What Are the Best Bedding Materials? Speedy Speaks

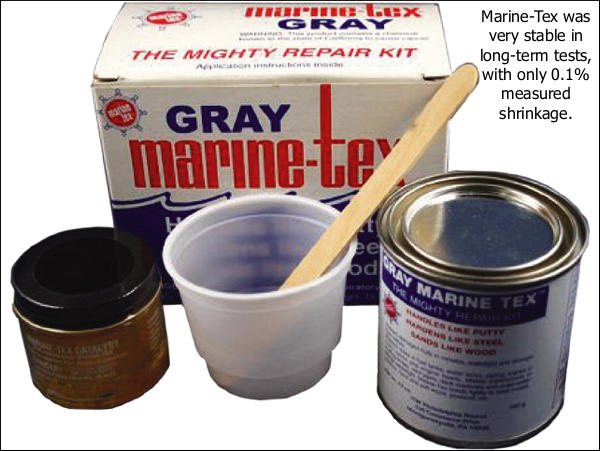

A customer of well-known gunsmith (and Hall-of-Fame shooter) Thomas “Speedy” Gonzalez recently asked Speedy about bedding compounds. Speedy offered some interesting advice based on long-term testing of various materials. Speedy favors Marine-Tex because it is very stable over time, while other materials can shrink up to 6% dimensionally. A good bedding job should be a perfect fit to your barreled action. If the bedding material shrinks over time, that is NOT a good thing….

Speedy’s customer asked: “I know you’re not a Devcon man in regards to bedding compounds but I respect your input in such matters and my question is this in regard to aluminum actions. If Devcon was considered, for an aluminum action, would you prefer aluminum compound formula or steel formula? I personally prefer Devcon steel and Marine-Tex for steel receivers but my experience with aluminum is limited. Also do you have a release agent preference that works better with aluminum?”

Speedy answered: “My only preference of one epoxy over another is their stability over time. My buddy who works for the Texas State Weights and Measures Department had me cast several of the most common types of epoxies used for bedding into 1.000″ machined blocks. After one year of being kept in a controlled climate and measured for shrinkage monthly, the Marine Tex shrunk only 1/10th of 1% (i.e. 0.1%) whereas almost all the others (including Devcon Steel formula, Devcon Aluminum formula…) shrunk 3% to 6%. The only other compounds that matched the Marine Tex were Araldite 1253 and Araldite 2014, with the latter being quite expensive for daily use.”

Speedy added: “The Marine Tex Grey has no atomized metal in its makeup even though it appears that it does. This can be proven by the use of a strong neodymium magnet. What is humorous to me is that people don’t like aluminum yet will bed their actions atop aluminum pillars that have twice the coefficient of expansion (COE) of steel. Like Devcon, it is what people have always done and used. Thus [they] perpetuate the same old stuff. That’s my two cents’ worth. But as I tell everyone, ‘I’ll tell you what I know or do, but it’s not my job to convince anyone to do it my way’.”

Release Agents — Try Shoe Polish

Regarding release agents, Speedy stated: “I use Kiwi Neutral or Tan shoe polish. This works great and you can find it anywhere. Do NOT use the black or brown as it will stick.”

View More Photos of Speedy Inletting and Bedding Job

CLICK HERE to see an interesting bedding job done by Speedy using a custom titanium bedding block. Speedy notes, “The stock was a raw blank requiring full inletting for the action to fit properly plus the titanium block. All the loading ports, bolt handle cut, bolt stop, and trigger guard cuts were done with diamond tooling to eliminate fraying and/or delamination of the wood.” You’ll find more projects by Speedy on his Facebook Page. Speedy is in San Antonio, Texas now, and accepting new projects with his company S.G. Rifles LLC.

Similar Posts:

- Bed It Right! Bedding Compounds Compared by Speedy

- Bedding Compounds Recommend by Speedy

- X-Treme Shooting Products Unveils New Titanium Actions

- H-S Precision Stocks on Sale — $259.99

- BAT Machine’s New Superlight Vampire & Bumblebee Actions

Tags: Bedding Block, Custom Rifles, Devcon, Inletting, Marine-Tex, SG Precision Rifles, Shrinkage, Speedy Gonzalez, Stock

Going to give the Kiwi Neutral or Tan shoe polish a try.

MARINE-TEX MIXING RATIO:

BY VOLUME: 5 parts epoxy resin to 1 part hardener – by volume.

BY WEIGHT: (When mixing by weight, the ratio is 6.3 parts resin to 1 part hardener.)

NOTE: Always keep the epoxy at room temperature before mixing.

I realize that shrinkage is bad ( it shrinks?) , but I am wondering about the number of bedding failures that occur with devcon?

I’m glad to see information like ths published- every little bit helps. Still, if seems at best an assumption that whatever happens to compounds curing by exothermic reaction would reproduce between a 1″ thick section stored under climate comtrol and the thinner sections typical of rifle bedding.

Also, a lack of magnetic attraction does not mean the absence of metal – only of magnetic metal. [Editor — that is absolutely correct. But we wanted to run Speedy’s comment as he wrote it.]

Finally, if a typical bedding section – say .03″ thick – shrinks by 3%, that translates to .00009″. Is this significant? How does it compare to the movement in the wooden stock shown in the article? An action of 416 S’stl, and 1.35″ diameter will expand .0004″ in diameter under a 50 deg F temperature change. If there are 6″ between guard screws, that will grow by .0016″. If the action body is 7075 aluminum, those numbers become .0009″ and .004″. All of this makes the change in bedding smaller by about an order of magnitude.

Editor: Many good points made above. But it’s not just surface thickness to think about. Think of the bedding like a ruler… thin but long. If 12″ of bedding shrinks lengthwise 3%, that’s 0.36 inches. (This begs the question of whether the bedding can shrink uniformly in length given the fact that it is anchored with pockets etc.) Also Josh makes some great points about the action itself expanding! Definitely something to consider there….

If it ain’t broke d on’t fix it.