|

|

May 23rd, 2015

In our Shooters’ Forum, one member recently asked: “What makes an AR accurate? What parts on an AR can really affect accuracy — such as free-floating handguards, barrels, bolts, bolt carriers?” He wanted an honest, well-informed answer, not just sales pitches. Robert Whitley posted a very comprehensive answer to this question, based on his experience building and testing dozens of AR-platform rifles. Robert runs AR-X Enterprises, which produces match-grade uppers for High Power competitors, tactical shooters, and varminters.

Building an Accurate AR — What is Most Important

by Robert Whitley

There are a lot of things that can be done to an AR to enhance consistent accuracy, and I use the words “consistent accuracy” because consistency is a part of it (i.e. plenty of guns will give a couple great 5-shot groups, but won’t do a very good 10- or 20-shot groups, and some guns will shoot great one day and not so good on others).

Here are 14 key things we think are important to accuracy.

1. Great Barrel: You’ll want a premium match-grade barrel, well-machined with a good crown and a match-type chambering, true to the bore and well cut. The extension threads must also be cut true to the bore, with everything true and in proper alignment.

2. Rigid Upper: A rigid, heavy-walled upper receiver aids accuracy. The typical AR upper receiver was made for a lightweight carry rifle and they stripped all the metal they could off it to make it light to carry (which is advantageous for the military). The net result are upper receivers that are so thin you can flex them with your bare hands. These flexible uppers are “strong enough” for general use, but they are not ideal for accuracy. Accuracy improves with a more rigid upper receiver.

Share the post "What Makes an AR Accurate — Whitley Offers Answers"

March 10th, 2015

How’d you like to run AR-15 Mags in your Rem 700 bolt gun? Sound far-fetched? Well think again. Pacific Tool and Gauge has developed a unique bottom metal system for Rem 700 short actions that works with standard AR-15 mags, providing reliable function with .223 Rem (5.56x45mm) rounds. The AR-mag compatible Rem 700 Bottom Metal costs $129.00 by itself, or $149.00 with a C-Products 10-round magazine. How’d you like to run AR-15 Mags in your Rem 700 bolt gun? Sound far-fetched? Well think again. Pacific Tool and Gauge has developed a unique bottom metal system for Rem 700 short actions that works with standard AR-15 mags, providing reliable function with .223 Rem (5.56x45mm) rounds. The AR-mag compatible Rem 700 Bottom Metal costs $129.00 by itself, or $149.00 with a C-Products 10-round magazine.

The system works with straight 5-round, 10-round, and 20-round metal mags as well as larger, angled 30-round metal mags. (Because they are thicker, Magpul mags and other polymer magazines do not work with this PT&G bottom metal system.)

At SHOT Show, Dave Kiff showed us the AR-Mag compatible bottom metal. “It took a lot of time to get the geometry just right, but we’re proud of this product”, Dave said. A PT&G exclusive, this special bottom metal as been designed to fit in all Remington 700 standard factory stocks right off the shelf with minimal inletting. This bottom metal features a handy mag release button incorporated into the side of the bottom metal (this is more reliable and secure than a mag release in the trigger guard).

Slight Modification Required During Installation

Customers purchasing this bottom metal will need to modify their Rem 700 actions very slightly, to create a little extra clearance. The Feed Bevel (left photo) needs to be opened to 0.660″, while the mag well needs to be opened to 0.900″.

Product tip from EdLongrange. We welcome reader submissions.

Share the post "Run AR Magazines in your Rem 700 Bolt Gun"

November 3rd, 2014

Many of our readers use AR-type rifles for Service Rifle matches, varmint hunting, 3-Gun competition, or defensive use. AR-platform rifles can be configured in a multitude of ways to suit the application. But if you plan to put together your own purpose-built AR rifle, how do you get started? Many of our readers use AR-type rifles for Service Rifle matches, varmint hunting, 3-Gun competition, or defensive use. AR-platform rifles can be configured in a multitude of ways to suit the application. But if you plan to put together your own purpose-built AR rifle, how do you get started?

For AR Do-It-Yourselfers, we suggest reading Glen Zedicker’s book, the Competitive AR15 Builders Guide. Following Zedicker’s New AR-15 Competitive Rifle (2008), the Builders Guide provides step-by-step instructions that will help non-professional, “home builders” assemble a competitive match or varmint rifle. This book isn’t for everyone — you need some basic gun assembly experience and an aptitude for tools. But the AR-15 Builders’ Guide provides a complete list of the tools you’ll need for the job, and Zedicker outlines all the procedures to build an AR-15 from start to finish.

Along with assembly methods, this book covers parts selection and preparation, not just hammers and pins. Creedmoor Sports explains: “Knowing how to get what you want, and be happy with the result, is truly the focus of this book. Doing it yourself gives you a huge advantage. The build will honestly have been done right, and you’ll know it! Little problems will have been fixed, function and performance enhancements will have been made, and the result is you’ll have a custom-grade rifle without paying custom-builder prices.”

The Competitive AR-15 Builders Guide is not available from most large book vendors. However, Amazon still has a few copies in stock. CLICK HERE to order.

Share the post "Building an AR? Check Out Zediker’s Book Before You Start"

August 25th, 2014

TECH TIP by Robert Whitley, AR-X Enterprises LLC

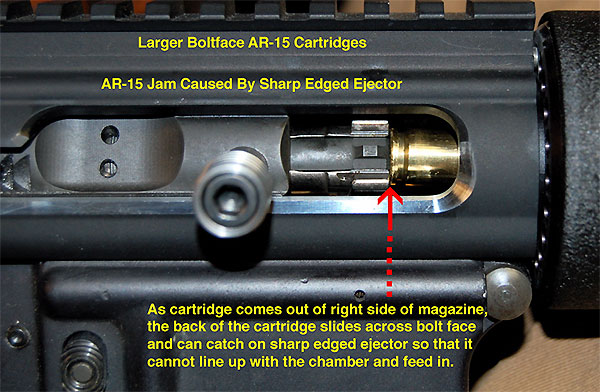

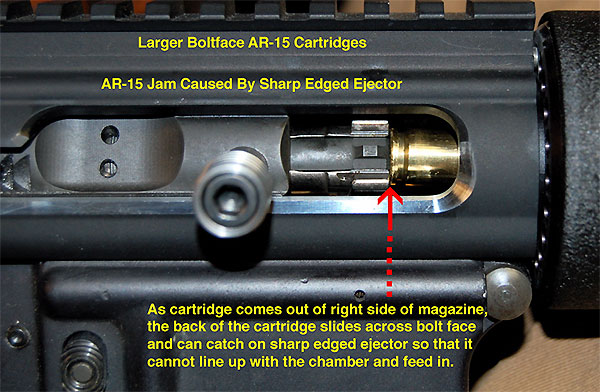

Over the years, while working with various AR-15 cartridges that require a larger bolt-face bolt (i.e. bigger than a 5.56 NATO/.223 Rem bolt-face, like those cartridges that use a 6.8 SPC bolt or the bolt face suitable for the 6.5 Grendel-based cartridges), I have found that there is an increased potential for a certain type of jam if a modification to the standard “Mil-Spec”, square-edged ejector is not made.

The original AR-15 square-edged ejector design was made for a much smaller-diameter bolt face and the smaller diameter 5.56 NATO/.223 Rem case, and it works perfectly in that application. However, as people have adapted the AR-15 platform to shoot bigger cartridges, some parts have been modified to accept the larger cartridges (i.e. bigger bolt-face bolts for the 6.8 SPC and the 6.5 Grendel, and different extractors), yet other parts have been all but ignored. One of these “ignored” parts has been the ejector. Most of the larger-bolt-face AR-15 bolts still use the standard “Mil-Spec”, square-edged 5.56 NATO/.223 Rem. ejector. That’s the problem. But there is a simple, reliable fix!

Chamfering AR Ejector for Improved Reliablity with 6mm, 6.5mm and 6.8mm Cartridges

With the larger bolt face and the larger-diameter AR cases, the old-style “Mil-Spec” ejector can cause infrequent but still annoying jams if the ejector is not modified. The jam can occur when a cartridge case feeds up and out of the right side of the magazine, and as it does so, the back of the case must slide across the bolt face and sideways over top of the ejector if it is to center up to the chamber and feed in. If the side of the case catches on the sharp-edged ejector you can get a jam. (See picture above).

Fortunately there is an easy fix for this. One way is to take the ejector out and spin it in a lathe or cordless drill and machine or grind it and round or chamfer the sharp edge. (See picture of rounded ejector next to square edged ejector).

Quick Fix Alternative — Bevel Your Ejector

Another “quick fix” is to leave the ejector in the bolt and chamfer the sharp edge with something like a Dremel tool. (See picture). This fix is easy to do and permanently resolves this potential feeding jam issue. There are no downsides to this modification if done right and I would recommend this modification for the ejectors in all larger bolt-face AR-15 bolts.

This gunsmithing tip provided by Robert Whitley of AR-X Enterprises LLC, 199 North Broad Street, Doylestown, PA 18901. Phone: (215) 348-8789. Website: 6mmAR.com.

Share the post "AR Ejector Mod For Improved Reliability with Larger Cartridges"

July 24th, 2014

Hate chasing brass ejected from your AR platform rifle? Well here’s a clever new accessory — a brass catcher that mounts easily to the Picatinny rail on top of your upper receiver. There are other types of brass-catching rigs on the market, but this is one of the best products we’ve seen for ARs with Picatinny rails. Caldwell’s AR Pic Rail Brass Catcher mounts easily with a quick-detach aluminum clamp. Both the clamp and wire frame are adjustable so they won’t interfere with your scope or scope mounts.

We like the quick-detach feature. This lets you quickly check and/or clear your chamber, or inspect the bolt. The bag itself, made from heat-resistant mesh fabric, will hold approximately one hundred .223 Rem cartridge cases. And here’s another nice feature — the bag has a zipper on the bottom so you can quickly dump your spent brass without having to remove the brass-catcher from your rifle.

|

Brass Catcher Features:

– Captures fired casings before they hit the ground.

– Quick-detach system mounts securely — no fumbling with straps.

– Compatible with most Picatinny rail-equipped AR-10s as well.

– Heat-resistant mesh bag holds 100 pieces of brass.

– Fully adjustable — can be placed at any point on Picatinny rail. |

|

If you shoot an AR and reload your own ammo, you should get some kind of brass-catching device. With a $39.19 “street price” ($49.99 MSRP), this is one of the more affordable options. Once you use a rig like this and no longer have to pick up brass from the ground, you may get spoiled. Moreover, a brass-catcher like this will earn you “Brownie Points” with other shooters at your range who no longer have to dodge your hot brass.

Product Tip from EdLongrange. We welcome reader submissions.

Share the post "New Caldwell Brass-Catcher Mounts on AR Picatinny Rails"

July 9th, 2014

Commentary by Robert Whitley

In recent years several major firearms component suppliers have promoted the idea of the “do-it-yourself” AR-15 build up. In one sense this is a good thing because it promotes peoples’ education and understanding of firearms, but the down side of this is some folks are assembling and modifying AR-15s without an understanding of the rifle and without the necessary skills and tools to do things properly. The net result of this “do-it-yourself” work can be an AR-15 that is non-functional, problematic or dangerous. Here are two examples of common issues with “do-it-yourself” modifications.

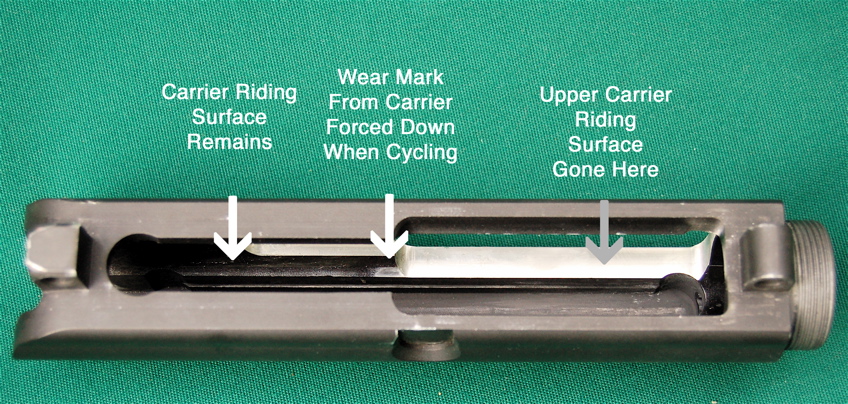

Opening Up the Ejection Port

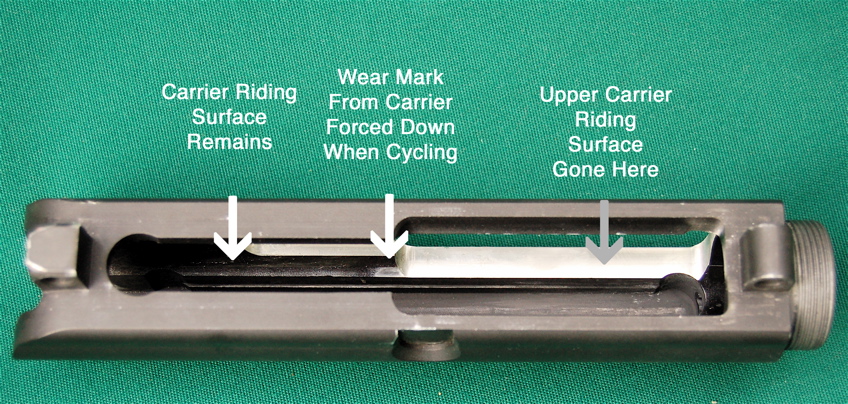

One common modification for AR-15’s is the opening up of the ejection port. This is typically done to permit more room for ejection or loading of the rifle, and it is also typically done in conjunction with a side charging handle modification.

A common issue I have seen with this modification is that the person opening up the port removes the upper right hand carrier support and riding surface. The net result of this is that the carrier sits loose in the upper receiver when the bolt is in lock-up and this can have very detrimental effects on the function and accuracy of the AR-15. Below are more pictures of one that I saw recently.

Click Arrows to See all FOUR Pictures

CaptionUpper Receiver Harmed by Modification  CaptionReceiver Showing Gas Key Hits Wrong Buffer Installed

Another common mistake is the use of an improper buffer with the rifle (i.e. like using a carbine buffer in a standard rifle length buffer tube). There are many after market buffers being sold out there, but if the wrong buffer is used with the rifle, it can allow the bolt carrier to cycle too far back so that the rear of the carrier gas key becomes the stop for the carrier (i.e. when it smashes into the upper part of the lower receiver – OUCH!).

We have even seen situations where the gas key is snapped right off the carrier from this, and it completely disables the rifle and can also cause extensive damage to the firearm as well. Unfortunately we have seen this situation far too often and it is clear that a person needs to fully understand how the buffer assembly works if “do-it-yourself” work is going to be done to the buffer assembly, since everything done to the buffer assembly has an effect on the rifle, its function and accuracy.

While I applaud the person who is self-reliant and has a “can do” attitude, the other side of this is when it comes to a firearm, “do-it-yourself” work should only be done when and if one fully understands the rifle and how it functions and how the work will affect the rifle.

Robert Whitley

AR-X Enterprises, LLC

199 North Broad Street

Doylestown, PA 18901

(215) 348-8789

www.6mmAR.com

Share the post "Problems with “Do-It-Yourself” AR-15s"

June 5th, 2014

Whidden Gunworks offers a nicely-engineered “bolt-on” front plate that will enhance the bench-rested accuracy of any rifle with an accessory rail on the forearm.

The Whidden Track Plate fits securely in the forearm accessory rail on prone, cross-the-course, and Palma rifles. These guns typically have a narrow and/or rounded fore-end so they rock and wobble when used with a front pedestal rest. The TrackPlate cures that. Once installed it provides a rock-solid, 2.9″-wide platform that mates perfectly with a benchrest-type front sandbag. This gives sling-shooters maximum stability when testing loads or zeroing their sights or scope. Plus you can now shoot F-Class competitively with a prone gun. The Whidden Track Plate fits securely in the forearm accessory rail on prone, cross-the-course, and Palma rifles. These guns typically have a narrow and/or rounded fore-end so they rock and wobble when used with a front pedestal rest. The TrackPlate cures that. Once installed it provides a rock-solid, 2.9″-wide platform that mates perfectly with a benchrest-type front sandbag. This gives sling-shooters maximum stability when testing loads or zeroing their sights or scope. Plus you can now shoot F-Class competitively with a prone gun.

The Track Plate is light-weight, has catamaran-style runners to aid tracking and prevent rocking, and can be easily stowed in a range bag. The machined aluminum Track Plate fits BOTH Anschutz-style and American-style recessed forearm rails.

The Track Plate is available from Whidden Gunworks for $40.99 or from Champion’s Choice for $40.00 (item W29P). Plate designer (and National LR Rifle Champion) John Whidden says: “The Plate is great for any rifle with a rail whether it ís smallbore, centerfire, or an air gun. Now you can try F-Class with your favorite prone rifle: the Plate has a perfect low-drag finish for riding a rest or sandbags and is competition legal in all dimensions.”

Front Bag-Rider for AR-15s from EGW

Similar to the Whidden Track Plate is a 3″-wide Delrin bag-rider from Evolution Gun Works (EGW). This was developed expressly to fit the fore-ends of AR15-type rifles with round float tubes. The EGW front bag-rider attaches to a front sling swivel stud anchor. That allows it to mount as easily as a Harris bipod — no rail needed! Just unscrew the swivel stud, put the front bag-rider in place and attach one hex-head machine screw. The front bag-rider is contoured to match the handguard profile so it fits securely with no wobble. Overall, it is a slick system. Front and rear bag-riders can be attached in a couple of minutes. The Delrin blocks slide easily in the bags and make the gun ultra-stable. The gun tracks straight back. The front bag-rider comes in two (2) variants, a $39.99 radiused version (item 32141) that attaches via swivel stud, and a $49.99 version (item 32143) that mounts via a Picatinny-style rail.

EGW AR Front Bag-Rider System

EGW Picatinny Rail-Attached Front Bag-Rider

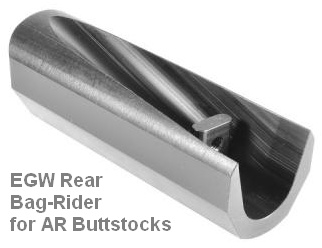

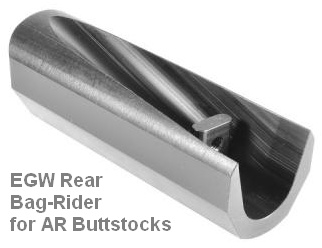

EGW Rear Bag-Rider for AR Buttstocks

EGW also offers a REAR bag-rider that attaches via the sling swivel anchor. The EGW AR Rear Bag-Rider accessory (item 32142), designed to work with A2-style buttstocks, sells separately for $39.99. This rear bag-rider provides a longer, straight “keel” that works very well in rear sandbags, giving the rifle more stability, and improving the tracking.

Share the post "Front Sleds Stabilize ARs and Rifles with Narrow Forearms"

May 14th, 2014

What happens when a round goes off unsafely in an AR? Watch this video and see. At about the 00:40 time-mark the shooter has a malfunction (click no bang), with a round. He then removes the magazine, and clears the chamber (we think). On the next round, at 00:53 you hear a “Bang” and see a big puff of smoke coming out of the upper receiver (see photo at right). This has been called a “detonation” by the video-maker, but we’re not 100% sure what happened. What do you guys think? Watch the video carefully, and state your conclusions in the comment section if you wish. What happens when a round goes off unsafely in an AR? Watch this video and see. At about the 00:40 time-mark the shooter has a malfunction (click no bang), with a round. He then removes the magazine, and clears the chamber (we think). On the next round, at 00:53 you hear a “Bang” and see a big puff of smoke coming out of the upper receiver (see photo at right). This has been called a “detonation” by the video-maker, but we’re not 100% sure what happened. What do you guys think? Watch the video carefully, and state your conclusions in the comment section if you wish.

What Caused this Malfunction? Watch Video…

In any event, the shooter is fortunate his upper did not completely fracture, launching shrapnel into his face or other body parts. This could have turned out much worse. Here are screen-shots from the video, showing details of the gun after the accident, along with the recovered brass case, which separated near the case-head.

Share the post "Ammo Failure (Detonation?) in 3-Gun Match — Watch and Wince"

May 3rd, 2014

AR this, AR that… sometimes it seems the gun world has gone AR crazy. There is even a book specifically dedicated to reloading for AR-platform rifles. This may seem superfluous when there are so many other reloading manuals on the market. However, there are some special factors to consider when reloading for ARs and other semi-automatic rifles. Cases should be full-length sized, with adequate shoulder bump and neck clearance (more than you might run with a bolt gun). Cartridge pressures must be appropriate for the AR platform, and you want to select powders that minimize fouling. Also, when loading for an AR you may want to experiment with cannelured bullets and crimping. And of course, rounds must be loaded to mag-length. Lastly, with the advent of the 300 AAC Blackout (and similar cartridges), many AR shooters now are experimenting with heavy 30-cal bullets in subsonic applications. AR owners will experience a “reloading learning curve” when moving from .223 Rem to the more exotic, subsonic 30-caliber cartridges. AR this, AR that… sometimes it seems the gun world has gone AR crazy. There is even a book specifically dedicated to reloading for AR-platform rifles. This may seem superfluous when there are so many other reloading manuals on the market. However, there are some special factors to consider when reloading for ARs and other semi-automatic rifles. Cases should be full-length sized, with adequate shoulder bump and neck clearance (more than you might run with a bolt gun). Cartridge pressures must be appropriate for the AR platform, and you want to select powders that minimize fouling. Also, when loading for an AR you may want to experiment with cannelured bullets and crimping. And of course, rounds must be loaded to mag-length. Lastly, with the advent of the 300 AAC Blackout (and similar cartridges), many AR shooters now are experimenting with heavy 30-cal bullets in subsonic applications. AR owners will experience a “reloading learning curve” when moving from .223 Rem to the more exotic, subsonic 30-caliber cartridges.

These and other concerns are covered in Lyman’s new AR Reloading Handbook. This comprehensive reloading guide provides the AR shooter with reloading data for nearly all popular AR-platform chamberings. In addition to data for the standard .223 Rem, the following cartridges are also covered: 6.8 Rem, 300 AAC Blackout, 7.62×39, 450 Bushmaster, 50 Beowulf and others.

Lyman touts its new book: “Reloaders will appreciate the wealth of AR-specific reloading data [for] all popular brands of bullets and powders. Specialty cast bullet and sub-sonic data further expand the usefulness of the handbook. Interesting articles by well known and popular firearms journalists are also included. These cover such areas as ‘Reloading for Suppressors’ and ‘Cartridge Interchangeability”. Finally all this AR data is presented in a full size, easy-to-use 8 1/2″ x 11″ format.”

Suppressed AR15 photo courtesy J&G Sales Ltd..

Book tip from EdLongrange. We welcome reader submissions.

Share the post "Lyman Releases New AR Reloading Handbook"

April 18th, 2014

Here’s a cool new optics mount at a very attractive price — just $87.95. Midsouth Shooter’s Supply is now featuring the Warne Skeletonized integrated scope mount for Picatinny Rails. This should work great on flat-top ARs. And for you fashionistas out there, the Warne mount is offered in four different colors: Matte Black, Dark Earth (tan), Ruby Red, and Bold Blue. Tactical shooters will probably pick black or tan sets, while image-conscious 3-Gun competitors might favor the Red or Blue versions. Here’s a cool new optics mount at a very attractive price — just $87.95. Midsouth Shooter’s Supply is now featuring the Warne Skeletonized integrated scope mount for Picatinny Rails. This should work great on flat-top ARs. And for you fashionistas out there, the Warne mount is offered in four different colors: Matte Black, Dark Earth (tan), Ruby Red, and Bold Blue. Tactical shooters will probably pick black or tan sets, while image-conscious 3-Gun competitors might favor the Red or Blue versions.

These Warne integrated ring/mount sets are offered for 1″, 30mm, and 34mm rings. The 1″ and 30mm versions come in all four (4) colors and cost $87.95. The 34mm is offered in Matte Black only for $115.00. You may want to order soon. These are popular. The most popular colors (black and dark earth) could sell out quickly at this price.

Share the post "Cool Integrated Optics Mount for under Ninety Bucks"

March 26th, 2014

Gun Digest will be producing a new quarterly print magazine, called Modern Shooter. It appears that the magazine focuses mostly on AR-platform rifles, AR accessories, and defensive shooting. The new magazine parallels the new Modern Shooter television show, which debuts on the Sportsman Channel next January. Look for Modern Shooter magazine on newsstands in April. The new magazine will also be available in digital format at www.gundigeststore.com. Gun Digest will be producing a new quarterly print magazine, called Modern Shooter. It appears that the magazine focuses mostly on AR-platform rifles, AR accessories, and defensive shooting. The new magazine parallels the new Modern Shooter television show, which debuts on the Sportsman Channel next January. Look for Modern Shooter magazine on newsstands in April. The new magazine will also be available in digital format at www.gundigeststore.com.

Each issue of Modern Shooter will focus on a popular firearms category. For example, the premier issue explains how to maintain an AR rifle, and how to “Defend Your Castle” with an AR. This first issue features Richard Mann’s 12 training drills for AR-platform rifles, plus reviews of AR accessories: optics, sights, rails, and adjustable stocks. The premiere edition of Modern Shooter profiles Colt manufacturing, discussing the history of the company. Colt’s new LE6920MP-USA and AR15A4 rifles will be reviewed.

Share the post "New Modern Shooter Print Magazine and TV Show"

February 26th, 2014

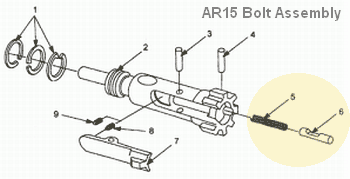

Accurate, modular, and supremely versatile, the AR15 is America’s favorite semi-auto rifle. But let’s face it, the AR is a maintenance hog. The AR’s gas tube blows carbon and soot right into the middle of the bolt assembly where it cakes on to the metal. The AR bolt also has many tiny parts, and small recesses, which must be cleaned regularly. This author has seen numerous ARs fail simply because there was gunk (dried lube, carbon, brass shavings) in the ejector slot or extractor spring recess.

A Clean AR is a Happy AR — Whether You Run ‘Wet’ or ‘Dry’ A Clean AR is a Happy AR — Whether You Run ‘Wet’ or ‘Dry’

There are various schools of thought when it comes to maintaining an AR. Some folks prefer to run their AR “dry” with minimal lube on the lugs and friction surfaces. Other shooters prefer to run their ARs “wet”, with lots of lube. But whatever your preference, you need to clean your AR regularly. And nothing is more important than the AR’s bolt/carrier assembly. Because it is involved in feeding, firing, and extracting, the AR-15 bolt/carrier assembly can be considered the most critical portion of the AR-15 from a maintenance standpoint.

Bolt Take-Down Guide on Top Quark Blog

The editor of the Top Quark Blog has created an excellent illustrated AR15 Bolt Take-Down Guide that shows how to disassemble an AR15 bolt and carrier for regular cleaning. Even if you’re an experienced AR15 shooter, you can learn something from this page (sample at right), and you may want to bookmark it for future reference. The photos are large and clear and there are helpful hints for each step of the process.

The author knows his stuff and offers some important insights. For example, he notes that “Extractor springs in most AR15 bolt assemblies are fairly weak, and this can lead to various extraction-related failures. One of the few high points about Colt assemblies is their usage of higher-strength extractor springs. You can tell the difference by looking at the inner plastic insert. ‘Normal’ springs feature a blue plastic insert, Colt strong springs have a black insert.”

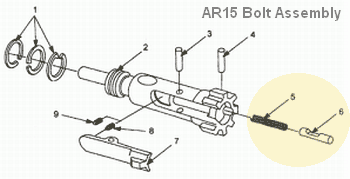

There is one notable oversight on this page — the author doesn’t cover disassembly and cleaning of the ejector assembly. This is actually quite important. A few small brass shavings, combined with carbon and lube in the ejector slot, WILL cause malfunctions. In fact, when this editor is called to diagnose problem ARs, the first things I look at (after swapping magazines) are the ejector recess and the slot for the extractor. Clogged ejectors are responsible for fail-to-ejects and other jams. It is essential that you keep the ejector hole clean. Old, gooey lube residues mixed with carbon and tiny brass shavings in the ejector recess will create all sorts of problems. As shown in the diagram below, it is simple to remove the ejector (#6) and ejector spring (#5), by drifting the ejector retaining pin (#4).

Share the post "TECH TIP: Take-Down Procedure for AR Bolt Assembly"

|

How’d you like to run AR-15 Mags in your Rem 700 bolt gun? Sound far-fetched? Well think again.

How’d you like to run AR-15 Mags in your Rem 700 bolt gun? Sound far-fetched? Well think again.

Many of our readers use AR-type rifles for Service Rifle matches, varmint hunting, 3-Gun competition, or defensive use. AR-platform rifles can be configured in a multitude of ways to suit the application. But if you plan to put together your own purpose-built AR rifle, how do you get started?

Many of our readers use AR-type rifles for Service Rifle matches, varmint hunting, 3-Gun competition, or defensive use. AR-platform rifles can be configured in a multitude of ways to suit the application. But if you plan to put together your own purpose-built AR rifle, how do you get started?

The Whidden

The Whidden

What happens when a round goes off unsafely in an AR? Watch this video and see. At about the 00:40 time-mark the shooter has a malfunction (click no bang), with a round. He then removes the magazine, and clears the chamber (we think). On the next round, at 00:53 you hear a “Bang” and see a big puff of smoke coming out of the upper receiver (see photo at right). This has been called a “detonation” by the video-maker, but we’re not 100% sure what happened. What do you guys think? Watch the video carefully, and state your conclusions in the comment section if you wish.

What happens when a round goes off unsafely in an AR? Watch this video and see. At about the 00:40 time-mark the shooter has a malfunction (click no bang), with a round. He then removes the magazine, and clears the chamber (we think). On the next round, at 00:53 you hear a “Bang” and see a big puff of smoke coming out of the upper receiver (see photo at right). This has been called a “detonation” by the video-maker, but we’re not 100% sure what happened. What do you guys think? Watch the video carefully, and state your conclusions in the comment section if you wish.

Here’s a cool new optics mount at a very attractive price — just $87.95.

Here’s a cool new optics mount at a very attractive price — just $87.95.