How to Wear Out a Barrel in One Afternoon…

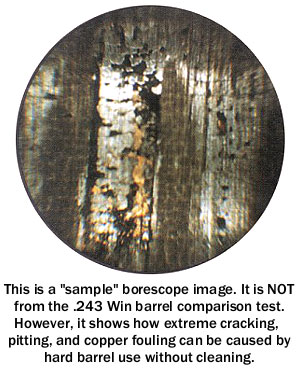

Can sustained rapid-fire shooting with no cool-down period wear out a quality barrel more quickly? The answer is “Yes” according to Forum member LCazador, who recently did an interesting comparison test with two .243 Win barrels. He started off with two, identical, match-grade HV taper stainless barrels. Both were NEW at the start of testing, and LCazador shot the same load through each: 95gr match bullets with 38 grains of Hodgdon Varget. After giving both barrels the same, gentle 20-round break-in, 300 rounds were then fired through each barrel — in very different ways. Barrel condition and wear were monitored with a borescope.

Barrel One — Slow Fire, Cool Down Periods, Cleaning Every 50 Rounds

At the end of the 300-round test, Barrel One looked brand new. There was none of the severe fire cracking found in Barrel Two. This barrel was shot no more than 10 times without a cool down and firing was done at a much slower pace. Cleaning for this barrel was done every 50 shots.

Barrel Two — Fast Firing, No Waiting, Cleaning Every 100 Rounds

The second barrel, which received hard use and minimal cleaning, was severely damaged with severe fire cracking at the leade and throat. As a result, the barrel had to be re-chambered. This barrel was shot 100 rounds at time without cleaning and was shot up to 20 times in succession without a cool down.

Don’t let your barrel get too hot, and keep it clean. One afternoon can ruin a barrel!

Monitoring Barrel Wear with Borescope

Monitoring Barrel Wear with Borescope

Some folks worry too much about what their borescopes reveal — many barrels do not have to be “squeaky clean” to perform well. In fact some barrels run better after ten or more fouling shots. However, a borescope can be very helpful when your barrel starts losing accuracy for no apparent reason. Forum member FdShuster writes:

“A borescope is a positive way of backing up your suspicions when the rifle starts to throw an occasional (soon followed by more frequent) wild shot. Using the scope is also an excellent way to determine that the cause is barrel wear and not simply a need for a concentrated cleaning session to remove built up copper and more importantly, carbon fouling.

I’ve had a few barrels that gave every indication of being shot out. But I ‘scoped them out and found the cause to be nothing more than requiring a good cleaning. They then returned to their usual performance. There’s no guessing involved when you are able to get ‘up close and personal’ using the scope. The borescope also provides an excellent view of the all-important condition of the crown. My borescope is one of the most valuable investments I’ve ever made.”

If you DO invest in a borescope, please keep in mind it’s a precision optical device that should be handled with appropriate care. For what you pay to add one to your tool box, you should be aware that they’re fragile items indeed despite the outside appearance.

I’ve had mine for about five years & thought I was treating it right until a few weeks ago when I went to use it & found it no longer worked. What I expected to see wasn’t what I got – the view in the eyepiece was completely black. $275 later – for shipping and the cost to repair – I have it back now & it works as good as when new but that new barrel I want is gonna be a bit longer in coming….

I am not doubting the results of this test, but I have performed the same test a number of times and found that there was NO noticeable difference in accuracy or wear when a bbl wasn’t broken in or cleaned. I do however know for sure that firing round after round and heating up the bbl rapidly does wear out a bbl much faster. IF I fired many rounds (slow fire), and didn’t clean often vs slow fire with cleaning every 5-10 rounds///there was NO difference to the bbl when borescoped. IMO…it’s the heating of the bbl that does the vast majority of the damage.

I have been shooting the same rifle and barrel for 12 years. I did a very detailed, slow-fire, 75 round barrel break-in, ensuring I never let the barrel get hot. I religiously clean my barrel every ten to fifteen rounds. My primary round is the Federal Gold Match, 168 Sierra BTHP. The barrel is a twenty inch tapered and fluted stainless Pac-Nor. Like every other shooter on my team, I am pretty OCD about taking care of my rifle, especially the barrel. I am convinced that proper cleaning extends the life of the barrel and I am amazed when I hear of others in my profession having to get re-barreled after 3-4,000 rounds. As of today I have 12,597 rounds through my barrel and I am still shooting sub-MOA.

Barrel life depends on more than one factor. Caliber, land configuration, powder used, pressure of the load, distance fired, etc. If you shoot a 308 Win. slow fire, with moderate loads and only shoot at 100 yds, you might get 20K rounds through the barrel before you start to see groups bigger than 1 MOA. If you shoot that same rifle at 600 yds you may start to see fliers at 3K to 4K rounds. In general most target shooters I know retire a barrel well before it gets to the point where it only shoots 1 MOA. The testing described in this article is similar to high power rifle competition, but with more shots fired in one day than at a typical high power match. It is not uncommon to shoot 120+ rounds in one day at a high power match, but only 40 of them are rapid fire. In addition, the 243 Win. is considered to be very hard on barrels. If this test was done using a 260 Rem., 708 Rem. or 6 Rem BR, the results would be different. I would suspect that with a 6 BR, the barrel would not show nearly the same amount of fire-cracking after only 300 rounds. I have had several 708 barrels that went 5,500+ rounds including rapid fire while still shooting well below 1 MOA at 600 yards. I know of one friend who won the collegiate agg at Camp Perry with a 708 that had a know history of over 8K rounds. One test like this does not define how often you need to change barrels. YMMV.

Agreed, a rainbow .308 is much different on barrels than a laser .243.

I hear what ya’ll are saying, and I appreciate the article, but the bottom line is barrels are wear parts. One shouldn’t be afraid to replace it when it doesn’t do what you need it to do anymore.

Interesting article, but as usual I cannot understand how to translate this to useable information. I am a varmint hunter and shoot thousands of rounds per year through my rifles. Two questions often occupy our down time. How hot is too hot, and how much do you want to clean? I started using temp tape on my barrels, but without some temp guidelines, it is pretty much for looks. One thing I have found is that it makes no difference on a quality barrel if I clean at 50 or 500 rounds, but I know BR shooters would never accept that.

If a barrel can be worn out in one afternoon, it wasn’t much of a barrel to begin with. Invest in a reputable [Krieger, Shilen, Bartlein, etc;] stainless steel barrel.