|

|

November 5th, 2021

4140, 4150, 316, 17-4, 6061, 7075-T6 — What is the significance of these numbers? No, they’re not winning lottery numbers. These are all designations for metals commonly used in firearm and barrel construction. 4140 and 4150 are carbon steels, with 4150 often used in mil-spec AR15 barrels. 316 and 17-4 are grades of stainless steel. 316 is “marine grade” stainless, while 17-4 has 17% chromium and 4% nickel. 17-4 is a harder steel used in barrels and receivers. 6061 and 7075-T6 are aluminum alloys. 6061 is “aircraft grade” aluminum, often used for rings and trigger guards, while 7075-T6 is a much stronger, heat-treated aluminum commonly used in AR15 uppers.

You can learn about all these metals (and more) in the online archives of RifleShooter magazine. You can learn about all these metals (and more) in the online archives of RifleShooter magazine.

Written by Patrick Sweeney, RifleShooter’s Guide to Gun Metal summarizes the primary types of steel and aluminum used in gun and barrel construction. Sweeney explains the nomenclature used to define metal types, and he outlines the salient properties of various steel and aluminum alloys. This is a useful resource for anyone selecting components or building rifles. We recommend you print out the page, or at least bookmark it.

Metals by the Number

The number system for steel classification came from the auto industry. Sweeney explains: “The Society of Automotive Engineers uses a simple designating system, the four numbers you see bandied about in gun articles. Numbers such as 1060, 4140 or 5150 all designate how much of what [elements are] in them. The first number is what class—carbon, nickel, chromium, and so forth. The next three numbers [list other elements in the alloy]. 4140, also known as ordnance steel, was one of the early high-alloy steels. It has about 1 percent chromium, 0.25 percent molybdenum, 0.4 percent carbon, 1 percent manganese, around 0.2 percent silicon and no more than 0.035 percent phosphorus and no more than 0.04 percent sulphur. That leaves most of it, 94.25 percent, iron.”

Aluminum Alloys

Numbers are also used to differentiate different types of aluminum alloys. Sweeny writes: “Aluminum is used in firearms in two alloys: 7075 and 6061. 6061 is commonly referred to as ‘aircraft aluminum’ and has trace amounts of silicon, copper, manganese, molybdenum and zinc. 7075 is a much stronger alloy and has markedly larger amounts of copper, manganese, chromium and zinc.” 7075 Aluminum has significantly better corrosion resistance, and that’s why it is used for AR receivers. The “T6″ you often see appended to 7075 refers to a heat-treating process.

Aluminum (or “Aluminium” in the UK) is a chemical element in the boron group with symbol Al and atomic number 13. It is a silvery-white, soft, nonmagnetic, ductile metal. Aluminum is the third most abundant element, and the most abundant metal, in the Earth’s crust. (Wikipedia)

To learn more about the metals used in your firearms’ barrels, rings, receivers, and internal parts, read Sweeney’s article in RifleShooterMag.com. Taking the time to read the article from start to finish will expand your knowledge of metal properties and how metals are chosen by manufacturers and gunsmiths. CLICK to Read Guide to Gun Metal.

Story Tip by EdLongrange. We welcome reader submissions. Aluminum Alloy chart courtesy AluminiumDesign.net.

October 15th, 2016

Click Photo to see large version.

Here is a very interesting rifle, a true metal/wood hybrid that combines an aluminum front section with figured walnut in the rear half. As you can see, this unique rifle also features a barrel block that allows the Savage action to float. You may be wondering “how is the metal section connected to the wood?” The gun’s owner/builder epoxied a stainless steel tube in the wood and that tube is secured in the aluminum fore-end with set screws.

Forum member Justin V. reports: “Sometime last fall my buddy wanted to build barrel-blocked Bavage. He is a machinist by trade so he was able to build all of the custom components himself. I know he put a ton of time into this thing over the winter, taking his time to get it done right. If you shoot in Cadillac or Midland, Michigan you will probably see him around. He tried to shoot a match this past weekend but was rained out. Hopefully it will stop raining in Michigan so he can see what it can do at 600 yards. Here are the results….” Learn more about this gun in this FORUM Thread.

March 23rd, 2016

4140, 4150, 316, 17-4, 6061, 7075-T6 — What is the significance of these numbers? No, they’re not winning lottery numbers. These are all designations for metals commonly used in firearm and barrel construction. 4140 and 4150 are carbon steels, with 4150 often used in mil-spec AR15 barrels. 316 and 17-4 are grades of stainless steel. 316 is “marine grade” stainless, while 17-4 has 17% chromium and 4% nickel. 17-4 is a harder steel used in barrels and receivers. 6061 and 7075-T6 are aluminum alloys. 6061 is “aircraft grade” aluminum, often used for rings and trigger guards, while 7075-T6 is a much stronger, heat-treated aluminum commonly used in AR15 uppers.

You can learn about all these metals (and more) in the online archives of RifleShooter magazine. You can learn about all these metals (and more) in the online archives of RifleShooter magazine.

Written by Patrick Sweeney, RifleShooter’s Guide to Gun Metal summarizes the primary types of steel and aluminum used in gun and barrel construction. Sweeney explains the nomenclature used to define metal types, and he outlines the salient properties of various steel and aluminum alloys. This is a useful resource for anyone selecting components or building rifles. We recommend you print out the page, or at least bookmark it.

Metals by the Number

The number system for steel classification came from the auto industry. Sweeney explains: “The Society of Automotive Engineers uses a simple designating system, the four numbers you see bandied about in gun articles. Numbers such as 1060, 4140 or 5150 all designate how much of what [elements are] in them. The first number is what class—carbon, nickel, chromium, and so forth. The next three numbers [list other elements in the alloy]. 4140, also known as ordnance steel, was one of the early high-alloy steels. It has about 1 percent chromium, 0.25 percent molybdenum, 0.4 percent carbon, 1 percent manganese, around 0.2 percent silicon and no more than 0.035 percent phosphorus and no more than 0.04 percent sulphur. That leaves most of it, 94.25 percent, iron.”

Aluminum Alloys

Numbers are also used to differentiate different types of aluminum alloys. Sweeny writes: “Aluminum is used in firearms in two alloys: 7075 and 6061. 6061 is commonly referred to as ‘aircraft aluminum’ and has trace amounts of silicon, copper, manganese, molybdenum and zinc. 7075 is a much stronger alloy and has markedly larger amounts of copper, manganese, chromium and zinc.” 7075 Aluminum has significantly better corrosion resistance, and that’s why it is used for AR receivers. The “T6″ you often see appended to 7075 refers to a heat-treating process.

Aluminum (or “Aluminium” in the UK) is a chemical element in the boron group with symbol Al and atomic number 13. It is a silvery-white, soft, nonmagnetic, ductile metal. Aluminum is the third most abundant element, and the most abundant metal, in the Earth’s crust. (Wikipedia)

To learn more about the metals used in your firearms’ barrels, rings, receivers, and internal parts, read Sweeney’s article in RifleShooterMag.com. Taking the time to read the article from start to finish will expand your knowledge of metal properties and how metals are chosen by manufacturers and gunsmiths. CLICK to Read Guide to Gun Metal.

Story Tip by EdLongrange. We welcome reader submissions. Aluminum Alloy chart courtesy AluminiumDesign.net.

October 16th, 2014

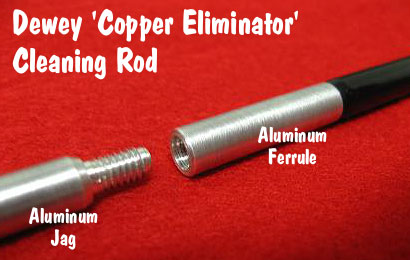

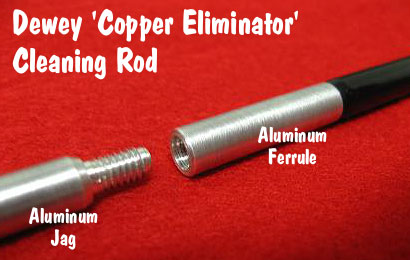

Conventional brass jags work great — except for one thing. They can react to solvents, leaving a blue “false positive” on patches. In recent years, jag-makers have experimented with many different materials in an effort to cure the solvent-reaction problem. Today we have polymer jags, nickel-plated jags, and stainless steel jags. And the latest innovation is the aluminum jag from Dewey.

J. Dewey Mfg. is now producing a series of “Copper Eliminator” jags and brush adapters made from aircraft-grade aluminum with the same hardness as brass. Dewey claims that its new aluminum jags will not become embedded with grit or particles that could harm your bore. At the same time, Dewey’s aluminum jags will not react to ammoniated bore solvents that can turn patches blue green when used with brass jags. Dewey aluminum jags are offered with either male OR female 8/32 threads. The $4.95 aluminum jags and $3.50 brush adapters are offered in a wide variety of calibers. You can order from Dewey Mfg. or Sinclair Int’l. J. Dewey Mfg. is now producing a series of “Copper Eliminator” jags and brush adapters made from aircraft-grade aluminum with the same hardness as brass. Dewey claims that its new aluminum jags will not become embedded with grit or particles that could harm your bore. At the same time, Dewey’s aluminum jags will not react to ammoniated bore solvents that can turn patches blue green when used with brass jags. Dewey aluminum jags are offered with either male OR female 8/32 threads. The $4.95 aluminum jags and $3.50 brush adapters are offered in a wide variety of calibers. You can order from Dewey Mfg. or Sinclair Int’l.

Story Tip from Boyd Allen. We welcome submissions from our readers.

April 10th, 2014

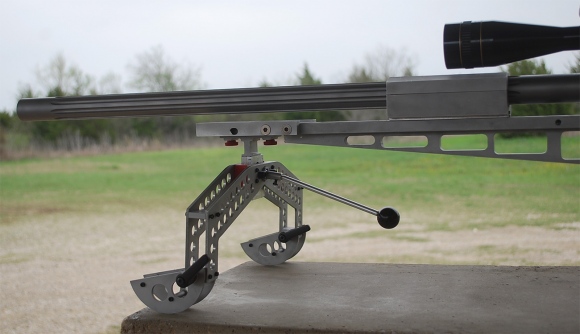

We know you guys like exotic hardware, so today we pulled something very exotic from our featured rifle archives. We doubt that you have ever seen anything quite like this before. Gun-builder Richard King says: “I thought you might like to see my latest project. This is my personal gun, built the way I wanted it. I know it’s radical and some may not care for it. But it works.”

Report by Richard King (King’s Armory, Texas; ‘Kings X’ on our Forum)

This is pretty much an all-aluminum rifle. The action is a Kelbly F-Class with a Shilen stainless steel competition trigger. The scope is a 1″-tube Leupold 36X with a Tucker Conversion set in Jewell spherical bearing rings. The .223 barrel is Pac-Nor 3-groove, 1:6.5″-twist mounted in a “V”-type barrel block. The bipod has vertical adjustment only via a dovetail slide activated by a stick handle. It works like a joy-stick, but for vertical only. I adjust for windage by moving the rear sandbag.

The 30″ barrel is 1.250″ in diameter. With the barrel block forward, the vibrations should be at a low frequency. Instead of one long rod whipping, I now have two short rods (barrel haves) being dampened. This is my fourth barrel block gun. They work, but so does a good pillar-bedded action. I just do stuff a little different.

The vertical “keel” down the bottom of the stock stops the “spring” of a flat-bar stock. There is little, if any, noticeable flex before or during recoil. The long length of the stock, the fat barrel, and the forward-mounted barrel block work together to keep the gun from rising off the ground. BUT, remember this is a .223 Rem rifle. A .308 Win version might act very differently. I may try a .308-barreled action soon, just to see what happens. But I will stick with the .223 Rem as my choice for match shooting.

The offset scope idea came from a benchrest “rail” gun. In truth, the whole concept came from a rail gun — just adapted to being shot off a bipod. Sure it isn’t directly over the bore. It is about 1.5″ over to the left. So if you want the scope to be zeroed on the center of the target, you have to adjust for the offset. At 100 yards that is 1.5 MOA. But at 300 it is only 0.5 MOA, at 600 only a ¼-MOA, and at 1000 about 1 click on my scope. The offset scope idea came from a benchrest “rail” gun. In truth, the whole concept came from a rail gun — just adapted to being shot off a bipod. Sure it isn’t directly over the bore. It is about 1.5″ over to the left. So if you want the scope to be zeroed on the center of the target, you have to adjust for the offset. At 100 yards that is 1.5 MOA. But at 300 it is only 0.5 MOA, at 600 only a ¼-MOA, and at 1000 about 1 click on my scope.

What the offset DOES do for me is eliminate any cheek pressure. My cheek never touches the stock. Since this is only a .223 Rem, I don’t put and shoulder pressure behind it. And I don’t have a pistol grip to hang on to, but I do put my thumb behind the trigger guard and “pinch” the two-ounce trigger.

The offset scope placement could interfere with loading a dual-port action from the left. That’s not a problem for me as I set my spotting scope up on the left side very close to the rifle. I have plenty of time to reload from the right side while the target is in the pits being scored.

Again — this is my rifle. It is designed for my style of shooting. It is not meant to be a universal “fit all” for the general public. However, I will say the design is adaptable. I can easily convert the system to run in F-Open Class. I would drop a big-bore barreled action into the “V” block, slide on a heavier pre-zeroed scope and rings, add plates on the sides up front to bring the width to 3”, and maybe a recoil pad. It might be interesting to offset the wings up from to counter torque of the big bullets. But I would also have to offset the rear bag rider to get the gun to recoil straight back.

How the Gun Performs

I have had “T” to the range only twice for load development. It groups like my present barrel-blocked 223 F-TR gun. But it’s much easier to shoot and it only moves about 3/4” — straight back. I tried to build am omni-directional joy-stick bipod but I could not get all the side-to-side wiggle out of it. So I have set it up so it only moves up and down (horizontal movement is locked-out). As it works now, the joystick on the bipod lets me set elevation on the target quickly (with up/down adjustment). Then, to adjust for windage, I slide my rear bag side-to-side as needed. Once set, I just tickle the trigger and smile.

Gun Handling — Shoot It Like a Bench-Gun

I basically shoot the gun with no cheek or body contact. I don’t grip it, other than maybe a pinch on the trigger guard. The scope was offset to the left to help the shooter move off the gun and avoid the possibility of head/cheek contact with the stock.

[haiku url=”http://accurateshooter.net/Video/RichKingTalks.mp3″ Title=”Richard King Talks”]

|

VOICE FILE: Richard King Explains How He Shoots his ‘Texas-T’ Rifle: |

CLICK PHOTOS to See Big Size

October 2nd, 2013

Less weight plus better heat dissipation — Sound good? Here is an innovative barrel technology that promises worthwhile performance benefits for hunters or match shooters. Lothar Walther (LW) has developed a new bi-metal barrel system that cuts weight dramatically while promising significantly-enhanced heat dissipation.

Walther’s Ultra-Lightweight Barrels combine steel with lightweight alloys. This results in a significant weight reduction without the use of carbon fiber, epoxy binders, or other heat-retaining materials. Beginning as an LW50 stainless blank, the barrel is precision-machined to remove excess weight. An outer casing of light-weight alloys is machined and the two are fitted together without adhesives. Basically you end up with the steel inner barrel inside a larger-diameter fluted aluminum outer barrel (see diagram). This gives you the ‘best of both worlds’ — light weight for ease of carry, and thick diameter for rigidity and enhanced heat dissipation. Near the action, the barrel remains all-steel.

The barrels come pre-chambered in your choice of caliber/cartridge, from .22LR up to .338 Lapua Magnum. Walther chambers the barrel — but a gunsmith is still required to finish the shoulder so that the headspace is set correctly for your action. These barrels are not inexpensive. A typical bi-metal Walther Barrel runs $850.00 – $875.00, for barrel lengths from 22″ to 30″. Threading for a muzzle brake or suppressor (if desired) is normally included in that price.

We haven’t tested one of these bi-metal composite barrels, but the potential for significant weight savings is obvious — aluminum is a lot lighter than steel. What’s more, a metals expert we contacted said that a bi-metal system employing fluted aluminum over steel, if assembled properly, could dissipate heat much better than steel alone (given the same diameter). Stainless steel has a thermal conductivity factor of 16. Aluminum has a thermal conductivity factor of 250.* We haven’t tested one of these bi-metal composite barrels, but the potential for significant weight savings is obvious — aluminum is a lot lighter than steel. What’s more, a metals expert we contacted said that a bi-metal system employing fluted aluminum over steel, if assembled properly, could dissipate heat much better than steel alone (given the same diameter). Stainless steel has a thermal conductivity factor of 16. Aluminum has a thermal conductivity factor of 250.*

Our expert also pointed out that some other composite barrel systems on the market actually increase heat retention because they place insulating materials next to the inner steel barrel. (Carbon, Fiberglass, and Epoxy are all considered “insulating substances” as they have very low thermal conductivity*.) The LW system of aluminum over metal should avoid this mistake, our expert believes. Lothar Walther says: “Unlike solid steel barrels, this barrel sheds heat fast. VERY FAST!”

Half the Weight of Conventional Barrels

How much weight can you save? With a 1.200″ shank diameter and a muzzle diameter of 0.850″, the LW Ultra-Lightweight Barrel is less than half the weight of a standard varmint barrel of the same size. Walther claims its UltraLight Barrel can be “carried for long distances and stand up to heavy firing.” This, LW says, makes these barrels “perfect… for varmint and tactical uses”.

Pre-Chambered Ultra-Lightweight Barrels Available in .22 to .338 Calibers

Lothar Walther offers Ultra-Lightweight barrels in a full range of calibers from .22LR to .338. Each Ultra-Lightweight Barrel comes complete with chamber, crown, and breech threads. These barrels are fluted by the factory. If you order a LW Ultra-Lightweight barrel, Lothar Walter provides the services of a specialist trained in building guns with these barrels. To order one of Lothar Walther’s bi-metal barrels, CLICK HERE or contact Lothar Walthar at the address below:

Lothar Walther Precision Tools, Inc.

3425 Hutchinson Rd. – Cumming, GA 30040

Phone: 770-889-9998 | Fax: 770-889-4919

E-Mail: lotharwalther [at] mindspring.com

Website: www.lothar-walther.com

*Thermal conductivity is the quantity of heat transmitted through a unit thickness in a direction normal to a surface of unit area, due to a unit temperature gradient under steady state conditions. The factor values are based on this formula: W/(m.K) = 0.85984 kcal/(hr.m. °C). Here are thermal conductivty values for common materials: Aluminum, 250; Brass, 109; Steel (Carbon 1%), 45; Stainless Steel, 16; Carbon, 1.7; Brick dense, 1.3; Concrete (medium) 0.7; Epoxy, 0.35; Fiberglass, .04.

Story tip from EdLongRange. We welcome reader submissions.

December 11th, 2012

Our friend and product tester Joe Friedrich is the proud owner of a spectacular front rest from James Pappas. This rest is used for both air rifle and rimfire benchrest matches. The fancy Pappas front rest is a shortened, front-support-only version of the Pappas one-piece rest, which is popular with rimfire benchresters. Pappas engineered this rest to comply with air rifle benchrest rules which do not allow use of integrated (one-piece) front and rear rests. The end result was a 30.8-lb masterpiece of machining.

The workmanship on this Pappas front rest is astounding. Accurately described as a “work of art” by Joe Friedrich, this rest, crafted of aircraft-grade aluminum, sets new standards for “Benchrest BLING”. It looks like it should be on display in an art museum. Nearly all components of this rest, including the adjustment controls, have been polished to a mirror finish.

Convenient Rear Windage and Elevation Controls

The Pappas front rest features separate fine-tuning controls for windage and elevation, plus a central gross-elevation control. Normally, once the rest is centered-up on the target, you can make all needed elevation and windage adjustments with the rear (fine-adjustment) controls. In the video below, Joe explains how the controls work as he practices with his modified Theoben Rapid MFR air rifle. Joe hopes to use this new Pappas rest in the upcoming Air Rifle Benchrest Worlds to be held in South Carolina this summer. (Note: In the last minute of the video, the back-lighting was so intensely bright that we lost detail in the foreground. We apologize for that flaw, but you can still hear the audio.)

Price for this Masterpiece? Don’t Ask…

If you are interested in getting a similar rest, visit PappasRimfireProducts.com, or call James Pappas directly at (817) 735-9883. Be forewarned — James said “If you need to ask about the price, you probably can’t afford it.” This is truly the “Rolls-Royce” of front rests, and it will be priced accordingly.

December 11th, 2012

For decades shooters have used brass jags attached to brass-tipped cleaning rods. These work effectively. But there is one problem. Many bore solvents will react with the brass metal to give “false positives”. You can get bluish-green patches even when there is no copper fouling in your bore.

To solve this problem DeweyRods.com offers a full line of aluminum jags, aluminum brush adapters, and nylon-coated cleaning rods with aluminum tips. Dewey explains: “Ammonia-based solvents attack copper & brass but also leave your patches a blue-green color so you are never sure if your bore is truly clean of copper. Our aircraft-grade aluminum has the same hardness of brass, it will not embed impurities or harm your bore, and ammonia will not attack it.” As shown below, along with caliber-specific aluminum jags (center), Dewey now offers aluminum thread adaptors (left) and aluminum-shaft brushes (right).

New Dewey ‘Copper Eliminator’ Cleaning Rods

These new rods have the same nylon coating and handle assembly as Dewey’s standard coated rods, but they feature a chemical-resistant, 8/32 female-threaded, aluminum ferrule. No brush adapters are required. Each rod is supplied with a male-threaded aluminum jag. Dewey charges $39.95 for these rods, but you may find them slightly cheaper at other vendors.

Copper Eliminator Rods are currently offered in two diameters (.22-.26 Cal, or .27+ Cal), and three lengths: 36″, 40″, 44″. Listed rod lengths do NOT include handle assembly. One last note: Dewey cautions users to avoid TM Solution, because this solvent may harm Dewey’s nylon rod-coatings.

Story sourced by Edlongrange.

August 10th, 2012

When Hornady (and CCI) developed the 17 HMR cartridge, they really hit a homerun. And the rifle manufacturers quickly marketed some nice rifles to chamber this 17-cal rimfire round. But unlike .22 LR rifles which, typically, require very little cleaning, 17 HMRs demand frequent bore cleaning to maintain good accuracy. That’s because 17 HMRs shoot copper-jacketed bullets at 2550 fps velocities.

17-Cal Bore Guides — The Challenge 17-Cal Bore Guides — The Challenge

The problem is, it’s hard to find a well-designed, quality bore guide for 17-caliber rimfire rifles. With many 17 HMR (and 17 Mach 2) rifles, you encounter mechanical interference when you try to use a standard bore guide to protect the delicate chamber edge and the bottle neck area of the chamber. A fixed ejector is in the way. On many 17 HMR rifles, this little “shark fin” ejector is right in line with the chamber and is fixed — it doesn’t retract. Therefore the kind of bore guide you might use for centerfire rifles won’t work in 17 HMRs — it will hang up on the ejector.

Polymer bore guides exist for this type of action, but they are typically open-bottom designs that do not enter and seal the chamber. These open-bottom designs don’t protect the delicate chamber edge or the bottleneck area of the chamber, and they also allow some seepage of solvents out of the chamber. That’s why Roy Bertalotto created his RVB Precision Bore Guide for 17 HMR rifles. The 7075 aluminum tube on his Bore Guide is thin enough to pass by the ejector, yet it is extremely rigid. (Photos below.)

Roy explains: “My bore guide is made of 7075 anodized aluminum tubing, which is totally unaffected by any type of cleaning solution. One end is swagged down to fit completely into the chamber of a 17 HMR rifle. This guides your cleaning rod perfectly to the bore without touching the chamber walls or front edge of the chamber. The tight fit of the bore guide in the chamber also stops cleaning solvents from getting into the action, magazine, and trigger housing.” (Editor: Solvent seepage can do damage. We had a 17 Mach 2 rifle that rusted internally because solvents leaked past an open-bottom bore guide.)

Using the RVB 17 HMR Guide – Once the bore guide is in place, slide the supplied aluminum bushing over the tube, and gently push the bushing into the rear of the action. This centers the guide rod in the action to keep the guide rod tube aligned. Once the guide rod and bushing are in place, you can use a 17-caliber cleaning rod* with patches and/or brushes to clean the barrel. Use the rod normally, but make sure your patches are quite small and don’t apply too much pressure as these small-diameter rods can kink if you try to force over-size patches down the bore. Using the RVB 17 HMR Guide – Once the bore guide is in place, slide the supplied aluminum bushing over the tube, and gently push the bushing into the rear of the action. This centers the guide rod in the action to keep the guide rod tube aligned. Once the guide rod and bushing are in place, you can use a 17-caliber cleaning rod* with patches and/or brushes to clean the barrel. Use the rod normally, but make sure your patches are quite small and don’t apply too much pressure as these small-diameter rods can kink if you try to force over-size patches down the bore.

The RVB Precision 17 HMR Bore Guide costs $19.95 plus $5.00 shipping. To order, email Roy Bertalotto via rvb100 [at] comcast.net. Roy will then send you shipping/payment details.

* NOTE: You really do need a dedicated .17-cal cleaning rod for this job. Most other rods are too fat to pass through the barrel. Dewey Mfg. makes a decent 17-caliber cleaning rod that is reasonably stiff and doesn’t kink too readily. It is available sizes from 7″ to 36″, either bare stainless or with a nylon coating. We prefer the nylon-coated version, in either 26″ or 36″ lengths, depending on barrel length.

If you have a high comb on your rifle, you may need extra length to avoid interference with the rod handle. Use this formula to determine correct rod length: Length of barrel + action or breech rod guide length + 2-3″ clearance + high comb if applicable = total rod length needed.

There are other quality 17-cal cleaning rods, but we’ve used the Dewey and it functioned well. The nylon coating cleaned easily and was gentle on the throat and crown. You should clean the coating before and after each use to ensure it does not embed grit or other contaminants.

August 9th, 2012

Some clever F-Class competitors, such as Forum Member Peter White, have fitted remote flexible-drive-shaft windage controls to their front rests. This allows you to easily adjust windage with the twist of a knob without leaving your shooting position. Until recently, if you wanted a flex-drive windage system on your rest you had to fabricate it yourself.

Now you can enjoy the advantages of remote flex-drive windage adjustment in a ready-made product. Bald Eagle Precision Products has introduced a trio of front rests with “factory” flex-drive windage controls. There are three (3) models. The model BE1006 boasts a heavy, cast-iron slingshot-style base with heavy-duty 1/2″ x 13 TPI threaded feet. Weight is 20 pounds without front bag. This heavyweight model BE1006 should be popular with F-Classers shooting the 7mm and magnum calibers, as the added mass provides great stability. Now you can enjoy the advantages of remote flex-drive windage adjustment in a ready-made product. Bald Eagle Precision Products has introduced a trio of front rests with “factory” flex-drive windage controls. There are three (3) models. The model BE1006 boasts a heavy, cast-iron slingshot-style base with heavy-duty 1/2″ x 13 TPI threaded feet. Weight is 20 pounds without front bag. This heavyweight model BE1006 should be popular with F-Classers shooting the 7mm and magnum calibers, as the added mass provides great stability.

The slingshot base design has a longer rear leg, bringing the windage control closer to the shooter’s hand. Bald Eagle’s model BE1005, shown below, shares the clever slingshot design of the ME1006 along with remote windage adjustment, but the BE1005’s base is cast aluminum. This drops total weight to 11 pounds (without front bag), making the BE1005 easier to carry than its heavyweight cousin. The aluminum-based BE1005 saves you 9 pounds compared to the BE1006.

The third new Bald Eagle front rest, model BE1004, features a more conventional triangle pedestal design. Like the model BE1005, it has a cast aluminum base, and weighs 11 pounds without front bag. All three Bald Eagle rests, BE1004, BE1005, and BE1006 can be equipped with over-size disc-type feet (item BE1007) for greater stability in soft or soggy ground. The third new Bald Eagle front rest, model BE1004, features a more conventional triangle pedestal design. Like the model BE1005, it has a cast aluminum base, and weighs 11 pounds without front bag. All three Bald Eagle rests, BE1004, BE1005, and BE1006 can be equipped with over-size disc-type feet (item BE1007) for greater stability in soft or soggy ground.

SEB-Made Bags with MicroFiber Tops Available for Bald Eagle Rest

Bald Eagle offers high-quality front bags to fit its line of front rests. These bags are crafted by SEB and feature a low-friction, smooth microfiber surface. We have used SEB front bags with micro-fiber tops and we think they are some of the best available. The microfiber allows your rifle to slide easily without powders, silicon sprays, or other surface lubricants. Having two fill spouts, the front bags are also easy to fill to the firmness level your gun prefers. The front bags measure 4-5/8″ wide by 1-3/4″ tall, and come in three configurations: 3″ wide for F-Class and Benchrest; 2-1/4″ wide for medium-wide flat forearms; and a 3″ radius for sporter/hunting stocks.

All Three Bald Eagle Rests, Front Bags, F-Class Feet, and other accessories can be purchased from Grizzly Industrial and other retailers nationwide. Here are “street prices” of the three rests, as sold on Grizzly.com:

BE1006 is priced at $475.00 but has an introductory sale price of $425.00.

BE1005 is priced at $450.00 but has an introductory sale price of $399.95.

BE1004 is priced at $450.00 but has an introductory sale price of $399.95.

|

You can learn about all these metals (and more) in the online archives of RifleShooter magazine.

You can learn about all these metals (and more) in the online archives of RifleShooter magazine.

The offset scope idea came from a benchrest “rail” gun. In truth, the whole concept came from a rail gun — just adapted to being shot off a bipod. Sure it isn’t directly over the bore. It is about 1.5″ over to the left. So if you want the scope to be zeroed on the center of the target, you have to adjust for the offset. At 100 yards that is 1.5 MOA. But at 300 it is only 0.5 MOA, at 600 only a ¼-MOA, and at 1000 about 1 click on my scope.

The offset scope idea came from a benchrest “rail” gun. In truth, the whole concept came from a rail gun — just adapted to being shot off a bipod. Sure it isn’t directly over the bore. It is about 1.5″ over to the left. So if you want the scope to be zeroed on the center of the target, you have to adjust for the offset. At 100 yards that is 1.5 MOA. But at 300 it is only 0.5 MOA, at 600 only a ¼-MOA, and at 1000 about 1 click on my scope.

We haven’t tested one of these bi-metal composite barrels, but the potential for significant weight savings is obvious — aluminum is a lot lighter than steel. What’s more, a metals expert we contacted said that a bi-metal system employing fluted aluminum over steel, if assembled properly, could dissipate heat much better than steel alone (given the same diameter). Stainless steel has a

We haven’t tested one of these bi-metal composite barrels, but the potential for significant weight savings is obvious — aluminum is a lot lighter than steel. What’s more, a metals expert we contacted said that a bi-metal system employing fluted aluminum over steel, if assembled properly, could dissipate heat much better than steel alone (given the same diameter). Stainless steel has a

17-Cal Bore Guides — The Challenge

17-Cal Bore Guides — The Challenge

Using the RVB 17 HMR Guide – Once the bore guide is in place, slide the supplied aluminum bushing over the tube, and gently push the bushing into the rear of the action. This centers the guide rod in the action to keep the guide rod tube aligned. Once the guide rod and bushing are in place, you can use a 17-caliber cleaning rod* with patches and/or brushes to clean the barrel. Use the rod normally, but make sure your patches are quite small and don’t apply too much pressure as these small-diameter rods can kink if you try to force over-size patches down the bore.

Using the RVB 17 HMR Guide – Once the bore guide is in place, slide the supplied aluminum bushing over the tube, and gently push the bushing into the rear of the action. This centers the guide rod in the action to keep the guide rod tube aligned. Once the guide rod and bushing are in place, you can use a 17-caliber cleaning rod* with patches and/or brushes to clean the barrel. Use the rod normally, but make sure your patches are quite small and don’t apply too much pressure as these small-diameter rods can kink if you try to force over-size patches down the bore.

Now you can enjoy the advantages of remote flex-drive windage adjustment in a ready-made product.

Now you can enjoy the advantages of remote flex-drive windage adjustment in a ready-made product.

The third new Bald Eagle front rest, model BE1004, features a more conventional triangle pedestal design. Like the model BE1005, it has a cast aluminum base, and weighs 11 pounds without front bag. All three Bald Eagle rests, BE1004, BE1005, and BE1006 can be equipped with over-size disc-type feet (item BE1007) for greater stability in soft or soggy ground.

The third new Bald Eagle front rest, model BE1004, features a more conventional triangle pedestal design. Like the model BE1005, it has a cast aluminum base, and weighs 11 pounds without front bag. All three Bald Eagle rests, BE1004, BE1005, and BE1006 can be equipped with over-size disc-type feet (item BE1007) for greater stability in soft or soggy ground.