August 13th, 2016

Muzzle brakes are controversial. Some people swear by them, while others swear at them. Still, there’s no question that a good brake can reduce felt recoil up to 45%. And likewise, the best brakes, when installed properly, seem to have no negative effect on accuracy.

Roy Bertalotto has done considerable experimentation with muzzle brakes, testing dozens of brake designs on his own rifles over the past few years. Roy’s article, Adventures with Muzzle Brakes, discusses various aspects of muzzle brake design and performance. Roy doesn’t claim that his testing is definitive, but his article is definitely worth a read. Here are some of Roy’s interesting findings:

Exit Hole Diameter

“Best accuracy and effectiveness of the brake was obtained with a hole .020″ over bullet diameter. If the exit hole is too small, such as +.005″ over bullet diameter, accuracy suffers. If the depth of the exit hole is too shallow, the metal around the hole will erode very quickly.”

Hole Placement

“The most effective braking was with a brake 1″ in diameter with a 3/4″ exit hole on each side, just in front of the muzzle. The bullet passes through a cone of 35 degrees before it exits the brake. (Like the tank example), Incredible reduction of recoil. But loud and ugly. Very easy to make since you don’t need a spin fixture or a dividing head.”

Bottom Gas Venting Helps Accuracy

“In my tests, not having holes all around the brake effects accuracy a bit. I believe it does something to the bullet by the air pushed ahead of the bullet creating unequal turbulence in the bullet path. I’ve tried a few brakes where I drilled only holes on the top, test fired, and then completed holes on the bottom and in every case, accuracy improved.” Below are spiral-ported brakes crafted by Clay Spencer.

Brakes Work Best with High-Pressure Cartridges

“The higher the pressure of the particular round, the more effective the brake. I have over 20 rifles with brakes. The 220 Swift is the king of reduction. Followed very closely by the 25-06, 6mm Remington, any Weatherby small bore. With a proper brake and a hot handload under a 40 gr bullet, the Swift will move 1/2″ to the rear and 0 muzzle rise! Big boomers with low pressure like 45-70s and shot guns benefit the least.” [Editor’s Note: Roy is judging effectiveness by the percentage of recoil reduction rather than absolute levels of recoil. Obviously if you start with a heavier-recoiling round, the absolute amount of recoil energy reduction is greater. Roy is really talking about efficiency–brakes are most efficient when used with high-pressure cartridges.]

Installation is Key to Accuracy

Roy’s findings are fascinating and suggest that further study of muzzle brakes is warranted. But we can all agree that precision installation of the brake is essential for accuracy. A poorly-installed, mis-aligned brake will degrade accuracy, that is well-known.

Harrell’s Precision has made thousands of muzzle brakes, in many styles and port arrangements. The Harrell brothers offer some good advice for gunsmiths installing brakes: “Muzzle brakes aren’t magic, they reduce recoil by redirecting exiting gas. What’s important is that they are straight and the threads are perpendicular with the base. The only way to get the base and threads perpendicular is to thread, not tap, them on a lathe.”

Share the post "TECH TIP: Optimizing Muzzle Brake Accuracy and Effectiveness"

Harrell’s Precision sells “semi-custom” full-length bushing dies for the PPC and 6BR chamberings. While the Harrell brothers do not cut the die to spec, they carry a large selection of dies made with slightly different internal dimensions. When you send in your fired brass, the Harrells choose a die from inventory with just the right amount of sizing (diameter reduction) at the top and bottom of the case. Given the quality, and precise fit, Harrell’s full-length dies cost $115.00 plus shipping. These are currently available for PPC family, 6mmBR, 6mm Dasher, and 6.5×47 Lapua. The folks at Harrells recommend checking if you have questions about die sizing: “Unless you know exactly which die you need, do not order online. We have 8 different sizes of each caliber. Please call (540)380-2683.”

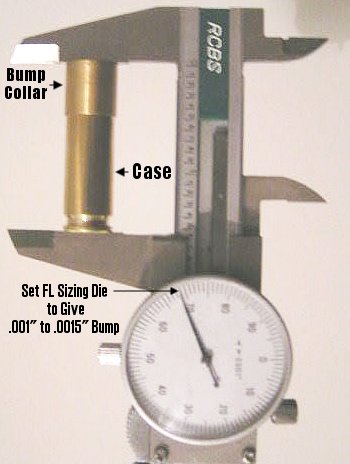

Harrell’s Precision sells “semi-custom” full-length bushing dies for the PPC and 6BR chamberings. While the Harrell brothers do not cut the die to spec, they carry a large selection of dies made with slightly different internal dimensions. When you send in your fired brass, the Harrells choose a die from inventory with just the right amount of sizing (diameter reduction) at the top and bottom of the case. Given the quality, and precise fit, Harrell’s full-length dies cost $115.00 plus shipping. These are currently available for PPC family, 6mmBR, 6mm Dasher, and 6.5×47 Lapua. The folks at Harrells recommend checking if you have questions about die sizing: “Unless you know exactly which die you need, do not order online. We have 8 different sizes of each caliber. Please call (540)380-2683.” Bump Measuring Collar

Bump Measuring Collar