Super Shoot 49 Takes Place Next Month in St. Louis, Missouri

After being held at the Kelbly’s Range in Ohio for decades, the Super Shoot benchrest competition will be held May 22-25, 2023 at the Bench Rest Rifle Club in Missouri. This is a great location, much favored by elite benchrest shooters. This excellent range was the host of the 2022 NBRSA Nationals (photo above).

This will be Super Shoot 49. Historically, the Super Shoot has been the largest 100/200-yard Benchrest score match in the world, drawing over 200 competitors. For the last 40+ years, the Super Shoot has been held at the Kelbly’s Range in Ohio. This year the Super Shoot will be held at one of the premier benchrest shooting facilities in the USA, the Bench Rest Rifle Club of St. Louis situated in Wright City, just northwest of St. Louis. This event will feature the best short-range benchrest shooters in the world. Competition will be fierce, with top places often decided by the tiniest margins in Agg measurements.

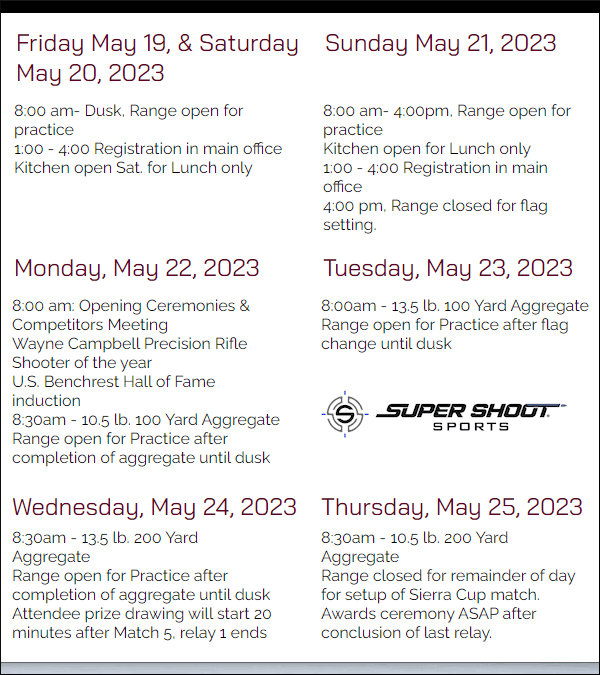

To shoot in the big match, it’s best to first register as a member of the SuperShootSports.com website. Membership is free. By becoming a member you will have access to online registration for the 49th Super Shoot and other features. There is no charge to join as a site member but there ARE fees to compete in the actual 2023 Super Shoot. In-person check-in and registration begins on Friday, May 19th. The range will be open for practice Friday through Sunday, May 19-21, closing at 4:00 pm on Sunday. Competition starts on Monday, May 22, 2023. Here is the full schedule:

For more information or to register as a competitor, visit SuperShootSports.com. You can also email info@supershootsports.com or call 972-875-5318.

The Bench Rest Rifle Club of St. Louis hosted the 2015 World Benchrest Championships:

The St. Louis shooting range facility is excellent. Forum member Alex M. posted: “The St. Louis Bench Rest Rifle Club is the finest shooting facility I have seen. The various rifle, pistol, shotgun, and archery ranges are great. They have a nice official trap field, together with manually operated traps. I shoot pistol and rifle with my wife at 25 to 600 yards. They have a very nice dedicated rimfire range, and training bays. I shoot their monthly F-Class matches (600 yards) where they award medals (1st, 2nd, 3rd) for F-Open, F-T/R and F-Bench. They also host the very popular Sierra Cup Challenge.”

Map to Bench Rest Rifle Club Range in Wright City, Missouri.

Major Sponsors for Super Shoot 49

Super Shoot 49 has many sponsors including Bruno Shooters Supply, Creedmoor Sports, Lilja Barrels, PMA Tool and a dozen other companies. Creedmoor Sports has explained the importance of the Super Shoot:

“We’re excited to sponsor the Super Shoot and give back to the Bench Rest community. The firearms and reloading innovation that has come out of this discipline has benefited every single shooting sport. Bench Rest Rifle Club of St. Louis is a great facility that is capable of hosting very large matches. I know that Wade Hull and the members at BRRC will do an exceptional job hosting the match.” — John Teachey, VP Operations/Marketing for Creedmoor Sports.