|

|

March 9th, 2021

When your cases become hard to extract, or you feel a stiff bolt lift when removing a cartridge, it’s probably time to full-length size your cases, and “bump” the shoulder back. Short-range benchrest shooters, running high pressures, typically full-length size every load cycle, bumping the shoulder .001-.002″. The vast majority of mid-range and long-range F-Class shooters also full-length size every time. High Power shooters with gas guns should definitely full-length size every time, and may need to bump the shoulders .003″ or more to ensure reliable feeding and extraction.

Use Shims for Precise Control of Shoulder Bump

Some shooters like to set the “default” position for their full-length die to have an “ample” .003″ or .004″ shoulder bump. When they need less bump, a simple way to reduce the amount of shoulder movement is to use precision shims in .001″ (one-thousandth) increments. Brownells offers a set of seven (7) shims for your standard 7/8-14 FL sizing dies for $14.99. These Sinclair Int’l shims are Brownells Item 749-001-325WB. They may be out of stock, but they can be back-ordered.

Sinclair explains: “Each shim is notched for easy size identification. Just set your die using one of the middle thickness shims. Adjustments can be made easily by changing shims to increase or decrease die depth without changing the stem setting. This is a great upgrade for non-micrometer adjustable dies.”

Here are reports from Forum members who use the shims:

“Great product. I have my die lock ring(s) adjusted for the shortest headspace length on my multiple 6BRs and 6PPCs. When needing a longer headspace, I just refer to my notes and add the appropriate shim under the lock ring. Keep it simple.” — F.D. Shuster

Mats Johansson writes: “I’ve been using [shims] since Skip Otto (of BR fame) came out with them. I set up my dies with the .006″ shim, giving me the option of bumping the shoulder a bit more when the brass gets old and hardens while still having room to adjust up for zero headspace, should I have missed the original setup by a thou or two. Hunting rounds can easily be bumped an extra .002-.003″ for positive, no-crush feeding. Being a safety-oriented cheapskate, I couldn’t live without them — they let me reload my cases a gazillion times without dangerous web-stretching. Shims are a must-have, as simple as that.” — Mats Johansson

Brownells offers the seven-piece set of Sizing Die Shims that let you adjust the height of your die (and thereby the amount of bump and sizing) in precise .001″ increments. Sinclair explains: “Some handloaders will set their die up to achieve maximum sizing and then progressively use Sinclair Die Shims between the lock ring and the press head to move the die away from the shellholder. Doing this allows you to leave the lock ring in the same position. These shims are usually available in increments of .001″ and work very well.” Brownells offers the seven-piece set of Sizing Die Shims that let you adjust the height of your die (and thereby the amount of bump and sizing) in precise .001″ increments. Sinclair explains: “Some handloaders will set their die up to achieve maximum sizing and then progressively use Sinclair Die Shims between the lock ring and the press head to move the die away from the shellholder. Doing this allows you to leave the lock ring in the same position. These shims are usually available in increments of .001″ and work very well.”

Seven Shims from .003″ to .010″

For use with 7/8-14 threaded dies, Sinclair’s $14.99 Die Shim Kit (Sinclair item 22400 or Brownells Code 749-001-325WB) includes seven shims in thicknesses of .003, .004, .005, .006, .007, .008, and .010. For ease of use, shim thickness is indicated by the number of notches cut in the outer edge of each shim. Even without looking you can “count” the notches by feel.

NOTE: These shim sets can also be use to adjust bullet seating depth for seating dies that lack micrometer adjustment. Use the same 7/8-14 shims with your non-micrometer seating dies.

Share the post "Handy Shim Sets for Sizing Dies — Quickly Adjust Shoulder Bump"

August 29th, 2020

When your cases become hard to extract, or you feel a stiff bolt lift when removing a cartridge, it’s probably time to full-length size your cases, and “bump” the shoulder back. Short-range benchrest shooters, running high pressures, typically full-length size every load cycle, bumping the shoulder .001-.002″. The vast majority of mid-range and long-range F-Class shooters also full-length size every time. High Power shooters with gas guns should definitely full-length size every time, and may need to bump the shoulders .003″ or more to ensure reliable feeding and extraction.

Use Shims for Precise Control of Shoulder Bump

Some shooters like to set the “default” position for their full-length die to have an “ample” .003″ or .004″ shoulder bump. When they need less bump, a simple way to reduce the amount of shoulder movement is to use precision shims in .001″ (one-thousandth) increments. Sinclair Int’l offers a set of seven (7) shims for your standard 7/8-14 FL sizing dies for $14.99.

Sinclair explains: “Each shim is notched for easy size identification. Just set your die using one of the middle thickness shims. Adjustments can be made easily by changing shims to increase or decrease die depth without changing the stem setting. This is a great upgrade for non-micrometer adjustable dies.”

Here are reports from Forum members who use the shims:

“Great product. I have my die lock ring(s) adjusted for the shortest headspace length on my multiple chambers 6BRs and 6PPCs. When needing a longer headspace, I just refer to my notes and add the appropriate shim under the lock ring. Keep it simple.” — F.D. Shuster

Mats Johansson writes: “I’ve been using [shims] since Skip Otto (of BR fame) came out with them. I set up my dies with the .006″ shim, giving me the option of bumping the shoulder a bit more when the brass gets old and hardens while still having room to adjust up for zero headspace, should I have missed the original setup by a thou or two. Hunting rounds can easily be bumped an extra .002-.003″ for positive, no-crush feeding. Being a safety-oriented cheapskate, I couldn’t live without them — they let me reload my cases a gazillion times without dangerous web-stretching. Shims are a must-have, as simple as that.” — Mats Johansson

Brownells offers the seven-piece set of Sizing Die Shims that let you adjust the height of your die (and thereby the amount of bump and sizing) in precise .001″ increments. Sinclair explains: “Some handloaders will set their die up to achieve maximum sizing and then progressively use Sinclair Die Shims between the lock ring and the press head to move the die away from the shellholder. Doing this allows you to leave the lock ring in the same position. These shims are usually available in increments of .001″ and work very well.” Brownells offers the seven-piece set of Sizing Die Shims that let you adjust the height of your die (and thereby the amount of bump and sizing) in precise .001″ increments. Sinclair explains: “Some handloaders will set their die up to achieve maximum sizing and then progressively use Sinclair Die Shims between the lock ring and the press head to move the die away from the shellholder. Doing this allows you to leave the lock ring in the same position. These shims are usually available in increments of .001″ and work very well.”

Seven Shims from .003″ to .010″

For use with 7/8-14 threaded dies, Sinclair’s $14.99 Die Shim Kit (Sinclair item 22400 or Brownells Code 749-001-325WB) includes seven shims in thicknesses of .003, .004, .005, .006, .007, .008, and .010. For ease of use, shim thickness is indicated by the number of notches cut in the outer edge of each shim. Even without looking you can “count” the notches by feel.

NOTE: These shim sets can also be use to adjust bullet seating depth for dies that lack micrometer adjustment. Use the same 7/8-14 shims with your non-micrometer seating dies.

Shims for Arbor Dies Shims for Arbor Dies

Do you seat with an Arbor Press? No problem…

Brownells offers a $14.99 10-shim Arbor Die set for use with L.E. Wilson seating dies employed with arbor presses. Frankly we prefer micrometer-top Wilson dies, but if you have the standard Arbor dies, these shims come in handy. Order either Brownells Code 749-001-370WB (.22 to .243 caliber) or Brownells Code 749-001-326WB (.25 to .30 caliber).

Share the post "Smart Reloader — Die Shims For Full-Length Sizing Dies"

August 22nd, 2020

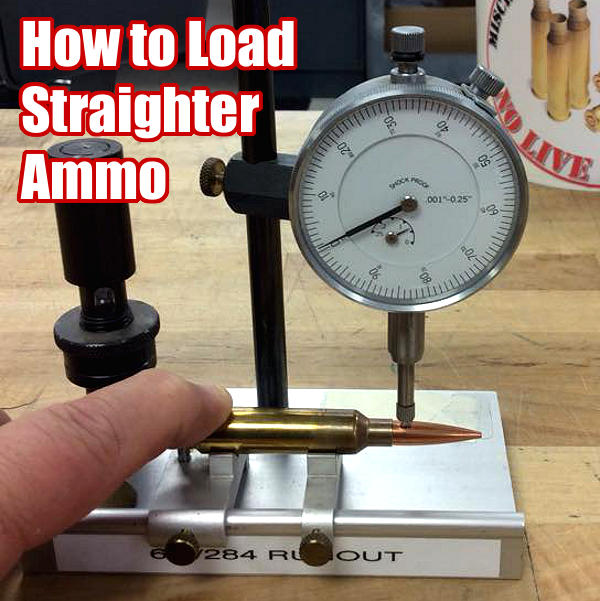

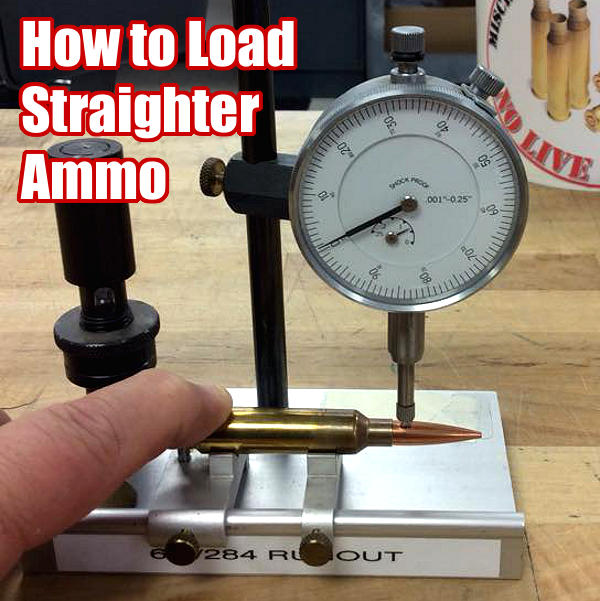

Each Wednesday, the U.S. Army Marksmanship Unit publishes a reloading “how-to” article on the USAMU Facebook page. A while back the USAMU’s reloading gurus looked at the subject of cartridge run-out and what can be done to produce straighter ammo. Tasked with producing thousands of rounds of ammo for team members, the USAMU’s reloading staff has developed smart methods for improving concentricity, even with budget=price dies. For other hand-loading tips, visit the USAMU Facebook page.

Minimizing Runout with Standard Seating Dies

This USAMU article explains how to set up standard bullet seating dies dies to minimize Total Indicated Run-out (TIR). The loading process is described using a single-stage press since most handloaders have one. A high-quality run-out gauge is essential for obtaining consistent, accurate results.

Having sized, primed, and charged our brass, the next step is bullet seating. Many approaches are possible; one that works well follows. When setting up a standard seating die, insert a sized, trimmed case into the shellholder and fully raise the press ram. Next, back the seating stem out and screw the die down until the internal crimping shoulder touches the case mouth.

Back the die out ¼ turn from this setting to prevent cartridge crimping. Next, lower the press ram and remove the case. Place a piece of flat steel (or window glass, which is quite flat) on the shellholder and carefully raise the ram.

Place tension on the die bottom with the flat steel on the shellholder. This helps center the die in the press threads. Check this by gently moving the die until it is well-centered. Keeping light tension on the die via the press ram, secure the die lock ring. If one were using a match style, micrometer-type seating die, the next step would be simple: run a charged case with bullet on top into the die and screw the seating stem down to obtain correct cartridge OAL.

However, with standard dies, an additional step can be helpful. When the die has a loosely-threaded seating stem, set the correct seating depth but don’t tighten the stem’s lock nut. Leave a loaded cartridge fully raised into the die to center the seating stem in the die. Then, secure the stem’s lock nut. Next, load sample cartridges and check them to verify good concentricity.

One can also experiment with variations such as letting the seating stem float slightly in the die to self-center, while keeping correct OAL. The run-out gauge will show any effects of changes upon concentricity. However, this method has produced excellent, practical results as evidenced by the experiment cited previously. These results (TIR Study 2) will reproduced below for the reader’s convenience.

First, however, let’s examine run-out figures of some factory-loaded match ammunition. This should give readers who are new to TIR gauges some perspective about the TIR ranges one might encounter.

TIR Study 1: 50 rounds Lake City M852 Match 7.62mm

(168 gr. Sierra MatchKings)

0.000” – 0.001” = 2%

0.001” – 0.002” = 30%

0.002” – 0.003” = 16%

0.003” – 0.004” = 22%

0.004” – 0.005” = 14%

0.005” – 0.006” = 14%

0.006” – 0.007” = 0%

0.007” – 0.008” = 2%

TIR Study 2: 50 rounds of .308 match ammo loaded using carefully-adjusted standard dies, vs. 50 using expensive “Match” dies from the same maker.

Standard dies, TIR:

0.000” — 0.001” = 52%;

0.001”– 0.002” = 40%;

0.002”– 0.003” = 8%.

None greater than 0.003”.

Lesser-quality “Match” dies, TIR:

0.000”– 0.001” = 46%;

0.001” — 0.002” = 30%;

0.002” — 0.003” = 20%;

0.003” — 0.004” = 4%.

Note: both samples were loaded using the O-Ring method, i.e. with a rubber O-Ring placed under the locking ring of the Full-length sizing die to allow that die to float.

These tips are intended to help shooters obtain the best results from inexpensive, standard loading dies. Especially when using cases previously fired in a concentric chamber, as was done above, top-quality match dies and brass can easily yield ammo with virtually *no* runout, given careful handloading.

Share the post "TECH Tip: How to Reduce Run-Out with Seating Dies"

August 9th, 2020

.009” Group Record Stood for 40 Years .009” Group Record Stood for 40 Years

In 1973 Mac McMillan shot an amazing 100-yard, .009″ five-shot group in a benchrest match. The .009″ group was measured with a 60x microscope for verification. Mac McMillan shot the group using a handbuilt prototype McMillan rifle with an early McMillan stock.

Mac’s .009″ group was the “Holy Grail” of rifle accuracy. This .009″ record was considered by many to be unbreakable, a record that would “stand for all time”. Well, it took 40 years, but someone finally broke Mac’s record with an even smaller group. In 2013, Mike Stinnett shot a .0077″ five-shot group using a 30 Stewart, a .30 caliber wildcat based on the 6.5 Grendel. Stinnett’s NBRSA record .0077″ group now stands as the smallest 100-yard group ever shot in registered benchrest competition.*

Read About .0077″ group HERE.

Stinnett’s success doesn’t diminish the significance of Mac McMillan’s .009″ group in the history of benchrest competition. For four decades Mac’s group stood as the ultimate standard of rifle accuracy*. For those of you who have never seen Mac McMillan’s .009″ group, here it is, along with the NBRSA World Record certificate. The target now hangs in the McMillan Family Museum.

*Somebody else might claim a smaller group, but unless moving backers or electronic targets were used, it cannot be verified. Moving target backers are used at registered benchrest matches to ensure that five (5) shots are actually fired in each group. That eliminates any doubt.

Share the post "Mac McMillan’s Legendary .009″ Group — Lookee Here"

August 30th, 2019

4-Gun winner Wayne Campbell is arguably the best group benchrest shooter in the world right now.

IBS 100/200 Yard Group Benchrest National Championships

Story by IBS President Jeff Stover President based on report by Harley Baker

Western Michigan was the site of the 2019 IBS Group Nationals. This major event was held August 12-17, 2019 at the Holton Gun & Bow Club. This club hosts many quality group benchrest matches throughout the season, and this one was no exception. The Holton team, especially match director Nancy Scarbrough, made everything seem easy. The shooters, however, don’t find conditions easy at all.

Summer Sun, Mirage, and Switchy Winds

In the middle of August, Holton’s sandy soils can generate fierce mirage. It can get so bad that competitors may not be able to see bullet holes clearly and target rings can become indistinguishable. In Warren Page’s classic gun book, “The Accurate Rifle”, he speaks of mirage as “shooting through the swimming pool”. Well Warren Page must have shot Holton. When mirage was not the problem at Holton, switchy winds were the order of the day. CLICK HERE for 2019 IBS Group Nationals Results.

IBS Group Nationals Course of Fire

The IBS Group Nationals can be an endurance test as the event spans six days. The sequence of competition has 100-yard targets shot the first three days, followed by three days at 200 yards. It is done this way to require only one change of wind flags. Nationals competition requires “full rotation”. That means that every time a shooter goes to the line for the next match target, he or she must move a requisite number of benches to the right. At the end of the day a shooter will shoot across the full width of the line. Some ranges offer unique properties that render some parts of the range harder or easier to shoot small groups. Bench rotation is important to even out those factors.

Classes At the IBS Group Nationals

It takes thirty targets of 5-shot groups and ten targets of 10-shot groups to win a “4-Gun Nationals”. That covers FOUR classes: Light Varmint, Heavy Varmint, Sporter, and Heavy Bench. For all practical purposes, the first three are known as “bag guns” while the heavy bench rifles are “rail guns”. In fact, most competitors shooting a bag gun opt for a single rifle, which has been benchrest standard for decades: a 10.5-lb rifle chambered in 6PPC.

Day by Day Report — Group Nationals Highlights

The first day of competition was for the Heavy Bench class — the Rail Guns. That is what Heavy Bench is these days. Jeff Peinhardt had a handle on conditions for his five 10-shot groups. His largest group was only a .202″. The rest were small dark holes where the 10 bullets honed away any paper fuzz. His average for the five groups in this aggregate was .1710″. Really small, but only .0074″ behind was Paul Mitchell. Rounding out third place was Michigander Lee Hachigian with a .1866″.

The “bag guns” come out on Tuesday for the 100-yard competition for Light Varmint and Sporter rifles. These are the 10.5-lb rifles. The only difference is that in Sporter you must have your rifle chamber with at least a 6mm bore. Since virtually everyone shoots a 6PPC it really doesn’t matter. Wayne Campbell from Virginia nailed a tight .1556” aggregate in Sporter at 100. Tony Alexander (.1758”) and Jack Neary (.1792”) rounded out the top three.

For Light Varmint at 100 yards. Larry Costa led the way with a .2022” when conditions were a little harder to read. Jack Neary and Kevin Donalds Sr. were close behind.

Wednesday morning of Nationals Week is Heavy Varmint at 100. Ken Donalds Sr. still had his rifle tuned to perfection as he won this aggregate with a .1624. Jack Neary and Harley Baker shot well with five-target averages in the .18XX. Wednesday afternoon the shooters take a break and hold a Powder Puff competition for non-shooters, including children and spouses were allowed to shot a group with bench coaching from seasoned competitors.

On Thursday the targets get moved to 200 yards along with a expanding sea of wind flags. Eventual multi-gun winner Wayne Campbell smoked the field Light Varmint 200 with a .1674 MOA Aggregate. His average group size at 200 yards was O.334 inches but in short-range group competition the scores are converted to minute of angle (MOA). The only other shooter Agging under 0.2 MOA was upstate New York restaurateur Pando Vasilovski with a 0.1927.

It was time for Sporter at 200 and Don Rosette from Ohio was the only shooter in the “teens” with a .1997 MOA Agg. Pando still had it working and was second.

Here are some of the “Top Guns” from the 2019 IBS Group Nationals in Holton, MI.

Former Super Shoot winner Larry Costa won the Heavy Varmint 200 with a .2007 MOA Agg and he had room to spare to beat Kevin Donalds Jr. and Jeff Peinhardt with a .22 and .23 respectively.

The last day, Saturday, the rail guns were hauled out again for the Heavy Bench 200. Mark Buettgen topped the field with a .2572 MOA Agg. No need to check the equipment list to know what barrel brand Buettgen used. Mark works for Bartlein Barrels in Wisconsin. Wayne Campbell was just on Mark’s heels.

|

Grand Aggregate (100+200)

Winners (all MOA):

Light Varmint: Wayne Campbell, .1939

Sporter: Wayne Campbell, .2133

Heavy Varmint: Larry Costa, .2026

Heavy Bench: Don Powell, .2342

|

Multi-gun results:

2-Gun (HV+LV 20 targets): Larry Costa, .2197

3-Gun (LV+SP+HV 30 targets): Wayne Campbell, .2205

4-Gun (LV+SP+HV+HB 40 targets): Wayne Campbell, .2279

(in 4-gun Tony Alexander was second with .2404, followed by Larry Costa with .2451)

|

| CLICK HERE for 2019 IBS Group Nationals Complete Match Results |

The Rifle for Short-Range Benchrest Competition

Hardware Choices: Actions, Stocks, Barrels, Optics and More

Tech Talk by Jeff Stover

Let’s examine the Top Ten rifles from this year’s IBS Group Nationals in the 10.5-lb Light Varmint Class. We’ll focus on the most popular rifle components — the choices for Actions, Stocks, Barrels, and Scopes.

For some years now, BAT has been the predominant action. This year BAT actions held nearly 100% of the Top Ten places in all the Bag Gun equipment lists. Bruce Thom’s Idaho-crafted actions, except for a couple stray actions in Heavy Bench, swept the top rankings.

Next, look at barrels. Bartlein or Krieger seem to rule with upstate New York’s venerable Hart barrels as competitive. Shooters tend to go with winners, so Wayne Campbell and Jeff Peinhardt dominate as gunsmiths for the top benchrest shooters.

In stocks there seems to be variety, but there is some commonality. The Scoville and Scarbrough stocks, both Michigan-made, are laminated wood (balsa and other wood) with carbon fiber and wrapped in carbon fiber. The Scoville stock on my 10.5-lb rifle weighs 18 ounces but is full size with a nice long fore-end. Bob Scarbrough makes a very similar product. Both are winners — it’s a choice of Ferrari or Lamborghini. The Roy Hunter and Terry Leonard stocks among these top rifles take a different route to winner’s circle. Both are wood (cedar or other), but super high-tech as they are laminated with carbon fiber. They are beautiful to boot. High-magnification Leupold, March, and Nightforce scopes rule the roost among benchrest optics.

Bullets and Powder

Bullets are important. Really important. A hot bullet gives you “Teen Aggs” and lots of trophies. An average bullet does not. Most of these are 68 grain 6mm boattails. The Peinhardt (StaMoly Precision) bullet is well represented on this list, but some top shooters make their own as you can see. Bullet jackets are likely StaMoly or J4. For powder, nearly everyone shoots Vihtavouri N133 except a few guys running LT30/32 or surplus 8208.

Share the post "IBS Match Report: 2019 Group Nationals in Holton, Michigan"

November 7th, 2018

Mirage shields are useful for all shooters, not just hard-core competitors. A mirage shield helps you see your target better, without distortion caused by heat waves coming off your barrel. This isn’t rocket science — it’s a simple, inexpensive way to see better and shoot more accurately. We’ve advocated that varmint shooters give mirage bands a try on those hot summer groundhog and prairie dog expeditions. And we observed that practically every F-Class shooter at the recent Berger SW Nationals was using a mirage shield of some kind.

Make Your Own Mirage Shiels from Venetian Blind

Criterion Barrels shows how you can make your own mirage shield from an ordinary Venetion blind.

|

A mirage shield is an extremely cost-effective way to eliminate a commonly-encountered problem. Making your own mirage shield is easy. Using old venetian blind strips and common household materials and tools, you can construct your own mirage shield for under one dollar.

READ FULL Article |

Materials Required:

1. Vertical PVC Venetian blind panel

2. Three 1”x1” pieces adhesive-backed Velcro

3. Ruler or tape measure

4. Scissors or box cutter

5. Pencil or marker |

Make Your Own Mirage Shield from X-Ray Film

Forum member Fabian from Germany, whose Sako 6BR rifle was featured as a Gun of the Week, has devised a clever and inexpensive mirage band option. Fabian is a radiologist by trade. He notes that many X-ray machines require a daily test film for calibration. These are normally just discarded in the trash, so you can get them for free.

Fabian explains: “I’m a radiologist, so I handle medical x-ray films every day. Modern X-ray machines use laser-based printers and they need to print a test-film every day. One x-ray film is about 43×35 cm (16.9″ x 13.7″). Made from polyester, the films are very stable and only 0.007″ inches thick. They are light-weight, semi-transparent, and very stable. Using normal scissors, you can easily cut four mirage shields from a single sheet of film. Then glue on some velcro to attach to your barrel. Try it, you will not be disappointed.”

High-Tech Carbon Fiber Mirage Shield

If you’re not into making your own mirage shield, aka “mirage band” or “mirage shade”, you can also purchase a cool carbon fiber mirage shield from Accurateshooter Forum member Mark Nagel. These custom Carbon-Fiber Mirage Shields start at $20.00. GET More INFO HERE.

Carbon Fiber Mirage Shield

Share the post "Mirage Shields — Make Your Own or Buy Carbon Fiber"

October 2nd, 2018

When your cases become hard to extract, or you feel a stiff bolt lift when removing a cartridge, it’s probably time to full-length size your cases, and “bump” the shoulder back. With a hunting load, shoulder bumping may only be required every 4-5 loading cycles. Short-range benchrest shooters, running higher pressures, typically full-length size every load cycle, bumping the shoulder .001-.002″. High Power shooters with gas guns generally full-length size every time, and may need to bump the shoulders .003″ or more to ensure reliable feeding and extraction.

Use Shims for Precise Control of Shoulder Bump

Some shooters like to set the “default” position for their full-length die to have an “ample” .003″ or .004″ shoulder bump. When they need less bump, a simple way to reduce the amount of shoulder movement is to use precision shims in .001″ (one-thousandth) increments.

Here are reports from Forum members who use the shims:

“Great product. I have my die lock ring(s) adjusted for the shortest headspace length on my multiple chambers 6BRs and 6PPCs. When needing a longer headspace, I just refer to my notes and add the appropriate shim under the lock ring. Keep it simple.” — F.D. Shuster

Mats Johansson writes: “I’ve been using [shims] since Skip Otto (of BR fame) came out with them. I set up my dies with the .006″ shim, giving me the option of bumping the shoulder a bit more when the brass gets old and hardens while still having room to adjust up for zero headspace, should I have missed the original setup by a thou or two. Hunting rounds can easily be bumped an extra .002-.003″ for positive, no-crush feeding. Being a safety-oriented cheapskate, I couldn’t live without them — they let me reload my cases a gazillion times without dangerous web-stretching. Shims are a must-have, as simple as that.” — Mats Johansson

Sinclair Int’l offers a seven-piece set of Sizing Die Shims that let you adjust the height of your die (and thereby the amount of bump and sizing) in precise .001″ increments. Sinclair explains: “Some handloaders will set their die up to achieve maximum sizing and then progressively use Sinclair Die Shims between the lock ring and the press head to move the die away from the shellholder. Doing this allows you to leave the lock ring in the same position. These shims are usually available in increments of .001″ and work very well.” Sinclair Int’l offers a seven-piece set of Sizing Die Shims that let you adjust the height of your die (and thereby the amount of bump and sizing) in precise .001″ increments. Sinclair explains: “Some handloaders will set their die up to achieve maximum sizing and then progressively use Sinclair Die Shims between the lock ring and the press head to move the die away from the shellholder. Doing this allows you to leave the lock ring in the same position. These shims are usually available in increments of .001″ and work very well.”

Seven Shims from .003″ to .010″

Sinclair’s Die Shim Kit (item 22400) includes seven shims in thicknesses of .003, .004, .005, .006, .007, .008, and .010. For ease of use, shim thickness is indicated by the number of notches cut in the outer edge of each shim. Even without looking you can “count” the notches by feel. Normally priced at $11.99, this shim kit is on sale now for $10.99.

Share the post "Bump Control: Precision Shims for Full-Length Sizing Dies"

March 30th, 2018

.009″ — The Record That Stood for 40 Years. .009″ — The Record That Stood for 40 Years.

In 1973 Mac McMillan shot an amazing 100-yard, .009″ five-shot group in a benchrest match. The .009″ group was measured with a 60x microscope for verification. Mac McMillan shot the group using a handbuilt prototype McMillan rifle with an early McMillan stock.

Mac’s .009″ group was the “Holy Grail” of rifle accuracy. This .009″ record was considered by many to be unbreakable, a record that would “stand for all time”. Well, it took 40 years, but someone finally broke Mac’s record with an even smaller group. In 2013, Mike Stinnett shot a .0077″ five-shot group using a 30 Stewart, a .30 caliber wildcat based on the 6.5 Grendel. Stinnett’s .0077″ group now stands as the smallest 100-yard group ever shot in registered benchrest competition.*

Read About .0077″ group HERE.

Stinnett’s success doesn’t diminish the significance of Mac McMillan’s .009″ group in the history of benchrest competition. For four decades Mac’s group stood as the ultimate standard of rifle accuracy*. For those of you who have never seen Mac McMillan’s .009″ group, here it is, along with the NBRSA World Record certificate. The target now hangs in the McMillan Family Museum.

*Somebody else might claim a smaller group, but unless moving backers or electronic targets were used, it cannot be verified. Moving target backers are used at registered benchrest matches to ensure that five (5) shots are actually fired in each group. That eliminates any doubt.

Share the post "Check Out the Legendary .009″ Group By Mac McMillan"

November 1st, 2017

This article was written in 2014 for the Sierra Bullets Blog. It describes one method of load development that is commonly used. There are other methods that can work also. Some guys first isolate seating depth and then fine-tune velocity with charge weights. Other guys may aim for a known velocity node (speed range) and then optimize accuracy by adjusting seating depth. Still others look for smallest ES and tightest vertical to minimize 1000-yard vertical dispersion. There are many ways to skin a cat. Different rifles (and even different barrels) can demand different styles of load development.

In this instance the writer achieved desired results seating his bullets .007″ back from max “jam” length. For other applications (and other barrels) you may get the best, most consistent results seating off the rifling by .020″ or more. In disciplines with quick-fire such as PRS, it may be wise to develop loads that “jump” the bullet.

F-Class Long Range Load Development Methodology

by Mark Walker, Sierra Bullets Product Development Manager

Since I just put a new barrel on my F-class rifle… I figured it might be a good time to discuss load tuning for long range shooting. Getting the most accuracy out of your rifle is one of the most important aspects of load tuning. For long range shooting in particular, using a load that produces the least amount of vertical variation is vital. There are several steps to the process that I use, so I will go through the basics of each.

When I first get a new barrel installed, I like to determine what the loaded cartridge “jam” length is. I do this by taking an empty case (no powder or primer) that has been neck sized with the proper bushing (I like to shoot for 0.002 smaller than the loaded cartridge neck diameter) and seat a bullet long in it so that the throat of the rifle will move the bullet back into the case when I close the bolt. I close the bolt several times until the bullet stops moving back into the case at which point I use a comparator with my calipers and get a length measurement on the cartridge. This is what I consider to be the “jam length” for this barrel and chamber. I came up with 3.477″ as the “jam length” for this particular barrel. [Editor: In this instance, Mark is using “Jam length” to mean max seating depth he can achieve without bullet set-back.]

Next, I will fire-form some brass using a starting load of powder and bullets seated to “jam” while breaking in the barrel. My barrel break in process is not very technical; it’s mostly just to get the brass formed and the rifle sighted in. I do clean every 5 rounds or so just because I feel like I have to.

Once I have the brass formed, I use them to load for a “ladder test” to see what powder charge the rifle likes. With a ladder test, you take your starting load and load one round each with a slightly increasing amount of powder until you reach your max load for that cartridge. You then fire each round using the same aiming point to see where the bullets start to form a group. For this barrel and cartridge, I started at 53.3 grains of H4831SC powder and increased the load by 0.3 grains until I reached 55.7 grains. I always seat my bullets to “jam” when doing a ladder test. We will determine the final seating depth in another test later. It’s usually best to shoot this test at a minimum of 200 yards because at closer ranges the bullets will impact too close together making it hard to determine which load works best. I shot this test at 300 yards.

As you can see from the target, the lightest load #1 had the lowest velocity and impacted lowest on the target. Shots #2 and #3 were a little higher and in the same hole. Shots #4 thru #6 were slightly higher yet and all had the same elevation. Shots #7 and #8 were the highest on the target however pressure signs were starting to show. For some reason shot #9 went back into the group and the chronograph didn’t get a reading so I ignored that shot.

When picking a load, I am looking for the most shots at the same vertical location on the target. As you can see that would be shots #4 through #6 so I would pick a powder charge from those shots which would be 54.2 grains to 54.8 grains. As a side note, shots #2 and #3 are only 0.851 lower so I wouldn’t be afraid of using one of those loads either. I settled on 54.5 grains as the load I wanted to use. It’s right in the middle of the group so if the velocity goes up or down slightly, the bullet should still hit in the same place on the target.

Now that we’ve settled on a powder charge, I want to find the seating depth the rifle likes. I usually start at jam length and [shorten the COAL] in 0.003 increments until I get to 0.015 deeper than jam. [Editor: By this he means he is seating the BULLET deeper in the case, NOT deeper into the lands. He ended up at .007″ shorter than his hard jam length of 3.477″.]

I load 3 rounds at each depth using the 54.5 grain powder charge and shoot a group with each depth at 150 yards. As you can see from the target, the first two groups are not good at all. Next one looks good and is the smallest group on the target. The next three are not quite as small but the vertical location on the target is almost the same which indicates a sweet spot which will help keep the vertical stringing to a minimum on target. I went with 3.470″ which is right in the middle once again and should give some flexibility with the seating depth.

So after all of that, my load is 54.5 grains of H4831SC and a cartridge length of 3.470. I plan on loading up enough ammo to shoot five groups of five shots and see exactly how this load works on target as well as what the extreme velocity spreads are over several groups.

I sincerely hope some of this information helps you to get the best accuracy out of your rifle. I do not take credit for coming up with any of this, a whole lot of good shooters use this same method or a variant of it when working up their loads.

For more information about load development, please contact the Sierra Bullets technical support team at 1-800-223-8799 or by email at sierra [at] sierrabullets.com.

Disclaimer: Load data represented here may not be safe in your rifle. Always start low and work up, watching for pressure signs.

Share the post "Long Range Load Development for F-Class"

December 30th, 2015

.009″ — The Record That Stood for 40 Years. .009″ — The Record That Stood for 40 Years.

In 1973 Mac McMillan shot an amazing 100-yard, .009″ five-shot group in a benchrest match. The .009″ group was measured with a 60x microscope for verification. Mac McMillan shot the group using a handbuilt prototype McMillan rifle with an early McMillan stock.

Mac’s .009″ group was the “Holy Grail” of rifle accuracy. This .009″ record was considered by many to be unbreakable, a record that would “stand for all time”. Well, it took 40 years, but someone finally broke Mac’s record with an even smaller group. In 2013, Mike Stinnett shot a .0077″ five-shot group using a 30 Stewart, a .30 caliber wildcat based on the 6.5 Grendel. Stinnett’s .0077″ group now stands as the smallest 100-yard group ever shot in registered benchrest competition.*

Read About .0077″ group HERE.

Stinnett’s success doesn’t diminish the significance of Mac McMillan’s .009″ group in the history of benchrest competition. For four decades Mac’s group stood as the ultimate standard of rifle accuracy*. For those of you who have never seen Mac McMillan’s .009″ group, here it is, along with the NBRSA World Record certificate. The target now hangs in the McMillan Family Museum.

*Somebody else might claim a smaller group, but unless moving backers or electronic targets were used, it cannot be verified. Moving target backers are used at registered benchrest matches to ensure that five (5) shots are actually fired in each group. That eliminates any doubt.

Share the post "Ultimate Precision: Mac McMillan’s Historic .009″ Group"

October 6th, 2015

When your cases become hard to extract, or you feel a stiff bolt lift when removing a cartridge, it’s probably time to full-length size your cases, and “bump” the shoulder back. With a hunting load, shoulder bumping may only be required every 4-5 loading cycles. Short-range benchrest shooters, running higher pressures, typically full-length size every load cycle, bumping the shoulder .001-.002″. High Power shooters with gas guns generally full-length size every time, and may need to bump the shoulders .003″ or more to ensure reliable feeding and extraction.

Use Shims for Precise Control of Shoulder Bump

Some shooters like to set the “default” position for their full-length die to have an “ample” .003″ or .004″ shoulder bump. When they need less bump, a simple way to reduce the amount of shoulder movement is to use precision shims in .001″ (one-thousandth) increments.

Here are reports from Forum members who use the shims:

“Great product. I have my die lock ring(s) adjusted for the shortest headspace length on my multiple chambers 6BRs and 6PPCs. When needing a longer headspace, I just refer to my notes and add the appropriate shim under the lock ring. Keep it simple.” — F.D. Shuster

Mats Johansson writes: “I’ve been using [shims] since Skip Otto (of BR fame) came out with them. I set up my dies with the .006″ shim, giving me the option of bumping the shoulder a bit more when the brass gets old and hardens while still having room to adjust up for zero headspace, should I have missed the original setup by a thou or two. Hunting rounds can easily be bumped an extra .002-.003″ for positive, no-crush feeding. Being a safety-oriented cheapskate, I couldn’t live without them — they let me reload my cases a gazillion times without dangerous web-stretching. Shims are a must-have, as simple as that.” — Mats Johansson

Sinclair Int’l offers a seven-piece set of Sizing Die Shims that let you adjust the height of your die (and thereby the amount of bump and sizing) in precise .001″ increments. Sinclair explains: “Some handloaders will set their die up to achieve maximum sizing and then progressively use Sinclair Die Shims between the lock ring and the press head to move the die away from the shellholder. Doing this allows you to leave the lock ring in the same position. These shims are usually available in increments of .001″ and work very well.” Sinclair Int’l offers a seven-piece set of Sizing Die Shims that let you adjust the height of your die (and thereby the amount of bump and sizing) in precise .001″ increments. Sinclair explains: “Some handloaders will set their die up to achieve maximum sizing and then progressively use Sinclair Die Shims between the lock ring and the press head to move the die away from the shellholder. Doing this allows you to leave the lock ring in the same position. These shims are usually available in increments of .001″ and work very well.”

Seven Shims from .003″ to .010″

Sinclair’s $12.49 Die Shim Kit (item 22400) includes seven shims in thicknesses of .003, .004, .005, .006, .007, .008, and .010. For ease of use, shim thickness is indicated by the number of notches cut in the outer edge of each shim. Even without looking you can “count” the notches by feel.

Share the post "Sinclair Full-Length Sizing Die Shims"

October 27th, 2013

Mirage shields are useful for all shooters, not just hard-core competitors. A mirage shield helps you see your target better, without distortion caused by heat waves coming off your barrel. This isn’t rocket science — it’s a simple, inexpensive way to see better and shooter more accurately. We’ve advocated that varmint shooters give mirage bands a try on those hot summer groundhog and prairie dog expeditions. And we observed that practically every shooter at the 2013 World F-Class Championship was using a mirage shield of some kind.

Forum member Fabian from Germany, whose Sako 6BR was featured as a Gun of the Week, has devised a clever and inexpensive mirage band option. Fabian is a radiologist by trade. He notes that many X-ray machines require a daily test film for calibration. These are normally just discarded in the trash, so you can get them for free.

Fabian explains: “I’m a radiologist, so I handle medical x-ray films every day. Modern X-ray machines use laser-based printers and they need to print a test-film every day. One x-ray film is about 43×35 cm (16.9″ x 13.7″). Made from polyester, the films are very stable and only 0.007″ inches thick. They are light-weight, semi-transparent, and very stable. Using normal scissors, you can easily cut four mirage shields from a single sheet of film. Then glue on some velcro to attach to your barrel. Try it, you will not be disappointed.”

If you’re not into making your own mirage shield, aka “mirage band” or “mirage shade”, you can also purchase these from Sinclair International. Two Velcro-attached sizes are offered, 18″ long (item 749-000-423WS) and 24″ inches long (item 749-000-426WS). Both sizes are priced at a reasonable $4.95.

Share the post "Free Mirage Shields from X-Ray Test Films"

|

Brownells offers the seven-piece set of Sizing Die Shims that let you adjust the height of your die (and thereby the amount of bump and sizing) in precise .001″ increments. Sinclair explains: “Some handloaders will set their die up to achieve maximum sizing and then progressively use Sinclair Die Shims between the lock ring and the press head to move the die away from the shellholder. Doing this allows you to leave the lock ring in the same position. These shims are usually available in increments of .001″ and work very well.”

Brownells offers the seven-piece set of Sizing Die Shims that let you adjust the height of your die (and thereby the amount of bump and sizing) in precise .001″ increments. Sinclair explains: “Some handloaders will set their die up to achieve maximum sizing and then progressively use Sinclair Die Shims between the lock ring and the press head to move the die away from the shellholder. Doing this allows you to leave the lock ring in the same position. These shims are usually available in increments of .001″ and work very well.”

Shims for Arbor Dies

Shims for Arbor Dies

.009” Group Record Stood for 40 Years

.009” Group Record Stood for 40 Years