|

|

January 4th, 2016

If you have ever turned a large quantity of case-necks using power assist, you know that a carbide mandrel can make the job go easier, with better end results. In our experience, when using carbide mandrels (as opposed to ordinary steel), the cases move more smoothly with less heat build-up. Pat Reagin of PMA Tool explains why carbide neck-turning mandrels work better:

|

Carbide offers several advantages over conventional steel and stainless steel when making any tooling, specifically neck-turning mandrels:

Dimensional Stability — Carbide maintains its dimensions indefinitely during heating and cooling. This eliminates the need to allow the mandrel time to cool every few cases.

Coefficient of Friction and Wear-Resistance — Carbide exhibits a low coefficient of friction value as compared to all steels and wears up to 100 times longer. This reduces (but does not eliminate) the amount of lubricant required.

Galling Resistance — Carbide has exceptional resistance to galling and welding at the surface. This basically eliminates the chance of getting a case stuck on a mandrel due to insufficient lubrication.

|

Given the benefits of carbide neck-turner mandrels, you may be asking “where can I get one?” Sinclair Int’l offers carbide mandrels for Sinclair neck-turners for $49.99, in a full range of calibers: 17, 20, 22, 6mm, 25, 6.5mm, 270, 30, and 338.

$49.95 Carbide Mandrels from PMA Tool $49.95 Carbide Mandrels from PMA Tool

PMA Tools now also offers carbide mandrels in a full variety of sizes. At $49.95 each, PMA’s carbide mandrels are priced competitively with Sinclair’s mandrels. PMA offers carbide mandrels in .17, .20, .22, 6mm, 6.5mm, 7mm and .30-caliber. These will work with Sinclair Int’l and 21st Century neck-turners, as well as PMA neck-turners. PMA tells us: “We now have carbide neck-turning mandrels in stock. These mandrels are made with high-tech CNC grinding-machinery, and should give you excellent results. We hope to be add other larger-caliber carbide mandrels to our lineup in the future.”

Share the post "Why Carbide Mandrels Work Better for Neck-Turning"

April 2nd, 2015

New for 2015, Redding Reloading Equipment will offer both Standard Full Length and Deluxe Die Sets with the most popular options already included. Branded as Premium Die Sets, these new offerings include a Carbide Expander Button and a Micrometer Adjusting Seat Stem. Redding’s new Black and Gold-boxed Premium Die Sets offer handloaders their most preferred die features in a convenient kit.

Redding recognized that many customers were upgrading their dies in the quest to produce more precise reloads. Accordingly, Redding decided to incorporate the most popular upgrades in the new Premium line. The Carbide Expander Button reduces stress on the case neck and also is free-floating which many believe improves overall concentricity. The Micrometer Adjusting Seat Stem allows for very precise control over bullet seating depth.

The two-die Premium Die Set has a Full Length sizing die and a Seating Die with Micrometer Seat Stem. The three-die, Premium Deluxe Set has those two dies but also adds a Neck Sizing Die. They are available in the most popular calibers offered in the Redding “Series A” calibers. For more info, or to request a copy of the 2015 Redding catalog visit www.redding-reloading.com.

Share the post "Redding Introduces New Black & Gold Premium Die Sets"

December 2nd, 2013

When neck-turning cases, it’s a good idea to extend the cut slightly below the neck-shoulder junction. This helps keep neck tension more uniform after repeated firings, by preventing a build-up of brass where the neck meets the shoulder. One of our Forum members, Craig from Ireland, a self-declared “neck-turning novice”, was having some problems turning brass for his 20 Tactical cases. He was correctly attempting to continue the cut slightly past the neck-shoulder junction, but he was concerned that brass was being removed too far down the shoulder. When neck-turning cases, it’s a good idea to extend the cut slightly below the neck-shoulder junction. This helps keep neck tension more uniform after repeated firings, by preventing a build-up of brass where the neck meets the shoulder. One of our Forum members, Craig from Ireland, a self-declared “neck-turning novice”, was having some problems turning brass for his 20 Tactical cases. He was correctly attempting to continue the cut slightly past the neck-shoulder junction, but he was concerned that brass was being removed too far down the shoulder.

Craig writes: “Everywhere I have read about neck turning, [it says] you need to cut slightly into the neck/shoulder junction to stop doughnutting. I completely understand this but I cant seem to get my neck-turning tool set-up to just touch the neck/shoulder junction. It either just doesn’t touch [the shoulder] or cuts nearly the whole shoulder and that just looks very messy. No matter how I adjust the mandrel to set how far down the neck it cuts, it either doesn’t touch it or it cuts far too much. I think it may relate to the bevel on the cutter in my neck-turning tool…”

Looking at Craig’s pictures, we’d agree that he didn’t need to cut so far down into the shoulder. There is a simple solution for this situation. Craig is using a neck-turning tool with a rather shallow cutter bevel angle. This 20-degree angle is set up as “universal geometry” that will work with any shoulder angle. Unfortunately, as you work the cutter down the neck, a shallow angled-cutter tip such as this will remove brass fairly far down. You only want to extend the cut about 1/32 of an inch past the neck-shoulder junction. This is enough to eliminate brass build-up at the base of the neck that can cause doughnuts to form.

The answer here is simply to use a cutter tip with a wider angle — 30 to 40 degrees. The cutter for the K&M neck-turning tool (above) has a shorter bevel that better matches a 30° shoulder. There is also a 40° tip available. PMA Tool and 21st Century Shooting also offer carbide cutters with a variety of bevel angles to match your case shoulder angle*. WalkerTexasRanger reports: “I went to a 40-degree cutter head just to address this same issue, and I have been much happier with the results. The 40-degree heads are available from Sinclair Int’l for $13 or so.” Forum Member CBonner concurs: “I had the same problem with my 7WSM… The 40-degree cutter was the answer.” Below is Sinclair’s 40° cutter for its NT-1000, NT-1500, and NT-4000 neck-turning tools. Item NT-3140, it sells for $12.95. There is also a 40° cutter for the NT-3000 tool, item NT-3340 ($13.95).

Al Nyhus has another clever solution: “The best way I’ve found to get around this problem is to get an extra shell holder and face it off .020-.025 and then run the cases into the sizing die. This will push the shoulder back .020-.025. Then you neck turn down to the ‘new’ neck/shoulder junction and simply stop there. Fireforming the cases by seating the bullets hard into the lands will blow the shoulder forward and the extra neck length you turned by having the shoulder set back will now be blended perfectly into the shoulder. The results are a case that perfectly fits the chamber and zero donuts.”

* 21st Century sells carbide cutters in: 15, 20, 21.5, 23, 25, 28, 30, 35, 40, and 46 degrees. PMA Tool sells carbide cutters in: 17.5, 20, 23, 25, 28, 30, 35, and 40 degrees.

Share the post "Tool Tip: Optimize Your Cutter Angle for Improved Neck-Turning"

February 9th, 2011

Gear Review: 21st Century Neck Turner

by Germán A. Salazar

A new neck-turning tool with easy adjustments, super-high quality of manufacturing and an ergonomic design sounds like a good thing to me. If you also like good tools and like to keep up with developments in the field, read on (most of the pictures can be enlarged by clicking on them).

I recently received the new Neck-Turning Tool made by John at 21st Century Shooting. I always enjoy seeing John’s work because he really has a good grasp on how a tool should be designed to work effectively and this tool certainly fits that mold. The basic requirements of a good neck turner are: (a) accurate adjustments, (b) good blade design, (c) ergonomic design and (d) a well thought-out system of ancillary items. Let’s look at each of those areas and give the tool a test drive.

Handy Cut-Depth Adjustment Dial Handy Cut-Depth Adjustment Dial

The 21st Century neck turner has a unique dial adjustment for the depth of the cut which makes small adjustments simple and fast. Each full number represents 0.001″ of cutter movement, and the fine lines in between let you zero in on the exact neck wall thickness that you need. The dial is simply turned in until the desired neck thickness is reached. If you go too far, it’s best to turn it out a full turn, then back in once again; this reduces the effect of any backlash that might exist in the threads. I found the dial easy to use and had no trouble getting to my usual thickness setting of 0.0125″.

Excellent Carbide Cutter Blade Design Excellent Carbide Cutter Blade Design

At its core, a neck turner is a cutting tool and good blade design is what sets any good cutting tool apart from the competition. Here, John really shows his ability as a designer and manufacturer. The blade supplied on my tool is carbide and cuts brass effortlessly, however, that’s not the real point of interest. Many neck turners have blades with less than ideal nose radius and create a “threading” effect on the neck unless the tool is fed over the brass at a very slow rate. The 21st Century blade has a good radius at the transition to the shoulder angle which allows for a smooth cut with a reasonable feed rate.

The shoulder angle is another well thought-out feature as it is a very close match to the actual shoulder angle of the case. This allows you to bring the cutter a bit further into the shoulder without weakening it and definitely avoid the subsequent occurrence of the donut of thick brass at the base of the neck. (When ordering, 21st Century lets you specify one of four (4) different cutter shoulder angles to match your particular cartridge: 20°, 30°, 35°, and 40°.) The photo of the case in the cutter shows the cutter making solid contact with the shoulder after a substantial cut on the neck, yet the shoulder was really just lightly touched. I backed the cutter off a bit from this setting for the final adjustment. If you tend to use heavy bullets which extend below the base of the neck, this feature alone makes John’s tool worthwhile.

Turning necks is tedious, especially if you’re turning a large number of cases as High Power shooters generally do. Accordingly, a design that takes ergonomics into consideration is highly appreciated. Note the slight hourglass shape of the tool, that really lets your hand take a grip that counters the natural tendency of the tool to turn with the rotation of the case, especially when turning with a power case driver. The size of the tool itself also helps; if you’ve used one of the smaller tools on the market, you know just how tired your hand can get from trying to hold on to it after a while! I turned 70 case necks in two sessions with the 21st Century tool and my hand and fingers remained comfortable throughout. Turning necks is tedious, especially if you’re turning a large number of cases as High Power shooters generally do. Accordingly, a design that takes ergonomics into consideration is highly appreciated. Note the slight hourglass shape of the tool, that really lets your hand take a grip that counters the natural tendency of the tool to turn with the rotation of the case, especially when turning with a power case driver. The size of the tool itself also helps; if you’ve used one of the smaller tools on the market, you know just how tired your hand can get from trying to hold on to it after a while! I turned 70 case necks in two sessions with the 21st Century tool and my hand and fingers remained comfortable throughout.

However good the turner may be, it doesn’t work alone. Any neck turner needs a matching expander. The 21st Century expander is a nicely designed unit that allows you to change expander sizes with no tools by simply unscrewing the cap of the die body and dropping in the appropriate expander.

K&M Arbor Adapters Available K&M Arbor Adapters Available

I’ve been using a K&M turner for some years now and have accumulated turning arbors (mandrels) in various sizes. John knows that’s the case for many of us, so he makes affordable adapter bushings for his tool that allow the use of K&M turner arbors. That’s a nice feature that will allow me to save the price of a few arbors and expanders. The adapter for K&M arbors costs $12.00.

Although I use a cordless screwdriver to turn the case, I still like to have a manual option for case turning. Sometimes the cordless driver dies with just a few cases left to go in a session and I know that, one day, when I most need it, it’ll just quit altogether. John’s case handle for manual case turning is another well-designed, ergonomic piece that shows his careful, thoughtful approach to tool design. He even makes a version of it for the .50 BMG if your tastes in cartridges run on the large side!

Neck-Turning Tool and Accessory Order Information

Order the Neck Turner and accessories through www.21stCenturyShooting.com, or call (260) 273-9909. The 21st Century neck-turning tool, by itself, costs $78.00, including a carbide cutter (standard size). You can chose among four different cutter shoulder angles, to match your particular cartridge: 20°, 30°, 35°, and 40°. Additional carbide cutters cost $26.00-$28.00. Caliber-specific turning arbors and expander mandrels are priced at $7.95 each. The standard size Universal Case-Holding Handle (photo above), costs $16.95.

You can also purchase a complete Neck-Turning Tool Kit from 21st Century. This $112.99 package includes everything you need: You can also purchase a complete Neck-Turning Tool Kit from 21st Century. This $112.99 package includes everything you need:

Neck Turning Tool w/cutter

Turning Arbor

Expander Mandrel

Expander Die Body

Loading Die Locking Ring

Neck Turning Universal Handle

Disclosure: 21st Century Shooting, an advertiser on this website, provided a neck turner tool and accessories to German Salazar for testing and evaluation.

Share the post "NEW Neck-Turning Tool From 21st Century Shooting"

August 11th, 2009

Do you frequently need to trim lots of cases, but can’t afford a powered trimmer such as the $280.00 Gracie machine? For manual trimming we like the L.E. Wilson units, and now there’s an upgrade that promises to increase the efficiency of your Wilson trimmer.

Sinclair Int’l has introduced a new Carbide Cutter Upgrade Kit that installs in place of a standard Wilson case trimmer cutter and crank handle. Very hard and ultra-sharp, the carbide cutter cuts quickly on contact without grabbing and leaves a nicely finished, square case mouth that is ready for deburring. With the carbide tip and larger, more comfortable handle, you should be able to trim cases more quickly, with less effort. The carbide cutter should also hold its edge longer than regular tool-steel cutter tips. The upgrade kit (item 05-4600) costs $69.95 and works with all Wilson case trimmer models (excluding 50 BMG).

Share the post "Carbide Cutter Upgrade for Wilson Case Trimmers"

September 30th, 2008

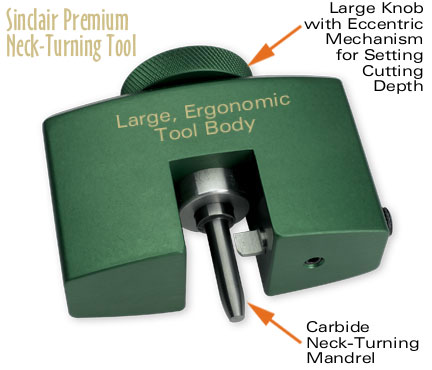

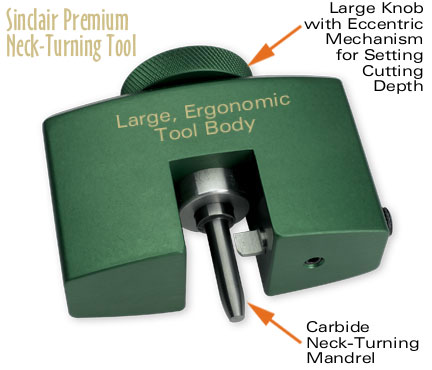

Sinclair International has just introduced a new Neck-Turning Tool. Part of a complete system with carbide mandrels, this product promises to be one of the best neck-turners on the market. The new tool has many improved features we really like:

▪ The cutter body is big, and curved to fit the hand. So, it is easier to hold than the old Sinclair tool or the K&M tool.

▪ The cutter-depth adjustment works really well. A large, knurled rotary knob on the back of the cutter body connects to an eccentric mechanism. This moves the mandrel shaft (and case) in and out relative to the cutter tip. You start by setting the cutter with feeler gauges, then fine-tune with the knob. Adjustments are very positive and precise, with laser-engraved index marks. This is a very good adjustment system, we think.

▪ The end of the tool is open so you can easily eyeball the caseneck as you’re cutting.

▪ High-grade carbide mandrels in 17 through 338 calibers will be offered with the new cutter system. At about $45 per caliber, they’re expensive, but the carbide mandrels DO work better — you’ll notice smoother case rotation and less heat build-up than with conventional (non-carbide) mandrels. If you already have mandrels, don’t worry. Sinclair says: “Our single-ended stainless mandrels will work fine with the new Neck-Turning Tool.”

Precise Adjustments Possible

With the eccentric adjustment system, you can make quick cut-depth changes with great precision. The cutter adjustment knob is click-adjustable in .0002″-.00025″ per click increments. The cut depth can be adjusted through a range of .004″-.005″ using the adjustment dial. A mandrel adjustment screw is included to make mandrel set-up and adjustment easier.

Sinclair’s new Premium Neck-Turning Tool includes three (3) feeler gauges for quickly setting cutter depth in the approximate range of the cut desired. With the cutter in range using the feeler gauge, the eccentric adjustment knob can make final adjustment for the exact neckwall thickness you desire. Sinclair claims: “Cutter adjustment is very fast and sure with none of the usual trial and error experienced with other tools.”

The $145.95 Premium Neck Turning Tool Kit (item NT-4000) includes three feeler gauges and a case-holder Turning Handle. Or you can save ten bucks and get the Tool and gauges without handle for $135.95 (item NT-4100). All popular Sinclair neck-turning tool accessories, including expander mandrels, will work with the Premium Tool. Order caliber-specific carbide turning mandrels separately for $44.75 per mandrel (items 95-0XX).

Share the post "Sinclair Releases New, Advanced Neck Turning System"

|

$49.95 Carbide Mandrels from PMA Tool

$49.95 Carbide Mandrels from PMA Tool

When neck-turning cases, it’s a good idea to extend the cut slightly below the neck-shoulder junction. This helps keep neck tension more uniform after repeated firings, by preventing a build-up of brass where the neck meets the shoulder. One of our Forum members, Craig from Ireland, a self-declared “neck-turning novice”, was having some problems turning brass for his 20 Tactical cases. He was correctly attempting to continue the cut slightly past the neck-shoulder junction, but he was concerned that brass was being removed too far down the shoulder.

When neck-turning cases, it’s a good idea to extend the cut slightly below the neck-shoulder junction. This helps keep neck tension more uniform after repeated firings, by preventing a build-up of brass where the neck meets the shoulder. One of our Forum members, Craig from Ireland, a self-declared “neck-turning novice”, was having some problems turning brass for his 20 Tactical cases. He was correctly attempting to continue the cut slightly past the neck-shoulder junction, but he was concerned that brass was being removed too far down the shoulder.

Turning necks is tedious, especially if you’re turning a large number of cases as High Power shooters generally do. Accordingly, a design that takes ergonomics into consideration is highly appreciated. Note the slight hourglass shape of the tool, that really lets your hand take a grip that counters the natural tendency of the tool to turn with the rotation of the case, especially when turning with a power case driver. The size of the tool itself also helps; if you’ve used one of the smaller tools on the market, you know just how tired your hand can get from trying to hold on to it after a while! I turned 70 case necks in two sessions with the 21st Century tool and my hand and fingers remained comfortable throughout.

Turning necks is tedious, especially if you’re turning a large number of cases as High Power shooters generally do. Accordingly, a design that takes ergonomics into consideration is highly appreciated. Note the slight hourglass shape of the tool, that really lets your hand take a grip that counters the natural tendency of the tool to turn with the rotation of the case, especially when turning with a power case driver. The size of the tool itself also helps; if you’ve used one of the smaller tools on the market, you know just how tired your hand can get from trying to hold on to it after a while! I turned 70 case necks in two sessions with the 21st Century tool and my hand and fingers remained comfortable throughout.

You can also purchase a complete

You can also purchase a complete