Berger Southwest Nationals 2018 — Registration Opens

Registration has opened for the 2018 Berger Southwest Nationals at the Ben Avery Range in Phoenix, Arizona. This is a GREAT match, the best in the West by far. The match runs February 5-11, 2018. By all means, attend if you can. The Grand Agg filled up last year, so we recommend you register soon.

Berger’s SWN team reports: “Registrations for the 2018 Southwest Nationals open on Sunday, August 27th, at 6:00 am (PST). CLICK HERE for the Match Program (it is also available on the Desert Sharpshooters website and Berger Bullets website). We are also moving to an online registration this year, and entry fees will be paid online. Please note that due to our capacity limitations, each stage of the match is listed as a separate event. Please be sure to enter each of the stages you plan to participate in. This will allow us to include as many people as possible. If you have any questions, send email to michelle.gallagher [at] bergerbullets.com.”

2018 SWN Match Program PDF | 2018 SWN Online Registration

Rekindle Old Friendships and Meet New Friends

Some shooters come to to the SW Nationals for the swag (the prize table is amazing). Others come for the sunshine (think warm 75-85° weather). And even more folks come to try out their shiny new toys and to test their skills against the nation’s best shooters.

But we’d say the number one reason most folks make the pilgrimage to Ben Avery every year is the camaraderie — the chance to connect with friends, rekindling connections that may go back decades. Fundamentally, then, the Berger SWN is about the people. For many of us, this is the only time of the year when we get a chance to meet fellow shooters from distant corners of the USA (and other nations).

Compete Against the Best

If you want to test your mettle against some of the best shooters in the world, get yourself to Ben Avery in February. Here you can compete, shoulder to shoulder, against the best Sling and F-Class shooters on the planet. Guys like Derek Rodgers (newly-crowned F-TR World Champion), John Whidden (reigning Long Range National Champion), Nancy Tompkins (the first women to win the National High Power Championship), and Kenny Adams (past World F-Open Class Champion). If you want to play in the Big Leagues, Ben Avery is the place. Having said that, novice shooters will enjoy the experience as well, because you’ll find that these top shooters are (almost universally) happy to share their knowledge.

Just to whet your appetite, here are videos from recent Berger SW Nationals. Yes, this match is as much fun as it looks!

Berger SW Nationals 2017

The North-by-Southwest team set new National Records in winning the 2017 F-TR team event.

Berger SW Nationals 2016

Berger SW Nationals 2015

The Brain Trust — Experts Galore

The best minds of the shooting world come to Ben Avery every year. Got a question about ballistics? Well, Ballistics Guru Bryan Litz (photo below) will be happy to answer your questions between relays. Want some expert advice about wind reading? Seek out Mid Tompkins (usually found hanging around the club-house) or Emil Praslick, one of the most knowledgeable wind coaches on the planet. And if you have a gunsmithing question, you’ll find some of the top barrel-fitters and stock makers, including Doan Trevor and Gary Eliseo.

In our

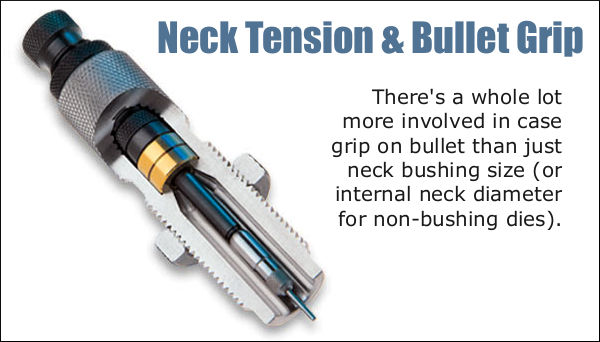

In our  Neck-Wall Thickness is Important Too

Neck-Wall Thickness is Important Too