How Plastic Shotshells Are Made

Ever wonder how shotshells are manufactured? Here’s a step-by-step trip through the shotshell production process, courtesy Federal Premium. Hulls are created from plastic pellets, of various colors, depending on shotshell type and gauge. Starting with pellets, here’s how shotshells are made:

Step 1: Plastic pellets are melted down into a plastic tube.

Step 2: In the extruding process the tube is heated, stretched, and cooled to form the hull. The machine that does this is called the “Riefenhauser” after the German engineer who built the first model.

Step 3: Hulls are cut to length as they come off the Riefenhauser. They then move along to the next stage in the process.

Step 4: The case head is stamped out of sheets of metal (brass or steel depending on shell type). A series of strikes of the stamp produces a fully-formed case head with flash-hole.

Step 5: The hulls move to the primer insert and heading machine to get primers and case heads.

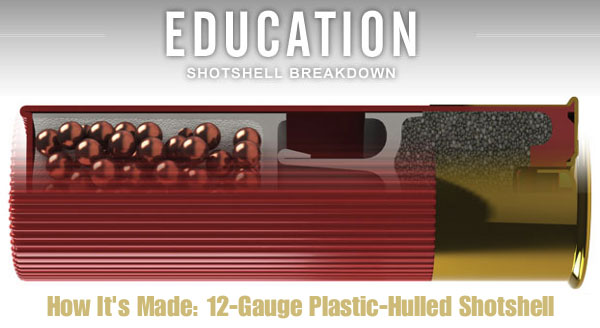

Step 6: Still untouched by human hands, the shell moves on to the loader where it gets its powder charge, shot wad, and pellets.

Step 7: The hulls are then crimped, labeled, and readied for inspection and packing.

Similar Posts:

- How to Hydro-Form Cartridge Brass — Dasher Video

- TECH Tip: Video Shows How to Hydro-Form Cartridge Brass

- Video Shows How to Hydro-Form 6 Dasher Cases

- How to Hydro-Form Cartridge Brass — Save Money and Barrel Life

- Hydro-Form 6mm Dasher Brass — Save Money & Barrel Life

Tags: Factory, Federal Premium, Hull, shotshell, Wad