Redding Add-On Micrometer Seating Stems Now Shipping

Well folks, the new Redding Micrometer Seating Stems for standard Redding seating dies are finally shipping. Robin Sharpless, Redding’s Executive VP, confirmed that “these Seating Stems started shipping this month, by the hundreds. MidwayUSA, Grafs, Midsouth — all the major vendors are getting inventory.” We confirmed that MidwayUSA now has, in stock, the Micrometer Seating Stems for .204 Ruger, .223 Rem, 22 PPC, 22-250 Rem, .243 Win, .308 Win, .284 Win, .30-06, and .338 Lapua Magnum, plus many other calibers. (One model Seating Stem can often work for multiple cartridge types of the same caliber.) MidwayUSA is charging $42.99 for both the regular and VLD-style seater stems.

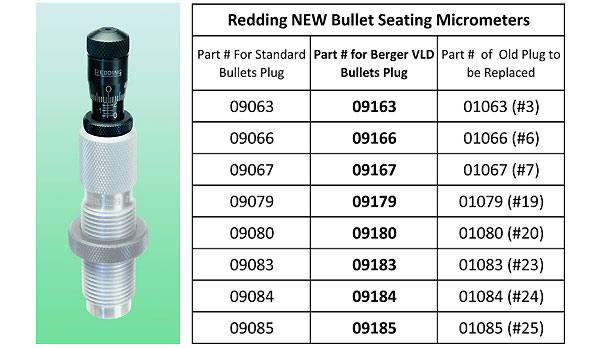

Micrometer Seating Stems Retro-Fit to Redding’s Standard Seating Dies

The big advantage of these new Seating Stems is that you can get the additional control and precision of a micrometer top by simply upgrading your existing dies at about half the cost of a new, complete Competition Seater Die. NOTE: the Seating Stem assemblies are a component of the bullet seating die. These are not the dies themselves. It is the top portion of the die that contains the plunger, which pushes the bullet into the case. The micrometer is graduated in increments of 0.001″ to assure precise seating depth control. The Seating Stems feature a dead stop on the threads allowing full repeatability even if changed from one die to another. NOTE: These Micrometer seating stems are direct replacements for the original stems. To comfirm die compatibility,the stem numbers match the numbers stamped on the tops of the original seat plug which was shipped with your standard seating dies.

The new Redding Micro Precision Seating Stems are available for both standard bullet shapes as well as VLD Bullets. These allow the user to accurately seat the longer-nosed VLD-style projectiles.

In this feature, Bill Gravatt, President of

In this feature, Bill Gravatt, President of  The only part of the decapping assembly that should come in contact with your brass is the expander ball and the decapping pin. Pay particular attention to the decapping ball as it determines the final interior dimension (bullet grip) of your case neck. Make sure you inspect it after cleaning to make sure that the surface is clean and free of burrs.

The only part of the decapping assembly that should come in contact with your brass is the expander ball and the decapping pin. Pay particular attention to the decapping ball as it determines the final interior dimension (bullet grip) of your case neck. Make sure you inspect it after cleaning to make sure that the surface is clean and free of burrs. Regular Cleaning and Storage Advice

Regular Cleaning and Storage Advice