Heat Build-Up and Firing Rate Can Kill a Barrel Prematurely

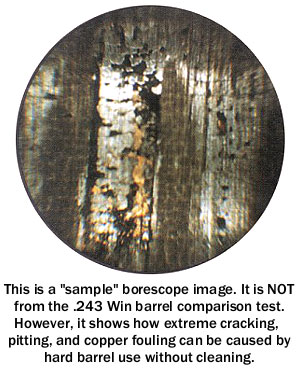

Can sustained rapid-fire shooting with no cool-down period wear out a quality barrel more quickly? The answer is “Yes” according to Forum member LCazador, who did an interesting comparison test with two .243 Winchester barrels. He started off with two, identical, match-grade HV taper stainless barrels. Both were NEW at the start of testing, and LCazador shot the same load through each: 95gr match bullets with 38 grains of Hodgdon Varget. After giving both barrels the same, gentle 20-round break-in, 300 rounds were then fired through each barrel — in very different ways. Barrel condition and wear were monitored with a borescope.

Barrel One — Slow Fire, Cool Down Periods, Cleaning Every 50 Rounds

At the end of the 300-round test, Barrel One looked brand new. There was none of the severe fire cracking found in Barrel Two. This barrel was shot no more than 10 times without a cool down and firing was done at a much slower pace. Cleaning for this barrel was done every 50 shots.

Barrel Two — Fast Firing, No Waiting, Cleaning Every 100 Rounds

The second barrel, which received hard use and minimal cleaning, was severely damaged with severe fire cracking at the leade and throat. As a result, the barrel had to be re-chambered. This barrel was shot 100 rounds at time without cleaning and was shot up to 20 times in succession without a cool down.

LESSON LEARNED — Heat Kills Barrel Life

Don’t let your barrel get too hot, and keep it clean. One afternoon can ruin a barrel!

Monitoring Barrel Wear with Borescope

Monitoring Barrel Wear with Borescope

Some folks worry too much about what their borescopes reveal — many barrels do not have to be “squeaky clean” to perform well. In fact some barrels run better after ten or more fouling shots. However, a borescope can be very helpful when your barrel starts losing accuracy for no apparent reason. Forum member FdShuster writes:

“A borescope is a positive way of backing up your suspicions when the rifle starts to throw an occasional (soon followed by more frequent) wild shot. Using the scope is also an excellent way to determine that the cause is barrel wear and not simply a need for a concentrated cleaning session to remove built up copper and more importantly, carbon fouling.

I’ve had a few barrels that gave every indication of being shot out. But I ‘scoped them out and found the cause to be nothing more than requiring a good cleaning. They then returned to their usual performance. There’s no guessing involved when you are able to get ‘up close and personal’ using the scope. The borescope also provides an excellent view of the all-important condition of the crown. My borescope is one of the most valuable investments I’ve ever made.”

Similar Posts:

- How to Kill a Barrel in One Afternoon — Firing Rate and Heat

- Firing Rate and Heat — How to Kill a Barrel in One Afternoon

- How to Prematurely Kill a Barrel — .243 Win Fast Firing Test

- How to Wear Out a Barrel in One Afternoon…

- Ultimate Reloader Reviews Hawkeye Borescope Systems

Tags: Borescope, Fast Firing, Heat, Rate of Fire

Interesting that the second barrel was exposed to what happens during NRA Long Range competitions. Generally we shoot 20 shot (plus sighters) strings with roughly 8-15 seconds between shots for 80+ rounds a day. Then come back and do it again the next day. And then the next week, etc.. Our barrels are not toast and my .308 Palma barrels last 2500-3000 rounds before being replaced.

Editor: The Rate of Fire for the ruined barrel was mush faster than that, the barrel got much hotter, and the firing didn’t halt after 20 rounds.

and then there’s PRS shooters who shoot 10-15 rounds strings 8-12 times a day, on back to back days. and maybe clean every 500 rounds. some guys go 1200 rounds from their BR based cartridges without a single cleaning

This isn’t wildly surprising.

It’s true that most NRA highpower shooters fire lots of rounds in a short time. Most of us are firing more mild cartridges that don’t cause rapid barrel death, unlike the .243.

Most of the .243 shooters I know don’t get very long life out of their barrels under the best of circumstances.

Unfortunately this test does not help very much, there are too many unknowns.

What was the rate of fire for barrel 1 compared to the rate of fire for barrel 2?

What was the maximum temperature reached when measured on the outside on the same place for both barrels?

Was the erosion due to the heat or the lack of cleaning?

Everything in life is relative . Including “F” class strings at different ranges and areas of the country . Shoot two or three strings , and sighters at Ben Avery in July or August , and do this every Thursday , and a 3 x 60 match on Saturday and I will almost guarantee you’ll have a bit more barrel wear / erosion than someone doing the same in Ohio or Wyoming . Climate has to be a included factor in barrel wear . I’ve got 3,500 on my .308 Brux , but I’m now monitoring it closely . And I don’t shoot a powder-puff load .