Primers and Pressure Analysis by James Calhoon

by James Calhoon

(First Printed in Varmint Hunter Magazine, October, 1995)

In the course of talking to many shooters, it has become clear to me that the manufacturers of primers have done a less than adequate job of educating reloaders on the application of their primers. Everybody seems to realize that some primers are “hotter” than others and some seem to shoot better for them than others, but few reloaders know that primers have different pressure tolerances.

Primer Pressure Tolerance

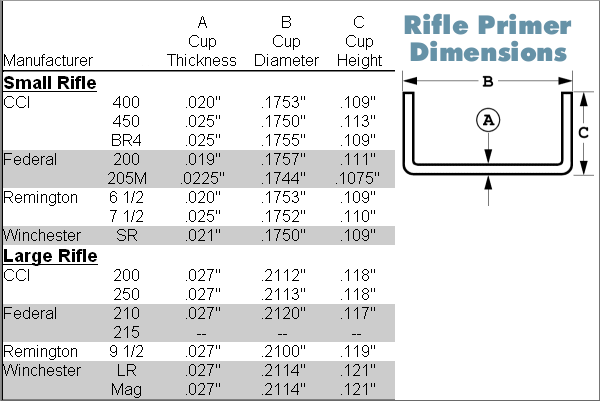

When loading a .223 to the maximum, I was getting primer piercing before I reached case overloading. I don’t know what prompted me to try CCI 450s instead of the 400s which I had been using, but I did. Presto! No more piercing! Interesting!? A primer that has a hotter ignition and yet withstands more pressure! Thats when I decided that it was time to do a dissection of all primers concerned. The chart below shows my results.

By studying the numbers (Cup “A” thickness), one can see which primers in the small rifle sections should be more resistant to primer cratering and/or piercing. Primer cup diameters are all similar and appear to follow a specification, but check out the cup thickness in the small rifle primers (Dimension “A”). Some cups are quite a bit thicker than others: .025″ for CCI 450 vs. .0019″ for Fed 200. Large rifle primers all appear to have the same cup thickness, no matter what the type. (As a note of interest, small pistol primers are .017″ thick and large pistol primers are .020″ thick.)

If you are shooting a 22 Cooper, Hornet, or a Bee, the .020″ cup will perform admirably. But try using the .020″ cup in a 17 Remington and you will pierce primers, even with moderate loads.

Considering that cup thickness varies in the small rifle primers, it is obvious that primer “flatness” cannot solely be used as a pressure indicator.

Another factor which determines the strength of a primer cup is the work-hardened state of the metal used to make the primer cup. Most primers are made with cartridge brass (70% copper, 30% zinc), which can vary from 46,000 psi, soft, to 76,000 psi tensile strength when fully hardened. Note that manufacturers specify the hardness of metal desired, so some cups are definitely “harder” that others.

What does all this mean to the reloader?

- Cases that utilize small rifle primers and operate at moderate pressures (40,000 psi) can use CCI 400, Federal 200, Rem 6 1/2, or Win SR. Such cases include 22 CCM, 22 Hornet and the 218 Bee. Other cases that use the small rifle primer can use the above primers only if moderate loads are used. Keep to the lower end of reloading recommendations.– Cases that utilize small rifle primers and operate at higher pressures (55,000 psi) should use CCI 450, CCI BR4, Fed 205 and Rem 7 1/2.

– All the large rifle primers measured have the same thickness. Therefore choose based on other factors, such as accuracy, low ES/SD, cost, cup hardness, and uniformity.

Hope this clears up some primer confusion. If you want more information about primers, priming compounds, or even how to make primers, the NRA sells an excellent book called “Ammunition Making” by George Frost. This book tells it like it is in the ammo making industry.