 25-caliber barrel. I called quite a few of the custom barrel-makers, including BlackStar Barrels in Texas (no longer operating). I have had wonderful success with the BlackStar barrel on my 6BR “Chantilly” — it delivered great accuracy and impressive velocities. Since the 25 BR was so similar, I went with another BlackStar. I ordered a 10-twist, 6-groove, 1.250″-diameter straight-contour tube. I did want a minimum no-turn neck optimized for Lapua brass. The drawing indicated that the reamer would cut a .281″ neck and a throat of 1.0315″. This was very close to ideal, though I did have to turn two thousandths off the necks of Lapua 6BR brass after I necked it up. I resized using a .277″ bushing and the loaded rounds came out to be .279″. Realizing that this was in the ball park, I decided to go with the Elk Ridge Reamer and build a 25 BR that could shoot 110gr or 115gr bullets. Now the question was where to get a match-grade 25-caliber barrel. I called quite a few of the custom barrel-makers, including BlackStar Barrels in Texas (no longer operating). I have had wonderful success with the BlackStar barrel on my 6BR “Chantilly” — it delivered great accuracy and impressive velocities. Since the 25 BR was so similar, I went with another BlackStar. I ordered a 10-twist, 6-groove, 1.250″-diameter straight-contour tube.

After chambering, the barrel finished at 1.245″ diameter and 27.5″ inches with an 11° crown. I actually had the throat lengthened to accept both Berger 110gr and 115gr bullets. The bases of the FB 110-grainers sit flush with the neck-shoulder junction, when they are seated .010″ into the lands. With the longer 115gr VLDs, the bottom of the bearing surface (i.e. start of boat-tail) is just about even with the neck-shoulder junction. After chambering, the barrel finished at 1.245″ diameter and 27.5″ inches with an 11° crown. I actually had the throat lengthened to accept both Berger 110gr and 115gr bullets. The bases of the FB 110-grainers sit flush with the neck-shoulder junction, when they are seated .010″ into the lands. With the longer 115gr VLDs, the bottom of the bearing surface (i.e. start of boat-tail) is just about even with the neck-shoulder junction.

Accurate Load Development

The barrel broke in easily with just 10 shots, using a “shoot one and clean” process. The load I started with was 31.5 grains of Varget with CCI 450 primers. The Berger 110s and Berger 115s had the same Point of Impact (POI) at 100 yards. However, the 115s impacted two inches higher at 600 yards with the same load. That shows the benefits of a higher BC. Pushed by the CCI 450s and 31.5 grains of Varget, the 115-grainers were running about 2837 FPS. I boosted the load up to 32.0 grains but I noticed primer cratering, so I backed off, settling on 31.5 grains for the 115gr Berger VLD.

Peppermint Wins at 600 Yards

For her debut in competition, I took “Peppermint” to our local 600 yard F-class match. Shooting the Berger 115s with 31.5 grains Varget, she won with a perfect score of 200 with 14 Xs. At my club, we use a SR3 target. The X-Ring measures 3″ in diameter and the 10-Ring measures 7″. At the match there were some very good shooters with top-flight custom rifles in accurate calibers such as 6.5-284 and 22 Dasher. I was very fortunate to come out on top, but I give the credit to Peppermint’s good bench manners and outstanding accuracy. For her debut in competition, I took “Peppermint” to our local 600 yard F-class match. Shooting the Berger 115s with 31.5 grains Varget, she won with a perfect score of 200 with 14 Xs. At my club, we use a SR3 target. The X-Ring measures 3″ in diameter and the 10-Ring measures 7″. At the match there were some very good shooters with top-flight custom rifles in accurate calibers such as 6.5-284 and 22 Dasher. I was very fortunate to come out on top, but I give the credit to Peppermint’s good bench manners and outstanding accuracy.

As you can see from the target, “Peppermint” is a very accurate rifle that has proven herself in competition. It takes a good gun to finish “on top” in her very first match. So far, I’m very happy with the project, and more than satisfied with the accuracy of the 25 BR. This is definitely a worthy cartridge for Egg Shoots, 500m varmint matches, and the 600-yard F-Class game.

| BR-Based Cartridge Comparison |

| CALIBER |

22 BR |

6mm BR |

25 BR

| 6.5 BR |

7 BR

| 30 BR |

| Bullet |

80gr SMK |

107gr SMK |

115gr Berger |

107gr SMK |

130gr SMK |

118gr BIB |

| BC |

.420 |

.527 |

.522 |

.420 |

.391 |

na |

| Load Grains |

31.0 H4350 |

30.0 Varget |

31.5 Varget |

32.0 Varget |

34.0 AA2460 |

34.0 H4198 |

| Barrel Length |

27″ |

27″ |

27.5″ |

27.5″ |

28″ |

24″ |

| Velocity |

3100 fps |

2880 fps |

2837 fps |

2851 fps

| 2719 fps |

2970 fps |

Comparing the BR-Based Variants

Now that I have several calibers in the BR cartridge family, (22 BR, 6mm BR, 6.5 BR, 7 BR, and a 30 BR), it is my humble opinion that they each have their own place. A varmint hunter’s dream, the 22 BR can push a bullet faster and more accurately than the 22-250. With an 8-Twist barrel, the 22 BR can send an 80gr SMK to 600 yards with extreme accuracy. Now that I have several calibers in the BR cartridge family, (22 BR, 6mm BR, 6.5 BR, 7 BR, and a 30 BR), it is my humble opinion that they each have their own place. A varmint hunter’s dream, the 22 BR can push a bullet faster and more accurately than the 22-250. With an 8-Twist barrel, the 22 BR can send an 80gr SMK to 600 yards with extreme accuracy.

The 6 BR can do it all. The 6mm caliber offers a wide variety of quality bullets suitable for any shooting situation. All the major custom barrel makers produce outstanding 6mm barrels in a full range of twists. Moreover, since the 6 BR cartridge is so popular, there is a great store of knowledge about reloading for the 6 BR. It is easy to find a load that will shoot superbly in any bullet weight.

The 25 BR has proved to be easily tuneable, proficient and not fickle. You can obtain extreme accuracy without great effort in load development. The 115gr Berger offers a good high-BC projectile for this caliber, making the 25 BR a viable alternative to the 6 BR. As I’ve shown, it is competitive with a 6 BR in head to head competition.

Compared to the 25 BR, the 6.5 BR has a small edge in ballistics. However, there are not many light bullet choices available, especially from custom makers. The 123gr Lapua Scenar is an excellent bullet with a .547 stated BC, but it may be a bit heavy for the case capacity.

The 7 BR was designed for silhouette shooting, and it excels at that task. The 7 BR can push a 130 grain bullet fast enough to knock over the steel silhouettes at 500 meters with real consistency.

The 30 BR is nothing less than outstanding. The 30 BR is now the dominant cartridge on the benchrest Score-shooting circuit. It is also highly accurate for group shooting at 200 yards and very capable of winning a 600-yard F-Class match. Barrel life of over 6,000 rounds is realistic.

I like all the “flavors” of BR derived from the 6mm BR Norma case. However, if I could only have one BR in my safe, give me my 8-Twist, 6 BR “Chantilly” and I will be a happy camper. The final point I would make is if a cartridge is stamped BR on the case, it will shoot extremely accurately if you can.

February 20th, 2022

The 300 Meter .22 PPC — Smaller Caliber for Less Recoil

By GS Arizona

[This article originally appeared in Precision Shooting Magazine many years ago, but we are reprising it because the .22 PPC remains a notable cartridge for many disciplines, from benchrest to silhouette.]

I’ve spent the past few years pursuing the largely solitary pastime of 300 Meter shooting in the US. While it is a hugely popular sport in Europe, with thousands of competitors in each of various countries and overflowing national championships, in the U.S., 300 Meter shooting is simply a forgotten discipline. As an example, consider that the entry at the USA Shooting 300 Meter National Championships held at Fort Benning did not reach 20 competitors in [years past]. For those not familiar with the discipline, the 300 Meter ISSF target has a 100 mm ten ring, 200 mm 9 ring and so forth. That’s a 3.9″ ten ring at 328 yards for those of you who may object to the metric system, electricity and other intrusions upon a well settled universe (which ends at the dragons). [Editor’s Note: GS Arizona was a championship-class prone shooter, in both rimfire and centerfire disciplines, who had a popular online Blog, which has been closed.]

300 Meter Basics

300 Meter matches can be either three-position (prone, standing, kneeling) or all prone. Being of that age at which limbs aren’t limber and the mid-section obscures one’s view of the toes, I shoot prone matches only and leave the 3P to those for whom the term “shooting athlete” doesn’t produce an automatic smirk from the better half.

Like most 300 Meter shooters, I shoot a 6BR as my main rifle. As used in 300 Meter shooting, the 6BR is loaded with a 105-108gr bullet, with a velocity in the 2850 fps range. There is simply no cartridge out there at this time that delivers the accuracy, low recoil and ease of loading that can be had from the 6BR. That doesn’t mean we shouldn’t embark on a quixotic adventure now and then to find something better. This article is about one such search. So, if you don’t mind spending some time learning about an uphill struggle in a forgotten corner of the shooting world, pour a hot cup of coffee, get a plate of chocolate chip cookies and read on.

Getting Started–The Concept Behind the Project

The premise for building a .22 PPC was simple — less is more. Less recoil, that is, while retaining good ballistics and accuracy, should allow for higher scores. The hard part is meeting the ballistic and accuracy standards set by the 6BR. If pressed I might also admit to a desire to do something different. I made a decision early on in the project to stick to 80-grain bullets. I believe the 80 is pushing the envelope for safe and sane pressure in a case the size of the PPC; additionally, there are a number of manufacturers of 80-grain .224″ bullets so selection and testing can be more meaningful. Barrels are another consideration and all of the better barrel makers offer a 1:8″ twist .224 barrel (unlike the limited selection of 1:6.5″ twist required for 90 grain .224″ bullets).

With the basic parameters of a full-length .22 PPC case (reformed Lapua .220 Russian to be exact) and an 80-grain bullet established, a few other details needed attention. The first of these was specifying certain dimensions for the reamer maker. I chose not to change any of the essential dimensions of the .22 PPC such as headspace, shoulder angle or body taper, but there were a couple of areas that I felt needed to be different from the typical Benchrest PPC. These were neck diameter and throat length. With the outstanding quality of the Lapua brass, I elected to go with a 0.255″ neck diameter which would allow the use of unturned brass and still leave 0.002″ clearance around the neck of a loaded cartridge. The throat was specified longer than a standard PPC to allow for the length of the 80-grain bullets and avoid having the bullet go past the neck/shoulder junction.

|

300 Meter .22 PPC — Equipment List 300 Meter .22 PPC — Equipment List

Hardware

Action: RPA Quadlite, RPADefense.com.

Stock: Master Class Highpower Prone MasterClassStocks.com

Barrel: Broughton .224″ bore, 1:8″ twist, 30″ Palma contour

Rear Sight: Warner #1, Anschutz Iris, Warner-Tool.com

Front Sight: Gehmann Iris from Scott Riles

Trigger: Jewell 4 oz. one-stage

Bolt Knob: Keychain from 7-11 ($2.00)

Gunsmithing

Barrel fitting, sight, scope bases: Warner Tool Company.

Stock inletting, pillar bedding, and hardware: Alex Sitman,

Master Class Stocks. |

Detours Along the Way

Like Quixote stumbling his way to his dreams, I’ve made a few mistakes. That 0.255″ neck diameter turned out to be the first. Turning brass isn’t a problem, but I was so captivated by the quality of the .220 Russian brass that I planned to skip turning or just take a light (0.001″) clean-up cut. Well, that’s fine, but as it turns out, PPC die makers assume you have turned necks and using unturned brass causes problems. The Redding Competition Seater, for instance, wanted to crimp the entire length of the neck onto the bullet. Turns out it was 0.250″ in the neck diameter of the sliding sleeve. This required reaming the sleeve which wasn’t too hard as the sleeve is made of relatively soft steel. Hand turning the chambering reamer with lots of care and oil took care of that problem. This opened up the neck to 0.255″ which might be 0.001″ more than ideal but I’ll live with it.

Sizing dies were another problem altogether. Forget using a non-bushing die with unturned brass–you’ll just overwork the neck to death. The Redding bushing dies worked well, though. Fired brass ends up at 0.254″ and is sized to 0.250″ in two steps (0.252″ and 0.250″) to maintain better concentricity. Sizing dies were another problem altogether. Forget using a non-bushing die with unturned brass–you’ll just overwork the neck to death. The Redding bushing dies worked well, though. Fired brass ends up at 0.254″ and is sized to 0.250″ in two steps (0.252″ and 0.250″) to maintain better concentricity.

I also got the throat length wrong as the base of the bullet (above the boat tail) is halfway up the neck and I want it just above the shoulder. I don’t know how I missed on that spec, but that’s what happened. As it turns out, the extra throat length hasn’t caused any problems with the Nosler 80, but it might with shorter or pointier bullets. Powder and primer choices became additional areas for demonstrating my inability to make good choices. You might think that adding a heavier bullet to an existing cartridge would be simple but it really turned into a full scale adventure.

Choice of Components and Smiths — Only the Best

Based on my previous favorable experience and that of a few friends, I ordered a Broughton barrel for the PPC, a .224″ bore 1:8″ twist, long enough to finish at 30 inches in what is generally referred to as a medium Palma taper. I haven’t been disappointed by the barrel: like all of those made by Tim North of Broughton Barrels, it is top notch. With the barrel and reamer in hand, they and the RPA Quadlite action were sent to Al Warner for barreling and then on to Alex Sitman for the stock. I can’t say enough good things about Alan’s metal work and Alex’s stock work. They have barreled and stocked many rifles for me over the years, all flawless. Alex’s Highpower Prone stock fits me like a comfortable moccasin. The trigger is a Jewell set at 4 oz., the rear sight is a Warner #1 and the front sight is a Scott Riles with a Centra aperture.

Eventually, the UPS man — purveyor of all things worth having — arrived with a long package and the real work began. Load testing and shooting can be a lot more frustrating than planning and talking to gunsmiths, but hopefully the eventual results make it worthwhile. I had a good supply of Nosler 80-grain bullets and some preconceived notions about powder and primers. Off to the loading bench.

Load Development + Accuracy Testing

Fire-forming the .220 Russian cases to the PPC chamber was a breeze: run an expander into the neck to get them to .224″, bump the shoulder 0.002″, load a caseful of IMR 4895 (about 23 grains) and insert a Nosler 77 (leftover from another project) and fire. I shot these at 100 yards while zeroing the rifle and was very impressed with the accuracy. Fouling was minimal, off to a promising start. Fire-forming the .220 Russian cases to the PPC chamber was a breeze: run an expander into the neck to get them to .224″, bump the shoulder 0.002″, load a caseful of IMR 4895 (about 23 grains) and insert a Nosler 77 (leftover from another project) and fire. I shot these at 100 yards while zeroing the rifle and was very impressed with the accuracy. Fouling was minimal, off to a promising start.

Once formed, I loaded the brass with Varget and the 80-grain bullets. Since Varget has given such good results in the 6BR, it was a natural starting point for this project. However, it quickly became evident that it might be too slow. While accuracy was excellent, powder fouling in the barrel was very heavy even at the highest charge tried (28.5 grains) and there was soot all the way down the shoulders of the cases. Cleaning the bore felt like patching a rusty water pipe after just 20 shots. I knew I’d never make it through a 60-shot match (about 70 shots with sighters) without cleaning[.]

Putting the .22 PPC to the Test in Competition

At this point, I took the PPC to a 300 Meter match with the Varget load. While it might not look perfect, I needed to try it. The first string was a 198 and I was able to clean the rifle immediately after firing. The second string was also a 198 but I had to fire the third string without cleaning. The effects of the fouling were evident in the last score, a 194.

While a 590 total isn’t bad for 300M, it was a bit below my average with the 6BR at this range – my home range that I knew well. More importantly, the score dropped as the group opened up in the third string when I wasn’t able to clean. At the Nationals all 60 shots are fired without a break for cleaning or additional sighters; therefore, Varget, while promising, wouldn’t work in the long run. While a 590 total isn’t bad for 300M, it was a bit below my average with the 6BR at this range – my home range that I knew well. More importantly, the score dropped as the group opened up in the third string when I wasn’t able to clean. At the Nationals all 60 shots are fired without a break for cleaning or additional sighters; therefore, Varget, while promising, wouldn’t work in the long run.

The next faster powder on my shelf was IMR 4895. I’d used it in the fire forming loads and if I had a lick of sense I would have tried it right away since the fire forming loads shot so well. However, stubbornly clinging to the preconceived notion that Varget was going to be a great powder for this combo cost me a month or so fooling with it. I then worked up loads with 4895 from 26.8 to 28.6 and saw that while 4895 was better suited to the case than Varget, it was still slow. The powder fouling was still occurring, though to a lesser degree. The shoulders still showed some soot, but less. I settled on 27.8 grains as a useful load and loaded 70 cases.

New Load for a New Home New Load for a New Home

At this point, I moved from Florida to Arizona causing a delay of several months in testing. The move also had an effect on the load as the hotter and drier climate in Arizona turned out to be much more suitable for 4895. Of course, I still had those 70 rounds loaded with 27.8 so I shot them in practice. Everything seemed OK but one primer (Federal 205M) pierced at the edge. I didn’t pay much attention to that as there were no other pressure signs and it was the first primer failure of any sort so far in this project. Extraction was fine, primer edges were nicely radiused and base growth was under two tenths. There was an opportunity to shoot a 500-yard prone match the following day so I reloaded the cases with the same load. At the match I pierced two more primers, this time right at the edge of the firing pin, causing two craters running into the firing pin hole. As you might imagine, all subsequent shots cratered into that area, although no more pierced.

I was contemplating a switch to Hodgdon Benchmark (slightly faster than H4895) until this point. Now, repairing the bolt face and switching to a tougher primer took priority. I loaded 25 rounds with CCI BR4 primers and 25 with Remington 7.5 primers. Both of these are well known for their tougher cups which I hoped would eliminate the piercing. I like the mild flash from the Federal 205 and believe it contributes to good accuracy, but I needed a primer that holds together more than I need to cut another tenth MOA. Bearing in mind that the powder charge itself might need reworking, I took those 50 rounds to the range to test them with the 27.8 gr. IMR 4895 load as it remains best to only change one thing at a time. Temperatures were in the 100 to 110 degree range during testing as they are for a good portion of the year here in Phoenix. If the load won’t work in hot temperatures, it just won’t work at all for me.

The primer testing at 200 yards showed the CCI BR4 primers to be better suited to this load than the Remington 7.5 primers. While no primer failed out of the 50 fired, the CCI BR4 primers gave distinctly better accuracy. I fired two ten-shot groups prone (scoped) with each, the Remington-primed groups averaged just over 1 MOA and the CCI-primed groups averaged 1/2 MOA. The difference between the two was principally in the amount of elevation in the groups. Given that result, as well as previous good experience with the CCI primers in the 6BR, I settled on the CCI BR4 primers for the PPC.

Final Testing at 500 Yards–It all Comes Together

While the purpose of the 80-grain PPC is 300 Meter shooting, those matches are somewhat hard to find so I’ve done most of my testing at 200 yards on the local public range (Ben Avery Shooting Facility in Phoenix) and at 500 yards in some of the local prone matches. With the primer issue potentially resolved, I went back to the 500-yard range to make sure the load held good elevation at that distance.

Final testing at 500 yards was a complete success. I fired one group of 24 shots from the prone position. Elevation for the bulk of the group was right at 3″ (0.6 MOA), the horizontal spread was somewhat larger as the group was fired in gusty, fast-switching conditions. The CCI BR4 primers functioned flawlessly, with no sign of pressure despite ambient temperatures over 100° F. None of this should be taken as a general statement of inadequacy of Federal primers. I have used (and continue to use) the very same lot of Federal 205M primers in my 6BR and have not experienced any problems at all. Simply stated, the 80-grain .22 PPC is an odd duck and has special requirements when fired under the conditions that prevail in my area. Final testing at 500 yards was a complete success. I fired one group of 24 shots from the prone position. Elevation for the bulk of the group was right at 3″ (0.6 MOA), the horizontal spread was somewhat larger as the group was fired in gusty, fast-switching conditions. The CCI BR4 primers functioned flawlessly, with no sign of pressure despite ambient temperatures over 100° F. None of this should be taken as a general statement of inadequacy of Federal primers. I have used (and continue to use) the very same lot of Federal 205M primers in my 6BR and have not experienced any problems at all. Simply stated, the 80-grain .22 PPC is an odd duck and has special requirements when fired under the conditions that prevail in my area.

At this point, I’ve determined that the basic premise of a .22 PPC for 300 Meter matches is perfectly viable, even if it is quite a bit more complex an undertaking than the 6BR. Recoil reduction over the 6BR was minimal, bordering on unnoticeable, but accuracy is on a par with the 6BR, perhaps slightly better. As a nice bonus, the PPC has proven to be quite useful for the 500-yard prone matches that are a regular part of the Phoenix shooting scene and it never fails to spark a good conversation with a new friend when I’m practicing or testing at the range. Future plans include testing Berger and Hornady 75 and 80-grain bullets and Hodgdon Benchmark powder. And, after conferring with your moderator, who ran some simulations in QuickLOAD, I’ll be trying Reloder 15 soon (QuickLOAD predicts RL15 allows 100% load density with good velocity). At some point I’ll also have the reamer reground for a shorter throat and tighter neck, but probably not until time comes to rebarrel.

6mmBR Norma versus .22 PPC

For the shooter who wants a superbly accurate, easy to load cartridge for 300 Meters to 600 yards, you simply can’t beat the 6BR. Everything you need, including brass, dies, reamers and knowledge are just a phone call away. The .22 PPC, by contrast, is an uphill struggle. The chambering reamer was custom ground to my specifications to allow unturned brass, as well as a longer freebore for the 75- and 80-grain bullets that are the heart of the project. The no-turn necks also meant that the Redding Competition Seater (an excellent unit) had to be reworked to allow for the thicker neck diameter. Once those hurdles were overcome I struggled to find the best powder for this combination–and I’m still searching. Unlike the 6BR where any of a half dozen or more powders will do the job (Varget, Reloder 15, N140, N540, IMR 4895, Norma 203B, etc.) the .22 PPC with heavy bullets has proven finicky with even the most accurate powders leaving fairly heavy carbon fouling.

Despite the problems, the .22 PPC offers a bit more pure accuracy than the 6BR and also a tiny bit less recoil. Both of these things can contribute to slightly higher scores in prone matches. However, to get the most out of the PPC, one must find the time to clean between 20 shot strings–a not inconsiderable effort sometimes in the mad rush of pit changes, scoring, shooting and just plain being tired.

This rifle was initially a .223 and when that cartridge proved unsatisfactory for my purposes, I had it rebuilt as the .22 PPC you see here. I like it and I enjoy the challenge, but I would not recommend this combination as someone’s primary rifle; it can get a bit frustrating. To put it into another context, the 6BR is like a 350 Chevy, it’ll just keep on doing the job forever, no matter what. The .22 PPC is like a Ferrari, it’ll scream when you do everything right, but it takes more attention to detail and a lot more maintenance. You wouldn’t want a Ferrari as your only car and likewise, you would be better off making the .22 PPC a second rifle.

|

Parting Shots — The .22 PPC vs. 6mm BR

If you’re looking for a simple, accurate and reliable cartridge for 200 to 600 yards, you probably can’t improve on the 6BR. However, if you’re someone who finds the journey as rewarding as reaching the destination, then you may very well enjoy a .22 PPC for prone shooting. While I received a great deal of help in this project from friends, gunsmiths, suppliers and parts makers far and wide, I really must acknowledge the huge debt we all owe to Ferris Pindell and Dr. Lou Palmisano. Without them there would be no PPC. We truly stand on the shoulders of giants.

Copyright © Precision Shooting Magazine and GS Arizona. Reprinted by permission.

July 18th, 2021

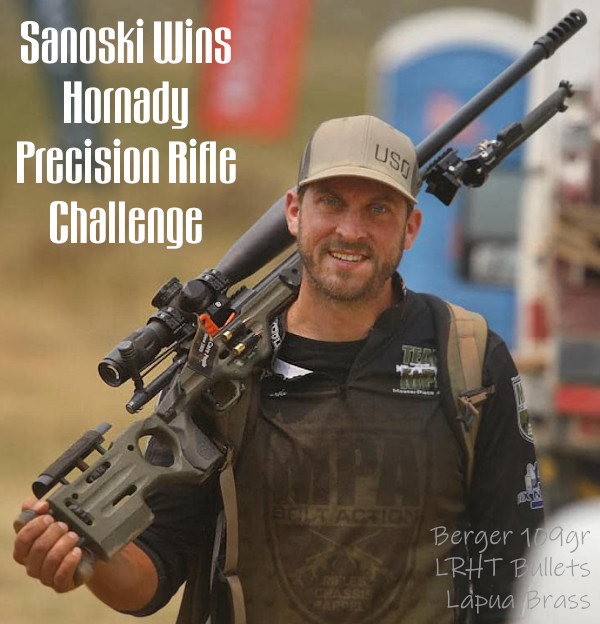

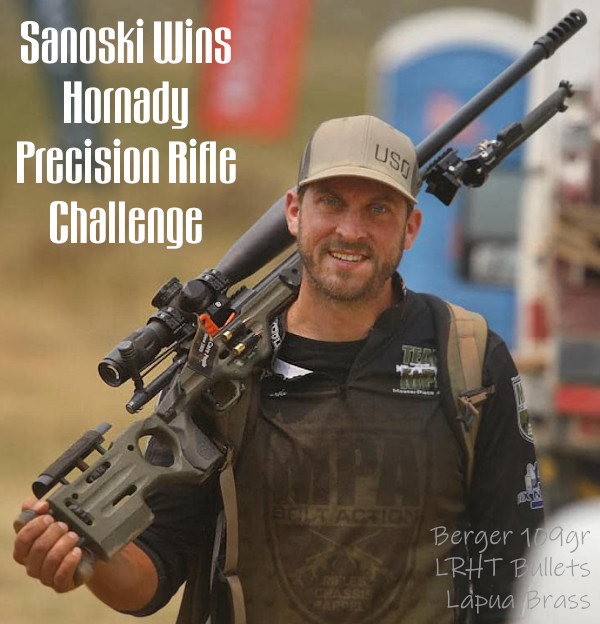

Berger-sponsored shooter Ken Sanoski claimed the top spot at the 2021 Hornady Precision Rifle Challenge (PRC) Match, winning the Open Division with the highest overall score. The 2021 Hornady PRC event was held July 9-10 outside of Evanston, WY on Hornady’s private ranch. Sanoski competed with an Exodus rifle chambered in 6mm Dasher with Berger 109gr Long Range Hybrid Target (LRHT) projectiles loaded in Lapua brass (fire-formed to 6mm Dasher).

“The Hornady PRC precision rifle series was exactly what you expect from a national-level 2-day match. Strong winds, small targets, and a stacked field of shooters”, commented Sanoski. “My Exodus Rifles in 6mm Dasher using Lapua fire-formed brass and Berger 109gr LRHTs were the winning combination to put me at the top of the leaderboard.”

Berger’s Long Range Hybrid Target projectiles feature an optimized hybrid-ogive design which easily tunes to your rifle, offers superior exterior ballistics, and high Ballistic Coefficients (BCs). Berger BCs are Doppler-verified with less than 1% BC variation. That verified BC helps make ballistic calculations ultra-precise for a high hit percentage.

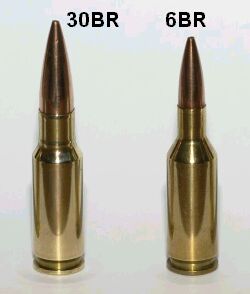

6mm Dasher — A Winning Wildcat

The 6mm Dasher has long been a winning wildcat in the 600-yard and 1000-yard benchrest game. This efficient 6mmBR Improved cartridge, with a 40-degree shoulder, has also been adopted by many top PRS/NRL shooters. The 6mm Dasher has long been a winning wildcat in the 600-yard and 1000-yard benchrest game. This efficient 6mmBR Improved cartridge, with a 40-degree shoulder, has also been adopted by many top PRS/NRL shooters.

The Dasher, quite simply, offers a winning combination of accuracy, low ES/SD, and moderate recoil. You can run a 105-109gr 6mm bullet at a very accurate 2950 fps node (or even higher in some barrels). And with its 40-degree shoulder, the brass is very stable. The cartridge that wins in benchrest now also wins in PRS.

The only downside to shooting a 6mmBR or 6 Dasher in PRS/NRL were issues with magazine-feeding due to the relatively short Cartridge OAL, compared to a 6mm Creedmoor or 6XC. Thankfully, that feeding issue has been solved via dedicated shorter-length actions and redesigned magazines.

As the practical/tactical game has evolved, with low recoil and high accuracy becoming ever more important, many top competitors have moved to smaller cartridges such as the 6mm Dasher and its parent, the 6mmBR Norma. These cartridges deliver outstanding accuracy plus good barrel life. However, the “short, fat” 6BR/Dasher design doesn’t feed optimally in magazines designed for the .308 Win family of cases. But now there is a turn-key solution from MDT (Modular Driven Technologies) — a magazine perfect for 6BRs and Dashers.

MDT Magazine for 6 Dasher, 6mmBR and Short Cartridges

MDT’s 6mm Dasher/BR magazine fits the parent 6mmBR cartridge and all the popular variants including the 6 BRA, 6 Dasher, and 6 BRX. MDT says this new 12-round magazine is a “one-step solution [delivering] smooth, reliable feeding for the most popular rifle cartridges in precision rifle competitions.”

MDT built this AICS-pattern mag for PRS/NRL competitors and anyone wanting to run 6mmBR-family cartridges in mag-fed actions: “The limiting factor for competitors running 6mm BR variants has been feeding. Until now, the only option has been to purchase an AICS-pattern magazine plus an additional kit to make the magazines work with the shorter cartridges. This solution costs upwards of $100 or more and can require additional tuning to work in most rifles.”

If you can’t afford MDT’s complete $89.99 6mm/Dasher AICS magazine, you can get a mag conversion kit from Primal Rights for half the price — $45.00. This is offered in 4+1 round or 10-round versions. Primal Rights states: “The 6BR AICS Magazine Conversion [delivers] reliable feeding of short standard bolt face cartridges such as the 6BR, 6.5 Grendel, 6 Dasher, and 6BRX. If you have ever tried to run a 6BR [or Dasher] out of a standard un-modified AICS magazine, you were probably met with the same disappointment the rest of us were… unreliable feeding.”

The Primal Rights 6BR AICS Mag Conversion Kit has been tested extensively with 6BR, 6.5 Grendel, 6 Dasher, and 6BRX. For these short cartridges, Primal Rights has logged “thousands of rounds of trouble-free operation” with the Mag mod kit.

July 18th, 2021

Many years ago, when we decided to do a story about SAKO’s TRG series of rifles, we remembered our friend Terje Fjørtoft in Norway. Terje has owned, and hunted with, both the TRG-22 (in .308 Win), and its big brother, the TRG-42 (chambered in .338 Lapua Magnum). Unlike many TRG owners in the USA, Terje has carried his “tactical hunters” into the field, and tested their effectiveness on large game in both coastal and mountain environments, in warm weather and cold. Terje tells us the TRGs have proven to be rugged and reliable. And they are accurate. The .308 Win TRG-22 delivers about 0.45 MOA groups at 420 yards shot from bipod. The .338 LM TRG-42 shoots about 0.55 – 0.7 MOA at that distance.

| A Tale of Two TRGs by Terje Fjørtoft

I live in Brattvåg, along the coast of Norway, but I hunt and shoot at the nearby island “Fjørtoft” (same as my last name) and a small island outside Fjørtoft. I grew up on Fjørtoft as a child, and we hunt seals there in the spring and fall. The large, top photo shows me with my black TRG-42 338 Lapua Mag (“LM”) during a seal hunt a couple years ago. Click on the thumbnail at right to watch a video that shows me shooting the .338 LM. Most of the photos in this story are from that hunt. Because the .338 LM was really “overkill” on the seals (and expensive to reload), I replaced that rifle with a TRG-22 in .308 Winchester.

We hunt seals primarily for wildlife control. This is because the seals carry an internal parasite, called “Kveis”, a small worm that breeds inside the seals (after eating contaminated fish). When the seals expel the Kveis into the water, the Kveis larvae are consumed by the fish and then the fish become unfit to eat. The parasite literally eats the fish from the inside out. It’s not very pretty and it has hurt our Norwegian fishing industry. So there is an important purpose for our seal hunting. We hunt mostly from islands, targeting the seals in the water, and retrieving them with a small boat. We hunt seals primarily for wildlife control. This is because the seals carry an internal parasite, called “Kveis”, a small worm that breeds inside the seals (after eating contaminated fish). When the seals expel the Kveis into the water, the Kveis larvae are consumed by the fish and then the fish become unfit to eat. The parasite literally eats the fish from the inside out. It’s not very pretty and it has hurt our Norwegian fishing industry. So there is an important purpose for our seal hunting. We hunt mostly from islands, targeting the seals in the water, and retrieving them with a small boat.

Because the seals spend most of their time in the water, a seal-hunter needs a very accurate rifle [to take head shots at distance]. I like the TRG-22 because it is very accurate out of the box, with a very nice bipod that works well in the field. The stock is comfortable with good adjustment range. The TRG features a 10-rd magazine and the barrel is pre-threaded for a muzzle brake or suppressor. Because the seals spend most of their time in the water, a seal-hunter needs a very accurate rifle [to take head shots at distance]. I like the TRG-22 because it is very accurate out of the box, with a very nice bipod that works well in the field. The stock is comfortable with good adjustment range. The TRG features a 10-rd magazine and the barrel is pre-threaded for a muzzle brake or suppressor.

I have also used my TRGs for hunting big game, deer and what Americans call “Elk”. You can see, further down on this page, a picture from a hunting stand taken late in the evening, in the fading light. Yes I successfully bagged a nice buck during that trip with my TRG-42. When hunting, I use a Leica 900 rangefinder, Swarovski 7×42 Habicht binoculars, and a Silva windwatch. For Optics on the TRG-22, I have a Zeiss 6-24×56 scope, in Tikka Optilock rings. To get more scope adjustment I milled 0.9 mm off the front scope base mount. The Zeiss is great for viewing small targets past 400 meters. It was very difficult to find a longer shooting place than 575 meters on this Island (Uksnøy) but I found a place where I can shoot out to 930 meters, and I’ve made an 80-cm steel gong for a target. At this range, the bullet must fly nearly all the distance over the water.

Terje Shooting the TRG-42 without suppressor. Big recoil, big flash.

Both the TRG-22 and TRG-42 are very accurate right out of the box. The only thing I did before I first shot the TRGs was to clean the barrels very thoroughly. This is because the SAKO factory test shoots the gun without cleaning the barrel. I also adjust the cheek piece upward when shooting the rifles with a big scope. However, if you raise the cheek piece too high you can’t get the bolt out without removing the whole cheek piece. The only real modification I’ve made to my TRGs was to put rubber foot pads on the feet of the SAKO factory bipod. This gives the bipod better grip on slick surfaces such as concrete, or the rocks on the offshore islands. Both the TRG-22 and TRG-42 are very accurate right out of the box. The only thing I did before I first shot the TRGs was to clean the barrels very thoroughly. This is because the SAKO factory test shoots the gun without cleaning the barrel. I also adjust the cheek piece upward when shooting the rifles with a big scope. However, if you raise the cheek piece too high you can’t get the bolt out without removing the whole cheek piece. The only real modification I’ve made to my TRGs was to put rubber foot pads on the feet of the SAKO factory bipod. This gives the bipod better grip on slick surfaces such as concrete, or the rocks on the offshore islands.

.338 LM vs. .308 Win — Smaller Can Be Better .338 LM vs. .308 Win — Smaller Can Be Better

A few years ago I had a black TRG-42 (338 LM), but after a year, I sold it, and ordered a TRG-22 from the SAKO factory. After a one-year wait, I got the new green TRG-22 in February this year. One main reason I changed to .308 Win was the cost of ammo. I can reload .308 Win ammo for about one-third the price that it costs to reload .338 LM. One other reason is that my usual shooting distance is about 390 meters–at that distance the .308 is more than effective enough. Also, with the .338 LM, the barrel and the suppressor heated up after only a few shots, but with my new .308, I can shoot at my own pace without this problem. After my most recent shooting trip I once again confirmed how accurate, and fun-to-shoot, the TRG-22 is. I think now the TRG-22 has become my favorite plinking gun.

Though it is fun to experience the big boom and flash of the .338 LM, I’ll admit that it is just too much rifle for most applications. The .338 LM is REAL overkill for seal hunting. Here in Norway we have a rule that the smallest caliber we can use is 6.5×55 with a 140gr (or heavier) bullet, but everyone who hunts seals knows that the seals stay mostly in the water, and therefore you must take a headshot at distance up to about 200 meters. Making the headshot with a smaller caliber is advised for two reasons. First, when a big .338 bullet hits the water, there is a danger it will skip and ricochet quite some distance. Second, if you use too powerful a load/gun/caliber and take a headshot on a swimming seal, the seal sinks like a rock.

|

Reloading for the TRG-22 (.308 Win) Reloading for the TRG-22 (.308 Win)

With the TRG-22, I found it was easy to get an accurate load. My groups with 155gr Scenars are consistently good with a variety of different powders. I’ve tried both light and heavy bullets, but I favor the 155gr Scenars over the 185gr Scenars because the 155s fly a lot faster and drop less.

Three loads (all with Fed 210m primers) that have worked well are: 155gr Scenar with VV N150, 885m/sec; 155gr Scenar with Norma N-11, 890m/sec, and 185gr Scenar, VV N150, 770m/sec. Norma N-11 is a low-cost powder for target shooting. N-11 is similar to Norma 203B or Norma 202 but it varies quite a bit from lot to lot.

I use a RCBS Rock Chucker press, and currently use a standard RCBS full-length die kit to reload my .308 rounds. However, I recently ordered a Redding Competition 3-die set with a .335 bushing. I look forward to trying the Reddings. I have just started to test different seating depths. The 155s just “kiss” the lands at 74.10 mm. I’ve tried 74.00 mm, 74.10 mm and 73.55 mm, but so far saw no significant differences.

Reloading for the TRG-42 (.338 LM) Reloading for the TRG-42 (.338 LM)

For the .338 LM, I started with a 250gr Scenar and 95 grains of Vihtavuori N-170. That load was very accurate at about 850 m/sec, but it produced excessive muzzle flash. And, in the winter, the muzzle velocity was inconsistent, and there was too much unburned powder. Next I tried Norma N-15, which proved very accurate at about 880 m/sec. With that load I shot my best TRG-42 group at 380 meters. I set the 250gr Scenar to touch the rifling with 93.2 mm COAL, and I used Federal 215m primers in Lapua-brand brass. Norma MPR2 and VV N-560 (860 m/sec) also were very accurate with the 250 Scenar.

My seal hunting bullet was the 200gr Nosler BT. This bullet grouped very well with 90-94 grains Norma N-15. Velocity was about 970m/sec if I remember correctly. I also tried the 300gr Sierra MK, and got 1/2″ 3-shot groups at 100 meters with 93.5 grains of VV N-170, but this combination produced terrible groups at longer range.

Loading for the .338 LM was not difficult — about the same as loading for .308 Win, except that you use nearly twice the amount of powder. I didn’t crimp the bullets in the neck, didn’t use any special tricks or neck lube. I used RCBS .338 LM full-length die. That functioned, but it would not be my first choice today. Overall, my better loads in the .338 shot in the 0.5-0.7 MOA range. My best group was four shots in 25mm (1″) at 380 meters (416 yards).

Hunting in Norway Hunting in Norway

I’m not a competitive sport-shooter. Normally, the only time I go to a “commercial” rifle range is to take the test for my hunting license. Every year, I must re-qualify for a shooting license to hunt big game and seals.

Hunters Tested Annually

In Norway, you must pass an actual shooting test before you can hunt big game. This test requires five shots at a deer silhouette target at 100 meters. No rests are allowed–you must shoot off-hand or with a sling only. You have to place five shots inside a 30 cm circle over the front leg.

Every big game hunter that passes this test is authorized to hunt at “dusk and dawn” and in moonlight. So, we do a lot of our hunting in the twilight hours. However, no night-vision or artificial illumination (spotlights) are allowed. We usually hunt deer at dusk and dawn. In the evening, we go on post two to three hours before it is dark, and sit there waiting for the deer to show up–hopefully before it is too dark. In the morning we go to the post one hour before you see any light of the sun, and wait for the deer to show up until the daylight. But when it is full moon we sometime have enough light to hunt in the middle of the night. In the photo, you can see a deer through the scope of my TRG-42. This was very late in the evening. CLICK HERE for BIG Photo.

|

| Sound Suppressors for Hunting Rifles

Suppressors are legal to use for hunting in Norway. I have suppressors on all my rifles, even my little CZ 452 in 17 HMR. To me, shooting a rifle without a suppressor is like driving a car without an exhaust system. The suppressor reduces both noise AND recoil significantly. With a good suppressor, there is no loss of accuracy. The only “negative” in using a suppressor is extra weight on the end of the barrel.

I crafted my own home-made suppressor. It’s similar to my commercially-made TRG-22 suppressor, but the core is made from titanium to be lighter in weight and more corrosion-resistant. I used a lathe at work to craft the inside of the new suppressor. The core of the unit is built from a 27.5 cm X 40mm round bar of titanium while the outer cylinder is made from a 42mm stainless steel tube. I wanted to use titanium for the exterior cylinder as well, but I couldn’t source the right size titanium tube.

|

Commercial Suppressor on TRG-42 |

Comparing .308 Win vs. 6mmBR

I also have a 6BR hunting rifle (compensated of course). I have a lot of field time with the 6BR rifle, and feel very confident with that gun. When I got the Krieger 6mmBR barrel on the SAKO Varminter, I fell in love with that rifle from day one, and that rifle is my first choice for small game hunting. I also have a 6BR hunting rifle (compensated of course). I have a lot of field time with the 6BR rifle, and feel very confident with that gun. When I got the Krieger 6mmBR barrel on the SAKO Varminter, I fell in love with that rifle from day one, and that rifle is my first choice for small game hunting.

I also like the TRG-22 gun very much and enjoy it more and more with each new field trip. That .308 is my big game rifle and my long-range target rifle.

I recently tested my TRG-22 rifle at 387 meters. This was just “fun shooting” at steel plates, and I didn’t measure groups. But I was happy with the results. Once I corrected for the 5 m/sec crosswind, I was able to put five successive shots on a 10 cm (4″) diameter steel target at 387 meters (423 yards).

My SAKO Varminter in 6mm BR and my TRG-22 are two very different rifles. The TRG-22 is much heavier. I guess the TRG-22 is about 6.5-7 kg while my SAKO 6BR is about 4.5-5 kg, both with suppressor, scope, and bipod. The 6BR with suppressor is much quieter than the TRG-22 with suppressor. The recoil of the 6BR is a lot softer than the TRG-22. So far my 6BR is more accurate. A typical three-shot group with the 6BR is 25-40 mm at 387 meter (423 yards), and that is with just 10X magnification from a Zeiss scope. With my TRG-22, my 3-shot groups run about 50-60 mm, shooting with bipod and beanbag. But I think with a better .308 Win reloading die and more practice, I can improve my groupings with the TRG-22.

|

SPEC SHEET

The SAKO TRG-22 and TRG-42 are built in Finland by SAKO, a subsidiary of Beretta. In America, the guns are distributed by Beretta USA. Both TRGs (22/42) are available in forest green or a matte black textured finish. A two-stage match trigger is standard.

The stock is somewhat unconventional. It is an external shell, bolted to an internal metal chassis. The action bolts directly to the chassis, without bedding. The injection-molded stock is adjustable for comb height, length of pull (with spacers), vertical butt-pad height and cast-off.

Weight TRG-22

4.7 kg (black)

4.9 kg (green)

Barrel TRG-22

660 mm (26″), hammer-forged, optional stainless or phosphate finish

Capacity

10-round Mag (TRG-22)

7-round Mag (TRG-42)

Calibers

.308 Win (TRG-22)

300WM, .338 LM (TRG-42) |

June 27th, 2021

Shooting Prairie Dogs at extreme long range takes some highly specialized equipment. Forum Member VolDoc and his friends have taken long-range varminting to a whole new level. With his Savage-based, Hart-barreled 20 BR, VolDoc managed a verified 1,032-yard Prairie Dog kill, possibly the longest recorded with a .20-Caliber rifle. But that’s just part of VolDoc’s impressive precision varminting arsenal. Here we showcase three of VolDoc’s accurate rigs: his stunning English Walnut Diamondback 6BR/Dasher, his Nesika-actioned “Orange Crush” Dasher, and the 1K Prairie Dog-slaying 20 BR Savage.

Diamondback Switch-Barrel Rifle Specifications

The action is a Stiller Diamondback, drop-port. The custom stock is similar to a Shehane ST-1000, but crafted from 40-year-old English Walnut. [Editor’s note: the wood on this gun is gorgeous!] There are three barrels for the gun with three different chamberings: 6BR Brux 1:8″-twist HV; 6BRX Krieger 1:8″-twist HV, and 6mm Dasher Krieger 1:8.5″ twist fluted straight contour (no taper). The scope is a Nightforce 12-42x56mm, with 2DD reticle.

Comments: This rifle is a good study in comparison of the three different chamberings. On the same rifle platform (same stock and action), each of these barrels had killed prairie dogs over 1,000 yards. So if someone asks which is best, a 6BR, or 6BRX, or 6 Dasher, VolDoc says they are all effective. The improved cartridges will deliver higher velocities, which can be an advantage. On the other hand it is simpler to load 6mmBR brass right out of the box, and it’s easy to find an accurate load for the 6mmBR (see photo).

Nesika 6mmBR/Dasher Rifle Specifications

VolDoc’s “Big Orange Crush” rifle has a stainless Nesika ‘J’ action, with 2 oz. Jewell trigger, in a painted fiberglass Shehane ST-1000 stock. Originally a 6BR, the gun is now chambered as a 6mm Dasher with a .271 no-turn neck. The barrel is a 1:12″-twist Krieger fited with Vais muzzle brake. On top is a NightForce NXS 12-42x56mm scope with double-dot reticle. The double-dot gives precise aiming and lower dot can be used as an aming point, when you need a few more MOA of elevation in the field.

Comments: Big Orange Crush shoots 87gr V-Maxs into bugholes at 3,400 fps. VolDoc’s load with the 87s is very stout, more than 32 grains of Vihtavuori N-135 with Wolf SRM primers. Cases are full-length sized, with an 0.266″ bushing for the necks.

This 3400 fps load with the 87gr V-Maxs has accounted for hundreds of Prairie Dogs killed from 97 yards to 1,050 yards. The 87gr V-Max at this speed literally picks Prairie Dogs up and throws them 10 feet vertically and laterally. VolDoc reports: “The barrel now has more than 3,000 rounds down the tube and exhibits little throat fire-cracking and no loss of accuracy. I can’t explain why, it just hasn’t deteriorated yet. This rifle is my best-ever ‘go-to’ Prairie Dog rifle.”

Savage 20 BR Rifle Specifications

The action is a Savage Dual Port, with an aftermarket Sharp Shooter Supply (SSS) 4 oz. Evolution trigger. The stock is a modified Savage factory unit that has been pillar-bedded. The factory barrel was replaced with a 28″ Hart stainless, 1:9″ twist barrel fitted with a Rayhill muzzle brake. The gun is chambered in 20 BR with a 0.235″ no-turn neck. Kevin Rayhill did the smithing. To provide enough elevation to shoot at 1,000 yards plus, Ray fitted a +20 MOA Bench Source scope base. This +20 rail is very well-crafted, and made especially for the Savage Model 12.

Comments: VolDoc reports: “When I got the Savage back from Kevin Rayhill, it still had my 6 BR factory barrel on it, as I use it to compete in Factory-class regional matches. I put on the new 20 BR Hart barrel Kevin had chambered and quickly put in a full day of load development using the 55gr Bergers (0.381 G1 BC) and the 40gr V-Maxs. Both proved very easy to tune and I soon had my loads. My 55gr Berger load with runs about 3590 fps. Varget was very accurate with the 55s (see load dev. targets below).

The mild recoil of the 20 BR, along with a very good muzzle break (Rayhill’s design) enables me to spot every hit or miss myself. Kevin also re-contoured the underside of the Savage stock so it tracks straight back on recoil, also making seeing hits easier.”

| The 20 Caliber 1000-Yard Prairie Dog Quest |

Making the 1032-Yard Shot with a 20 BR Making the 1032-Yard Shot with a 20 BR

by Dr. John S. (aka “VolDoc”)

This article covers my recent successful quest for a 20-caliber varmint kill past 1,000 yards. This may be a first — I couldn’t find anyone else with a confirmed 20-Cal Prairie Dog kill at 1000+. I started a thread on the Varmint section of the AccurateShooter.com Forum about building a 20 BR capable of 1,000-yard Minute of Prairie Dog accuracy and many said 20 Cal bullets just could not do it. Some came to my defense and said those that doubted had never studied the ballistics of the 20BR with the new Berger 55gr bullets now available. Well, folks, I can tell you, hitting a Prairie Dog at 1000 yards isn’t easy — but it IS possible. Here’s how it was done….

Gale-Force Winds and High Temps

After arriving at our Prairie Dog Ranch in Colorado, I soon realized my quest was going to be especially difficult because we had continual 40+ mph winds and 100° heat every day. We had a special place where Birdog and I had made many 1,000-yard+ kills in years past, so I knew the ideal location but needed a small window of opportunity either early morning or late afternoon. Based on past experience, I knew I needed about 21 MOA from my 100-yard zero to get to 1,000 yards. On the first day of the Safari, I shot the 20 BR in the 45 mph brutal winds and heat of 97°. But after about 20 shots, I connected on a dog and lifted him about three feet high. Well, that’s a start.

Winds Subside — Here’s Our Chance …

On the second day of our shoot, I had listened to the early weather forecast, so I knew that there was to be a brief period of light winds early in the morning. We were out on the Colorado prairie at daylight and the conditions were perfect. The sunrise was at my back and we had about a 10 mph tailwind. I looked through my Leica Geovid Rangefinder Binos and the Prairie Dogs were out for breakfast. I quickly ranged the targets and found a group at about 1,050 yards. The technique is to find the dogs, range them, click-up according to your ballistic chart and shoot.

My first shot was very, very close. I added about four clicks up and a couple of clicks left for windage and let another go. That shot threw dirt all over, but the dog didn’t even flinch. This is another good point to remember about long-range Prairie Dog hunting. To be successful, the dogs can’t be too skittish, because if they have been shot at even a few times, they will go down and stay down. So, you should have an agreement with those in your party as to where each member is going to be shooting and respect this boundary. Drive-by shooting style is OK if that’s your thing, it’s just not mine.

Hitting the Mark — Dead Dog at 1032 Yards Hitting the Mark — Dead Dog at 1032 Yards

On the fourth shot, I saw the dog go belly up and kick its final throws. My quest for the 20-Caliber 1,000-yard Prairie Dog had become a reality. We confirmed the distance with our lasers at 1,032 yards. Our technique for retrieving a dead dog at that range is worth mentioning. When I killed that dog, I left it in the crosshairs of my Nightforce scope. My shooting buddy kept looking through the scope (of my gun) and guided me to the deceased dog using Motorola walkie-talkies. When I got to the dog I was jubilant. I marked it with my tripod and orange jacket, and we took some pictures. (See view through scope photo below). The 55gr Bergers require a center mass hit as they will not expand, especially at that range. I centered this dog in the head — his BAD LUCK, my GOOD.

After making the 1,032-yard kill, I shot many many other Prairie Dogs with the Savage 20 BR using the 40gr V-Maxs. The dog flights were spectacular — red mist and helicopters, counter-clockwise or clockwise on demand. I killed at least five at over 500 yards. I will not use the 55 Bergers on Prairie Dogs again since the quest is over. I will use the 40gr V-Maxs and 39gr Sierra BlitzKings for next trip’s 20 BR fodder.

CLICK HERE for More Info on Voldoc’s 20 BR Savage Varmint rifle »

May 16th, 2021

Chuck’s Pair of Pennsylvania Dashers

The 6mm Dasher wildcat cartridge is very popular among competitive benchrest shooters, varminters, and even PRS competitors. So this Sunday we thought we’d showcase a matched Duo of Dasher rifles belonging to a Forum member Chuck L. (aka “Ridgeway”). The 6mm Dasher began as a wildcat improved version of the 6mmBR Norma cartridge. The Dasher has been very successful in competition, and now factory Peterson 6mm Dasher brass is sold by Grafs.com. And Alpha Munitions also offers high-quality 6mm Dasher cartridge brass.

Chuck has a prize pair of 6mm Dashers for competitive benchrest and varmint matches in Pennsylvania. Both guns feature Kelbly Panda RBLP actions, Bartlein 8-twist barrels, and Shehane Laminated Tracker Stocks. However, the two rifles are not exact twins, as you can see. One, which we’ll call the Big Dasher, is built on a Shehane ST1000 Tracker stock. The other gun, the Small Dasher, sports Shehane’s “Baby Tracker” stock — a design used with great success by Richard Schatz. The Big Dasher, optimized for 1000-yard competition, has a slightly longer freebore — 0.136″ vs. 0.104″ for the Small Dasher.

| Specifications for the Dasher Duo:

Small Dasher (13.5-pounder): Chambered for 6mm Dasher with approximately .104 freebore and a .264 NK. (No way of knowing exactly since its freebore was set in a separate operation by Kelbly.) Components are: Shehane Baby Tracker laminated stock, Kelbly Panda RPLB action, Bartlein 1:8″ LV barrel at 26 ¾”, Kelbly Rings, Weaver T36, Jewell trigger. The barrel was chambered by Kelblys and the stock was bedded, glued and balanced by a shooting buddy (Forum Member johara1). Chuck clear-coated the stock with auto urethane. Total weight is 13 lbs., 4 ounces.

Big Dasher (1K Light Gun, 17-pounder): Chambered for 6mm Dasher with a .136 freebore and .264 neck (PTG Reamer). Components are: Shehane ST-1000 laminated stock, Kelbly Panda RPLB action, Bartlein 1:8″ HV 5R barrel at 28″, Shehane +20-MOA rings, Nightforce NXS 12-42x56mm, Jewell trigger. The barrel work, pillar installation, and bedding was done by Dave Bruno. The stock was clear-coated by Chuck with auto urethane. Chuck also made the rear butt plate and balanced the rifle. Total weight: 16 lbs., 13 ounces. |

Chuck tells us: “I don’t get out shooting competition as much as I want due to time and family, but when I do compete, I shoot a Groundhog match at Southfork Rifle Club in Beaverdale, PA. Info on Southfork Club events can be found at Southforkrifleclub.com. The Southfork match is basically a 100-, 300- and 500-yard match with one sighter the entire match and 5 shots at each yardage for score. The Small Dasher, with the shorter ‘Baby Tracker’ stock, was set up for the Southfork Rifle Club’s ‘Light Unlimited’ class which has a 13.5-lb max weight.” (Editor: ‘unlimited’ is a misnomer for a weight-limited category.)

Chuck adds: “The Big Dasher with the heavy ST-1000 stock is set up for 1000-yard benchrest matches in Light Gun class. I shoot 1K matches with it at Reade Range in southwest Pennsylvania. One ironic thing is, it shoots the same load I’m shooting out of the lighter gun rather well. The only difference between the two chambers is the freebore is roughly thirty thousandths longer on the 1K gun (Large Dasher). I will also shoot this at Southfork in the ‘Heavy Unlimited’ class.”

Both Dashers Group in the Ones at 100 Yards

Chuck favors 107gr Sierra MK bullets in both Dashers. Other components are: Reloder 15 powder, Lapua cases, and CCI 450 primers. His main load for the Small Dasher is 33.0 grains of Reloder 15. This load shoots in the ones at 100 yards. For the Big Dasher Chuck reported: “I’m still working on a load, although the same 33.0 grain load shoots in the ones in the heavier gun as well. I’m still looking for more velocity and my ‘max’ node.”

Dasher Brass — Three Options

1. Buy Peterson 6mm Dasher Brass

In years past, you had to create your own Dasher brass, by fire-forming (with or without projectiles), or by hydro-forming. However, Peterson Cartridge now offers factory-made 6mm Dasher brass.

If you do not want to waste time with fire-forming or hydro-forming, you can look for Peterson 6mm Dasher brass. This is excellent quality brass that has earned high praise from purchasers. The price — $62.99 for 50 cases at Graf’s (i.e. $1.26 per case) — is less than what you’d pay for Lapua 6mmBR brass, which is $149.99 for 100 cases or $1.50 per case. The advantage is that you save time, barrel life, and you won’t lose any cases to split necks. Peterson brass can be ordered from Grafs.com.

2. Fire-Form Dasher Brass with Bullets Hard in Lands

Chuck fireforms his Dasher brass for both rifles. Because he has a tighter-neck chamber, he neck-turns the brass first: “To fireform, I turn my cases down to fit the chamber and stop where the false shoulder makes snug contact with the chamber. Fire-forming rounds are loaded up with a 29-grain charge of H4895 or Varget and a 108gr Berger bullet seated hard into the lands about 0.020″ past initial contact with the rifling. It takes about three firings to make a nice clean Dasher case with a sharp shoulder.”

Chuck anneals his Dasher brass regularly to help maintain consistency: “I anneal about every 3-4 firings. I have many cases that have about 10+ firings on them and they are still shooting well. The primer pockets are a little looser, but still hold a primer.”

3. Have Darrell Jones Hydro-Form Your 6BR Brass to 6mm Dasher

DJ’s Brass can hydro-form a wide variety of cases for a modest fee

Fire-forming all your own 6mm Dasher brass takes time, costs money (in bullets and powder), and consumes precious barrel life. Well there IS a better solution — you can have your new brass hydro-formed by DJ’s Brass to your exact specifications for a $60.00 per hundred, which includes annealing. Fire-forming all your own 6mm Dasher brass takes time, costs money (in bullets and powder), and consumes precious barrel life. Well there IS a better solution — you can have your new brass hydro-formed by DJ’s Brass to your exact specifications for a $60.00 per hundred, which includes annealing.

DJ’s Brass Service now offers custom case hydro-forming to your exact specs. Darrell Jones offers this service for a variety of popular cartridges: 6 PPC, 30 PPC, 30 BR, 6 BRA (BR Ackley), 6mm Grinch, 6 BRDX, 6 BRX, .260 Ackley, .284 Shehane and of course the very popular 6mm Dasher. After hydro-forming your brass, Darrell can also neck-up or neck-down the cases to meet your needs. He can also turn the necks to your specs for an additional $0.60 per case.

February 21st, 2021

Spring is coming soon, and that means it’s time to get ready for early varmint season. Here are eight great rifles from our Shooters’ Forum Favorite Varmint Rifles Thread. You’ll see a variety of action types and stock designs, both custom and factory. And we’ve featured a wide range of chamberings, from 17 Fireball up to a .243 Super Rock Chucker (aka 6mm-06). The common factor is serious accuracy. All these rigs are great shooters that have brought smiles to their owners while bringing doom to varmints.

1. Rem 700 in 20-222 — with Birthday Gift Barrel from Dad

This is proof that you don’t have to spend a fortune to have a great varmint rig. Forum member JDS Holler posted: “Here’s my baby, ‘Plain Jane’. I took a $500 birthday check that my Dad gave me, and ordered a great barrel from PacNor, chambered in 20-222. I got busted up in a fall, and had four months down time to accumulate the components to add to my old .222 Rem 700 donor action. I couldn’t be happier with the outcome. That old Bushnell has been replaced by a Vortex Viper, and this rifle just flat shoots.”

2. 6 BRA with Krieger Barrel from Alex Wheeler

Alex Wheeler of Wheeler Accuracy knows a thing or two about accurate rifles, having built many match-winning benchrest rifles. For varmint work he likes the 6 BRA (BR Ackley) wildcat cartridge: “My favorite varmint setup is this 6mm rifle with BAT SV action in a Nesika bay varmint stock with a 1:8″-twist Krieger HV contour barrel chambered for 6 BRA. I like the 6mmBR and variants (Dasher, BRX, 6BRA) with zero freebores.” He gets great results with 55-60 grain Sierras and Noslers with H322 powder: “I shot 55 Sierra Blitzking, 55 Nosler Ballistic Tip, and 60gr Sierra Varminter HP. H322 was the best powder. Jam ‘em 10 thou in the rifling — and of them — and man they were like magic.” Alex also feels the 6mm rifles are easier to tune than 22-caliber varmint rigs and the 6mm barrel throats last longer. He often puts an older 6mm match barrel on a varmint gun and it still holds quarter-MOA.

Alex recommends sticking with a 1:8″-twist even when shooting light 6mm bullets. The extra RPM makes the bullets MUCH more explosive on critters: “I’ve done one 1:13.5″-twist and I’ll never do that again. I’m not kidding, with the 8-twist it’s twice as energetic. It can lift those ground squirrels 20 feet in the air. With the 13.5-twist it’s not half that.”

About the Suppressor — The rifle is wearing a “can” in the photo. However, Alex tells us that he now avoids suppressors for most varmint work: “I didn’t like the suppressor — it put off so much heat that the mirage was terrible. With the heat mirage, after 5-10 shots you couldn’t see. I learned my lesson. I pulled that sucker off after the first time I shot it.”

3. 6mm Dasher in Convertible Laminated Stock

The 6mm Dasher has won many benchest matches, and it’s also an ultra-accurate varminting cartridge. This Dasher belong to Forum member MTLager who posted: “Here’s my baby — 6 Dasher with BAT SV action. First one built. Serial number PT1.” This impressive rig features a tack-driving, 1:8″-twist Brux Heavy Varmint contour barrel. This rig is “Smokin the 75gr V-Maxs” reports MTLager. The stock is very interesting. MTLager explains: “This is a Richard Franklin laminated blank made into a stock by J.T. Barber. It has a 3″-wide fore-end for varmint shooting. But I can change the front to 4″-width and a rear section can be removed.” The angled rear “toe” of the buttstock can be taken off, allowing a flat, straight bottom for benchrest competition.

4. Slick 17 Fireball with BAT Action and Stunning Stock

This rifle is almost too pretty to carry out into the varmint fields. Look at that wood! This handsome small-caliber varminter belongs to Forum member “20 TAC”. Chambered for the 17 Fireball wildcat (.221 Fireball necked down), this rig features a BAT Action, Jewell Trigger, and a custom exhibition-grade walnut stock sporting a true ebony fore-end cap. The checkering is exceptional. Owner 20 Tac report this rig “shoots 20 grain V-Max bullets with H4198 very well.” That’s a Nightforce scope on top.

5. 6mmBR in McMillan Stock with Krieger Barrel

This website stated 17 years ago as 6mmBR.com, so we had to include a classic 6mmBR Norma in today’s varmint rifle line-up. Forum member Powderbrake posted: “Here is my favorite varmint rifle — [a 6BR with] Stiller Predator V RBLP action, bedded in a McMillan stock.” This accurate varminter features a 1:8″-twist 6mm Krieger barrel and Jewell trigger. Up top is a Nightforce NXS 8-32x56mm scope. Below are the owner’s key gear items: Leica Laser-Rangefinding Binoculars, Smartphone with Applied Ballistics software, and Kestrel Weather Meter. Powderbrake told us he recently upgraded to a Model 5700 Kestrel with ballistics software and LiNK. (Editor: The $399.00 Kestrel 5700 has ballistics software, but if you want the full Applied Ballistics suite, order the $699.00 Kestrel 5700 Elite).

6. Efficient 20 Vartarg for Prairie Dog Adventures

The .20 Vartarg is based on the .221 Fireball case, necked down to .204 and slightly modified for extra capacity. This very efficient cartridge offers low recoil and great accuracy. It’s one of our first choices for ground squirrels and P-dogs out to 300 yards. 20 Vartarg here belongs to Forum Member DogBuster, an avid varminter based in Utah. He posted: “If I recall, I had a hot spot in this location — probably kilt 150+ prairie dogs that morning. The hay wagon helped too, offering added elevation.”

7. Long-barrel SAKO Action Varminter in .243 Super Rock Chucker

Here is another .243 wildcat, chambered for the .243 “Super Rock Chucker”. This long-barreled rig belongs to Forum member MikeGaiz. The rifle features a SAKO action fitted with a 30″ Kreiger barrel chambered for the .243 Super Rock Chucker. From what we have read, the .243 Super Rock Chucker is a .25-06 cartridge necked down to .243 (6mm). Yes this is a barrel burner, but it can definitely “reach out and touch” varmints at VERY long range. Owner Mike reports hits at 1275 yards on prairie dogs in South Dakota. This cartridge drives Sierra 6mm 85gr HPBTs at 3440 FPS. That’s serious speed for an 85-grainer.

8. AR-10 Custom in .243 Winchester

Forum Member Urban Rifleman calls this .243 AR10-platform rifle the “Goblin Killer”. This Gen 2 DPMS rifle features a Craddock Precision Bartlein 1:8″-twist 5R barrel chambered in .243 Winchester with a Tubb assymmetrical muzzle brake. Up front is the unique Tubb Bipod which reduces hop. The buttstock is a Magpul PRS Gen 2. The scope is a Leupold VX-3i LRP 6.5-20x50mm FFP TMR. We’re told this rig “will easily shoot 1/2 MOA, sometimes much smaller”.

Urban Rifleman produces a variety of great gun accessories sold through TheUrbanRiflemanStore.com. That green grip is his Urban Rifleman/Tubb ergonomic grip.

Parting Shot from Groundhog Country, SW Pennsylvania

This nice tripod with rifle mount (and Rem 40XB 22-250 on top) belongs to Forum Member Snert.

November 10th, 2020

Many visitors to the site ask us, “I’ve got a .223 and .308. What will a 6mmBR Norma (6BR) give me that I’m not getting already?” Well first you may well average somewhat smaller groups than your current .223 or .308 rifle (assuming the 6BR has a quality barrel and trigger). A good .308 Winchester can be superbly accurate, no question about that, but the lesser recoil of the 6BR works in the shooter’s favor over a long string of fire. Even with a Rem 700 or Savage action factory action, a 6BR with a benchrest stock, premium barrel, and a high-quality chambering job should deliver 5-shot groups in the high twos to mid-threes, provided you do your job. We have one 6BR rifle that shoots Lapua factory-loaded 6BR ammunition in the low twos and high ones. That’s exceptional, we admit, but it still shows how the 6BR is an inherently accurate cartridge, even with factory loads. Many visitors to the site ask us, “I’ve got a .223 and .308. What will a 6mmBR Norma (6BR) give me that I’m not getting already?” Well first you may well average somewhat smaller groups than your current .223 or .308 rifle (assuming the 6BR has a quality barrel and trigger). A good .308 Winchester can be superbly accurate, no question about that, but the lesser recoil of the 6BR works in the shooter’s favor over a long string of fire. Even with a Rem 700 or Savage action factory action, a 6BR with a benchrest stock, premium barrel, and a high-quality chambering job should deliver 5-shot groups in the high twos to mid-threes, provided you do your job. We have one 6BR rifle that shoots Lapua factory-loaded 6BR ammunition in the low twos and high ones. That’s exceptional, we admit, but it still shows how the 6BR is an inherently accurate cartridge, even with factory loads.

Compared to a .223, the 6BR offers a better selection of high-BC projectiles and small-maker match projectiles (such as Bart Sauter’s “Hammer” and the Vapor Trail line). The 6BR will also deliver considerably more power on the target. Compared to the .308 shooting 168gr MatchKings, a 6BR shooting 105-107gr bullets offers better ballistics all the way out to 1000 yards. (The story changes with .308s with very long barrels pushing the 180-210 grain projectiles). Plus, for most people, the 6BR is just easier to shoot than a .308. Recoil is less than half of the .308 Win cartridge. Both the .308 and 6BR chamberings offer good barrel life, but the 6BR uses 15-18 grains less powder, saving you money. Here’s how the 6BR stacks up vs. a number of popular calibers:

June 23rd, 2020

The 30 BR is an amazing little cartridge. However, 30 BR shooters do have to neck-up 6mmBR or 7mmBR brass and then deal with some issues that can arise from the expansion process. One of our Forum members was concerned about the donut that can form at the new (expanded) neck-shoulder junction. Respected bullet-maker Randy Robinett offers tips on how to deal with the “dreaded donut”. The 30 BR is an amazing little cartridge. However, 30 BR shooters do have to neck-up 6mmBR or 7mmBR brass and then deal with some issues that can arise from the expansion process. One of our Forum members was concerned about the donut that can form at the new (expanded) neck-shoulder junction. Respected bullet-maker Randy Robinett offers tips on how to deal with the “dreaded donut”.

The Forum member was concerned about thinning the brass if he turned his 30 BR necks after expansion: “Everything I have found on 30 BR case-forming says to simply turn off the bulge at the base of the neck caused by the old 6BR shoulder. I expanded my first case and measured the neck at 0.329″ except on the donut, where it measures 0.335″. Looking inside the case… reveals a groove inside the case under the donut. Now, it is a fact that when I turn that neck and remove the donut, the groove is still going to be there on the inside? That means there is now a thin-spot ring at the base of the neck that is .005 thinner than the rest of the neck. Has anyone experienced a neck cracking on this ring?”

Randy Robinett, who runs BIB Bullet Co., is one of the “founding fathers” of the 30 BR who help prove and popularize the 30 BR for benchrest score shooting. Randy offers this advice on 30 BR case-forming:

While the thinner neck-base was one of our original concerns, unless one cuts too deeply INTO the shoulder, it is not a problem. For my original 30BR chamber, thirty (30) cases were used to fire 6,400 rounds through the barrel. The cases were never annealed, yet there were ZERO case failures, neck separations, or splits. The case-necks were turned for a loaded-round neck diameter of .328″, and, from the beginning, sized with a .324″ neck-bushing.

The best method for avoiding the ‘bulge’ is to fire-form prior to neck-turning (several methods are successfully employed). Cutting too deeply into the shoulder can result in case-neck separations. I have witnessed this, but, with several barrels and thousands to shots fired, have not [personally] experienced it. The last registered BR event fired using that original barrel produced a 500-27x score and a second-place finish. [That’s] not bad for 6K plus shots, at something over 200 firings per case.

Check out the 30 BR Cartridge Guide on AccurateShooter.com

You’ll find more information on 30 BR Case-forming in our 30 BR Cartridge Guide. Here’s a short excerpt from that page — some tips provided by benchrest for score and HBR shooter Al Nyhus:

30 BR Case-Forming Procedure by Al Nyhus

The 30 BR cartridge is formed by necking-up 6mmBR or 7mmBR brass. You can do this in multiple stages or in one pass. You can use either an expander mandrel (like Joe Entrekin does), or a tapered button in a regular dies. Personally, I use a Redding tapered expander button, part number 16307. This expands the necks from 6mm to .30 cal in one pass. It works well as long as you lube the mandrel and the inside of the necks. I’ve also used the Sinclair expander body with a succession of larger mandrels, but this is a lot more work and the necks stay straighter with the Redding tapered button. This button can be used in any Redding die that has a large enough inside diameter to accept the BR case without any case-to-die contact.