|

|

June 26th, 2015

Applied Ballistics has just released a fully upgraded version of its popular Tactical App for Android devices. Bryan Litz tells us: “AB Tactical has received a major overhaul (including a new Bullet Library with over 420 options). The upgrade will require that you uninstall the previous version that you have of the application and then install this new version. This is due to the complete re-write of the internal database handling.” NOTE: You need to record your gun-specific data before you install the new version. Details of the updated AB Tactical App are featured in the new 19-page USER Manual.

NOTE: This upgrade is for the Applied Ballistics Tactical Version only. There is no iPhone version of this App, and this is not the standard app that can be purchased from Google Play, or iTunes.

The new version of AB Tactical has a host of important enhancements:

June 14th, 2015

Berger Twist-Rate Stability Calculator Berger Twist-Rate Stability Calculator

On the updated Berger Bullets website you’ll find a handy Twist-Rate Stability Calculator that predicts your gyroscopic stability factor (SG) based on mulitiple variables: velocity, bullet length, bullet weight, barrel twist rate, ambient temperature, and altitude. This very cool tool tells you if your chosen bullet will really stabilize in your barrel.

LIVE DEMO BELOW — Just enter values in the data boxes and click “Calculate SG”.

June 10th, 2015

Berger Bullets has just announced a new 6.5 mm (.264 caliber) 130gr Hybrid projectile. Optimized for magazine-length seating (and AR10-friendly), the new 130gr bullets should be ideal for tactical comps and the PRS series. We expect this new bullet to work great when loaded in modern mid-size cartridges such as the 6.5×47 Lapua and 6.5 Creedmoor. Berger’s new 6.5mm 130gr Match AR Hybrid OTM Tactical bullet (could Berger come up with a longer name?) will soon be released to the public. Berger says this new 130-grainer is the first of many new bullet designs to be introduced in the next few years. Here is a run-down on the new bullet from its designer, Bryan Litz of Applied Ballistics.

NEW 130gr Hybrid — Behind the Design

by Bryan Litz, Berger Chief Ballistician

Intelligent bullet design and selection begins with an understanding of application constraints. For bullets that will be used in unlimited rifles, there are few constraints and performance can truly be maximized. However, many shooting applications have realistic constraints such as magazine feeding of loaded rounds. In constrained applications, you need to ask the question: “What’s the best bullet that will work within the constraints of my shooting application?”

The new Berger 6.5mm 130 grain AR Hybrid OTM Tactical bullet is specifically optimized for maximum performance in magazine-length ammo.

6.5mm cartridges are the second most common cartridges used by top shooters in many of the Precision Rifle Series (PRS) matches, with 6mm being the most common. These kinds of tactical matches all have stages that require repeating rifles — either AR-10 platforms or bolt guns — so magazine feeding is a must. Recognizing that Berger did not have an option that was truly optimized for this particular application, we went to work and the latest 6.5mm Hybrid is the result.

SUMMARY

The new Berger 6.5mm 130 grain AR Hybrid OTM Tactical bullet is specifically optimized for use in loaded ammo with COAL constraints for magazine feeding. This bullet maximizes overall performance through BC as well as achievable muzzle velocity in mid-capacity 6.5mm cartridges fed from AR-length magazines.

What makes this bullet optimal for magazine length ammo? To start with, the nose of the bullet is constrained in length so that when it’s loaded to mag length in 6.5mm cartridges such as the 6.5mm Creedmoor, 260 Remington and 6.5×47 Lapua, the nose of the bullet won’t be pushed below the case mouth. This can be an issue with some of the heavier 6.5mm bullets like the 140s. Furthermore, the hybrid ogive design is not sensitive to jump distance like some other designs such as the VLD.

Another consideration of length-constrained ammo is how much of the bullet is pushed down into the case. The inside of the case is for powder, and the more space you take up with bullet, the less powder you can fit in. Less powder means less total energy available, and muzzle velocity is depressed. A bullet weight of 130 grains is an optimal balance between external ballistic performance (BC) and internal case capacity considerations which translate into muzzle velocity. Further to this objective, the AR Hybrid has a minimal air gap in the front of the nose, which allows the bullet to have an even shorter OAL. When dealing with length-constrained designs, you need to pack as much bullet into as little length as possible< to optimize overall performance. Another advantage of making the bullet shorter is that stability, including transonic stability, is improved.

Although this design is length-constrained, the combination of a hybrid ogive and 7 degree Boat Tail produce a very respectable G7 form factor of 0.920 which is within 1% of the popular 6mm 105 grain Hybrid. See below for full live fire ballistic performance data.

The 6.5mm 130 grain AR Hybrid will be barely stable from a 1:9″ twist, and reaches full stability from a 1:8″ twist which is common for many 6.5mm rifles. Visit the Berger Bullets twist rate calculator to get more detailed stability information on your specific barrel twist, muzzle velocity and environment.

Cartridge Selection for Magazine Length Constraint — Advanced Analysis

The trend to smaller calibers in magazine-fed rifles is happening for a very good reason. For a .308 Winchester round, you only have 2.37 calibers of nose length available for the bullet to protrude from the case. Such a short nose will have relatively high drag for the caliber. By contrast, smaller calibers such as 6.5mm and 6mm have proportionally more length available for the nose to protrude from the case and still fit in the same COAL constraint.  Proportionally longer noses mean lower drag. Proportionally longer bullets mean higher sectional density. Combine an elevated sectional density with lower drag, and you get higher BC bullets. For example, consider a 175 grain .30 caliber bullet commonly used in .308 Winchester M118LR-type ammo. These 175 grain bullets have G7 BCs in the neighborhood of .243 to .260. Neck the .308 down to 6.5mm (260 Remington) or 6mm (.243 Winchester) and now look at the BCs of the bullets available in these calibers which work within the same magazine length constraint. The 6.5mm 130 grain AR Hybrid has a G7 BC of 0.290, and the 6mm 105 grain Hybrid has a G7 BC of 0.278 — both of which are higher than the .30 cal 175 grain bullet BC. Furthermore, you get hundreds of feet per second more velocity with the necked-down cartridges as well. Proportionally longer noses mean lower drag. Proportionally longer bullets mean higher sectional density. Combine an elevated sectional density with lower drag, and you get higher BC bullets. For example, consider a 175 grain .30 caliber bullet commonly used in .308 Winchester M118LR-type ammo. These 175 grain bullets have G7 BCs in the neighborhood of .243 to .260. Neck the .308 down to 6.5mm (260 Remington) or 6mm (.243 Winchester) and now look at the BCs of the bullets available in these calibers which work within the same magazine length constraint. The 6.5mm 130 grain AR Hybrid has a G7 BC of 0.290, and the 6mm 105 grain Hybrid has a G7 BC of 0.278 — both of which are higher than the .30 cal 175 grain bullet BC. Furthermore, you get hundreds of feet per second more velocity with the necked-down cartridges as well.

All of the above translates into higher hit percentage. See the caliber comparison chart below* which is an excerpt taken from the book: Modern Advancements in Long Range Shooting which addresses this and many other topics in even more detail.

*The Weapon Employment Zone (WEZ) analysis shown above is for a 1000-yard shot on a standard IPSC silhouette in an uncertain environment having: +/- 2 mph wind, +/- 1 yard range, Muzzle Velocity SD of 10 fps, and a rifle shooting 1 MOA groups.

May 9th, 2015

Following Sierra’s introduction of Tipped MatchKing (TMK) bullets, Bryan Litz of Applied Ballistics LLC has received many requests to determine the Ballistic Coefficient (BC) of these bullets through testing. Below are Litz’s findings for four out of the six bullets he has able to acquire and test so far.

As you can see from the above table, when Sierra’s G1 BC is averaged for all speed ranges (which is representative of long range shooting) the results closely match the Applied Ballistics’ measurements of the same bullets, averaged from 3000 to 1500 FPS. The G7 BC doesn’t suffer nearly the velocity sensitivity as G1 and should be used for modern long range bullets when possible. Bryan tells us: “When I get the .22 caliber 77gr, and the .308 caliber 168gr tested, I’ll update the table.”

How do these Tipped MatchKings compare to standard MatchKings? According to Bryan’s measurements, here are some comparisons:

- The 69gr TMK BC is +8% compared to the 69gr SMK

- The 125gr TMK BC is -5% compared to the 125gr SMK (Litz believes this SMK was ‘pointed’)

- The 155gr TMK BC is identical to that of the 155gr SMK (#2156, which is also pointed)

- The 175gr TMK BC is +10% compared to the 175gr SMK

Bryan provided this additional advice for users of Ballistics programs: “Sierra’s stated BCs are measured by live fire, and are typically pretty accurate if the velocity bands are properly observed (7mm being the exception). A common error is to look at the BC that Sierra gives for your MV and just use that. Doing so overestimates the performance of the bullets over long range, and will cause you to hit low compared to your trajectory predictions.”

March 13th, 2015

Today is Friday the 13th. Oddly enough, this is the second month in a row with the 13th falling on a Friday. Does that mean double bad luck? For those of you who are superstitious — maybe you should avoid climbing ladders or using power tools today. Today is Friday the 13th. Oddly enough, this is the second month in a row with the 13th falling on a Friday. Does that mean double bad luck? For those of you who are superstitious — maybe you should avoid climbing ladders or using power tools today.

When it comes to shooting, there are many things that shooters chalk up to “bad luck”. In fact, most of these instances of “bad fortune” just come from a failure to anticipate problems. When you have a major, critical problem at a shooting match, i.e. a “train wreck”, this can be the end of your weekend. In this article, Ballistics Guru Bryan Litz talks about “train wrecks” and how to avoid them, even if you are shooting on Friday the 13th. As Bryan told us: “I don’t believe in superstition — we make our own luck!”

Urban Dictionary “Train Wreck” Definition: “A total @#$&! disaster … the kind that makes you want to shake your head.”

Train Wrecks (and How to Avoid Them) Train Wrecks (and How to Avoid Them)

by Bryan Litz of Applied Ballistics LLC.

Success in long range competition depends on many things. Those who aspire to be competitive are usually detail-oriented, and focused on all the small things that might give them an edge. Unfortunately it’s common for shooters lose sight of the big picture — missing the forest for the trees, so to speak.

Consistency is one of the universal principles of successful shooting. The tournament champion is the shooter with the highest average performance over several days, often times not winning a single match. While you can win tournaments without an isolated stellar performance, you cannot win tournaments if you have a single train wreck performance. And this is why it’s important for the detail-oriented shooter to keep an eye out for potential “big picture” problems that can derail the train of success!

Train wrecks can be defined differently by shooters of various skill levels and categories. Anything from problems causing a miss, to problems causing a 3/4-MOA shift in wind zero can manifest as a train wreck, depending on the kind of shooting you’re doing.

Below is a list of common Shooting Match Train Wrecks, and suggestions for avoiding them.

1. Cross-Firing. The fastest and most common way to destroy your score (and any hopes of winning a tournament) is to cross-fire. The cure is obviously basic awareness of your target number on each shot, but you can stack the odds in your favor if you’re smart. For sling shooters, establish your Natural Point of Aim (NPA) and monitor that it doesn’t shift during your course of fire. If you’re doing this right, you’ll always come back on your target naturally, without deliberately checking each time. You should be doing this anyway, but avoiding cross-fires is another incentive for monitoring this important fundamental. In F-Class shooting, pay attention to how the rifle recoils, and where the crosshairs settle. If the crosshairs always settle to the right, either make an adjustment to your bipod, hold, or simply make sure to move back each shot. Also consider your scope. Running super high magnification can leave the number board out of the scope’s field view. That can really increase the risk of cross-firing.

2. Equipment Failure. There are a wide variety of equipment failures you may encounter at a match, from loose sight fasteners, to broken bipods, to high-round-count barrels that that suddenly “go south” (just to mention a few possibilities). Mechanical components can and do fail. The best policy is to put some thought into what the critical failure points are, monitor wear of these parts, and have spares ready. This is where an ounce of prevention can prevent a ton of train wreck. On this note, if you like running hot loads, consider whether that extra 20 fps is worth blowing up a bullet (10 points), sticking a bolt (DNF), or worse yet, causing injury to yourself or someone nearby.

3. Scoring/Pit Malfunction. Although not related to your shooting technique, doing things to insure you get at least fair treatment from your scorer and pit puller is a good idea. Try to meet the others on your target so they can associate a face with the shooter for whom they’re pulling. If you learn your scorer is a Democrat, it’s probably best not to tell Obama jokes before you go for record. If your pit puller is elderly, it may be unwise to shoot very rapidly and risk a shot being missed (by the pit worker), or having to call for a mark. Slowing down a second or two between shots might prevent a 5-minute delay and possibly an undeserved miss.

4. Wind Issues. Tricky winds derail many trains. A lot can be written about wind strategies, but here’s a simple tip about how to take the edge off a worse case scenario. You don’t have to start blazing away on the command of “Commence fire”. If the wind is blowing like a bastard when your time starts, just wait! You’re allotted 30 minutes to fire your string in long range slow fire. With average pit service, it might take you 10 minutes if you hustle, less in F-Class. Point being, you have about three times longer than you need. So let everyone else shoot through the storm and look for a window (or windows) of time which are not so adverse. Of course this is a risk, conditions might get worse if you wait. This is where judgment comes in. Just know you have options for managing time and keep an eye on the clock. Saving rounds in a slow fire match is a costly and embarrassing train wreck. 4. Wind Issues. Tricky winds derail many trains. A lot can be written about wind strategies, but here’s a simple tip about how to take the edge off a worse case scenario. You don’t have to start blazing away on the command of “Commence fire”. If the wind is blowing like a bastard when your time starts, just wait! You’re allotted 30 minutes to fire your string in long range slow fire. With average pit service, it might take you 10 minutes if you hustle, less in F-Class. Point being, you have about three times longer than you need. So let everyone else shoot through the storm and look for a window (or windows) of time which are not so adverse. Of course this is a risk, conditions might get worse if you wait. This is where judgment comes in. Just know you have options for managing time and keep an eye on the clock. Saving rounds in a slow fire match is a costly and embarrassing train wreck.

5. Mind Your Physical Health. While traveling for shooting matches, most shooters break their normal patterns of diet, sleep, alcohol consumption, etc. These disruptions to the norm can have detrimental effects on your body and your ability to shoot and even think clearly. If you’re used to an indoor job and eating salads in air-conditioned break rooms and you travel to a week-long rifle match which keeps you on your feet all day in 90-degree heat and high humidity, while eating greasy restaurant food, drinking beer and getting little sleep, then you might as well plan on daily train wrecks. If the match is four hours away, rather than leaving at 3:00 am and drinking five cups of coffee on the morning drive, arrive the night before and get a good night’s sleep.”

Keep focused on the important stuff. You never want to lose sight of the big picture. Keep the important, common sense things in mind as well as the minutia of meplat trimming, weighing powder to the kernel, and cleaning your barrel ’til it’s squeaky clean. Remember, all the little enhancements can’t make up for one big train wreck!

March 4th, 2015

By Bryan Litz, Applied Ballistics

Last month, in the Daily Bulletin, we talked about twist rate and muzzle velocity. That discussion was based on a detailed study published in Modern Advancements in Long Range Shooting. Last month, in the Daily Bulletin, we talked about twist rate and muzzle velocity. That discussion was based on a detailed study published in Modern Advancements in Long Range Shooting.

More Spin, Less Drag

In this article, we look at how twist rate and stability affect the Ballistic Coefficient (BC) of a bullet. Again, this topic is covered in detail in the Modern Advancements book. Through our testing, we’ve learned that adequate spin-stabilization is important to achieving the best BC (and lowest drag). In other words, if you don’t spin your bullets fast enough (with sufficient twist rate), the BC of your bullets may be less than optimal. That means, in practical terms, that your bullets drop more quickly and deflect more in the wind (other factors being equal). Spin your bullets faster, and you can optimize your BC for best performance.

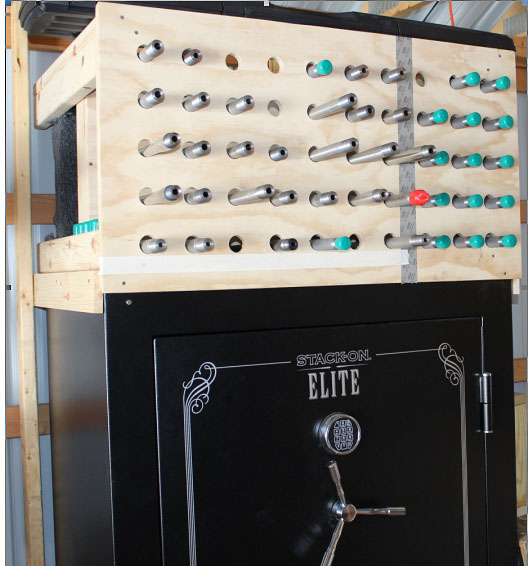

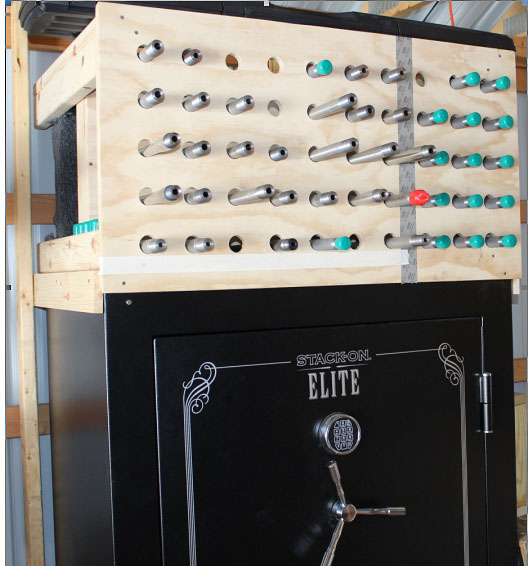

Any test that’s designed to study BC effects has to be carefully controlled in the sense that the variables are isolated. To this end, barrels were ordered from a single barrel smith, chambered and headspaced to the same rifle, with the only difference being the twist rate of the barrels. In this test, 3 pairs of barrels were used. In .224 caliber, 1:9” and 1:7” twist. In .243 caliber it was 1:10” and 1:8”, and in .30 caliber it was 1:12” and 1:10”. Other than the twist rates, each pair of barrels was identical in length, contour, and had similar round counts. Here is a barrel rack at the Applied Ballistics Lab:

Applied Ballistics used multiple barrels to study how twist rate affects BC.

“The Modern Advancements series is basically a journal of the ongoing R&D efforts of the Applied Ballistics Laboratory. The goal of the series is to share what we’re learning about ballistics so others can benefit.” –Bryan Litz

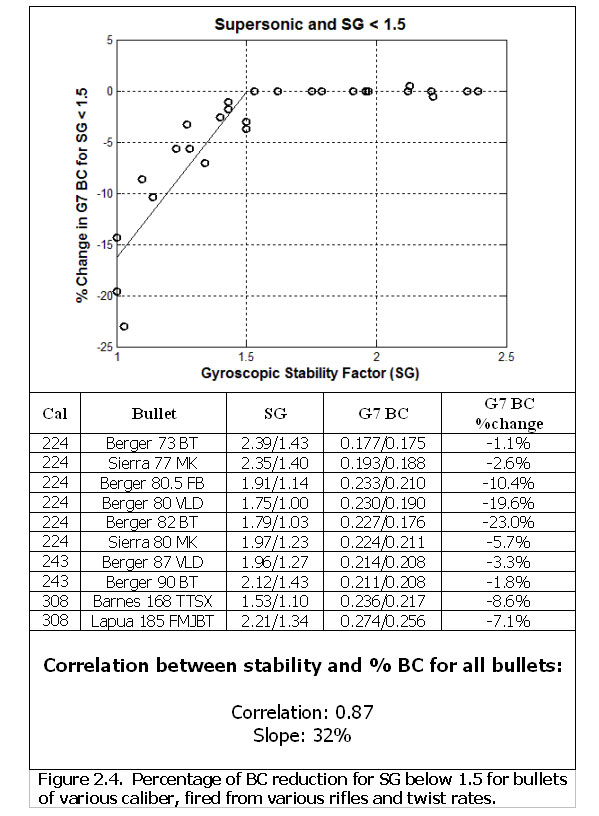

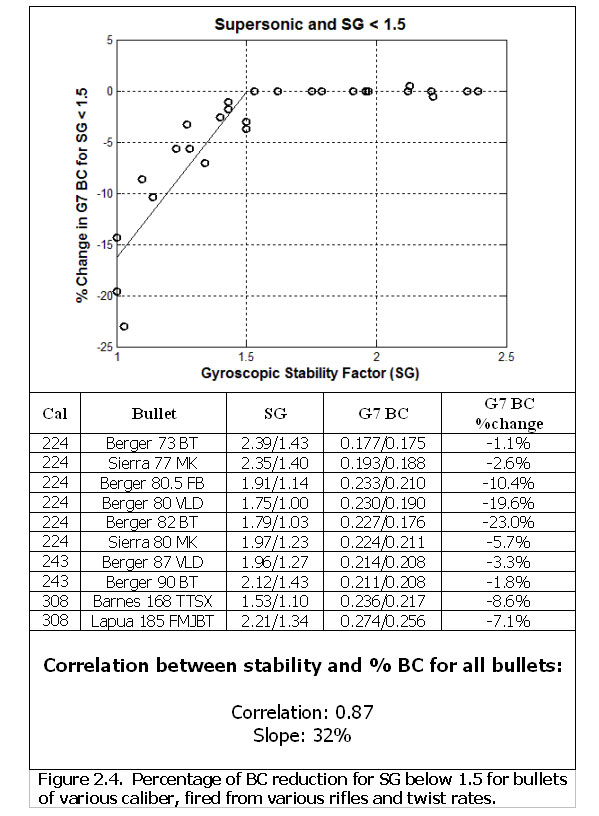

Barrel twist rate along with velocity, atmospherics, and bullet design all combine to result in a Gyroscopic Stability Factor (SG). It’s the SG that actually correlates to BC. The testing revealed that if you get SG above 1.5, the BC may improve slightly with faster twist (higher SG), but it’s very difficult to see. However, BC drops off very quickly for SGs below 1.5. This can be seen in the figure below from Modern Advancements in Long Range Shooting.

The chart shows that when the Gyroscopic Stability Factor (SG) is above 1.5, BC is mostly constant. But if SG falls below 1.5, BC drops off dramatically.

Note that the BC drops by about 3% for every 0.1 that SG falls below 1.5. The data supports a correlation coefficient of 0.87 for this relationship. That means the 3% per 0.1 unit of SG is an accurate trend, but isn’t necessarily exact for every scenario.

It’s a common assumption that if a shooter is seeing great groups and round holes, that he’s seeing the full potential BC of the bullets. These tests did not support that assumption. It’s quite common to shoot very tight groups and have round bullet holes while your BC is compromised by as much as 10% or more. This is probably the most practical and important take-away from this test.

To calculate the SG of your bullets in your rifle, visit the Berger Bullets online stability calculator. This FREE calculator will show you the SG of your bullets, as well as indicate if your BC will be compromised (and by how much) if the SG is below 1.5. With the stated twist rate of your barrel, if your selected bullet shows an SG of 1.5 (or less), the calculator will suggest alternate bullets that will fully stabilize in your rifle. This valuable online resource is based directly on live fire testing. You can use the SG Calculator for free on the web — you don’t need to download software.

Learn More About SG and BC

This article is just a brief overview of the interrelated subjects of twist rate, Gyroscopic Stability, and BC. The coverage of twist rates in Modern Advancements in Long-Range Shooting is more detailed, with multiple live fire tests. This article is just a brief overview of the interrelated subjects of twist rate, Gyroscopic Stability, and BC. The coverage of twist rates in Modern Advancements in Long-Range Shooting is more detailed, with multiple live fire tests.

Other chapters in the book’s twist rate section include:

· Stability and Drag – Supersonic

· Stability and Drag – Transonic

· Spin Rate Decay

· Effect of Twist rate on Precision

Other sections of the book include: Modern Rifles, Scopes, and Bullets as well as Advancements in Predictive Modeling. This book is sold through the Applied Ballistics online store. Modern Advancements in Long Range Shooting is also available in eBook format in the Amazon Kindle store.

February 11th, 2015

The Berger Southwest Nationals (SWN) kicked off Tuesday, February 10th, with an instructional clinic at the Ben Avery 1000-yard Range. This combined a lecture/Q&A session with live-fire training. Ballistics “Professor” Bryan Litz reports: “The clinic was a big hit as usual, with lots of competitor participation. There was a big crowd this year, as you can see.”

The clinic started with a class on Exterior Ballistics hosted by Bryan. This focused on why ballistics is important to competitive shooters, and how to balance ballistic performance objectives against real world constraints. Topics included bullet weight options for F-TR (155 to 215 grains), barrel/chamber considerations, plus the real-world trade-offs involved with heavy bullets (yes the BC may be better but recoil becomes an issue). Many of the questions related to content from Bryan’s recent books, and discussions in AccurateShooter.com’s Ballistics sub-Forum and Daily Bulletin.

Following the ballistics class, shooters made their way to the firing line for one-on-one instruction with experienced shooters in each discipline (sling, F-TR and F-Open). During this segment of the clinic, champion shooters worked directly with novice and intermediate shooters. Bryan said: “It was great to see the ‘top guns’ sharing their knowledge.”

Last but not least, Mid Tompkins directed a wind clinic with live fire demonstrations. Bryan reports: “Mid has a way of getting your attention. Personally, I thought his 2 MOA wind call that put the very first shot in the 5 inch X-ring at 1000 yards got everyone’s attention!” After the demonstrations, clinic “students” went to the firing line to put wind-clinic lessons into practice, and to verify their zeroes.

Mid Tompkins at the SWN Shooters’ Clinic

Here are some more images from the instructional clinic held last year at the 2014 SW Nationals.

January 9th, 2015

AccurateShooter.com has added something NEW to our Shooter’s Forum. We recently launched a new Ballistics & Bullets Board, with Bryan Litz as the “Guru in Residence”. Bryan and his team at Applied Ballistics will help answer your questions about bullet trajectories, wind drift, BC values, bullet sorting methods, meplat trimming/pointing, and other general ballistics matters. This is your chance to get your questions answered by Bryan, a expert ballistician, and an ace long-range shooter. In addition, our new Ballistics Forum area features free excerpts from Applied Ballistics’ respected publications, including Applied Ballistics for Long Range Shooting, and Bryan’s new book, Modern Advancements in Long Range Shooting. CLICK HERE for FREE Samples. AccurateShooter.com has added something NEW to our Shooter’s Forum. We recently launched a new Ballistics & Bullets Board, with Bryan Litz as the “Guru in Residence”. Bryan and his team at Applied Ballistics will help answer your questions about bullet trajectories, wind drift, BC values, bullet sorting methods, meplat trimming/pointing, and other general ballistics matters. This is your chance to get your questions answered by Bryan, a expert ballistician, and an ace long-range shooter. In addition, our new Ballistics Forum area features free excerpts from Applied Ballistics’ respected publications, including Applied Ballistics for Long Range Shooting, and Bryan’s new book, Modern Advancements in Long Range Shooting. CLICK HERE for FREE Samples.

If you have a ballistics question, or are simply curious about subjects such as bullet pointing, trajectory prediction, ballistics programs, ballistic coefficients, etc., then visit our Shooters’ Forum and join the discussion in our new Ballistics & Bullets Board.

Get $5.00 Off Applied Ballistics Books

As a special benefit for AccurateShooter.com Forum members, Applied Ballistics is offering $5.00 off Books and DVDs. If you haven’t acquired one of Bryan’s books yet, here’s a way to get with the program and save five bucks in the process. CLICK HERE for $5.00 discount info.

Get Answers from the Man Who Literally

‘Wrote the Book’ on Ballistics…

As an aerospace engineer, Bryan worked six years for the government on air-to-air missile designs. He is now owner of Applied Ballistics and Chief Ballistician for Berger Bullets. Bryan is also a champion long range shooter, so he brings a great deal of practical knowledge and experience to the table regarding the science of accuracy.

A Place to Share Knowledge and Advance the Science of Ballistics

Applied Ballistics is pleased to sponsor AccurateShooter.com’s new Ballistics & Bullets Board: “The new Ballistics Forum area provides an established place for shooters go and discuss ballistics-related issues in general. In addition to this basic objective of connecting shooters to each other, the staff of Applied Ballistics will frequent the Forum to provide expert advice on ballistics, and the use of ballistics programs. Bryan Litz will regularly visit the ballistics Forum, looking for ways to help shooters with ballistics questions. Beyond that, we’re eager to take suggestions on what kinds of tests we might consider for the AB Laboratory. We’re here to advance the science of ballistics, and we’d like to do that in ways that benefit the greatest amount of people. The ballistics forum gives us a place to explore these questions. We can answer the questions that we know, and formulate tests to explore those questions we don’t understand as well, then share the results online for everyone to see.”

How to Find the Ballistics & Bullets Board

To join in the discussions, visit our Shooters’ Forum. Scroll down until you see “Ballistics & Bullets Board, Presented by Bryan Litz and Applied Ballistics”. Just click on the orange title and you’re “in like Flynt”.

Guests can read all the topics. However, if you want to post or start a thread you’ll need to REGISTER with our Forum. There’s no charge (membership is FREE), and registration only takes a few minutes.

November 14th, 2014

Gear Review by GS Arizona

This article originally appeared in the Rifleman’s Journal website.

Many of you have doubtlessly read Bryan Litz’s articles in our Daily Bulletin and on his Applied Ballistics website about various current long-range bullets. Bryan’s work carries a great deal of weight in the world of ballistics, so his comments (and mathematical proofs) regarding the benefits of bullet pointing certainly caught my attention. Bullet pointing, like meplat trimming, is an effort to reduce the ballistic inconsistency created by the somewhat jagged tip of the jacket where the bullet forming dies bring it to a point in the manufacturing process. Of course, we could eliminate this problem altogether by shooting closed-tip, open-base bullets like the Lapua D46, but that merely shifts the jacket problem to the other end of the bullet.

In any event, hollow point bullets rule the accuracy world today, so John Whidden, multi-time National Long Range Champion at Camp Perry and a talented gunsmith and designer to boot, came up with a very handy tool to let us make those hollow points pointier. Let’s have a look at John’s tool and see how it works.

The Whidden Bullet Pointing Die System uses a Forster bullet seating die body as its basic structure and that’s a good choice given the quality machining Forster does on these. The real heart of the tool comes in two parts: the caliber sleeve and the pointing die that fits inside the sleeve. In fact, to point up different caliber bullets, you only need to change the caliber sleeve, everything else remains the same. The last item is the bullet base that slips into a standard .308 shellholder and supports the bullet as it goes into the die body.

It took me less than five minutes to get everything set up, including changing the caliber sleeve from 6mm to .30 caliber. John’s instruction sheets are well illustrated and clearly written; you should have no problem getting up and running. It took me less than five minutes to get everything set up, including changing the caliber sleeve from 6mm to .30 caliber. John’s instruction sheets are well illustrated and clearly written; you should have no problem getting up and running.

Pointing the bullets is as easy as sizing a piece of brass. You can see in the top photo the difference between a few pointed bullets and a few un-pointed ones. The innermost pointed bullet in the picture was my first attempt and I adjusted the die a little after that, you can see that the others are closed a little more. John even includes a couple of sample bullets so that you can see one done right and one done wrong. That is a nice addition that can help you achieve the desired results.

I think Bryan’s work supports the validity of this concept and John’s tool puts it into practice in a simple-to-use manner that makes it just about impossible to do any damage to the bullet. I have shot pointed bullets in various calibers at many matches now. Pointing is not a “miracle cure”, but I believe that pointing bullet tips can produce long-range accuracy gains, through reduced vertical dispersion, for many popular types of match bullets. The Whidden Bullet Pointing Die System retails for $220.00 (with one insert). Additional die inserts are $42.00 each. Extra caliber sleeves are also $42.00. You can purchase directly from Whidden Gunworks, or from Sinclair International.

October 28th, 2014

In discussions of ballistics, you’ll see references to “tangent” and “secant” bullet shapes. We know that, for many readers, these terms can be confusing. To add to the confusion, bullet makers don’t always identify their projectiles as secant or tangent designs. This article provides a basic explanation of tangent and secant designs, to help you understand the characteristics of both bullet shapes. In discussions of ballistics, you’ll see references to “tangent” and “secant” bullet shapes. We know that, for many readers, these terms can be confusing. To add to the confusion, bullet makers don’t always identify their projectiles as secant or tangent designs. This article provides a basic explanation of tangent and secant designs, to help you understand the characteristics of both bullet shapes.

Tangent vs. Secant vs. Hybrid

Most match bullets produced today use a tangent ogive profile, but the modern VLD-style bullets employ a secant profile. To further complicate matters, the latest generation of “Hybrid” projectiles from Berger Bullets feature a blended secant + tangent profile to combine the best qualities of both nose shapes. The secant section provides reduced drag, while the tangent section makes the bullet easier to tune, i.e. less sensitive to bullet seating depth position.

Berger Bullets ballistician Bryan Litz explains tangent and secant bullet ogive designs in a glossary section of his Applied Ballistics website, which we reprint below. Bryan then explains how tangent and secant profiles can be combined in a “hybrid” design.

How Bullet Ogive Curves are Defined

While the term “ogive” is often used to describe the particular point on the bullet where the curve reaches full bullet diameter, in fact the “ogive” properly refers to the entire curve of the bullet from the tip to the full-diameter straight section — the shank. Understanding then, that the ogive is a curve, how is that curve described?

LITZ: The ogive of a bullet is usually characterized by the length of its radius. This radius is often given in calibers instead of inches. For example, an 8 ogive 6mm bullet has an ogive that is a segment of a circular arc with a radius of 8*.243 = 1.952”. A .30-caliber bullet with an 8 ogive will be proportionally the same as the 8 ogive 6mm bullet, but the actual radius will be 2.464” for the .30 caliber bullet.

For a given nose length, if an ogive is perfectly tangent, it will have a very specific radius. Any radius longer than that will cause the ogive to be secant. Secant ogives can range from very mild (short radius) to very aggressive (long radius). The drag of a secant ogive is minimized when its radius is twice as long as a tangent ogive radius. In other words, if a tangent ogive has an 8 caliber radius, then the longest practical secant ogive radius is 16 calibers long for a given nose length.”

Ogive Metrics and Rt/R Ratio

LITZ: There is a number that’s used to quantify how secant an ogive is. The metric is known as the Rt/R ratio and it’s the ratio of the tangent ogive radius to the actual ogive radius for a given bullet. In the above example, the 16 caliber ogive would have an Rt/R ratio of 0.5. The number 0.5 is therefore the lowest practical value for the Rt/R ratio, and represents the minimum drag ogive for a given length. An ogive that’s perfectly tangent will have an Rt/R ratio of 1.0. Most ogives are in between an Rt/R of 1.0 and 0.5. The dimensioned drawings at the end of my Applied Ballistics book provide the bullets ogive radius in calibers, as well as the Rt/R ratio. In short, the Rt/R ratio is simply a measure of how secant an ogive is. 1.0 is not secant at all, 0.5 is as secant as it gets.

Hybrid Bullet Design — Best of Both Worlds? Hybrid Bullet Design — Best of Both Worlds?

Bryan Litz has developed a number of modern “Hybrid” design bullets for Berger. The objective of Bryan’s design work has been to achieve a very low drag design that is also “not finicky”. Normal (non-hybrid) secant designs, such as the Berger 105gr VLD, deliver very impressive BC values, but the bullets can be sensitive to seating depth. Montana’s Tom Mousel has set world records with the Berger 105gr VLD in his 6mm Dasher, but he tells us “seating depth is critical to the best accuracy”. Tom says a mere .003″ seating depth change “makes a difference”. In an effort to produce more forgiving high-BC bullets, Bryan Litz developed the hybrid tangent/secant bullet shape.

Bryan Litz Explains Hybrid Design and Optimal Hybrid Seating Depths

Story sourced by Edlongrange.

|

Proportionally longer noses mean lower drag. Proportionally longer bullets mean higher sectional density. Combine an elevated sectional density with lower drag, and you get higher BC bullets. For example, consider a 175 grain .30 caliber bullet commonly used in .308 Winchester M118LR-type ammo. These 175 grain bullets have G7 BCs in the neighborhood of .243 to .260. Neck the .308 down to 6.5mm (260 Remington) or 6mm (.243 Winchester) and now look at the BCs of the bullets available in these calibers which work within the same magazine length constraint. The 6.5mm 130 grain AR Hybrid has a G7 BC of 0.290, and the 6mm 105 grain Hybrid has a G7 BC of 0.278 — both of which are higher than the .30 cal 175 grain bullet BC. Furthermore, you get hundreds of feet per second more velocity with the necked-down cartridges as well.

Proportionally longer noses mean lower drag. Proportionally longer bullets mean higher sectional density. Combine an elevated sectional density with lower drag, and you get higher BC bullets. For example, consider a 175 grain .30 caliber bullet commonly used in .308 Winchester M118LR-type ammo. These 175 grain bullets have G7 BCs in the neighborhood of .243 to .260. Neck the .308 down to 6.5mm (260 Remington) or 6mm (.243 Winchester) and now look at the BCs of the bullets available in these calibers which work within the same magazine length constraint. The 6.5mm 130 grain AR Hybrid has a G7 BC of 0.290, and the 6mm 105 grain Hybrid has a G7 BC of 0.278 — both of which are higher than the .30 cal 175 grain bullet BC. Furthermore, you get hundreds of feet per second more velocity with the necked-down cartridges as well.

Today is Friday the 13th. Oddly enough, this is the second month in a row with the 13th falling on a Friday. Does that mean double bad luck? For those of you who are superstitious — maybe you should avoid climbing ladders or using power tools today.

Today is Friday the 13th. Oddly enough, this is the second month in a row with the 13th falling on a Friday. Does that mean double bad luck? For those of you who are superstitious — maybe you should avoid climbing ladders or using power tools today. Train Wrecks (and How to Avoid Them)

Train Wrecks (and How to Avoid Them)

4. Wind Issues. Tricky winds derail many trains. A lot can be written about wind strategies, but here’s a simple tip about how to take the edge off a worse case scenario. You don’t have to start blazing away on the command of “Commence fire”. If the wind is blowing like a bastard when your time starts, just wait! You’re allotted 30 minutes to fire your string in long range slow fire. With average pit service, it might take you 10 minutes if you hustle, less in F-Class. Point being, you have about three times longer than you need. So let everyone else shoot through the storm and look for a window (or windows) of time which are not so adverse. Of course this is a risk, conditions might get worse if you wait. This is where judgment comes in. Just know you have options for managing time and keep an eye on the clock. Saving rounds in a slow fire match is a costly and embarrassing train wreck.

4. Wind Issues. Tricky winds derail many trains. A lot can be written about wind strategies, but here’s a simple tip about how to take the edge off a worse case scenario. You don’t have to start blazing away on the command of “Commence fire”. If the wind is blowing like a bastard when your time starts, just wait! You’re allotted 30 minutes to fire your string in long range slow fire. With average pit service, it might take you 10 minutes if you hustle, less in F-Class. Point being, you have about three times longer than you need. So let everyone else shoot through the storm and look for a window (or windows) of time which are not so adverse. Of course this is a risk, conditions might get worse if you wait. This is where judgment comes in. Just know you have options for managing time and keep an eye on the clock. Saving rounds in a slow fire match is a costly and embarrassing train wreck.

It took me less than five minutes to get everything set up, including changing the caliber sleeve from 6mm to .30 caliber. John’s instruction sheets are well illustrated and clearly written; you should have no problem getting up and running.

It took me less than five minutes to get everything set up, including changing the caliber sleeve from 6mm to .30 caliber. John’s instruction sheets are well illustrated and clearly written; you should have no problem getting up and running.

In discussions of ballistics, you’ll see references to “tangent” and “secant” bullet shapes. We know that, for many readers, these terms can be confusing. To add to the confusion, bullet makers don’t always identify their projectiles as secant or tangent designs. This article provides a basic explanation of tangent and secant designs, to help you understand the characteristics of both bullet shapes.

In discussions of ballistics, you’ll see references to “tangent” and “secant” bullet shapes. We know that, for many readers, these terms can be confusing. To add to the confusion, bullet makers don’t always identify their projectiles as secant or tangent designs. This article provides a basic explanation of tangent and secant designs, to help you understand the characteristics of both bullet shapes.

Hybrid Bullet Design — Best of Both Worlds?

Hybrid Bullet Design — Best of Both Worlds?