|

|

June 11th, 2017

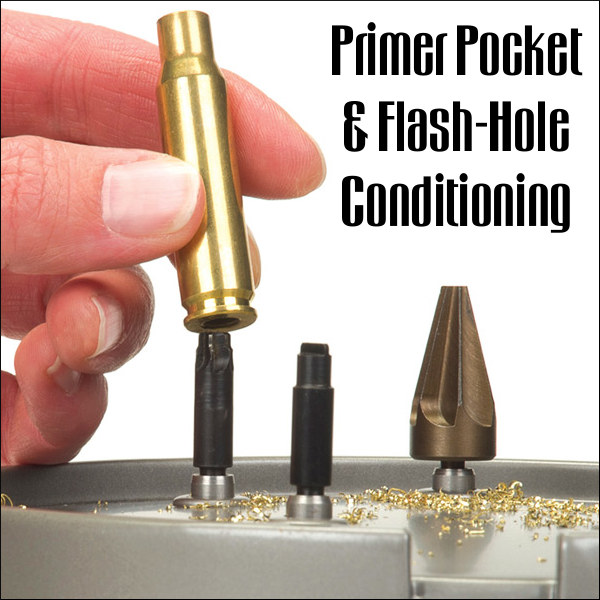

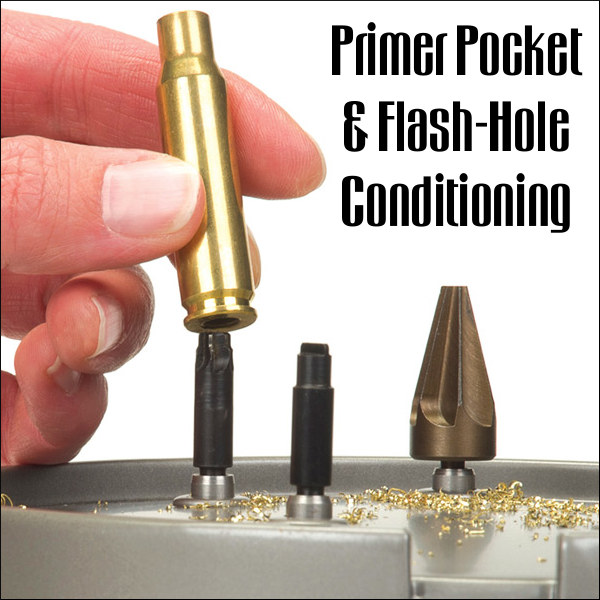

Case Prep Xpress photo courtesy Lyman Products.

Each Wednesday, the U.S. Army Marksmanship Unit publishes a reloading “how-to” article on the USAMU Facebook page. This week’s “Handloading Hump Day” article covers two basic case prep chores — uniforming primer pockets and deburring flash-holes. Visit the USAMU Facebook page for other tips.

Primer Pocket & Flash-Hole Conditioning

This week, we’ll address a question that frequently arises: “Do you uniform primer pockets and deburr flash-holes?” As we tailor our handloading methods to the specific needs of each instance, the answer, not surprisingly, is “Sometimes!” However, don’t flip that dial just yet, as what determines our approach may be helpful in deciding how to address one’s own techniques. Moreover, we have a buried “Easter Egg” morsel that may bring a chuckle, as well as useful safety information!

Generally, the USAMU Handloading Shop does not uniform primer pockets (PP) or deburr flash holes (FH) of our rifle brass. We’re certainly not against it… Rather, this reflects the very high volume of ammunition we load, the fact that very few cases are ever re-loaded for a second firing, and the types of brass we use. However, as a need is perceived, we DO deburr flash holes. Of interest, we have fired many very small, 1000-yard test groups and aggregates using weight-selected, domestic brass that had not had PPs uniformed or FHs deburred.

Before and After — On the left is a fired, deprimed 7.62×51 case with primer residue intact. On the right the primer pocket has been uniformed to SAAMI specs. Note the shiny finish at the bottom of the pocket — evidence of the the removal of metal when uniforming the primer pocket.

As to the type cases we use, many thousands of our long-range 5.56mm cases come to us from the arsenal with the primer of our choice pre-installed and staked-in, per usual practice. Obviously, we cannot uniform either FHs or PPs on this live, primed brass. However, after careful sorting, inspection and preparation, we do obtain match-winning results with it.

Shooters who reload their brass several times may decide to uniform PPs and deburr FHs, especially on their “300-yard and beyond” brass. Here, they will use the cases many times, while the uniforming is performed only once. Also, most handloaders only process moderate amounts of brass, compared to our multi-thousand round lots.

Having high quality Long Range (LR) brass helps. Many of the better brass manufacturers install their flash holes so that no burrs are created. Still, it does pay to inspect even THESE manufacturer’s products, as occasional slips are inevitable. Very rarely, some of the best makers will have a significant burr in, say, 1 per 1000 or 2000 cases, and it’s worth catching those.

Exceptions can always be found. Recently, we began processing a large lot of match brass from a premier manufacturer. We were startled to find that every case had a significant burr in the FH — something we’d never before seen from this maker. We then broke out the FH deburring tools and went to work.

Some observers have noted that it can be difficult to truly verify the contribution to accuracy of these procedures — particularly when firing from the shoulder, in conditions. Members of this staff, as individual rifle competitors, do often perform these operations on their privately-owned LR rifle brass. One could ascribe this to the old Highpower Rifle maxim that “if you think it helps, then it helps.”

However, a World Champion and Olympic Gold/Silver medalist here commented on his own handloading (for International competition, which demands VERY fine accuracy). He noted that he did seem to see a decline in accuracy whenever he did not uniform FHs, deburr FHs and clean primer pockets before each reloading. (One might be tempted to counter that only a truly World Class shooter could reliably detect the difference.) However, with the wisdom of decades experience, our Champion also remarked that “It could have been that I just wasn’t shooting as well that day.”

For those who do opt for these procedures, note that various tool models may have adjustable depth-stops; pay attention to the instructions. Some FH-deburring tools (which enter the case mouth, not the primer pocket) are dependent upon uniform case length for best results.

Above is a flash-hole deburring tool on an RCBS powered case-prep unit. These case prep machines can save a lot of pain and misery, helping one perform various functions quickly and efficiently.

Above is a flash-hole deburring tool on an RCBS powered case-prep unit. These case prep machines can save a lot of pain and misery, helping one perform various functions quickly and efficiently.

Share the post "Reloading 101: Primer Pocket and Flash-Hole Conditioning"

April 16th, 2017

Folks have asked if there is a tool that can remove obstructions from a Lapua small, BR-sized flash hole without opening the hole size. The Lapua PPC/BR flash hole is spec’d at 1.5mm, which works out to 0.059055″. Most of the PPC/BR flash-hole uniforming tools on the market use a 1/16″ bit which is nominally 0.0625″, but these often run oversize — up to 0.066″.

If you want to just clear out any obstructions in the flash hole, without increasing the flash hole diameter, you can use an inexpensive “pin vise” with an appropriate drill bit. For $1.00, eHobbyTools.com sells a 1.5mm pin vise bit, item 79186, that matches the Lapua flash hole exactly. Other vendors offer a #53 pin vise bit that measures .0595″ or .060″ (depending or source). An 0.0595″ bit is close enough. You can find pin vises and bits at hobby stores.

Share the post "Pin Vise with 1.5mm Bit Fits Lapua BR/PPC Flash Holes"

November 16th, 2013

Conventional .308 Winchester brass has a large primer pocket with a large, 0.080″-diameter flash hole. Last year, Lapua began producing special edition .308 Win “Palma” brass that has a small primer pocket and a small flash hole, sized 1.5mm (.059″) in diameter. Tests by U.S. Palma Team members showed that the small-flash-hole .308 brass possibly delivers lower Extreme Spread (ES) and Standard Deviation (SD) with some bullet/powder/primer combinations. All things being equal, a lower ES should reduce vertical dispersion at long range.

Why Might a Small Flash Hole Work Better?

The performance of the small-flash-hole .308 brass caused some folks to speculate why ES/SD might be improved with a smaller flash hole. One theory (and it’s just a theory) is that the small flash hole creates more of a “jet” effect when the primer fires. Contributing Editor German Salazar sought to find out, experimentally, whether this theory is correct. German explained: “During one of the many internet forum discussions of these cases, Al Matson (AlinWA) opined that the small flash hole might cause the primer flash to be propagated forward more vigorously. In his words, it should be like shooting a volume of water through a smaller nozzle, resulting in a flash that reaches further up the case. Now that kind of comment really sparked my curiosity, so I decided to see what I could see.”

More Primer Testing by Salazar

You can read more about this test and other primer experiments on RiflemansJournal.com.

Salazar Primer Tests: Small Rifle Primer Study | Large Rifle Primer Study

Large and Small Flash Hole .308 Cases — But Both with Small Primer Pockets

To isolate the effect of flash hole diameter alone, German set up a test with the two types of .308 case that have a small primer pocket: Remington BR brass with a 0.080″ flash hole and Lapua Palma brass with a 0.062″ flash hole. NOTE: German reamed the Lapua brass to 0.062″ with a Sinclair uniforming tool, so it was slightly larger than the 0.059″ factory spec. The Remington brass has a .22 BR headstamp as this brass was actually meant to be re-formed into .22 BR or 6 BR before there was factory brass available for those cartridges.

German set up his primer testing fixture, and took photos in low light so you can see the propagation of the primer “blast” easily. He first tested the Remington 7 1/2 primer, a primer known for giving a large flame front. German notes: “I thought that if there was a ‘nozzle effect’ from the small flash hole, this primer would show it best. As you can see from the photos, there might be a little bit of a flash reduction effect with this primer and the small flash hole, the opposite of what we expected, but it doesn’t appear to be of a significant order of magnitude.”

Remington BR case, 0.080″ Flash Hole, Remington 7.5 Primer.

Lapua Palma case, 0.062″ Flash Hole, Remington 7.5 Primer.

Next German tested the Wolf .223 primer, an unplated version of the Small Rifle Magnum that so many shooters use. German notes: “This is a reduced flame-front (low flash) primer which has proven itself to be very accurate and will likely see a lot of use in the Lapua cases. With this primer, I couldn’t detect any difference in the flash produced by the small flash hole versus the large flash hole”.

Remington BR case, 0.080″ Flash Hole, Wolf .223 Primer.

Palma case, 0.062″ Flash Hole, Wolf 223 Primer.

German tells us: “I fired five or six of each primer to get these images, and while there is always a bit of variance, these are an accurate representation of each primer type and case type. You can draw your own conclusions from all this, I’m just presenting the data for you. I don’t necessarily draw any conclusions as to how any combination will shoot based on the pictures.”

Results of Testing

Overall, looking at German’s results, one might say that the smaller diameter of the small flash hole does not seem to have significantly changed the length or size of the primer flame front. There is no discernible increased “jet effect”.

Share the post ".308 Winchester — Large vs. Small Flash Hole Test"

May 10th, 2013

Conventional .308 Winchester brass has a large primer pocket with a large, 0.080″-diameter flash hole. In 2010, Lapua began producing special edition .308 Win “Palma” brass that has a small primer pocket and a small flash hole, sized 1.5mm (.059″) in diameter. Tests by U.S. Palma Team members showed that the small-flash-hole .308 brass possibly delivers lower Extreme Spread (ES) and Standard Deviation (SD) with some bullet/powder/primer combinations. All things being equal, a lower ES should reduce vertical dispersion at long range.

Why Might a Small Flash Hole Work Better?

The performance of the small-flash-hole .308 brass caused some folks to speculate why ES/SD might be improved with a smaller flash hole. One theory (and it’s just a theory) is that the small flash hole creates more of a “jet” effect when the primer fires. German Salazar (Rifleman’s Journal Editor) sought to find out, experimentally, whether this theory is correct. German explained: “During one of the many internet forum discussions of these cases, Al Matson (AlinWA) opined that the small flash hole might cause the primer flash to be propagated forward more vigorously. In his words, it should be like shooting a volume of water through a smaller nozzle, resulting in a flash that reaches further up the case. Now that kind of comment really sparked my curiosity, so I decided to see what I could see.”

More Primer Testing by Salazar

You can read more about this test and other primer experiments on RiflemansJournal.com.

Salazar Primer Tests: Small Rifle Primer Study | Large Rifle Primer Study

Large and Small Flash Hole .308 Cases — But Both with Small Primer Pockets

To isolate the effect of flash hole diameter alone, German set up a test with the two types of .308 case that have a small primer pocket: Remington BR brass with a 0.080″ flash hole and Lapua Palma brass with a 0.062″ flash hole. NOTE: German reamed the Lapua brass to 0.062″ with a Sinclair uniforming tool, so it was slightly larger than the 0.059″ factory spec. The Remington brass has a .22 BR headstamp as this brass was actually meant to be re-formed into .22 BR or 6 BR before there was factory brass available for those cartridges.

German set up his primer testing fixture, and took photos in low light so you can see the propagation of the primer “blast” easily. He first tested the Remington 7 1/2 primer, a primer known for giving a large flame front. German notes: “I thought that if there was a ‘nozzle effect’ from the small flash hole, this primer would show it best. As you can see from the photos, there might be a little bit of a flash reduction effect with this primer and the small flash hole, the opposite of what we expected, but it doesn’t appear to be of a significant order of magnitude.”

Remington BR case, 0.080″ Flash Hole, Remington 7.5 Primer.

Lapua Palma case, 0.062″ Flash Hole, Remington 7.5 Primer.

Next German tested the Wolf .223 primer, an unplated version of the Small Rifle Magnum that so many shooters use. German notes: “This is a reduced flame-front (low flash) primer which has proven itself to be very accurate and will likely see a lot of use in the Lapua cases. With this primer, I couldn’t detect any difference in the flash produced by the small flash hole versus the large flash hole”.

Remington BR case, 0.080″ Flash Hole, Wolf .223 Primer.

Palma case, 0.062″ Flash Hole, Wolf 223 Primer.

German tells us: “I fired five or six of each primer to get these images, and while there is always a bit of variance, these are an accurate representation of each primer type and case type. You can draw your own conclusions from all this, I’m just presenting the data for you. I don’t necessarily draw any conclusions as to how any combination will shoot based on the pictures.”

Results of Testing

Overall, looking at German’s results, one might say that the smaller diameter of the small flash hole does not seem to have significantly changed the length or size of the primer flame front. There is no discernible increased “jet effect”.

Share the post "Large vs. Small Flash Holes in .308 Win Brass"

December 6th, 2012

Even with high-quality brass from Lapua, Norma, and RWS, occasionally you may find one or two cases per box which have a small flake or obstruction in the flash-hole. This will appear like a thin crescent on one side of the flash hole (see photo). You should inspect ALL new brass before loading to identify any pieces with a partially-obstructed flash hole. It’s a good idea to remove any flake or thin crescent left as an artifact of the flash-hole forming process. Because the flash-hole itself is normally centered and of the correct diameter, it is not necessary to ream the flash-hole to a larger diameter. All you really need to do is remove the small obstruction(s). This can be done quickly with inexpensive tools.

Use a Small Pin Vise to Remove Flash-Hole Obstructions

Folks have asked if there is a tool that can remove obstructions from a Lapua small, BR-sized flash hole without opening the hole size. The Lapua PPC/BR flash hole is spec’d at 1.5mm, which works out to 0.059055″. Most of the PPC/BR flash-hole uniforming tools on the market use a 1/16″ bit which is nominally 0.0625″, but these often run oversize — up to 0.066″.

If you want to just clear out any obstructions in the flash hole, without increasing the flash hole diameter, you can use an inexpensive “pin vise” with an appropriate drill bit. For $1.00, eHobbyTools.com sells a 1.5mm drill bit, item 79186, that matches the Lapua flash hole exactly. Other vendors offer a #53 pin vise drill bit that measures .0595″ or .060″ (depending or source). An 0.0595″ bit is close enough. You can find pin vises and these small-diameter drill bits at hobby stores.

For quite some time, Sinclair Int’l has sold a similar device for small (PPC and BR-size) flash holes. Like the new 07-3081 unit for large flash holes, the 07-3000 Reamer for small flash holes works from the outside, so it can index off the primer pocket. It reams to .0625″, and also costs $45.99. The standard dimension for Lapua 220 Russian and 6mmBR flash holes is 1.5mm or .0590″. This tool will permit standard-size decapping rods with .0625″ tips to work without binding. However, note that both Forster and Redding normally supply .057″ decapping pins with their PPC and BR dies. So, it is NOT necessary to ream your Lapua BR/PPC flashholes, unless you prefer to do so for uniformity. It IS, however, a good idea to check BR/PPC flash holes for burrs before loading the first time.

NOTE: If you purchase either the 07-3081 or 07-3000 Sinclair Flash Hole Reamer tools, we recommend you mic the cutter tip before you process a bunch of cases. Sometimes a tip comes through that is oversize. This will ream the flash holes larger than you may intend.

Share the post "Flash-Hole First Aid — Removing Flash Hole Obstructions"

November 1st, 2009

For years, Sinclair Int’l has offered a reamer for small, BR-sized flash-holes, product #07-3000. This popular tool features an 0.0625″ cutting tip to uniform the .059″ flash-holes on Lapua 220 Russian, 6mmBR, 6.5 Grendel, and 6.5×47 brass. Sinclair’s tool works from the outside, indexing off the primer pocket. For those people who believe in the utility of reaming small flash-holes (an open question), the Sinclair “outside-in” design may be the best. But until now, there has been no equivalent “outside-in” reamer for cases with large flash-holes.

Sinclair recently introduced its NEW .081″ large flash-hole reamer, item #07-3081. This $37.50 tool is designed to ream standard flash holes (.080″) to exactly .081 inch, both for small primer pockets and large primer pockets. This tool will remove most burrs left in manufacturing and will uniform the flash-hole diameter of all your brass to ensure consistent ignition. Sinclair recently introduced its NEW .081″ large flash-hole reamer, item #07-3081. This $37.50 tool is designed to ream standard flash holes (.080″) to exactly .081 inch, both for small primer pockets and large primer pockets. This tool will remove most burrs left in manufacturing and will uniform the flash-hole diameter of all your brass to ensure consistent ignition.

Double-Ended Design Works with Both Small and Large Primer Pockets

Sinclair’s all-stainless three-piece tool features a double-ended reamer guide for both large and small primer pockets, a knurled handle for easy turning and a straight fluted .081″ reamer. It is designed for all cartridges (with either small OR large primer pockets) with standard .080″ flash holes.

As one Sinclair customer noted: “This is a tool that has been needed for a long time.” As a result, the .081″ flash-hole reamers have been back-ordered through 12/1/2009. But if you order now you should have yours within 5-6 weeks.

IMPORTANT: We recommend, if you order this tool, that you mic the actual diameter of the cutter tip. We have found that some flash-hole reamers, of ALL brands, arrive with slightly oversized cutter tips. Indeed we’ve seen tip diameters of other brands (not Sinclair) vary by as much as .006″ (six-thousandths). You want to make sure you don’t have an oversize cutter before you ream hundreds of cases.

Share the post "New "Outside-In" Flash Hole Reamer for Large Flash Holes"

August 6th, 2009

Sinclair Int’l has introduced two important new reloading products. Both are items that reloaders have requested for quite some time. Sinclair listened and now offers: 1) a precision large (.081″) flash hole reamer; and 2) a neck-turning tool for large cartridges such as the 50 BMG.

Large Flash-Hole Reamer

Sinclair has released a new, .081″-spec “outside-in” Flash Hole Reamer (item 07-3081) designed to designed to uniform standard flash holes to exactly .081 inch. This 3-piece tool features all stainless steel construction, a double-ended reamer guide for both large and small primer pockets, a knurled handle for easy turning, and a straight-fluted .081 inch reamer. With this tool you can remove burrs or obstructions in the flash hole and ensure that all your flash holes are the same size. NOTE — this tool works for both small primer pockets AND large primer pockets, for cartridges with .080″ nominal diameter flash holes. The new 07-3081 tool costs $37.50.

For quite some time, Sinclair Int’l has sold a similar device for small (PPC and BR-size) flash holes. Like the new 07-3081 unit for large flash holes, the 07-3000 Reamer for small flash holes works from the outside, so it can index off the primer pocket. It reams to .0625″, and also costs $37.50. The standard dimension for Lapua 220 Russian and 6mmBR flash holes is 1.5mm or .0590″. This tool will permit standard-size decapping rods with .0625″ tips to work without binding. However, note that both Forster and Redding normally supply .057″ decapping pins with their PPC and BR dies. So, it is NOT necessary to ream your Lapua BR/PPC flashholes, unless you prefer to do so for uniformity. It IS, however, a good idea to check BR/PPC flash holes for burrs before loading the first time.

NOTE: If you purchase either the 07-3081 or 07-3000 Sinclair Flash Hole Reamer tools, we recommend you mic the cutter tip before you process a bunch of cases. Sometimes a tip comes through that is oversize. This will ream the flash holes larger than you may intend.

Large Caliber (35-50) Neck Turning Tool

Jumbo rifle cartridges, such as the 408 Chey Tac and 50 BMG, are becoming more popular with precision shooters, and Sinclair’s customers have asked for a neck-turning tool which will handle the large calibers. Sinclair’s new NT-5000 Neck Turning Tool will work for cartridges from 35 caliber all the way up to 50 cal, including the 50 BMG. This new tool uses the same smooth, cutter adjustment system as Sinclair’s NT-1000 Neck Turner, but a special oversize case-holder is furnished with each NT-5000 tool. Special large-caliber Expander Dies, and large-caliber turning and expander mandrels are available individually or as part of a Large Caliber Neck Turning Tool Kit.

Share the post "NEW Large Flash-Hole Reamer and Large-Caliber Neck-Turner from Sinclair Int'l"

|

Sinclair recently introduced its NEW

Sinclair recently introduced its NEW